Jepson POWER Magpro40 1S User manual

Magnetic Drilling Machine

MAGPRO 40/ 1S Adjust Swivel

OPERATOR'S MANUAL

EC Declaration of Conformity

according to EC Machinery Directive 2006/42/EC

We, Jepson Power GmbH

Ernst-Abbe-Straße 5

52249 Eschweiler

Germany

declare under our sole responsibility that the product

Product : Electromagnetic Drilling Machine

Type Designation(s): MAGPRO 40/1S Adjust Swivel

Serial No. :

Year ofManufacture : 2019

to which this declaration relates isin conformity with the following standard(s) or other normative

document(s);

EN ISO12100

(2010)

Safety of machinery - General principles for design – Risk assessment

and risk reduction

EN60204-1/A1

(2009)

Safety of machinery - Electrical equipment of machines

Part 1 : General requirements

following the provisions of Directive(s);

2006/42/EC

Directive on the approximation of the laws of Member States relating to machinery

(OJ L157 Jun, 9, 2006)

2006/95/EC Directive on the laws of Member States relating to electrical equipment designed for

use with certain voltage limits (OJ L374 27.12.2006)

Pierre Michiels, Managing Director

Name, Position Eschweiler, 01.01.2019

- 1 -

CONTENTS OF THE MANUAL.

[1]

SPECIFICATIONS OF MAGNETIC DRILLING MACHINE

[2]

SAFETY PROCEDURES

[3]

OPERATING INSTRUCTIONS

[4]

EXTENSION CABLE SELECTION

[5]

MOUNTING OF CUTTERS

[6]

REMEDIES FOR HOLE MAKING PROBLEMS

[7]

CIRCUIT

Page

3

4

6

7

7

8

11

[8]

PART LIST 12

List of Contents with Magnetic Drill Unit Check

List

1 Operator's Manual YES/NO

2 Coolant Bottle YES/NO

3 Pilot Pin for 25mm cutters YES/NO

4 Pilot Pin for 50mm cutters YES/NO

5 5mm Hexagon Key YES/NO

6 Drill drift YES/NO

- 2 -

MAGPRO 40/ 1S Adjust Swivel

(Ref.: 490140S)

- 3 -

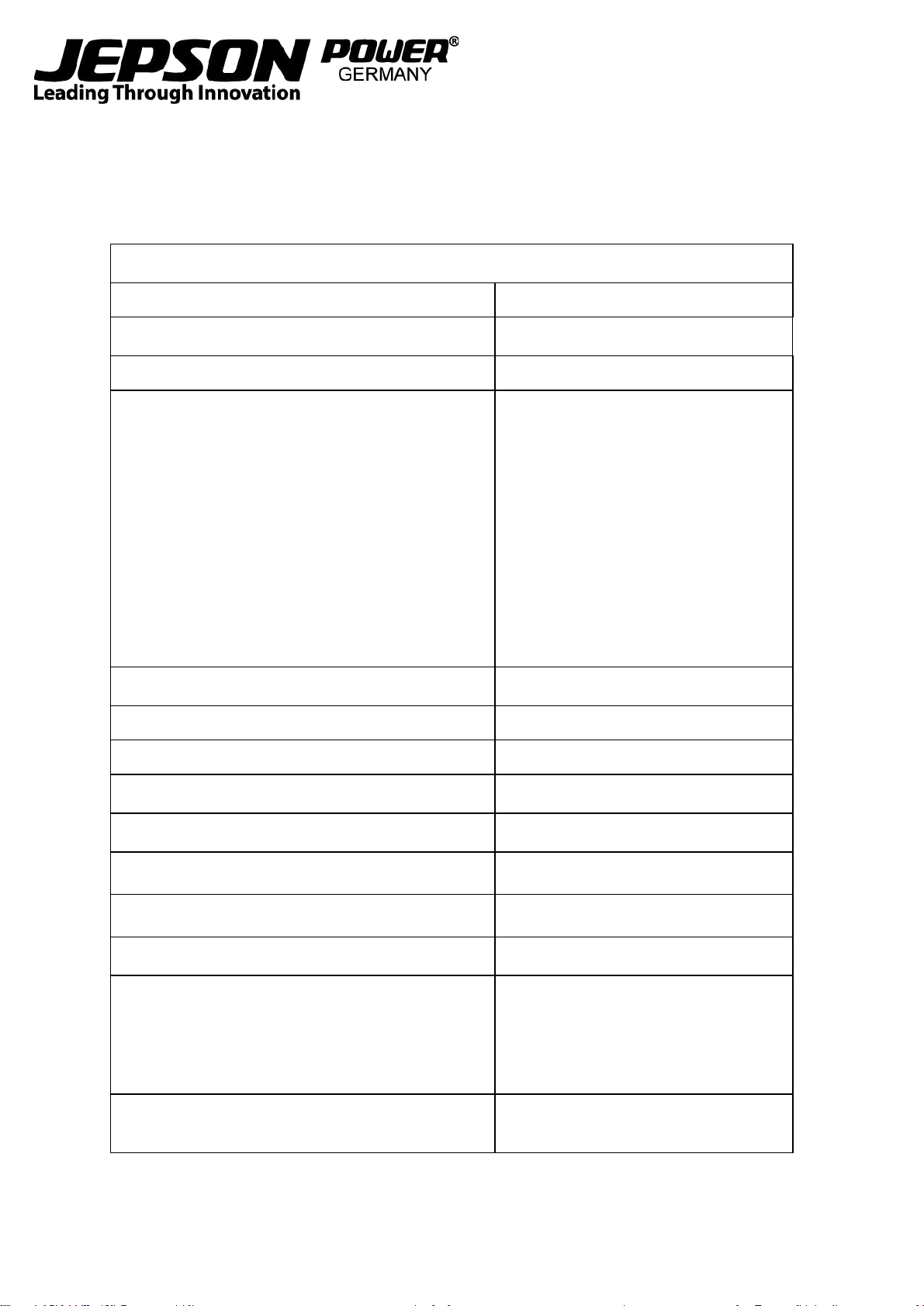

[1] SPECIFICATIONS OF MAGNETIC DRILLING MACHINE

[MODEL Magpro40/ 1S Adjust Swivel, Reference: 490140S]

Maximum hole cutting capacity in .2/.3C steel = 40mm dia. x 50mm depth

Motor Unit

Voltages 220/240V(100/110V), 50/60Hz

Rated output 1,100 W

Magnet Size 155 x 78 x 45 mm

Magnet Force at 20°C with

20 mm minimum plate thickness

The use on any material less than 20mm thick

will progressively reduce the magnetic

performance. If possible, substitute material

should be positioned under the magnet and

work piece to equate to a suitable material

thickness. If this is not possible, an alternative

secure method of restraining the machine

MUST be used.

420kgf at drilling point

Overall Dimensions

Height - maximum extended 540mm

Height - minimum 340mm

Width (including Hand wheel) 190mm

Length Overall (including Guard) 230mm

Stroke 150(200)mm

RPM ( No LOAD ) 450

Net Weight 12.0kg

Maximum hand/arm vibration magnitude

(measured at handle during operation in

accordance with ISO5349, using a 22mm

cutter through 13mm MS plate)

0.82 m/s²

Average noise level during cutting at

operators ear position.

90dB(A)

- 4 -

READ BEFORE USING THE MACHINE

[2] SAFETY PROCEDURES

●When using electrical tools, basic safety precautions should always be

followed to reduce the risk of electric shock, fire, and personal injury.

●Do NOT use in wet or damp conditions. Failure to do so may result in

personal injury.

●Do NOT use in the presence of flammable liquids or gases. Failure to do

so may result in personal injury.

●ALWAYS SECURE THE MACHINE WITH THE SAFETY CHAIN WHEN

WORKING VERTICALLY OR OVERHEAD BEFORE STARTING TO OPERATE.

●Always wear approved eye and ear protection when the equipment is in

operation. Failure to do so may result in personal injury.

●Disconnect from the power source when changing cutters or working on

the machine.

●When changing cutters, or removing swarf, ALWAYS wear approved

gloves.

●ALWAYS ENSURE CUTTER RETAINING SCREWS ARE SECURE – they

sometimes vibrate loose when the machine is in continuous use.

●Regularly clear the work area and machine of swarf and dirt, paying

particular attention to the underside of the magnet base.

●With a gloved hand, and after switching off, remove any swarf which might

have gathered around the cutter and arbor before proceeding with the next

hole.

- 5 -

●Before operating the machine, always remove tie, rings, watches and any

loose adornments which might entangle with the rotating machinery.

●Should the cutter become 'fast' in the workpiece, stop the motor

immediately to prevent personal injury. Disconnect from the power

source and turn arbor to and fro. DO NOT ATTEMPT TO FREE THE

CUTTER BY SWITCHING THE MOTOR ON AND OFF.

●If the machine is accidentally dropped, always thoroughly examine the

machine for signs of damage and check that it functions correctly before

trying to drill a hole.

●Regularly inspect the machine and check that nuts and screws are tight.

●Always ensure when using the machine in an inverted position that only the

minimum amount of coolant is used and that care is taken to ensure that

coolant does not drip on to the motor unit.

●On completion of the cut, a slug will be ejected. DO NOT operate the

machine if the ejected slug may cause injury.

- 6 -

[3] OPERATING INSTRUCTIONS

●Keep the inside of the cutter clear of swarf. It restricts the operating depth of

the cutter.

●Ensure that the coolant bottle contains sufficient cutting oil to complete the

required operating duration. Refill as required.

●Occasionally depress the pilot to ensure cutting fluid is being correctly metered.

●To start the machine, first switch on the magnet. And then start the motor by

depressing the GREEN start button.

●Apply light pressure when commencing to cut a hole until the cutter is introduced

into the work surface. Excessive pressure is undesirable, it does not

increase the speed of penetration.

●Always ensure that the slug has been ejected from the previous hole before

commencing to cut the next.

(Right) (Wrong)

●Always cut overlapping holes as illustrated above – do not use excessive pressure

and ensure cutting fluid is reaching teeth of the cutter.

●If the slug sticks in the cutter, move the machine to a flat surface, switch on the

magnet and gently bring the cutter down to make contact with the surface. This will

usually straighten a cocked slug and allow it to eject normally.

●Cutter breakage is usually caused by insecure anchorage and a loosely fitting slide.

(Refer to routine maintenance instructions).

- 7 -

[4] EXTENSION CABLE SELECTION

The machines are factory fitted with a 2 metre length of cable having three

conductors 1.5mm² LIVE, NEUTRAL and EARTH.

If it becomes necessary to fit an extension cable from the power source,

care must be taken in using a cable of adequate capacity. Failure to do so

will result in a loss of traction by the magnet and a reduction of power

from the motor.

Assuming a normal AC supply of the correct voltage, it is recommended

that the following extension lengths shall not be exceeded:

For 110v supply: 3.5metres of 3 core x 1.5mm²

For 230v supply: 26metres of 3 core x 1.5mm² or

17metres of 3 core x 1.0mm²

ALWAYS DISCONNECT THE MACHINE FROM THE POWER SOURCE WHEN

CHANGING CUTTERS.

[5] MOUNTING OF CUTTERS

The machine has normal Weldon shank, 3/4“.

The following procedure is to be used when mounting cutters.

-Take appropriate pilot and place through hole in shank of cutter.

-The machine is delivered with a qick release system. To open the shank turn

the release anti clockwise.

-Put the Weldon arbor into the shank and close the release.

- 8 -

[6] REMEDIES FOR HOLE MAKING PROBLEMS

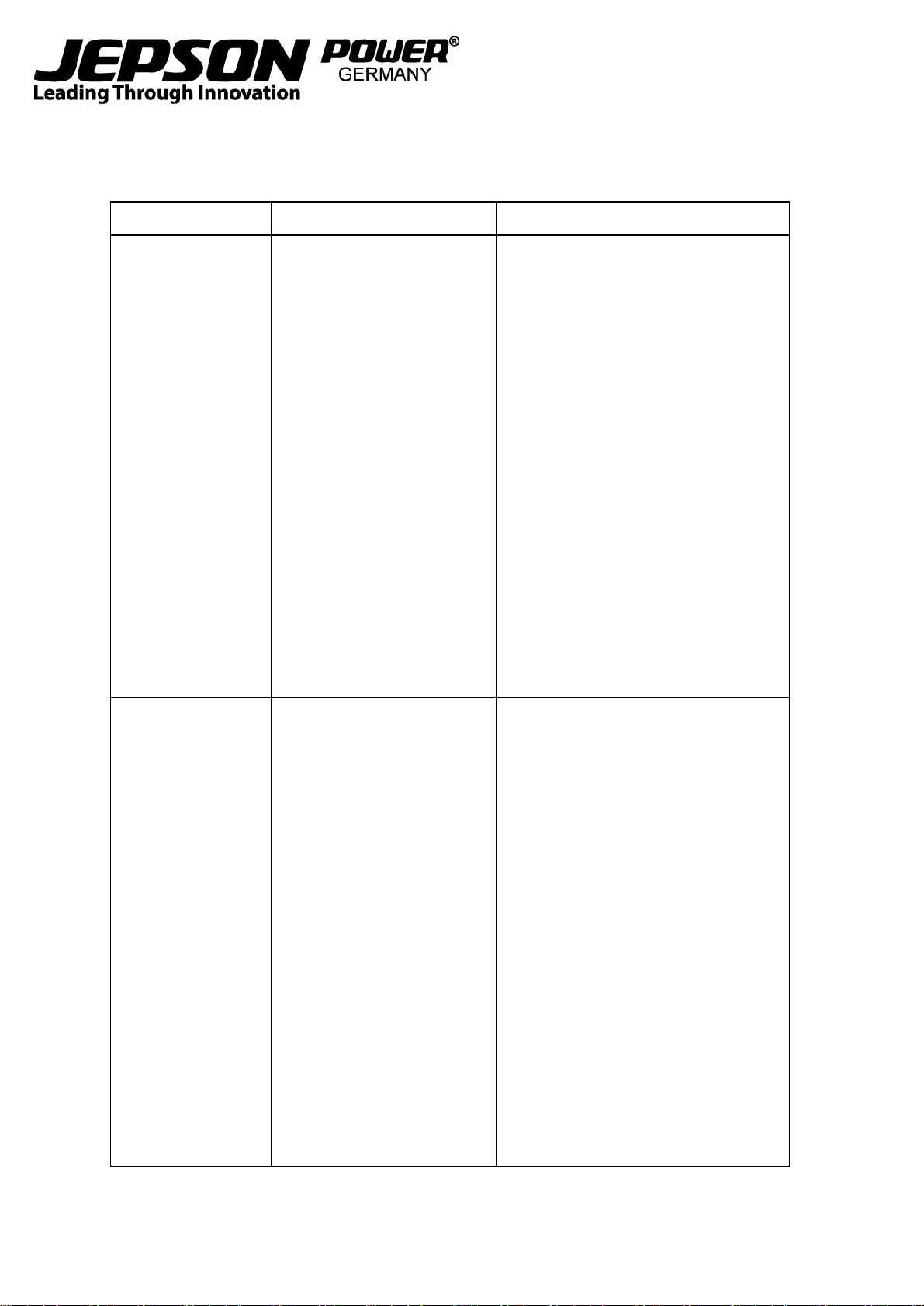

Problem Cause Remedy

1) Magnetic

base won't hold

effectively

Material being cut may

be too thin for efficient

holding of magnet

Swarf or dirt under

magnet

Irregularity on magnet

face or work-piece

Insufficient current going

to magnet during

drilling cycle

Attach an additional piece of

metal under work-piece where

magnet will be located, or

mechanically clamp magnetic

base to work-piece

Clean magnet

Use extreme care, file only

imperfections flush to surface

Confirm power supply and

output from control unit.

2) Cutter skips

out of

centre-punch

mark at initiation

of cut

Magnetic base is not

holding effectively.

Too much feed pressure

at start of cut.

See causes and remedies above.

Light pressure until a groove is

cut. The groove then serves as

a stabilizer.

Cutter is worn, chipped

or incorrectly sharpened

Replace or re-sharpen.

Sharpening service is available.

Poor centre-

punch mark;

weak pilot spring; pilot

not centred in

centre-punch mark.

Improve centre-punch and/or

replace worn parts.

Worn or bent pilot,

worn pilot hole

Replace parts.

- 9 -

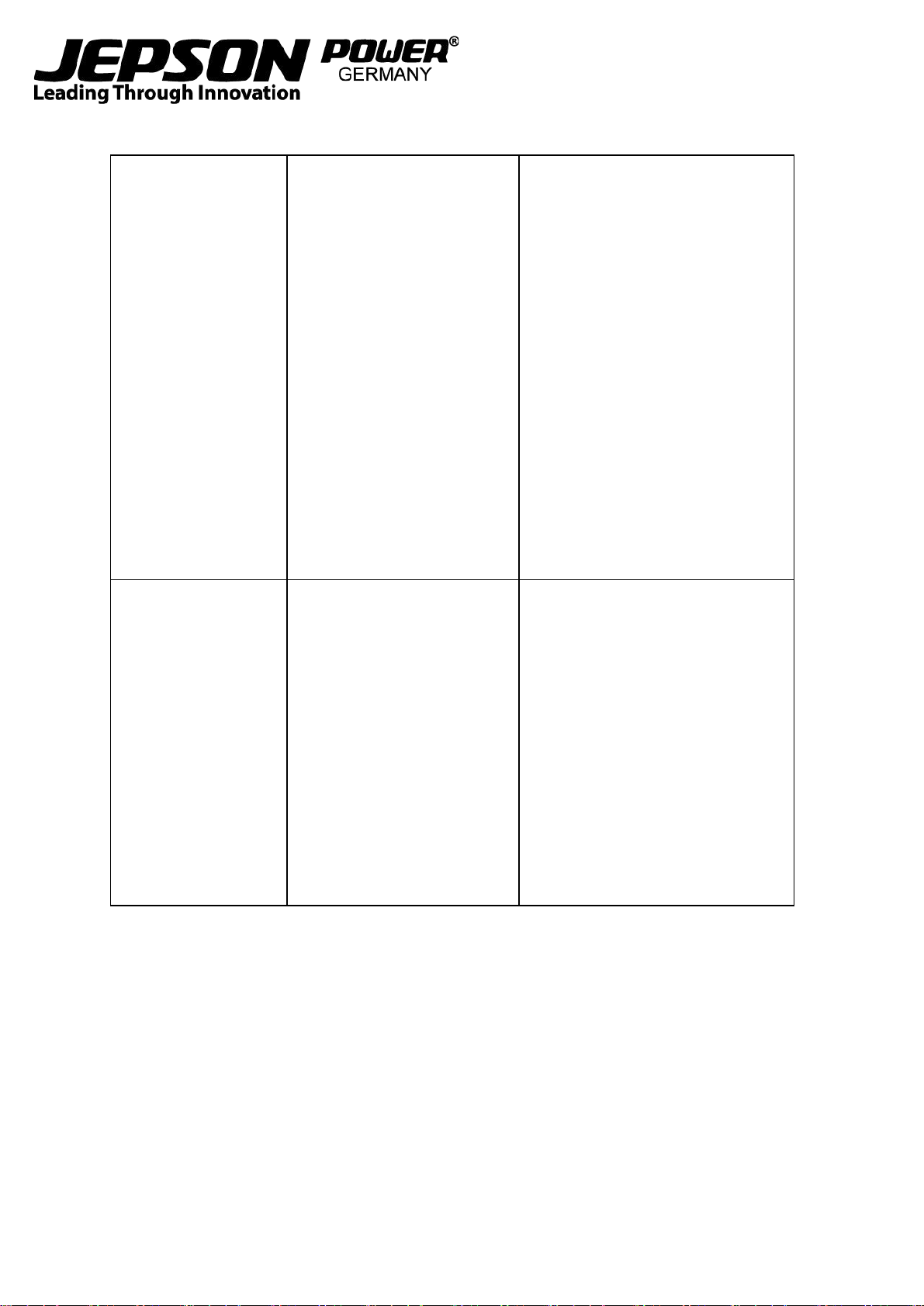

Problem Cause Remedy

3) Excessive

drilling pressure

required.

Incorrectly re-sharpened,

worn or chipped cutter

Re-sharpen or replace

Coming down on swarf

lying on surface of

work-piece

Clean work-piece.

Take care not to start a cut

on swarf

Gibs out of adjustment

or lack of lubrication

Lubricate gib and/or adjust

grub screws

Swarf accumulated

(packed) inside cutter

Clear cutter

Incorrect speed selection. Select appropriate speed.

4) Excessive cutter

breakage

Steel swarf or dirt under

cutter

Remove cutter, clean part

thoroughly and replace

Incorrectly re-sharpened

or worn cutter

Always have a new cutter on

hand to refer to for correct

tooth geometry, together with

instruction sheet

Cutter skipping See causes and remedies (2)

Slide-ways need

adjustment

Tighten slide-way

Cutter not attached

tightly to arbor

Retighten

- 10 -

Insufficient use of cutting

oil or unsuitable type of

oil

Incorrect speed selection.

Fill arbor with an oil of light

viscosity and check to be sure

oil is being metered into

cutter when pilot is

depressed. If not, check

pilot groove and arbor

internally for dirt or apply oil

externally.

Even a small amount of oil is

very effective.

Select appropriate speed.

5) ) Excessive

cutter wear

Incorrectly re-sharpened

cutter.

Insufficient or spasmodic

cutting pressure

Refer to instructions and a

new cutter for proper tooth

geometry

Use sufficient steady pressure

to slow the drill down. This

will result in optimum cutting

speed and chip load.

This manual suits for next models

1

Table of contents

Other Jepson Drill manuals