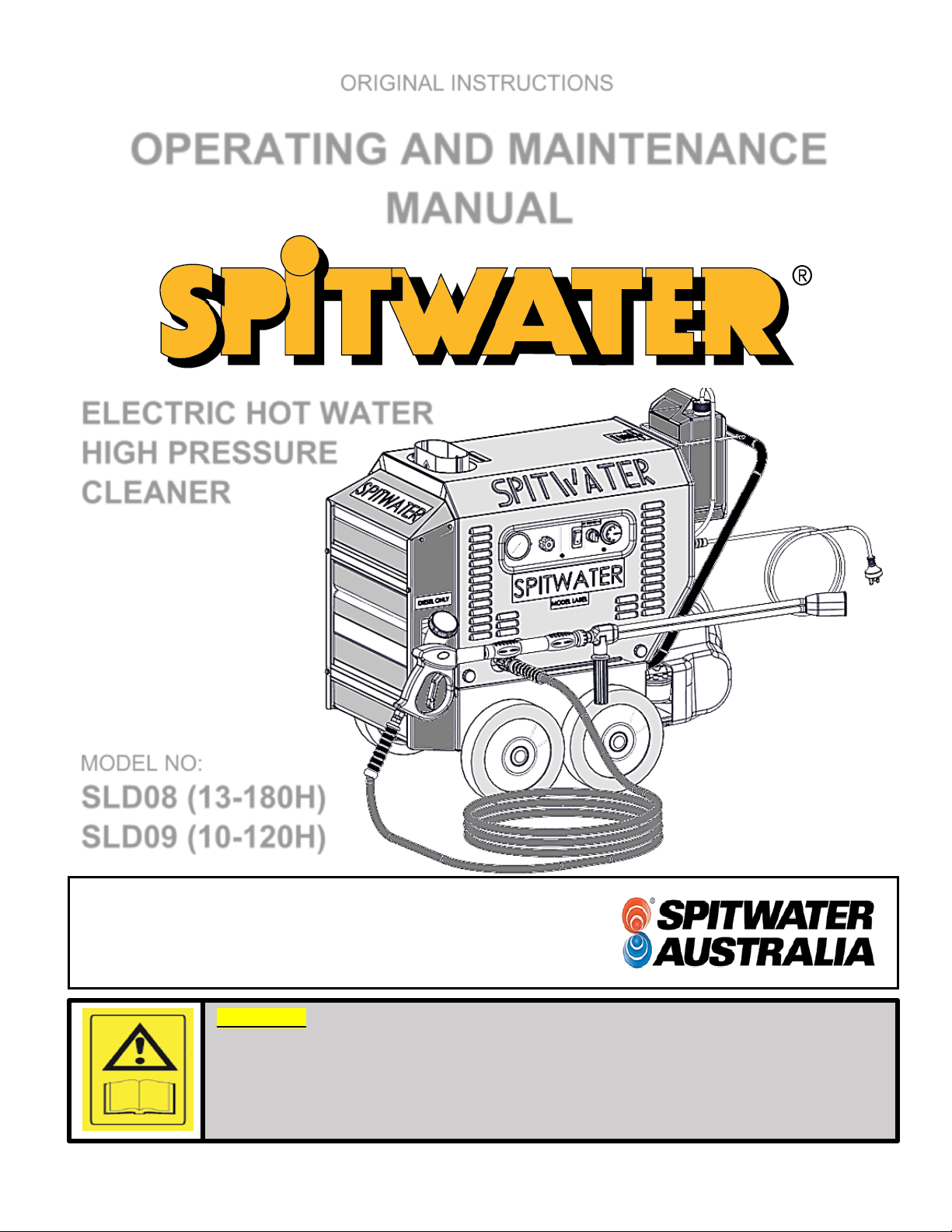

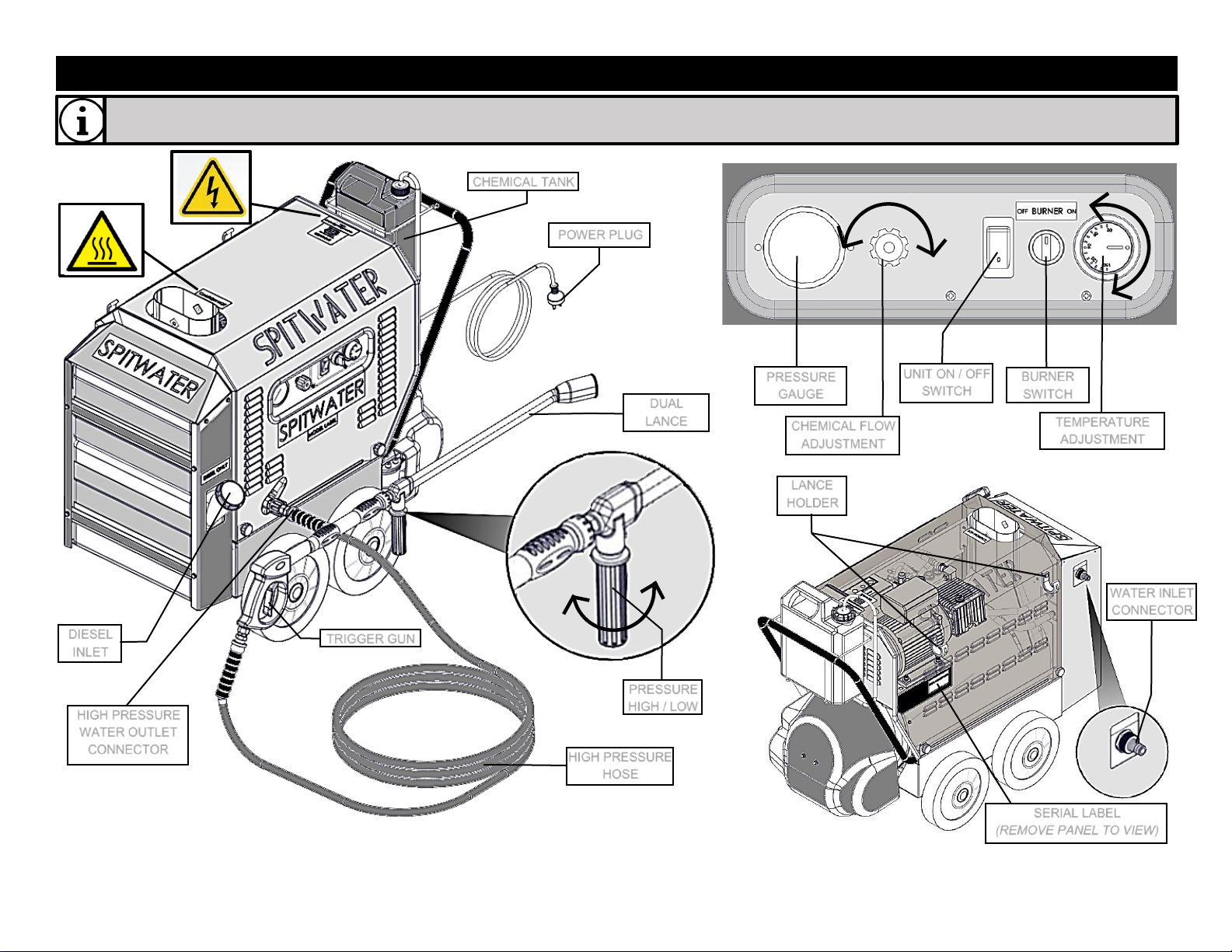

Spitwater SLD08 Operating instructions

This manual suits for next models

3

Other Spitwater Pressure Washer manuals

Spitwater

Spitwater SHW88 Operating instructions

Spitwater

Spitwater SCW69 Operating instructions

Spitwater

Spitwater SHW85 Operating instructions

Spitwater

Spitwater SLD19 Operating instructions

Spitwater

Spitwater SCWA60/A Operating instructions

Spitwater

Spitwater 8-140P Operating instructions

Spitwater

Spitwater HC11140P Installation and operation manual

Spitwater

Spitwater HP15200E GT Installation and operation manual

Spitwater

Spitwater SHW90 Operating instructions

Spitwater

Spitwater SHW78 Operating instructions

Spitwater

Spitwater SHW87 Operating instructions

Spitwater

Spitwater SCWA61 Operating instructions

Spitwater

Spitwater SLD24 Operating instructions

Spitwater

Spitwater HP30275P Installation and operation manual

Spitwater

Spitwater SLD25 Operating instructions

Spitwater

Spitwater SCW82/G Operating instructions

Spitwater

Spitwater HP201 Operating instructions

Spitwater

Spitwater HP25400DE Installation and operation manual

Spitwater

Spitwater SCWD082 Operating instructions

Spitwater

Spitwater SHW69 Operating instructions