Jefferson Professional Tools & Equipment JEFWELHT3C User manual

User Manual

JEFWELHT3C

www.jeffersontools.com

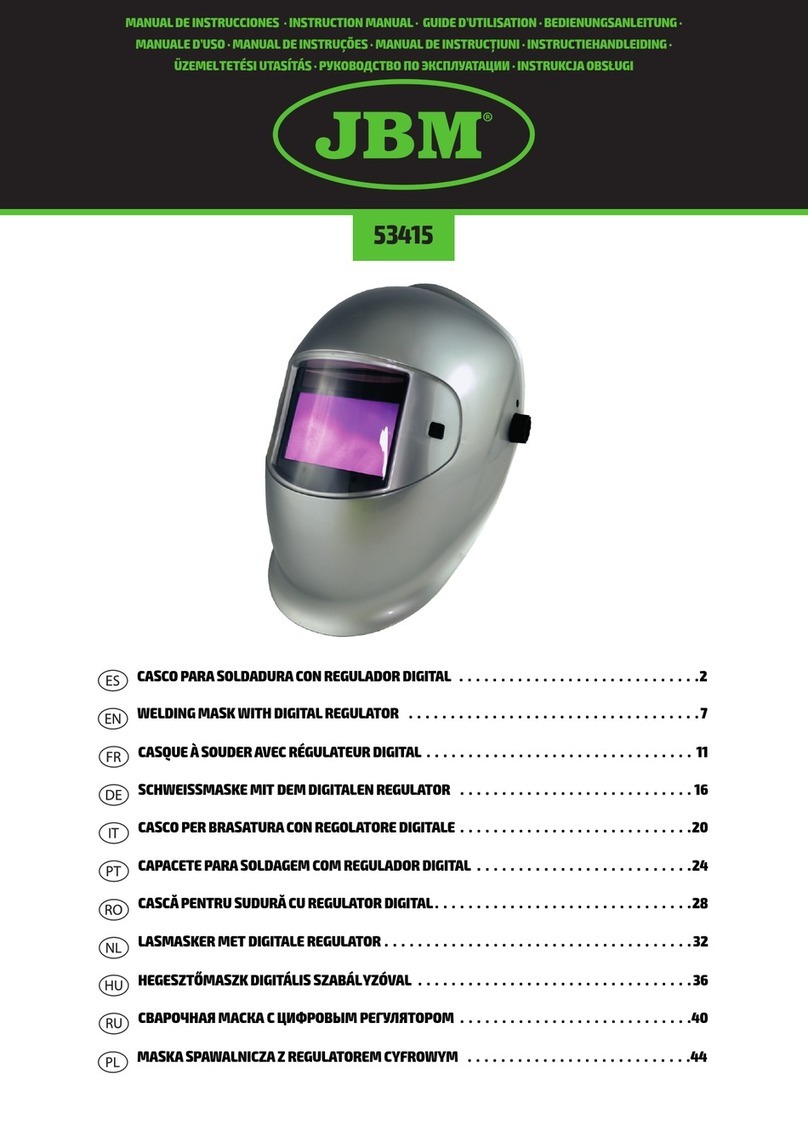

Auto Darkening Welding Helmet

V1.2

2

USER MANUAL

Auto Darkening Welding Helmet

JEFWELHT3C

Specification

1) Ensure that the lter, front cover lens, inside cover lens and four optical sensors are clean and secure.

2) Inspect all operating parts before use for signs of wear or damage. Any scratched, cracked or pitted parts should be replaced

immediately before use to avoid severe personal injury.

3) Ensure that the position of the headband is adjusted to t comfortably and safely. The helmet should be seated as low as possible on the

head and close to the face.

4) Select the correct DIN Shade setting for your application see table below:

1. Before Welding

2. DIN Shade Settings

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

•Viewing Area

•Cartridge Size

•UV / IR Protection

•Light State

•Dark State

●Power Supply

●Power On / Off

98mm x 55mm (3.86” x 2.17”)

110 x 90 x 9mm (4.33” x 3.54” x 0.35”)

Permanent Shade DIN16

DIN Shade 4

From DIN9 to DIN13 (Variable)

Solar cells, with built in replaceable battery

Fully automatic

•Switching Time Light to Dark

•Switching Time Dark to Light

•Operating Temperature

•Storage Temperature

•Function Modes

●Helmet Material

●Net Weight

●Minimum Amperage

1/20000s (0.00005s)

0.3s - 0.9s

-5ºC to + 55ºC (23ºF to 131ºF)

-20ºC to + 70ºC (-4ºF to 158ºF)

Grinding Mode | Welding Mode

Hi Impact Polymide Nylon (EN175B)

470g

40 Amps

The shade number can be set manually between 9-13. Check the Shade Guide Table below to determine the proper shade number for your ap-

plication. Select a shade number by turning the shade knob until the arrow points to the required setting:

Note: This product is manufactured to conform with related EN 379 and EN 175:B safety standards

Arc Current (Amperes)

0.5 2.5 10 20 40 80 125 175 225 275 350 450

1 5 15 30 60 100 150 200 250 300 400 500

||||||||||||||||||||||||

SMAW 9 10 11 12 13 14

MIG

(Heavy)

10 11

12 13 14

MIG

(Light) 10 11 12 13 14 15

TIG,

GTAW 9 10 11 12 13 14

MAG/

C0210 11 12 13 14 15

SAW

10 11 12 13 14 15

PAC

11 12 13

PAW

8 9 10 11 12 13 14 15

Process

3

USER MANUAL

Auto Darkening Welding Helmet

JEFWELHT3C

3. Operation & Safety

WARNING: IF YOU ENCOUNTER ANY PROBLEMS WITH THE HELMET BEFORE OR DURING USE IT IS IMPORTANT THAT YOU DO NOT CONTINUE WITH THE WELDING

PROCESS. IF THE FILTER FAILS TO DARKEN CORRECTLY, FLASHES OR IS UNABLE TO ATTAIN THE APPROPRIATE SHADE TO PROTECT YOUR EYES YOU SHOULD STOP

IMMEDIATELY AND CONTACT YOUR JEFFERSON DEALER OR SUPPLIER.

3.3 DIN Shade Delay Setting

It is important that the correct delay setting is used for your welding process to avoid

any sudden aring when you nish the welding process and the welding arc is broken.

When the welding arc is broken it is possible for residual arc to are from the molten

welding pool which can be hazardous if the helmet has already automatically adjusted

the DIN shade to a lighter setting. To accommodate for this, the helmet is equipped with

a Delay Time Switch for additional eye protection which can be set to three positions -

depending on the welding process:

1) Long = 0.6 to 0.9 second delay

2) Middle = 0.4 to 0.6 second delay

3) Short = 0.3 to 0.5 second delay

It is important that you use the correct delay & sensitivity setting to suit your

welding process and that you test the battery and filter before use.

DIN Shade

Delay Setting ●

Filter

Test Button

●

Battery

Indicator Light

●

Fig 2

3.1 Welding Protection

●Ensure that the helmet is not used in conditions were welding spatter is more than

43g and exceeding 120m/s.

●The helmet is manufactured to DIN BS EN175:1997 (Impact Level B) please ensure

that the appropriate protective clothing is worn to protect any other parts of the body

exposed during the welding process.

3.2 Sensitivity, Mode and DIN Shade Settings

●Before you start welding adjust the Mode, Sensitivity and DIN Shade to the

appropriate settings for the welding process (see Fig1a & Fig1b) and arc amperage

(see table on page 2).

●Continue to adjust the DIN shade settings to attain the appropriate brightness to allow

you to see the welding molten pool and the welding spot without glare.

3.4 Testing

1. Testing the Battery:

You can test the lithium battery is charged by checking that the Bat-

tery Indicator Light is on. The Battery Indicator Light is located

beside the Test button on the control panel (see Fig 2). If the red light

is not displaying or if the light is weak you need to replace the

batteries. The helmet takes two CR2450 type batteries.

2. Testing the Filter:

You can test the lter by pressing the Test button on the control panel

(see Fig 2).

If the battery indicator is on and the lter shade is not darkening when

you press the Test button there is a fault with the lter and it should

not be used to prevent the risk of injury.

Function Mode:

1) Welding 2) Grinding

Sensitivity Dial

DIN Shade Settings Fig 1b

Fig 1a

C

4

USER MANUAL

Auto Darkening Welding Helmet

JEFWELHT3C

3. Operation & Safety (continued...)

3.6 Adjusting the Headgear

●It is important that the Helmet ts the user comfortably and securely before

welding begins.

●The helmet can be adjusted in 4 places to allow you to establish the best t

(see Fig 4).

Fig 4

Fig 3

3.5 The Magnifying Lens

A magnifying lens is available for this model (sold separately).

The lens is xed over the visor shown in Fig 3.

1. Top Headband - Adust the depth of the headband to fit accordingly

2. Filter Harness - Adjust to set the correct distance between the welders eyes and the lter lens

3. Back Headband - Loosen or tighten to attain a comfortable and secure t

4. Incline Angle - Adjust to set the incline angle of the helmet relative to the welders face and the position of the welders eyes relative to the lter

lens

Note: This helmet headband is designed with a mechanism that helps to adjust the centre of gravity on the helmet when the visor is up and down.

This mechanism helps to reduce the weight on the neck and reduce fatigue - making the helmet more comfortable and secure when you are

working.

C

5

USER MANUAL

Auto Darkening Welding Helmet

JEFWELHT3C

4. Replacement Parts List (part 1)

1. Shell (Welding Mask) 8. Headband fixing screw rack

2. 2x Block Nut 9. Sweatband (cloth)

3. 2x check washer 10. Front band

4. Angle adjusting shim (left) 11. Left band

5. Angle adjusting shim (right) 12. Right band

6. Headband rack (left) 13. Black Elastic Pad

7. Headband rack (right) 14. Headband regulator assembly

6

USER MANUAL

Auto Darkening Welding Helmet

JEFWELHT3C

5. Replacement Parts List (Part 2)

1. Shell (Welding Mask) 8. Front Cover Lens

2. Shade Scale Plate 9. Shade Screen

3. Sensitivity Scale Plate 10. Sensitivity Screen

4. Welding / Grinding Mode Switch 11. Lithium Battery Housing

5. Filter setting Frame 12. Auto-Darkening Filter

6. 2x Shade Nuts 13. Inside Cover Lens

7. 2x Shade Sensitivity Knobs 14. Magnifying Lens (sold separately)

7

USER MANUAL

Auto Darkening Welding Helmet

JEFWELHT3C

EC Declaration Of Conformity

We, Jefferson Professional Tools & Equipment, as the authorised European

Community representative of the manufacturer, declare that the following

equipment conforms to the requirements of the following Directives:

Equipment Category: Personal Protective Equipment:

Automatic Welding Filter, Variable Shade, Grinding Mode:

•Optical Class: 1, Diffusion of Light Class: 2

•Variations in Luminous Transmittance Class: 1

•Angle Dependence of Luminous Transmittance: 1

Face Shield:

•Polyamide, Safety plates, Active welding filter, Protection against high-speed particles,

medium energy impact [B]

Product Name/Model: JEFWELHT3C

Notified Body: ECS European Certication Service (1883) Germany

A copy of this certificate has been submitted to the European Commission and to the

EU Member State, United Kingdom

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 19 June 2014

This technical document is held by: Jimmy Hemphill

Technical file holder's address as shown below

Name and address of manufacturer or authorised representative:

Jefferson Tools, Herons Way, Chester Business Park, Chester, United Kingdom, CH4 9QR

EN 379:2003 (as amended) Personal eye-protection - Automatic welding lters

Essential requirements according to Annex II of the PPE-Directive 89/686/EEC

EN 175:1997 (as amended) Equipment for eye and face protection during welding and allied processes

Essential requirements according to Annex II of the PPE-Directive 89/686/EEC

8

USER MANUAL

Auto Darkening Welding Helmet

JEFWELHT3C

Limited Warranty Statement

Jefferson Professional Tools & Equipment, or hereafter "Jefferson" warrants its customers that its products

will be free of defects in workmanship or material. Jefferson shall, upon suitable notication, correct any

defects, by repair or replacement, of any parts or components of this product that are determined by

Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration,

abnormal operations, improper care, unauthorised service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty

periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of

purchase is unavailable from the end user, then the date of purchase will be deemed to be 3 months after

the initial sale to the distributor.

2 Year

•All Jefferson welding & plasma cutting machines

1 Year

• All Jefferson welding helmets (excluding batteries)

• All Jefferson welding regulators

90 Days

• All Jefferson welding torches (excluding consumables)

• All Jefferson plasma torches (excluding consumables)

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a

minimum of 90 days cover or the remaining duration of the warranty period from the original date of

purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following

address: www.jeffersontools.com/warranty and completing the online form. Online warranty registration is

recommended as it eliminates the need to provide proof of purchase should a warranty claim be

necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will be corrected

by repair or replacement at an authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection.

Jefferson will arrange collection and transportation of any equipment returned under warranty. Upon

inspection of the equipment, if no defect can be found or the equipment is not covered under the terms of

the Jefferson warranty, the customer will be liable for any labour and return transportation costs incurred.

These costs will be agreed with the customer before the equipment is returned.

9

USER MANUAL

Auto Darkening Welding Helmet

JEFWELHT3C

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians or engineers.

Jefferson's liability under this warranty will not exceed the cost of correcting the defect of the Jefferson

products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business or hire of

substitute equipment etc.) caused by the defect or the time involved to correct the defect. This written

warranty is the only express warranty provided by Jefferson with respect to its products. Any warranties of

merchantability are limited to the duration of this limited warranty for the equipment involved.

Jefferson is not responsible for cable wear due to flexing and abrasion. The end user is responsible for

routine inspection of cables for possible wear and to correct any issues prior to cable failure.

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment (Tel: +44 (0) 1244 646 048) or their

nearest authorised Jefferson dealer where final determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

• Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form. You can

complete the form online and submit it to us directly or download the form to print out and return by

post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of

your nearest authorised Jefferson repair centre. On receipt of this form Jefferson will arrange to collect the

equipment from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer's responsibility to ensure that the equipment is appropriately and securely packaged for

collection. Please ensure that you include a copy of your proof of purchase. Please note that Jefferson

cannot assume any responsibility for any damage incurred to equipment during transit. Any claims against a

third party courier will be dealt with under the terms & conditions of their road haulage association

directives.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will be determined if

the equipment is defective and in need of repair and any repairs needed are covered by the warranty policy.

In order to qualify for warranty cover all equipment presented must have been used, serviced and main-

tained as instructed in the user manual.

10

USER MANUAL

Auto Darkening Welding Helmet

JEFWELHT3C

Where repair is not covered by the warranty a quotation for repair, labour costs and return delivery will be

sent to the customer (normally within 7 working days).

Note: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1 hour

labour time at £30 per hour plus return carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the equipment is

identified as the cause of the problem, a minimum of 1 hour labour at £30 per hour plus carriage costs will

be required before the equipment will be despatched back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to the cus-

tomer within 7 working days upon receipt of the equipment at an authorised Jefferson Repair centre (sub-

ject to part availability). Where parts are not immediately available Jefferson will contact you with a revised

date for completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call +44 (0) 1244 646 048 or send

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all recommendations or suggestions are

made without guarantee. Since the conditions of use are beyond their control, Jefferson Tools® disclaim any liability for loss or

damage suffered from the use of this data or suggestions. Furthermore, no liability is accepted if use of any product in accordance

with this data or suggestions infringes any patent. Jefferson Tools® reserve the right to change product specifications and

warranty statements without further notification. All images are for illustration purposes only.

Jefferson Tools,

Herons Way,

Chester Business Park,

Chester, United Kingdom, CH4 9QR

Tel. +44 (0)1244 646 048

Email: [email protected]

IMPORTANT! SAFETY FIRST!

Before attempting to use this product please read

all the safety precautions and operating instructions

outlined in this manual to reduce the risk of fire,

electric shock or personal injury.

www.jeffersontools.com

This product must not be disposed with normal household waste.

Table of contents

Popular Welding Accessories manuals by other brands

Miller

Miller Classic Series owner's manual

ESAB

ESAB Origo Feed 304 P4 User manual and spare parts

Rockford Fosgate

Rockford Fosgate DETECT-A-FINGER RKC-502 installation manual

iBell

iBell IBL 550S Operator's manual

Spartus

Spartus 130XT user manual

Lincoln Electric

Lincoln Electric X-Tractor 8A Operator's manual