—6 —

3.2.3 Mounting of Drive

Motor, reducer, coupling, drive bracket and guard have already been assembled before

the delivery. To mount the drive to the elevator body, the detailed requirement of Assembling

General Drawing should be followed and the drive should be fixed to drive platform or head

housing. The drive may become loose due to transportation or other factors, so check should

be made prior to installation and starting. After the drive is fixed, check to see if the connecting

bolts become loose and if coupling reach the requirement of installation.

3.2.4 When elevator has drive platform, the parallelism allowance of installation datum

plane of reducer on the platform to level should not be larger than 1mm.

3.2.5 When mounting bucket belt and buckets, firstly adjust the tail pulley base of elevator

foot to the top position, and then pull the pre-stretched bucket belt in from elevator head. One

end rounds the tail pulley and is pulled out of the access door, and is connected with another

end. Bucket belt adopts lap joint or angular joint. For lap joint, it would be better that length of

lap joint section equals the length of 3-5 buckets. See Figure 5 for lap joint and Figure 6 for

angular joint. Then mount the buckets one by one to the bucket belt at the access door of

bearing branch section. The central line of bucket should align the central line of bucket belt

with deviation not larger than 4mm. For users who have the inspecting and repairing motor,

after mounting the drive and connecting the power, they can start the inspecting and repairing

motor by touch to drive the belt and then mount buckets one by one.

3.2.6 After mounting the buckets, adjust the tensioner to make bucket belt be tensioned to

proper extent. Observe the position of tail shaft and take note that the remaining tension stroke

is not less than 50% of total stroke. If it is not qualified, connect the belt again until it is qualified.

3.2.7 Adjust the position of return retainer at elevator head to make the gap between it and

outer edge of bucket keep at 5mm-10mm.

3.2.8 The arrangement of position of elevator head should follow the requirement of

technological process. Its discharging outlet and feeding inlet of elevator foot can be arranged

in same side (The feeding type is direct feeding), also in opposite side (The feeding type is

converse feeding). The fill-up coefficient of bucket for converse feeding is higher than that of

bucket for direct feeding. Converse feeding type is recommended.

3.2.9 Quality Requirement and Inspection Method of Casing

After mounting of the casing is finished, the mounting quality should be checked by using

the following method. If there is anything not meeting the requirement, the casing cannot be

fixed until correction is made by means of adding the pad.

3.2.9.1 The parallelism allowance of upper plane of elevator foot to level is not larger than

1.2mm.

3.2.9.2 The parallelism allowance of head pulley shaft to level is not larger than 0.3/1000.

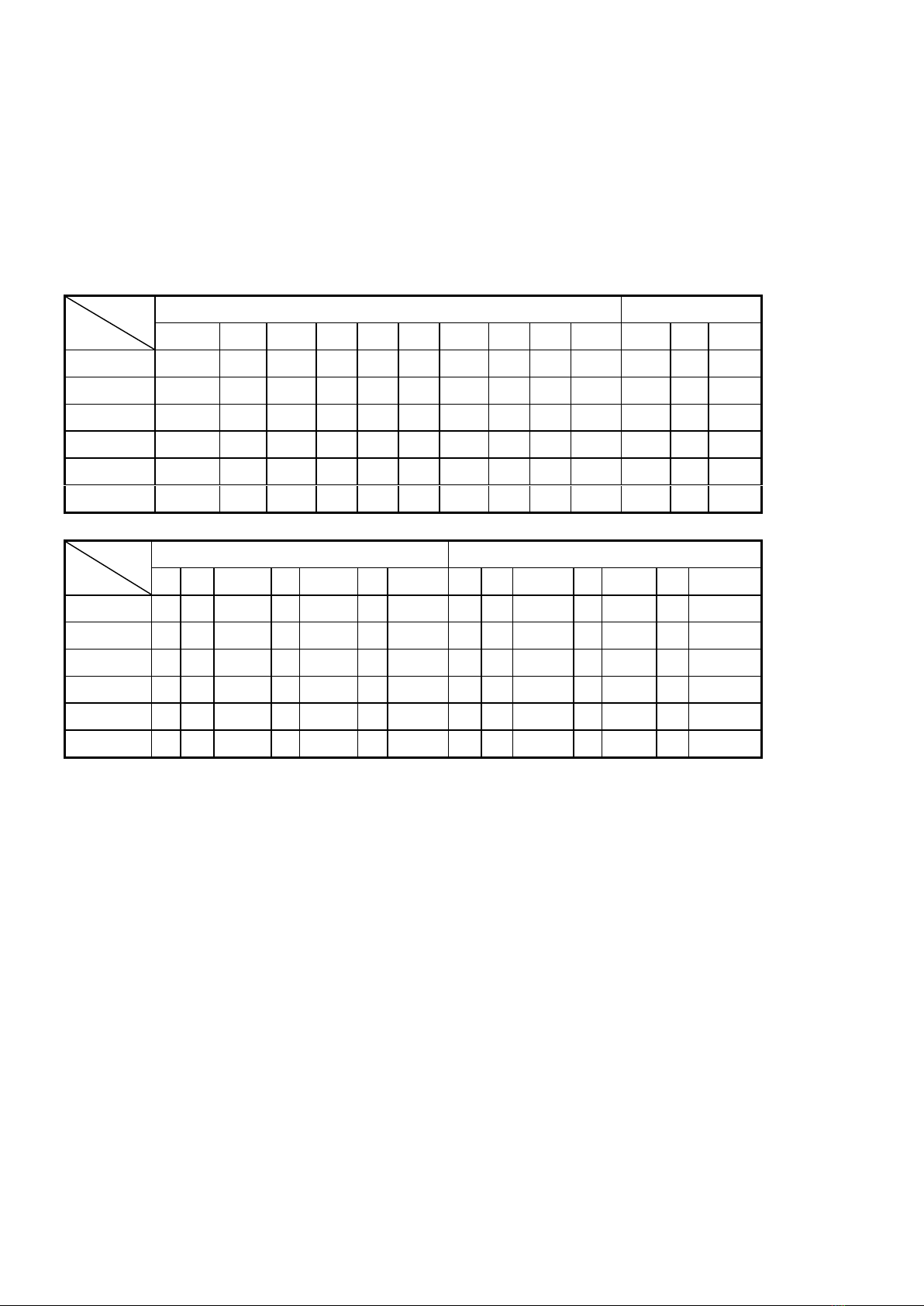

3.2.9.3 Check the perpendicularity and curvature and see Table 4 for requirement on

deviation.