Jefferson JEFWASE402-150 User manual

JEFWASE402-150

150Bar •1700W

High Pressure Washer

1

www.jeffersontools.com

User Manual

v.1.1

150Bar • 1700W

High Pressure Washer

JEFWASE402-150

JEFWASE402-150

150Bar •1700W

High Pressure Washer

2

www.jeffersontools.com

1. Introduction

This equipment is designed for a wide range of

cleaning operations including: vehicles; buildings;

tools; terraces; decking; farming equipment; boats

etc. using a high pressure water jet and detergents

if required.

Please read these instructions carefully and

keep in a safe location for future reference.

Ensure that the manual is passed on should

ownership of the equipment change at any

time.

Contact your nearest Jefferson Dealer for advice on

correct usage, accessories (including compatible

detergents), servicing and replacement parts.

Do not modify this equipment for any other purpose

than those originally intended buy the manufacturer.

Ensure that the product is used in accordance

with the guidelines described in this manual.

Failure to do so can result in personal injury

and may void the warranty.

Never touch the mains plug or plug socket when

hands are wet. Ensure that the mains plug and any

extension cables are kept watertight and dry and

never lie under water.

Check the washer and all accessories carefully

before use. Do not use the equipment if any damage

is detected. Contact your nearest dealer for servicing

and repair advice.

This equipment must not be used not be used in

working environments where a risk of explosion is

present.

Important: High pressure jets can pose a hazard to

health and can damage property is used incorrectly.

The high-pressure jet must never be directed at

people, animals, live electrical equipment or at the

appliance itself. Never use the high pressure jet to

clean clothing or footwear during operation.

2. General Safety Guidelines

Never use the appliance to clean objects containing

hazardous substances (e.g. asbestos).

Be careful when cleaning vehicle tyres and tyre

valves as these can be damaged by the high

pressure jet and may burst if used incorrectly.

Damaged vehicle tyres and tyre valves are highly

dangerous. Ensure that a distance of at least

30cm is kept when cleaning tyres with a high

pressure jet.

Do not spray flammable liquids or fluids containing

solvents or undiluted acids including petrol, paint

thinner and heating oil. Any spray mist generated

from such fluids can be highly inflammable,

explosive and poisonous.

High pressure hoses, fixtures and couplings are

important for the safety of the appliance. Only

use high pressure hoses, fixtures and couplings

recommended by Jefferson Tools. Seek advice on

compatibility before using any accessories with this

equipment.

This appliance is not intended for use by persons

with reduced physical, sensory or mental

capabilities. The appliance must not be operated

by children or by any persons who have not been

instructed in the correct operation.

Children and pets should be kept away from the

working environment at all times during operation.

Do not leave the equipment running unattended

for any length of time. Always disconnect from the

mains and water supply when not in use.

Always operate this equipment on a flat level

surface in an upright position.

Ensure that there is sufficient free air circulating

around the equipment to prevent overheating.

Ensure that the operator and any bystanders

wear the appropriate protective clothing and

safety goggles to protect against splash back

containing water or dirt during operation.

JEFWASE402-150

150Bar •1700W

High Pressure Washer

3

www.jeffersontools.com

3. Specications

Model Number JEFWASE402-150

Maximum Pressure 150bar (2200psi / 15.0MPa)

Rated Pressure 110bar (1600psi / 11.0MPa)

Effective Cleaning Power 257bar (3740psi / 25.7Mpa)

Water Flow: 402L/Hr - 6.7L/Min

Motor Power / Speed: 1700W / 2800rpm

Input: 230V (50Hz)

Vibration: 1.606 m/s²

Guaranteed Sound Level: 88dB

Protection: IP25

*Automatic TSS System: Yes

*TurboNozzle: Yes

Hose Length: 8m

Max Water Temperature: 60˚C

Soap Volume: 1.75L

Weight: NW 19.5kg / GW 21kg

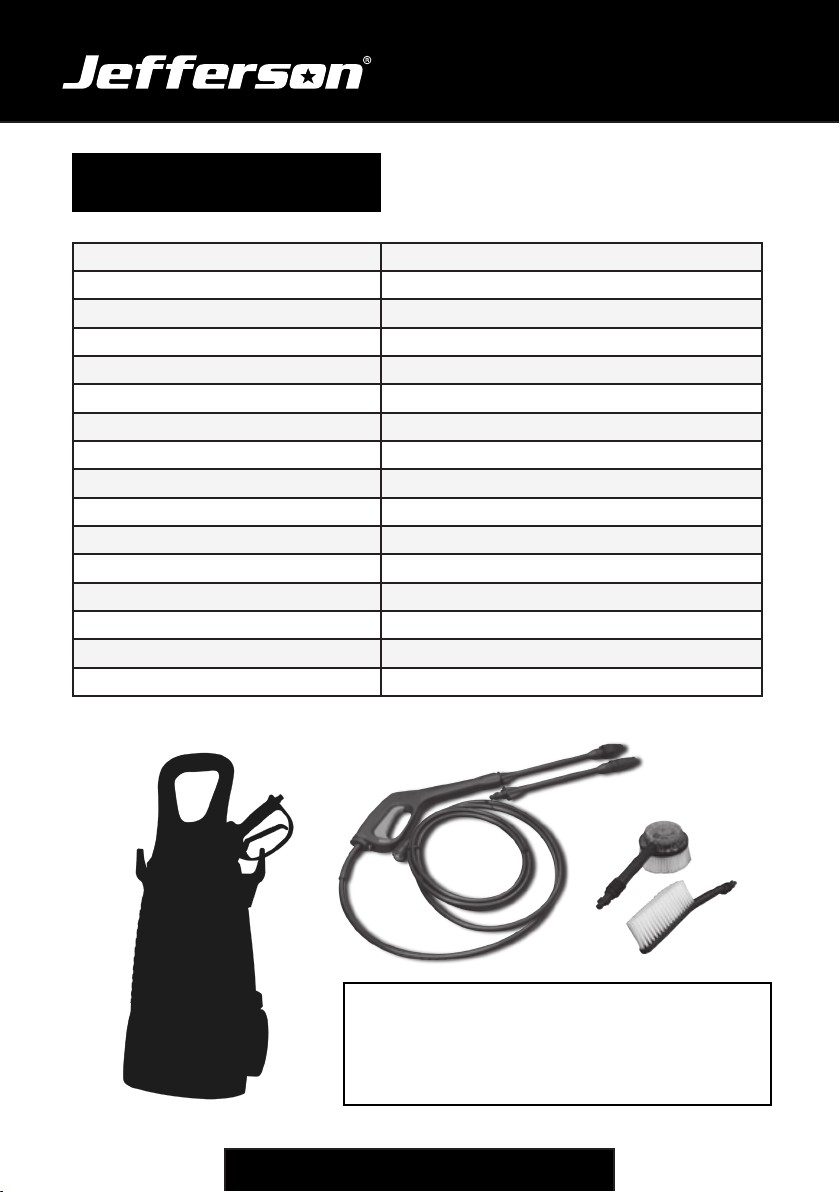

Box contents:

1. 120Bar Pressure Washer 5. 8m Hose

2. TurboNozzle 6. Rotary Brush

3. Adjustable Nozzle 7. Fixed Brush

4. Spray Gun Trigger Handle

2.

3.

4.

5.

6.

7.

1.

JEFWASE402-150

150Bar •1700W

High Pressure Washer

4

www.jeffersontools.com

2. Connecting to the water supply.

Connecting To The Water Supply

Use a reinforced hose pipe with an internal diameter of 1/2" when

connecting to the mains supply. Ensure that the hose is clean before

connecting to the pressure washer by flushing out with clean water.

Connect a 3/4" BSP female hose fitting to the male connection on

the rear of the pressure washer as shown in Fig.1.

Ensure that you comply with all your local water supply regulations

before use. Pressure washers can only be connected to the mains

water supply if a check valve is connected to the supply hose to

prevent contaminating the supply. Ensure that the supply hose is

reinforced with an internal diameter of 1/2" (13mm). Ensure that the

supply water temperature does not exceed 50˚C and pressure is not

greater than 6bar.

Connecting The High Pressure Hose

Attach the high pressure hose to the pressure washer as shown

in Fig.2. and Fig.3. Ensure that the fitting is connected securely

before connecting to the mains supply. Attach the other end of the

high pressure hose to the trigger gun as shown in Fig.4. Ensure that

the hose lock is open before inserting the fitting as shown. Once in

place move the hose lock back towards the hose connection to lock

the hose securely in position.

Lance / Nozzle Connection

Push the lance into position as shown in Fig.5. and rotate by 90˚

to lock into place (Fig.6.). Ensure that the lance and nozzle are

securely connected before connecting to power or water supply

as the nozzle and lance can be discharged at high velocity if fitted

incorrectly.

4. Set-Up

Fig.2.

Fig.1.

Fig.3.

Fig.4.

Fig.5.

90˚

Fig.6.

JEFWASE402-150

150Bar •1700W

High Pressure Washer

5

www.jeffersontools.com

1. Initial Checks

Warning: water and electricity are

dangerous when used together. Be aware

that this equipment uses an electric motor.

Always connect to mains supply using

an RCD. Unplug from the mains before

changing accessories or carry out any

servicing.

Check that the inlet filter is clean and free

of debris and that a filter is fitted inside

the inlet connector. Ensure that the hose,

trigger gun, lance and nozzle are connected

correctly.

Ensure that the safety catch is engaged

when not in use.

Bleed the spray gun prior to connection

to the electrical supply by squeezng the

trigger. This ensures that any excess air is

released before use.

2. Connecting to the electrical supply

Ensure that the ON/OFF switch is in the

OFF position. Connect to the mains supply

using an RCD plugged into a 13A mains

socket.

Ensure that the equipment is PAT tested at

least once a year. Ensure that the voltage

marked on the appliance matches the

supply.

4. Operation

Hold the spray gun firmly in preparation for

the recoil caused by the high pressure of

the water when the trigger is pulled.

Ensure that the lance and nozzle are not

pointed at individuals. Turn the pressure

washer on by turning the switch to the

"ON" position.

5. Operation Release the handle safety catch and point the

lance at the cleaning area and pull the trigger

to release the jet.

Note: The Total Stop System (TSS) ensures

that the motor and water supply are cut off

when the trigger is released to preserve the

life of the motor.

You can adjust the water jet by twisting the

nozzle as required.

Warning: High pressure cleaning can be

damaging to objects and property and cause

loose debris to be projected at high speeds.

It is recommended that you start with a spray

angle of approximately 20˚and increase the

power of the jet gradually as required.

Using detergents: Pour compatible

detergent into the detergent tank. Set the

adjustable nozzle to the low pressure setting

by pushing the nozzle forwards as shown

in Fig 7. Allow the detergent to act for 1-2

minutes before washing off.

Pull the nozzle back again to the regular

pressure setting and remove the detergent

with a wide fan setting.

Clean the detergent bottle and tube after use.

Low Pressure Mode

Standard Mode

Fig.7.

JEFWASE402-150

150Bar •1700W

High Pressure Washer

6

www.jeffersontools.com

6. Maintenance

Warning: Turn off the appliance and remove the mains plug prior to carrying out any maintenance

work.

Ensure that nozzles are kept clean and free from dirt, grease & debris.

Remove and clean the water filter regularly to protect dirt and debris from getting into the pump

and ensure water pressure is maintained at optimum level for operation.

Ensure that the air vents around the pressure washer are kept clean and clear to allow air to be

drawn freely into the coolant system.

7. Troubleshooting Guide

PROBLEM CAUSE

Motor will not start 1. Check plug for loose connections or blown fuse

Water leaking from the pump 1. The system will generate small amounts of leakage during operation

and this is normal. If leaking is extreme disconnect from water and

mains power before checking all connections are secure and fittings

are free from dirt or damage.

Circuit breaker tripping or blown fuse 1. Circuit is overloaded

2. Check extension cable. Problems can arise if cable is too long or too

thin.

3. Nozzle is partially blocked causing excessive pressure to build up

Trigger jams 1. Check that the gun safety lock is not engaged

Pump and motor do not stop when trigger

is released

1. Trigger is damaged. Contact your dealer or nearest Jefferson Repair

Center.

The motor is running but pump is not

operating at the correct pressure.

1. Air trapped in the pump. (Let the washer run with the gun open and

lance removed for a period of time until a steady stream of water is

released.

2. Suction or discharge valves are clogged or worn out. Check that

water filter is not clogged or damaged. Contact your dealer or nearest

Jefferson Repair Center.

3. Check for a kink in supply hose and that water tap is turned on to full

supply pressure.

JEFWASE402-150

150Bar •1700W

High Pressure Washer

7

www.jeffersontools.com

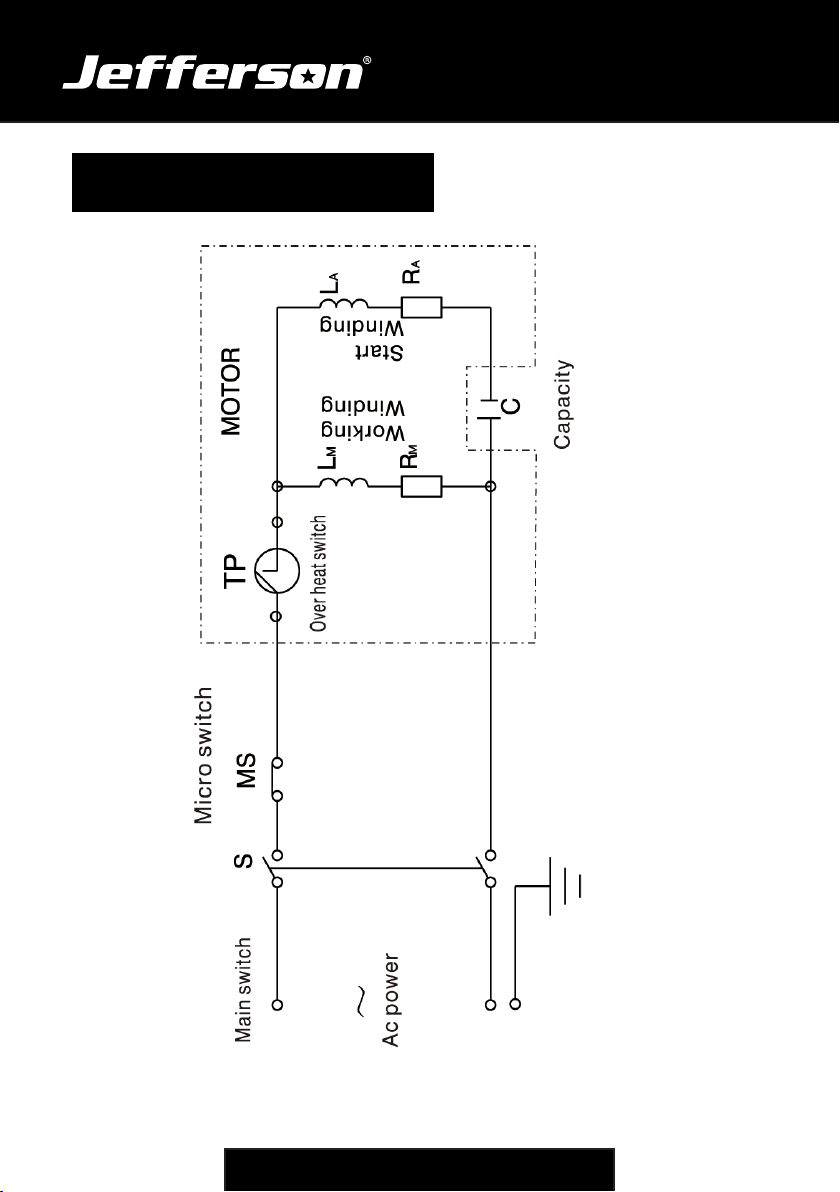

8. Circuit Diagram

JEFWASE402-150

150Bar •1700W

High Pressure Washer

8

www.jeffersontools.com

EC Declaration Of Conformity

We, Jefferson Professional Tools & Equipment, as the authorised European

Community representative of the manufacturer, declare that the following equipment

conforms to the requirements of the following Directives:

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 11 November 2014

This technical document is held by: Jimmy Hemphill

Technical file holder's address as shown below

Name and address of manufacturer or authorised representative:

Jefferson Tools, Herons Way, Chester Business Park, Chester, United Kingdom, CH4 9QR

2000/14/EC (as amended) Noise Emission in the Environment by

Equipment for Use Outdoors:

2006/42/EC (as amended) Machinery Directive:

2006/95/EC (as amended) Low Voltage Directive:

2004/108/EC (as amended) EMC Directive:

Notified Body: SNCH Luxembourg GmbH. (No. 0499)

Measured Sound Power Level: 87dB

Guaranteed Sound Power Level: 88dB

Equipment Category: Electric Pressure Washer

Product Name/Model: JEFWASE402-150 •150Bar High Pressure Washer (1700w)

The conformity assessment procedure followed was in accordance with Annex V of the

Outdoor Noise Directive.

JEFWASE402-150

150Bar •1700W

High Pressure Washer

9

www.jeffersontools.com

Limited Warranty Statement

Jefferson Professional Tools & Equipment, or hereafter "Jefferson" warrants its customers that its products will

be free of defects in workmanship or material.

Jefferson shall, upon suitable notication, correct any defects, by repair or replacement, of any parts or

components of this product that are determined by Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal

operations, improper care, unauthorised service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty

periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of purchase is

unavailable from the end user, then the date of purchase will be deemed to be 3 months after the initial sale to

the distributor.

1 Year

•All Jefferson Electric Pressure Washers (excluding Spray Guns and Nozzles)

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a

minimum of 90 days cover or the remaining duration of the warranty period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following address:

www.jeffersontools.com/warranty and completing the online form. Online warranty registration is

recommended as it eliminates the need to provide proof of purchase should a warranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will be corrected by

repair or replacement at an authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection together

with a copy of the original proof of purchase. Jefferson will arrange collection and transportation of any

equipment returned under warranty.

Upon inspection of the equipment, if no defect can be found or the equipment is not covered under the terms

of the Jefferson warranty, the customer will be liable for any labour and return transportation costs incurred.

These costs will be agreed with the customer before the machine is returned.

JEFWASE402-150

150Bar •1700W

High Pressure Washer

10

www.jeffersontools.com

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians or engineers.

Jefferson's liability under this warranty will not exceed the cost of correcting the defect of the Jefferson

products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business or hire of

substitute equipment etc.) caused by the defect or the time involved to correct the defect. This written warranty

is the only express warranty provided by Jefferson with respect to its products.

Any warranties of merchantability are limited to the duration of this limited warranty for the equipment involved.

Jefferson is not responsible for cable wear due to flexing and abrasion. The end user is responsible for routine

inspection of cables for possible wear and to correct any issues prior to cable failure.

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment (Tel: +44 (0) 1244 646 048) or their

nearest authorised Jefferson dealer where final determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

• Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form. You can

complete the form online and submit it to us directly or download the form to print out and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of

your nearest authorised Jefferson repair centre. On receipt of this form Jefferson will arrange to collect the

equipment from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer's responsibility to ensure that the equipment is appropriately and securely packaged for

collection. Please ensure that you include a copy of your proof of purchase. Please note that Jefferson cannot

assume any responsibility for any damage incurred to equipment during transit. Any claims against a third party

courier will be dealt with under the terms & conditions of their road haulage association directives.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will be determined if

the equipment is defective and in need of repair and any repairs needed are covered by the warranty policy. In

order to qualify for warranty cover all equipment presented must have been used, serviced and maintained as

instructed in the user manual.

JEFWASE402-150

150Bar •1700W

High Pressure Washer

11

www.jeffersontools.com

Where repair is not covered by the warranty a quotation for repair, labour costs and return delivery will be sent

to the customer (normally within 7 working days).

Note: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1 hour

labour time at £30 per hour plus return carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the equipment is

identified as the cause of the problem, a minimum of 1 hour labour at £30 per hour plus carriage costs will be

required before the equipment will be despatched back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to the customer

within 7 working days upon receipt of the equipment at an authorised Jefferson Repair centre (subject to part

availability). Where parts are not immediately available Jefferson will contact you with a revised date for

completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call +44 (0) 1244 646 048 or send your

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all recommendations or suggestions are

made without guarantee. Since the conditions of use are beyond their control, Jefferson Tools® disclaim any liability for loss or

damage suffered from the use of this data or suggestions. Furthermore, no liability is accepted if use of any product in accordance

with this data or suggestions infringes any patent. Jefferson Tools® reserve the right to change product specifications and

warranty statements without further notification. All images are for illustration purposes only.

Parts & Servicing

For Jefferson approved replacement parts contact your

nearest dealer or contact Jefferson tools

Telephone: +44 (0)1244 646 048

Fax: +44 (0)1244 241 191

Email: [email protected]

Jefferson Tools,

Herons Way,

Chester Business Park,

Chester, United Kingdom, CH4 9QR

Tel. +44 (0)1244 646 048

Email: [email protected]

IMPORTANT! SAFETY FIRST!

Before attempting to use this product please read

all the safety precautions and operating instructions

outlined in this manual to reduce the risk of fire,

electric shock or personal injury.

www.jeffersontools.com

This product must not be disposed with normal household waste.

Table of contents

Other Jefferson Pressure Washer manuals

Popular Pressure Washer manuals by other brands

PowerWasher

PowerWasher 60113 Operation manual

Martha Stewart

Martha Stewart MTS-1300PW Assembly instructions

Kärcher

Kärcher K 2.40 Operator's manual

Craftsman

Craftsman 580.768350 Operator's manual

North Star

North Star M157305G Installation, operation and maintenance manual

Nilfisk-Advance

Nilfisk-Advance SelectSpray 1250E Instructions for use and parts list

Black & Decker

Black & Decker PW1750 instruction manual

Nilfisk-Advance

Nilfisk-Advance MH 4M operating instructions

Cleaner Wash

Cleaner Wash CW1850-135 Original instructions

MADER

MADER APW-VAS-150P-A operating instructions

Gerni

Gerni Classic 120.2 user guide

Kärcher

Kärcher HDS 3.9/30 Pe Cage Operator's manual