JEMA AGRO T20 User manual

AGRO

Manual

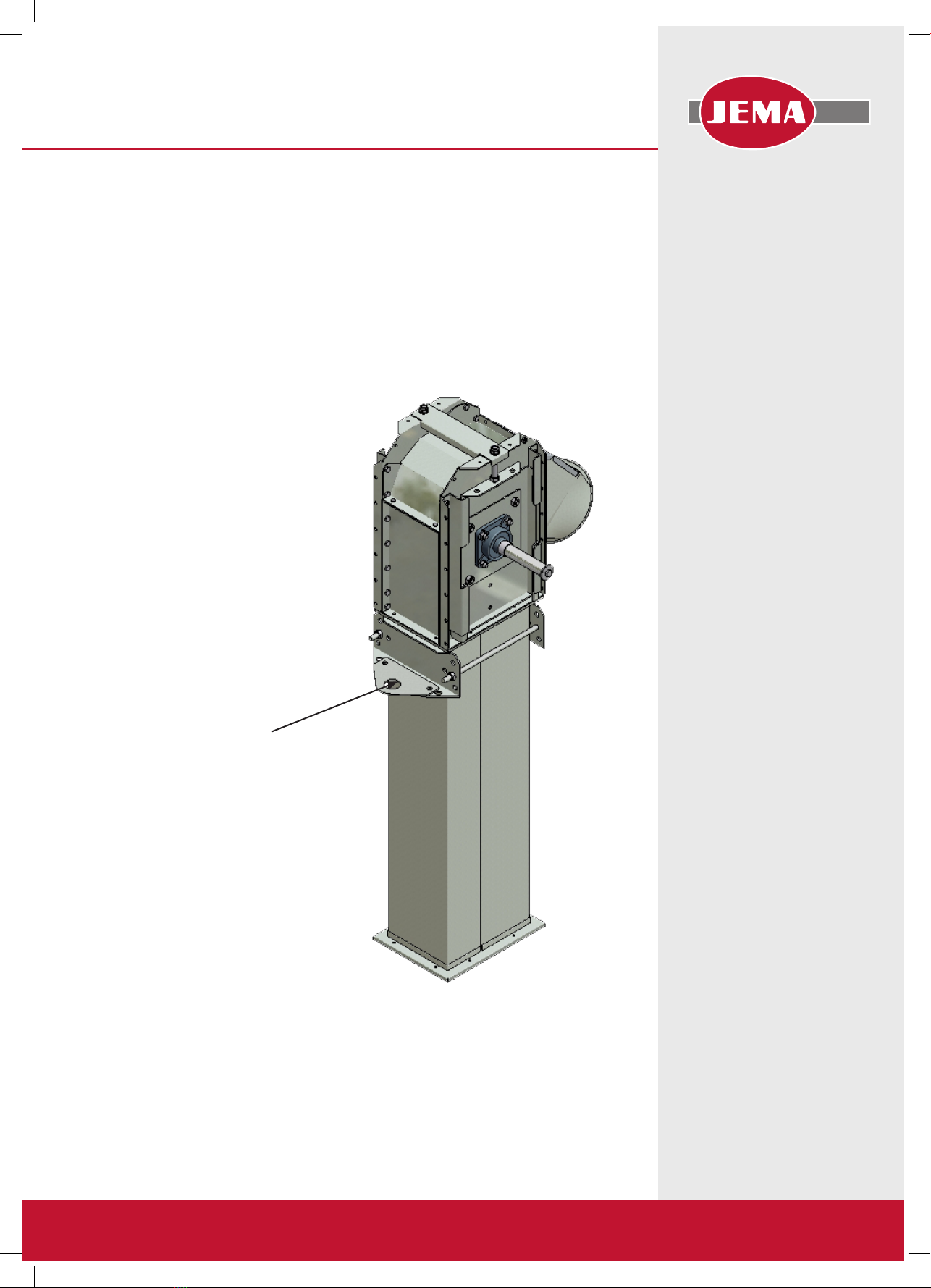

Chain elevator

T20/T40

Version 70501.1

2 | www.jema.as

Contents

Contents.........................................................................................................................................2

Introduction ....................................................................................................................................4

EU Declaration of conformity ..........................................................................................................5

Conditions for use...........................................................................................................................6

General information ........................................................................................................................7

Delivery ..................................................................................................................................7

Storage...................................................................................................................................7

Noise level measuring.............................................................................................................7

Type plate ..............................................................................................................................8

Construction...........................................................................................................................8

Capacity .................................................................................................................................9

Technical specifications – power consumption ......................................................................10

Elevator head .......................................................................................................................12

Elevator extension ................................................................................................................12

Elevator boot .......................................................................................................................13

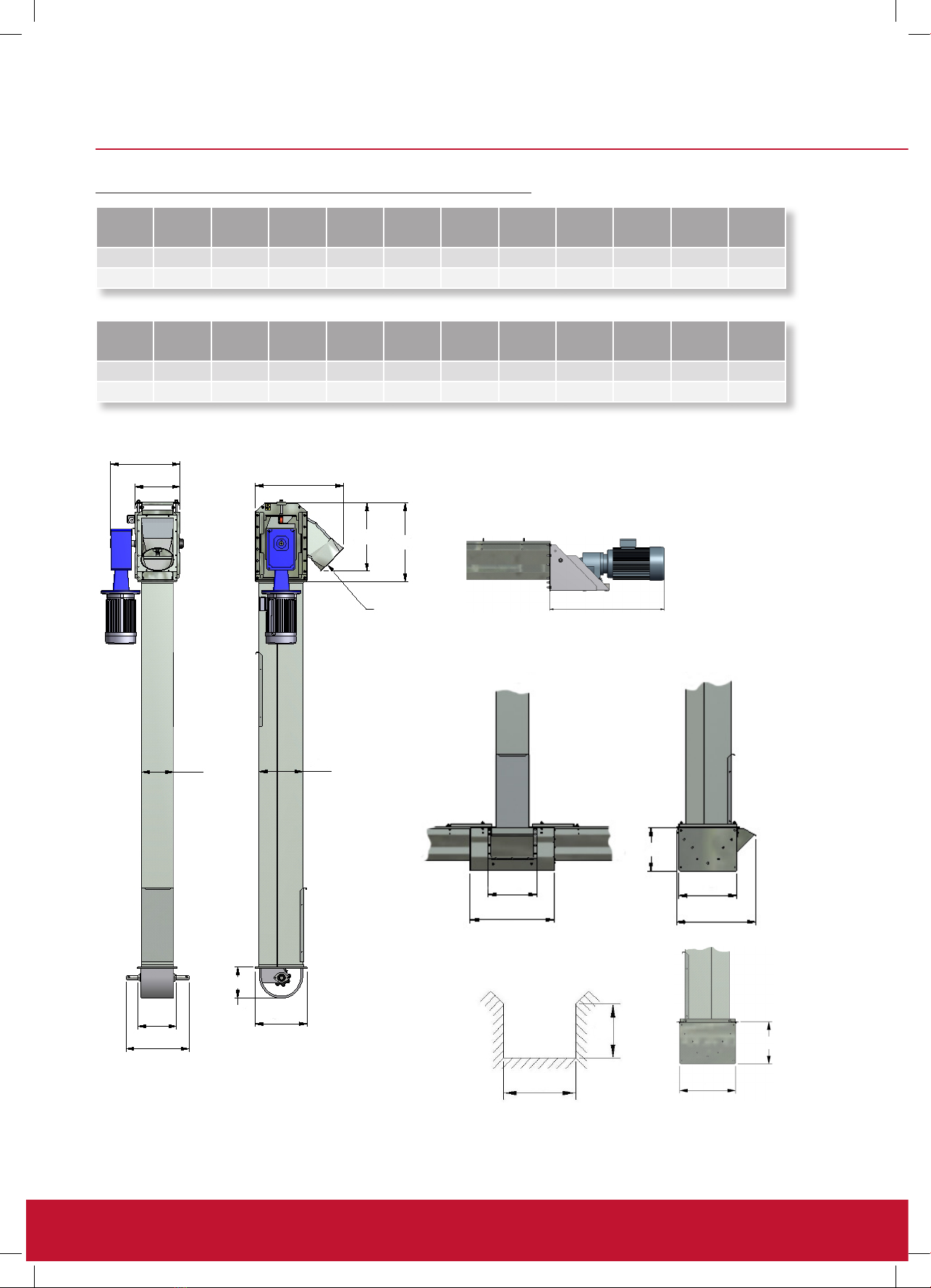

Scale drawing T20/T40 (gear motor).....................................................................................14

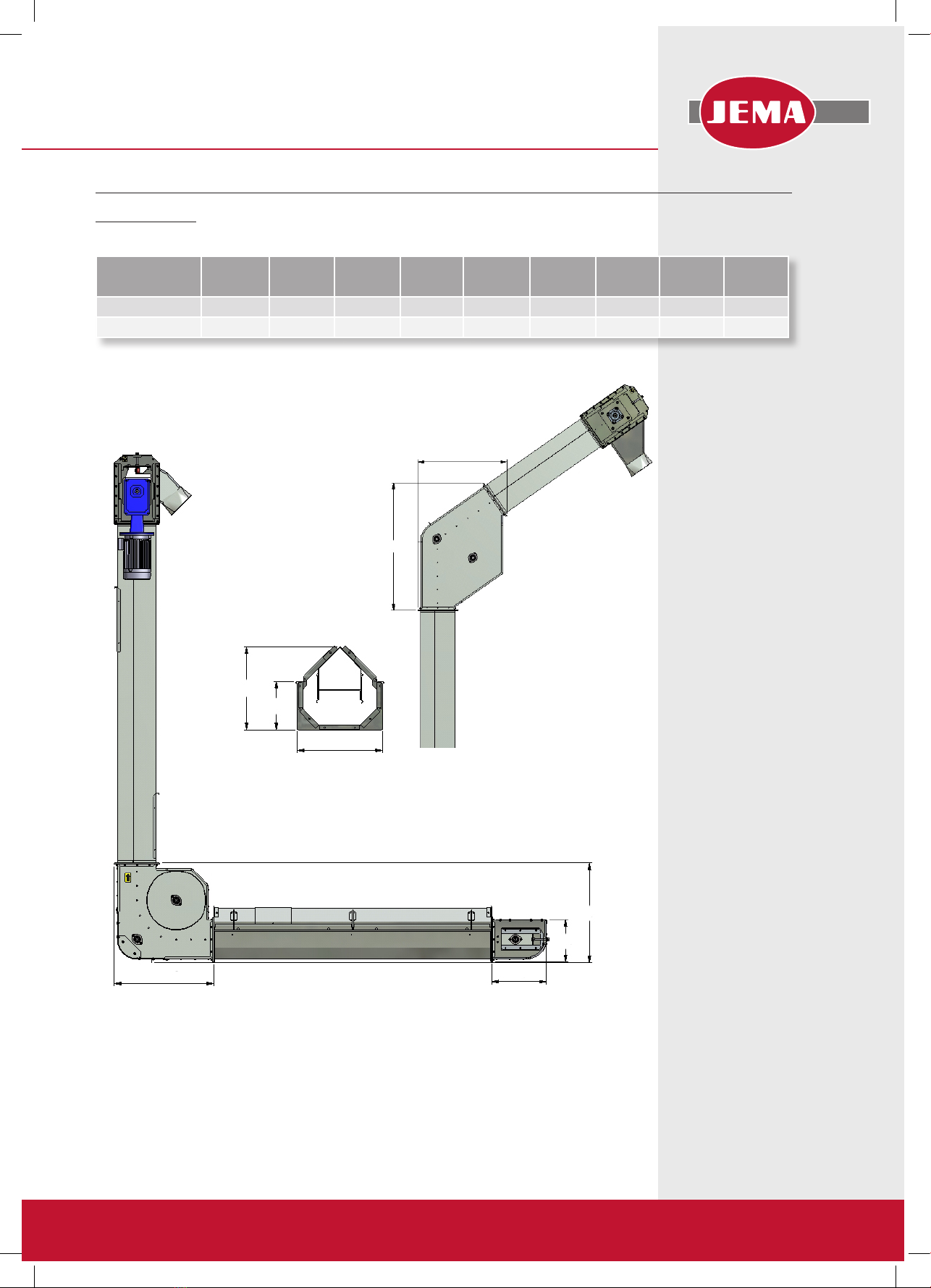

Scale drawing T20/T40 90°/ 55° bend and chain conveyor T44/T45............................. 15

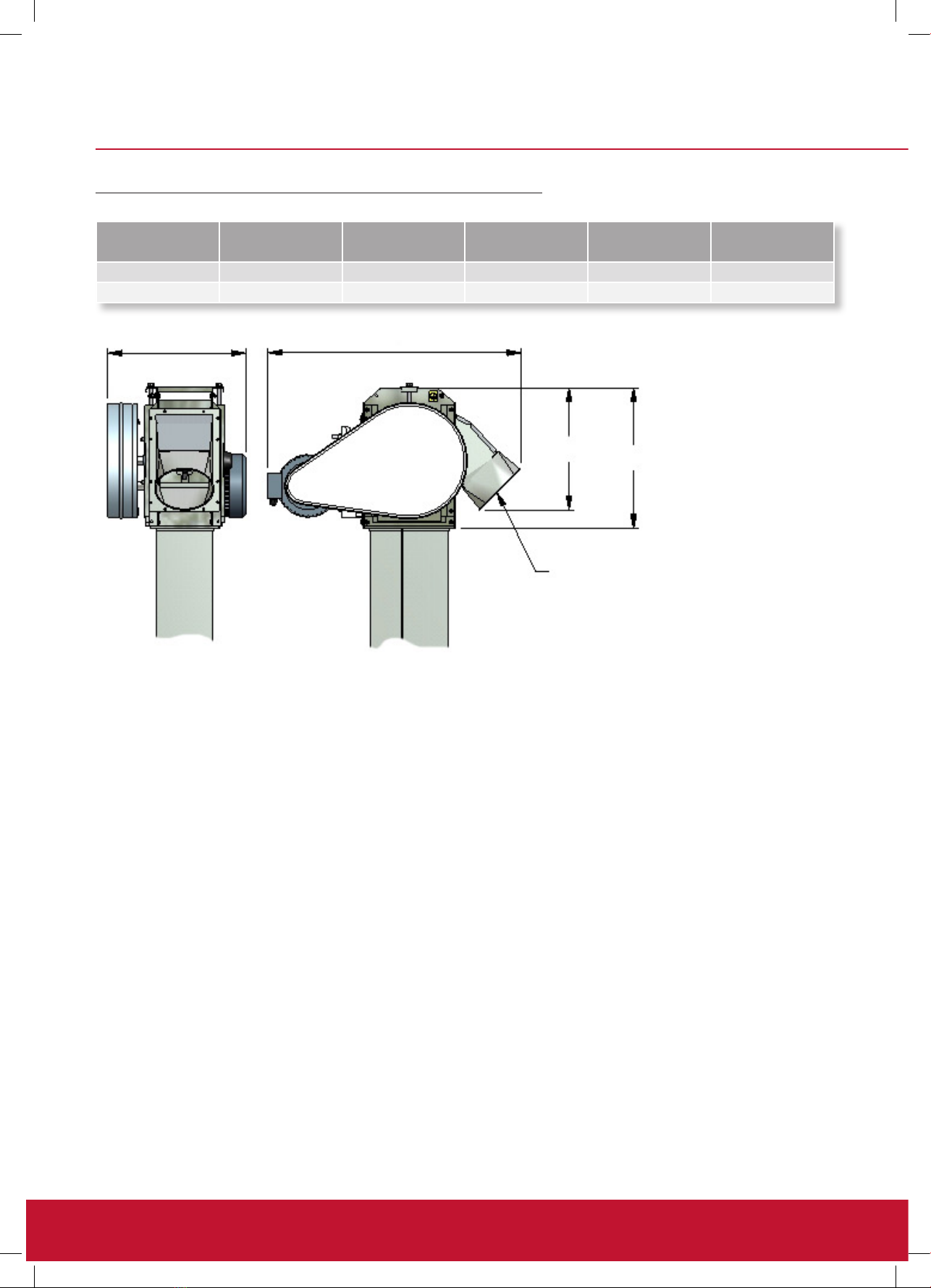

Scale drawing T20/T40 (pulley drive) ....................................................................................16

Upon receipt.........................................................................................................................17

Warning labels......................................................................................................................17

Foundation...........................................................................................................................18

Lifting equipment ................................................................................................................18

Lifting instructions................................................................................................................19

Weight table – individual components T20/T40.....................................................................20

Weight table chain elevator T20/T40.....................................................................................22

Weight table chain elevator T20/T40.....................................................................................23

Weight table T20 (gear motor) .............................................................................................24

Weight table T20 (pulley drive) .............................................................................................25

Weight table T40 (gear motor) .............................................................................................26

Weight table T40 (pulley drive) .............................................................................................27

Assembly ......................................................................................................................................28

Sealing .................................................................................................................................29

Elevator bottom section ........................................................................................................30

Elevator top section..............................................................................................................31

AGRO

www.jema.as | 3

Chain elevator with auger trough................................................... 33

Chain elevator with 55° and 90° bend .......................................... 34

Fitting of gear motor ..................................................................... 35

Fitting of motor and pulley kit........................................................ 36

Elevator extensions........................................................................ 37

Elevator chain................................................................................ 38

Assembly of elevator ..................................................................... 41

Potential equalization .................................................................... 42

Height attachment......................................................................... 43

Support of increasing elevator ....................................................... 44

Upstart ......................................................................................... 45

Elevator stops – faultfinding .......................................................... 45

Maintenance .......................................................................................... 46

Gear motor.................................................................................... 46

Motor ............................................................................................ 46

Pulley kit ....................................................................................... 46

Elevator chain................................................................................ 47

Rubber slats .................................................................................. 47

Bearings........................................................................................ 47

Lubrication of bearings.................................................................. 48

Elevator head ................................................................................ 48

Elevator boot ................................................................................ 48

Leaks ............................................................................................ 48

Noise and vibrations...................................................................... 48

Disposal............................................................................................. 49

Options/accessories ........................................................................... 50

Inspection door with inlet.............................................................. 50

Inlet piece for Flex elevator boot.................................................... 51

Inlet d200 for Flex elevator boot, one-way..................................... 52

Extensions with pivot inlet ............................................................. 53

Extensions 0.5 m with 45° inlet ..................................................... 54

Outlet for elevator head ................................................................ 55

Hopper for elevator ....................................................................... 56

Parts T20/T40 .................................................................................... 57

Parts list T20/T40 .......................................................................... 59

4 | www.jema.as

JEMA AGRO A/S is a modern factory, which specializes in producing and delivering equipment for transport systems for raw

or cleaned grain, seeds and granulates.

Our current product range is the result of more than 60 years experience in machine development especially for the

agricultural sector in close collaboration with our customers – and our company is highly regarded in the industry due to

the quality and versatility of our products.

JEMA AGRO A/S conveyors and transport systems are compatible with ALL types of dryer- and silage systems.

Important!

Please read these instructions carefully before assembly and use.

Introduction

AGRO

www.jema.as | 5

The manufacturer: JEMA AGRO A/S

Kløservejen 2, Sahl

DK-8850 Bjerringbro

Phone +45 86 68 16 55

Hereby declares that:

Product: Chain elevator

Type: T20/T40

Year of production: 2006

• ConformstotheMachinedirective2006/42/EFwithspecialreferencetothedirective

appendix 1 regarding major health- and safety regulations regarding construction and

production of the machines

The following standards have been applied:

EN ISO 12100-1:2005 Basic terminology and methodology

EN ISO 12100-2:2005 Technical principles

EN 1050:1997 Principles for risk assessment

• isinaccordancewithEMC-directive04/108/EFof15thDecember2004regarding

electromagnetic compatibility.

Director Jens-Peter Pedersen

Title Name

04.12.2008

Date Signature

EU Declaration of conformity

6 | www.jema.as

Conditions of use

JEMA AGRO A/S chain elevators T20/T40 have been constructed for transport of grain, granular materials and

seed mix.

• ThechainelevatorsT20/T40mustonlybeusedfortheproduct(s)specifiedinthecontract.

• Theelectricalconnectionsmustbedonebyaqualifiedelectrician.

• ThechainelevatorsT20/T40mustbepotentialadjustedinaccordancewiththecurrentlocalregulations

• Thechainelevatorshavebeenthoroughlycontrolledregardingmaintenance,andachecklisthasbeendrawnup

containing regular cleaning- and maintenance intervals. If these intervals are not observed, the JEMA AGRO

conditions for a trouble-free operation cease to exist and the warranty will be invalid.

• Duringinstallation,maintenanceorrepairtheelectricsupplytothechainelevatorsmustbedisconnected

and secured against accidental reconnection.

• Theusermanualmustbekept/beavailableincloseproximitytothechainelevatorT20/T40

AGRO

www.jema.as | 7

Delivery

The chain elevator is disassembled for shipment. Standard packing (pallet/wooden boxes,

grid boxes, etc.) Regarding the actual transport there are no specific requirements apart

from normal consideration.

The shipment includes the parts stated in the order confirmation.

Please read this manual carefully before installation and use.

Storage

There are no precautions regarding long-time storage.

After delivery the components must be kept in a suitable, dry storage area before

installation.

Noise level

A noise level test was conducted for the chain elevator. The level has been measured in a

distance of 1 m from the conveyor surface and at a height of 1.6 m from the floor level.

During the test the chain elevator was running unloaded, which is the operational state of

maximum noise level.

The measured noise level is not higher than 70 dB

General information

8 | www.jema.as

Type: XXXXX

Model: XXXX

År: XXXX

JEMA AGRO A/S

Sahl, DK-8850 Bjerringbro

tlf. +45 86 68 16 55

www.jema.as

Type Plate

The type plated is fitted on the drive station.

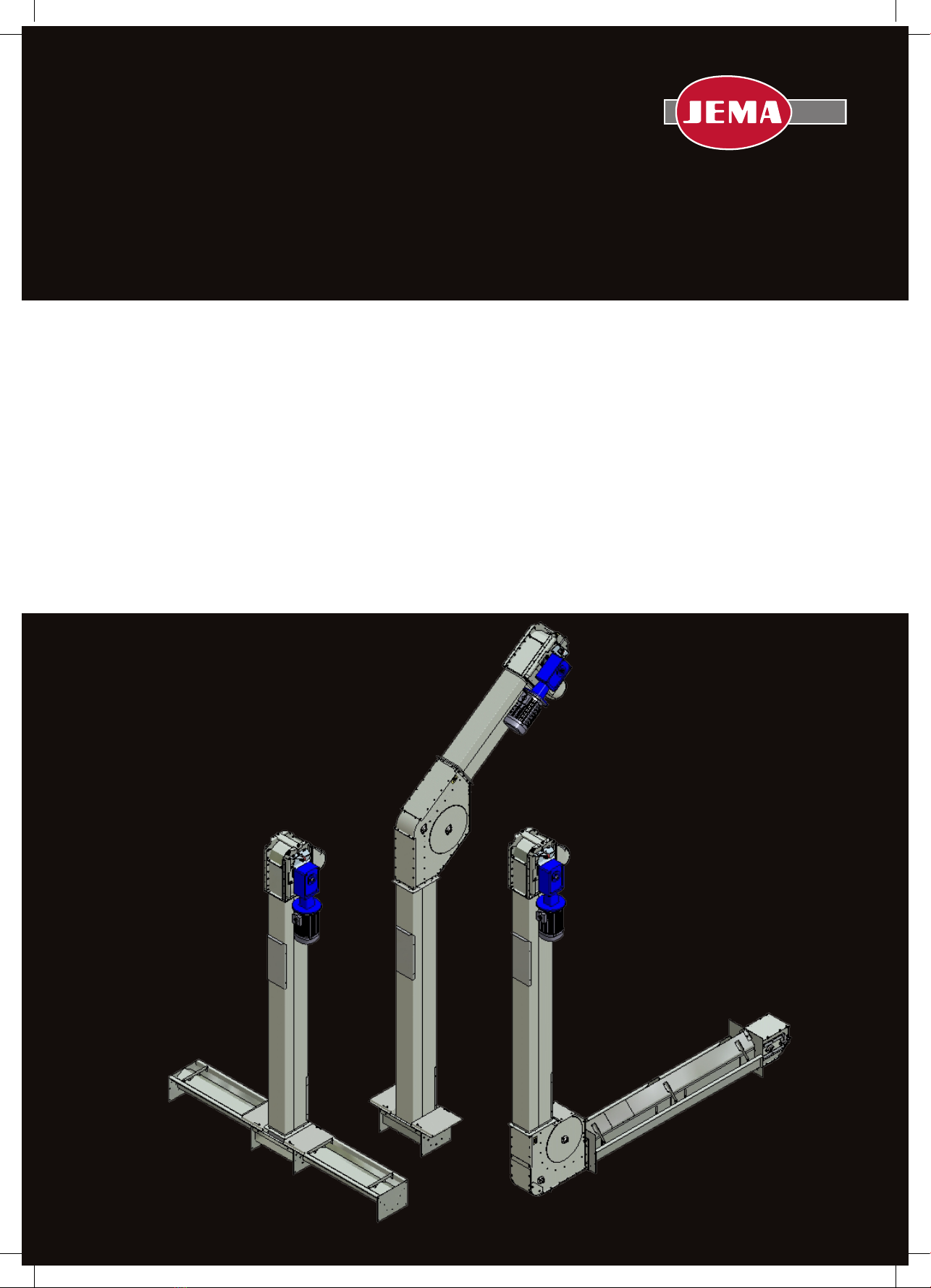

Construction

The chain elevator type T20/T40 is made up of standard elements, which can be combined and easily integrated into all

grain conveyor systems. It is characterized by a large capacity and compact dimensions. Both elevators work efficiently in

all positions and compared to their capacity (output), they both have low power consumption.

The chain elevator is made of galvanized steel, which makes it perfectly suited for outdoor use. It is furthermore fitted

with a high quality roller chain with bolted rubber flights.

The chain elevator can be combined for both vertical and horizontal transport by using side augers in troughs. These are

driven from the elevator bottom shaft, so both elevator and side auger are driven by the same motor, alternatively the

side auger can by driven separately by a directly connected gear motor.

The side auger in trough is available for both left and right elevator. The 135 diameter augers have an inclination of

incl.60, incl.90, incl.125, available in lengths of 2.0m, 1.25m, 1.0m, and 0.5m.

Another combination of vertical and horizontal transport can be obtained by using a 90° bend. The inlet trough is fitted

horizontally and attached with a 90° bend to the vertical part of the elevator. The inlet troughs are available in lengths of

2.0m, 1.25m, 1.0m and 0.5m.

A third combination is possible by using a 55° bend, which makes it possible to change from vertical position to 55°, e.g.

above a silo roof.

The chain elevator consists of:

• Elevatorhead

• Elevatorboot

• 2.5mextensionswithinspectiondoor

• Chainwithrubberslats

• Extensionsfrom0.125mto2.5m.

• Outlet

• Motor

Additional inlet piece is available.

AGRO

www.jema.as | 9

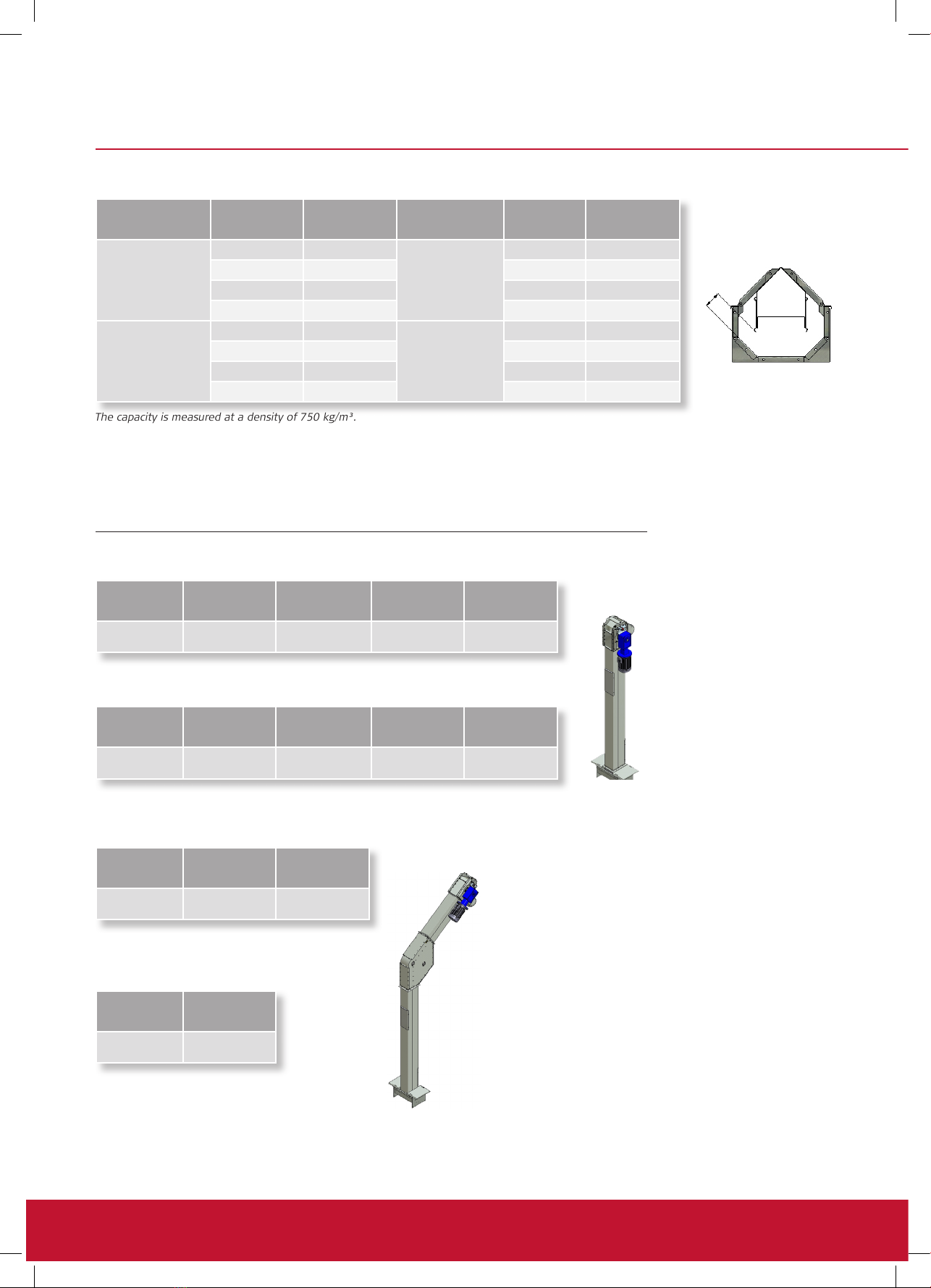

Capacity

The table below shows the various density capacities:

Measured in cleaned, storable material at a power supply of 50 Hz

The capacity varies according to the nature of the material.

Capacity for chain elevator T20/T40:

Above capacity measured in cleaned, storable material at a density of 750 kg/m³.

Capacity per side auger fitted on chain elevator T20/T40:

Above capacity measured in cleaned, storable material at a density of 750 kg/m³.

Density T20 (33 m3/h) T40 (60 m3/h)

650 kg. pr. m3 21 t/h 39 t/h

700 kg. pr. m323 t/h 42 t/h

750 kg. pr. m3 (wheat) 25 t/h 45 t/h

T20, inlet from both sides without propeller 14 t/h

T20, inlet from both sides with propeller 25 t/h

T20 with d135, S60 auger from one side 14 t/h

T20 with d135, S90 auger from one side 19,5 t/h

T20 with d135, S125 auger from one side 25 t/h

T40, with inlet from both sides with propeller d135 45 t/h

T40 with d135, S125 auger from both sides 45 t/h

Auger

d135 S125 Auger

d135 S90 Auger

d135 S60

Elevator with gear motor 280 rpm

Elevator with pulley kit motor 1440 rpm

rpm.: bottom shaft / auger 315 rpm

22,0 17,0 13,0

Elevator with gear motor 180 rpm

Elevator with pulley kit motor 1000 rpm

rpm. bottom shaft / auger 210 rpm

15,0 11,0 9,0

Auger driven by separate gear motor 250 rpm 17,5 12,5 10,0

Auger driven by separate gear motor 280 rpm 19,5 15,0 11,5

Auger driven by separate gear motor 315 rpm 22,0 17,0 13,0

Auger driven by separate gear motor 405 rpm 28,0 22,0 17,0

10 | www.jema.as

J

Inlet trough adjustment

The capacity is measured at a density of 750 kg/m³.

Important! – The J dimension in the sketch is just for guidance.

Important! - Remember to adjust the inlet plates before starting.

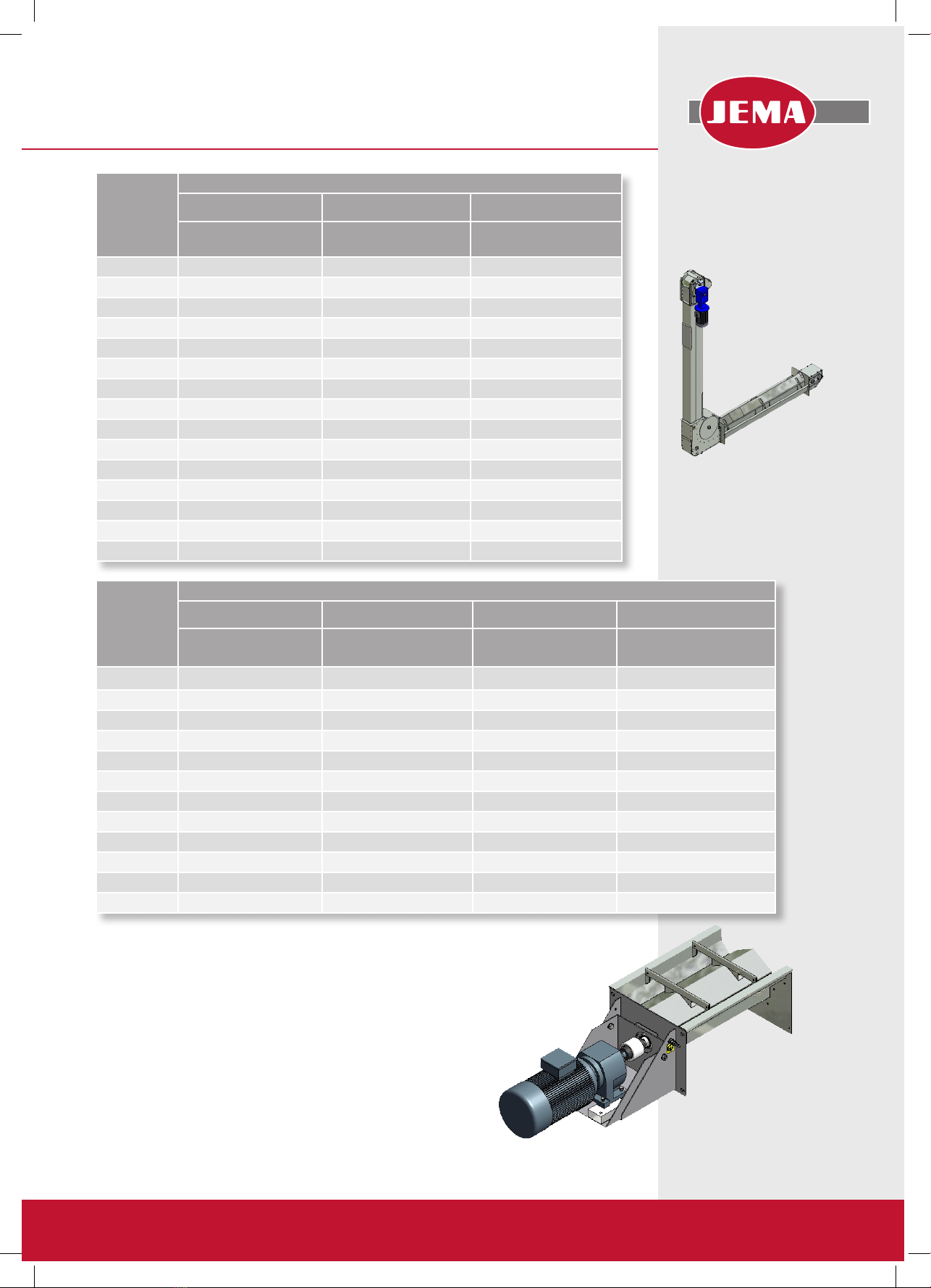

Technical specifications – power consumption

Chain elevator T20 - power consumption in kW:

Chain elevator T40 - power consumption in kW:

Conveyor T20 - power consumption in kW:

Conveyor T40 - power consumption in kW:

T20 J

opening Capacity

t/h T40 J

opening Capacity

t/h

Pulley drive with

motor 1.500 rpm

Gear motor

280 rpm

15 5 Pulley drive with

motor 1.500 rpm

Gear motor

280 rpm

15 25

25 11 25 31

35 18 35 38

45 25 45 45

Pulley drive with

motor 1.000 rpm

Gear motor

180 rpm

20 10 Pulley drive with

motor 1.000 rpm

Gear motor

180 rpm

20 30

35 16 35 40

50 23 50 50

65 30 65 60

Type 0-9 m 10-12 m 13-16 m 17-20 m

T20 2,2 kW 3,0 kW 4,0 kW 5,5 kW

Type 0-7 m 8-10 m 11-14 m 15-20 m

T40 2,2 kW 3,0 kW 4,0 kW 5,5 kW

Type 15-17 m 18-20 m

T20 4,0 kW 5,5 kW

Type 15-20 m

T40 5,5 kW

AGRO

www.jema.as | 11

Additional power consumption per meter auger in trough d135 = 0.35 kW.

At a total consumption above 5.5 kW, separate drive for the side augers will be used.

Power consumption separate drive for auger in trough d135:

Op to 6.0 m auger = 2.2 kW

Above 6.0 m auger = 3.0 kW

Side augers separate drive

Heigth,

metres

Length

2,35 m 3,35 m 4,35 m

kW

T20/T40 kW

T20/T40 kW

T20/T40

3,65 2,2/3,0 2,2/3,0 2,2/3,0

4,61 2,2/3,0 2,2/3,0 2,2/3,0

5,61 2,2/3,0 2,2/3,0 3,0/3,0

6,61 2,2/3,0 3,0/3,0 3,0/4,0

7,57 3,0/3,0 3,0/4,0 3,0/4,0

8,57 3,0/4,0 3,0/4,0 4,0/4,0

9,66 3,0/4,0 4,0/4,0 4,0/4,0

10,66 4,0/4,0 4,0/4,0 4,0/5,5

11,66 4,0/4,0 4,0/5,5 4,0/5,5

12,62 4,0/5,5 4,0/5,5 5,5/5,5

13,62 4,0/5,5 5,5/5,5 5,5/5,5

14,58 5,5/5,5 5,5/5,5 5,5/5,5

15,58 5,5/5,5 5,5/5,5 5,5/5,5

16,58 5,5/5,5 5,5/5,5

17,66 5,5/5,5

Heigth,

metres

Length

5,35 m 6,35 m 7,35 m 8,35 m.

kW

T20/T40 kW

T20/T40 kW

T20/T40 kW

T20/T40

3,65 2,2/3,0 3,0/3,0 3,0/4,0 3,0/4,0

4,61 3,0/3,0 3,0/4,0 3,0/4,0 4,0/4,0

5,61 3,0/4,0 3,0/4,0 4,0/4,0 4,0/5,5

6,61 3,0/4,0 4,0/4,0 4,0/4,0 4,0/5,5

7,57 4,0/4,0 4,0/4,0 4,0/5,5 4,0/5,5

8,57 4,0/4,0 4,0/5,5 4,0/5,5 5,5/5,5

9,66 4,0/5,5 4,0/5,5 5,5/5,5 5,5/5,5

10,66 4,0/5,5 5,5/5,5 5,5/5,5 5,5/5,5

11,66 5,5/5,5 5,5/5,5 5,5/5,5 5,5/5,5

12,62 5,5/5,5 5,5/5,5 5,5/5,5

13,62 5,5/5,5 5,5/5,5

14,58 5,5/5,5

12 | www.jema.as

Elevator extensions

The extensions are available in various lengths:

2.5 m, 2.0 m, 1.0 m, 0.5 m, 0.25 m, 0.125 m.

Extensions with inspection doors are available in

lengths of 2.5 m.

Inlet troughs are available in lengths of:

2.0 m, 1.25 m, 1.0 m, and 0.5 m.

The elements can be combined to obtain any

lengths - for the vertical elevator with steps

of 0.125 m. and with intervals of 0.25 m for the

horizontal elevator - up to a total length of 20.0 m.

Elevator head

The elevator head is delivered as a complete unit. The motor is supplied separately.

AGRO

www.jema.as | 13

Elevator boot

The boot section is fitted in trough from vertical position to 45°. Augers in trough can be

fitted to the boot section in one or both sides.

Elevator boot with inlet Closed boot

Flex-boot section with console and clutch

14 | www.jema.as

A B C D E F G H I J K

T20 378 215 175 335 135 530 430 500 OK160 278 215

T40 457 277 240 400 200 550 480 500 SK200 278 215

L M N O P Q R S T U V

T20 320 400 760 300 520 365 265 300 265 365 500

T40 320 400 760 300 520 365 265 300 265 365 500

A

B

C

D

E

F

G

H

I

J

K

L

N

P

Q

R

O

M

S

T

U

V

Scale drawing T20/T40 (gear motor)

Fill up the auger trough with dry sand, and then trim around the edges.

Measure for trough under elevator

Concrete measure for auger in trough Ø135

AGRO

www.jema.as | 15

A B C D E F G H I

T20 / T44 375 230 355 720 430 300 720 730 1045

T40 / T45 390 230 415 720 430 300 720 730 1045

H

I

A

B

C

DE

F

G

Scale drawing T20/T40 90°/55° bend and chain conveyor

T44/T45

(gear motor)

16 | www.jema.as

A B C D E

T20 505 890 440 500 OK160

T40 525 940 450 500 Ø200

AB

E

C

D

Scale drawing T20/T40 (pulley drive)

AGRO

www.jema.as | 17

Upon receipt

Please check that all parts and components are included in the shipment and check for

possible transport damages.

NB: Make sure that the relevant supplier documentation is attached to the gear and motor.

In case of missing documentation, please contact JEMA AGRO A/S – remember to state the

order no.

Remember all necessary safety equipment before installation.

Please read this manual carefully before assembly or installation work begins.

Warning labels

The chain elevator is fitted with warning labels.

Warning!

The covers and shields must

never be opened or removed, when

the machine is working.

Warning!

Always keep hands away from

rotating augers/propellers.

18 | www.jema.as

Foundation

The chain elevator should be placed on a sufficiently hard, level surface that is able to carry the load in question.

Lifting equipment

Make sure to have the required SWL-approved lifting equipment/crane, required for the actual job.

The lifting equipment must be approved to carry the load in question.

The load capacity for the individual components can be found in “Parts list T20/T40” in this manual.

The total weight of the machine is stated in the section “Weight table chain elevator T20/T40”.

NB: Always make sure that nobody is standing under a suspended load.

AGRO

www.jema.as | 19

Lifting instructions

The drawing below shows how to lift the chain elevator using the attached brackets.

Lifting point

20 | www.jema.as

Weight table – individual components T20/T40

Description T20

Part no.

Weight

kg

T40

Part no.

Weight

kg

Drive station for pulley drive 51577 36 52116 39

Drive station for pinion gear motor,

RHS 51583 36 52483 39

Drive station for pinion gear motor,

LHS 51585 36 52485 39

Tension section 44095 12,61 45095 13,77

Elevator boot d135, without chain 51142 7 52142 8

Elevator boot d135, with ball

bearings in sprocket, without chain 51143 8 52143 9

Elevator boot, closed without chain 51231 6,6 52231 7,3

Flex elevator boot, without chain 51312 20 52312 20,7

Flex elevator boot, with ball bearings in

sprocket, without chain 51316 22 52316 22,7

Extension 2.5 m with inspection door 51012 35 52012 37

Extension 2.5 m 51021 35 52021 37

Extension, 2.0 m 51022 28 52022 32

Extension, 1.0 m 51024 14 52024 16

Extension, 0.5 m 51025 7 52025 8

Extension, 0.25 m 51026 3 52026 5

Extension 1.25 m 51027 2 52027 3

This manual suits for next models

1

Table of contents