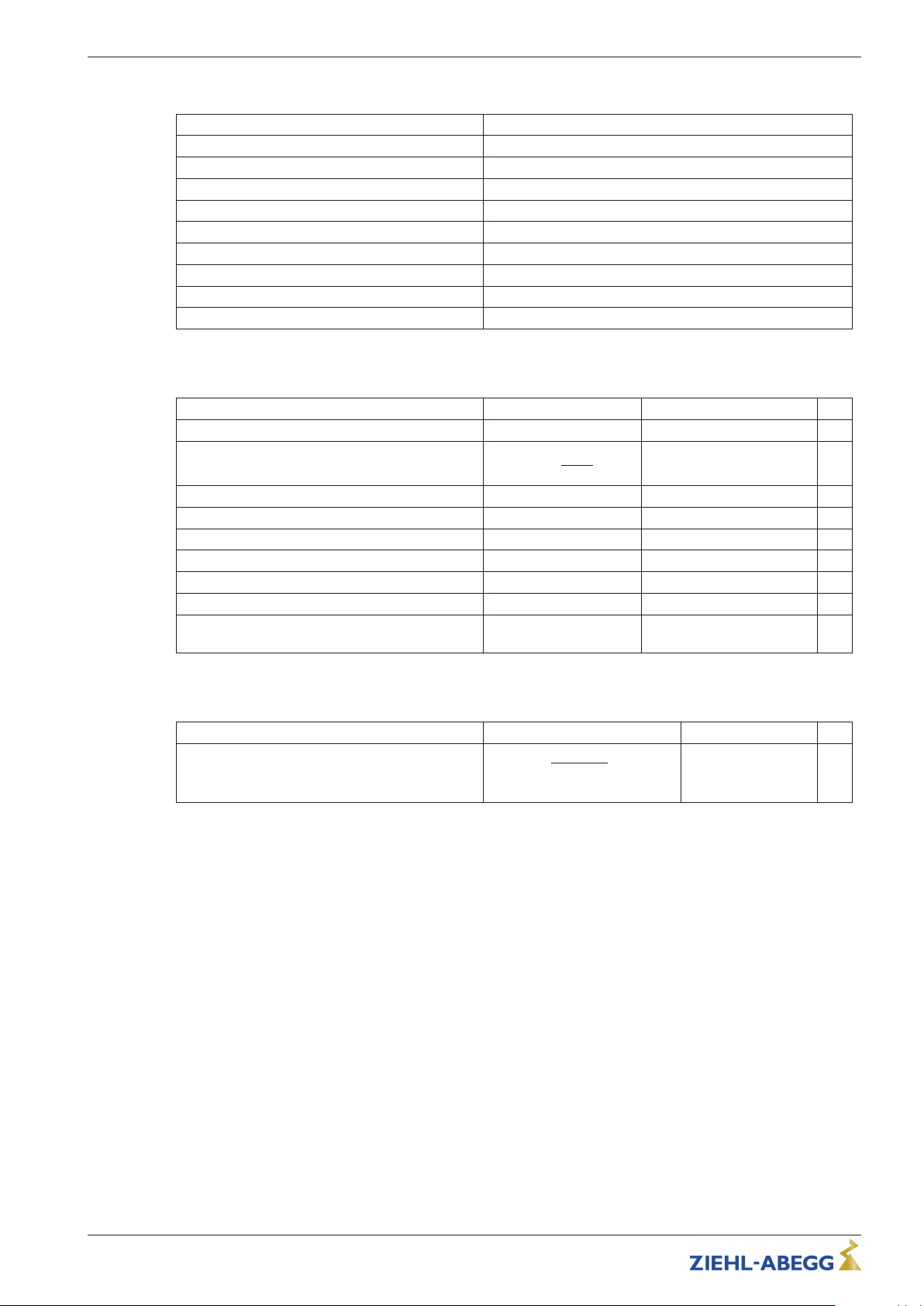

3 Inspection intervals and regular maintenance work

Information

"All maintenance and service work must be performed carefully and only by well-trained personnel.

The guarantee conditions include keeping the inspection intervals!

Measures Intervals Remarks

Check gear temperature every three months admissible 80 °C on the housing

Check gears for unusual noises every three months

Check oil level every three months Oil level according to marks on the

dipstick.

Check gearbox for leaks every three months

First oil change after start-up after 3 years

Further oil changes after another 6 years

Clean bleeding screw when changing the oil

Clean drive when changing the oil

Operating brake

Check brake liners

With speed control: Yearly There maining thickness of the liner

must be at least 3 mm.

Operating brake

Check remaining stroke on brake

bleeding device

With speed control: Yearly Set remaining stroke.

Operating brake

Check electromagnets

every year

Safety brake

Check air gap

Every six months Air gap nominal value

0.6 ±0,1 mm

maximum air gap after wear

0.8 mm

Check the micro switch

Locking varnish must be undam-

aged.

every year Check the distance between the set-

ting screw for the micro switch and

adjust if necessary.

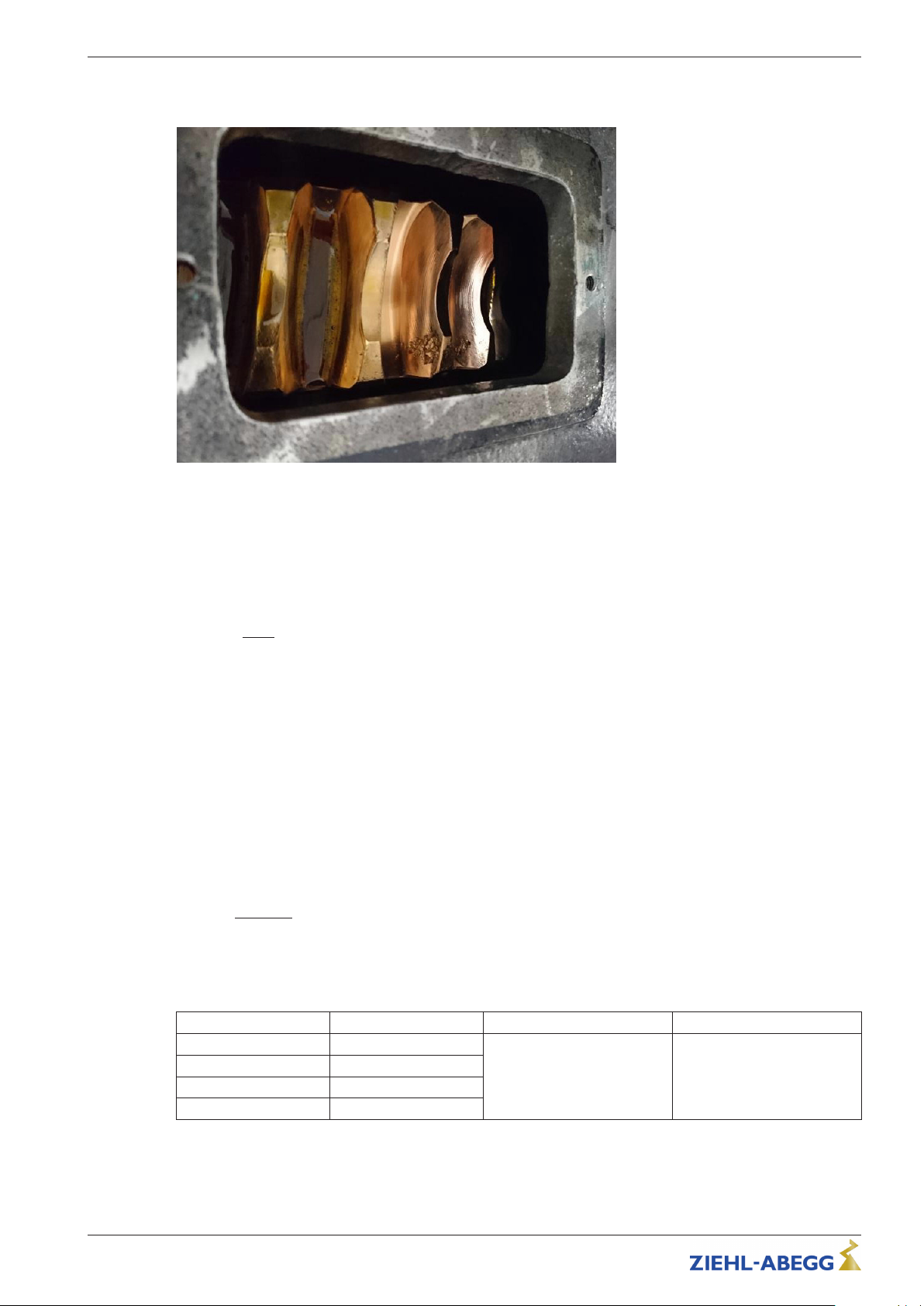

Check the vicinity of the clutch for

unusual wear articles

every year Plastic particles indicate inadmissi-

ble wear of the elastic plastic buffer

of the clutch.

Check rotation play of the clutch after 5 years for the first time

then annually

5 mm for a diameter of 360 mm at

the motor hand wheel are admissi-

ble.

Replacement of the elastic plastic

buffer

after 10 years

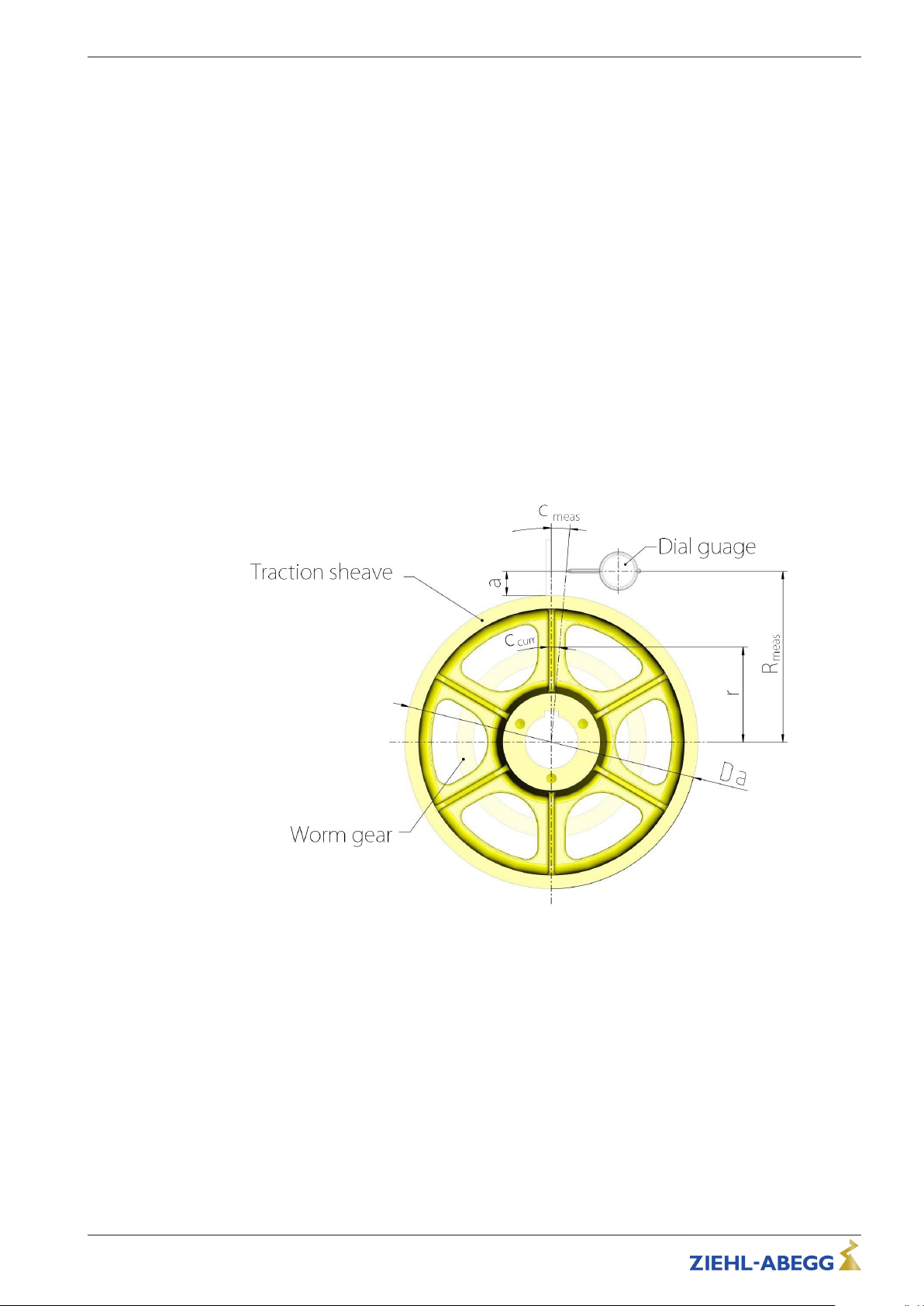

Check rotation play of the traction

sheave

Yearly (see chapter 4 “Flank clear-

ance measurement”)

The permitted limit is 3 mm on a

260 mm radius on the traction

sheave for comprehensive measure-

ment of the flank clearance (see

chapter 4.3 “Comprehensive flank

clearance measurement”).

Check the traction sheave if worn

out

every year

Check distance cable protection every year

Visual inspection of the fastening

screws of the gearbox, drive, brakes

and traction sheave. Sealing varnish

must be undamaged.

every year

Visual inspection of the fitting of the

nuts for the worm gear screw con-

nections

every year See chapter 5 “Visual inspection of

nut fitting”.

Service instructions ZAS0, ZAS1, ZAS2, ZAS3 Inspection intervals and regular maintenance work

A-TIA19_07-GB 1936 Index 001 Part.-No. 01013457-GB

5/12