The warranty of Jereh electrostatic spray disinfection equipment is implemented

from the date of purchase. The warranty terms are as follows:

Warranty Policy

During the warranty period (calculated from the date of invoice date), Jereh

provides warranty service, if the product fails during normal use Please note the

following:

Basic Statement

This warranty certicate will not be reissued if lost, please keep it properly.

This warranty certicate is valid only in the Republic of China (Hong Kong / Macau

/ Taiwan is temporarily unavailable).

Jereh does not provide on-site services for overseas customers (outside mainland

China). For damages during the warranty period, Jereh will provide replacements

for free; for damages caused by natural or human factors beyond the warranty

period, Jereh will provide paid replacements, and the freight and custom duty

shall be paid by the customers.

•

•

•

During the warranty period, the following conditions are not covered by the free

warranty:

Product warranty (For domestic customers)

Free warranty for the device and main components (Air compressor, spray gun) is

one year.

Consumables are provided in accordance with the relevant provisions.

•

•

•

10/11

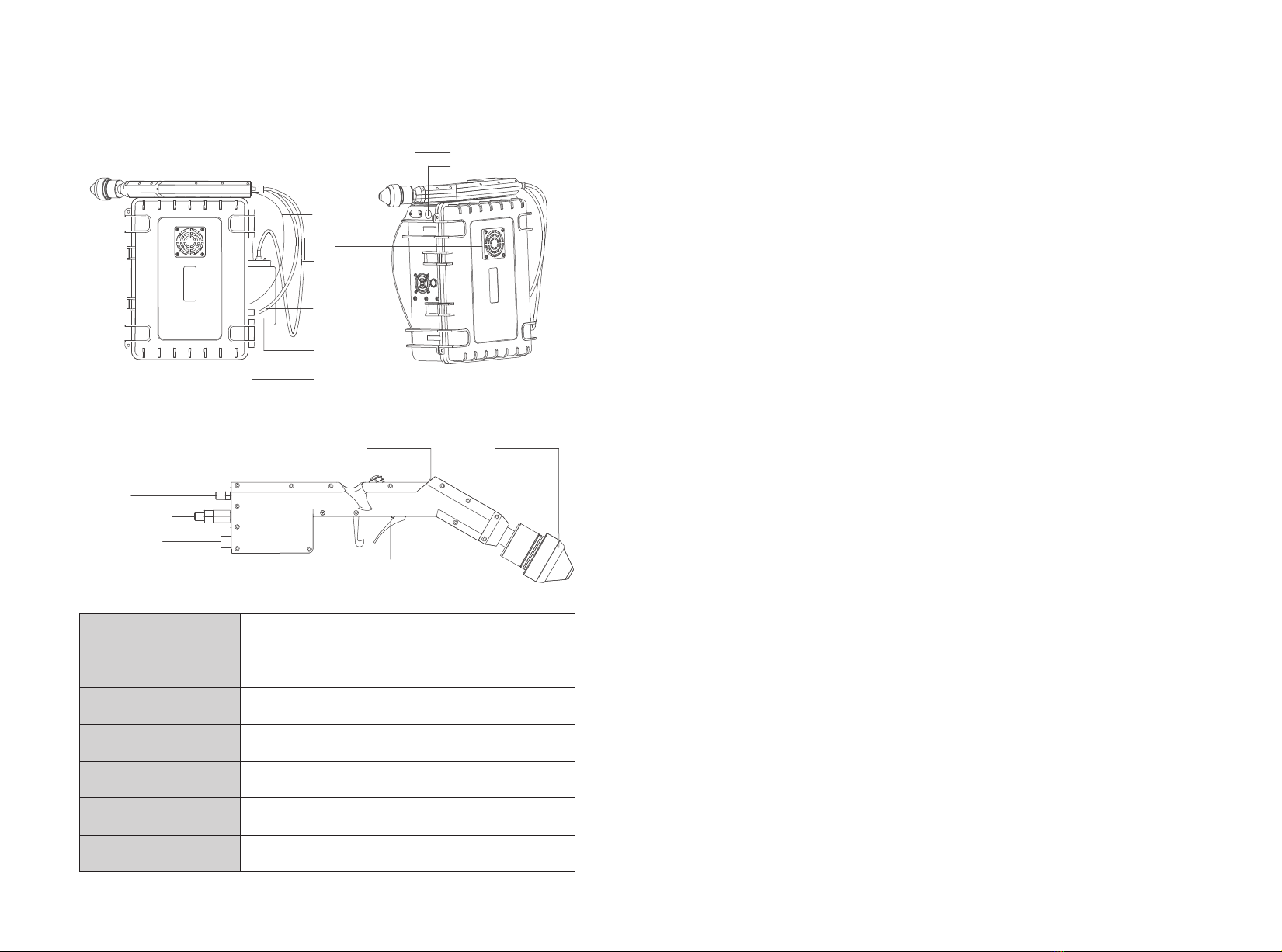

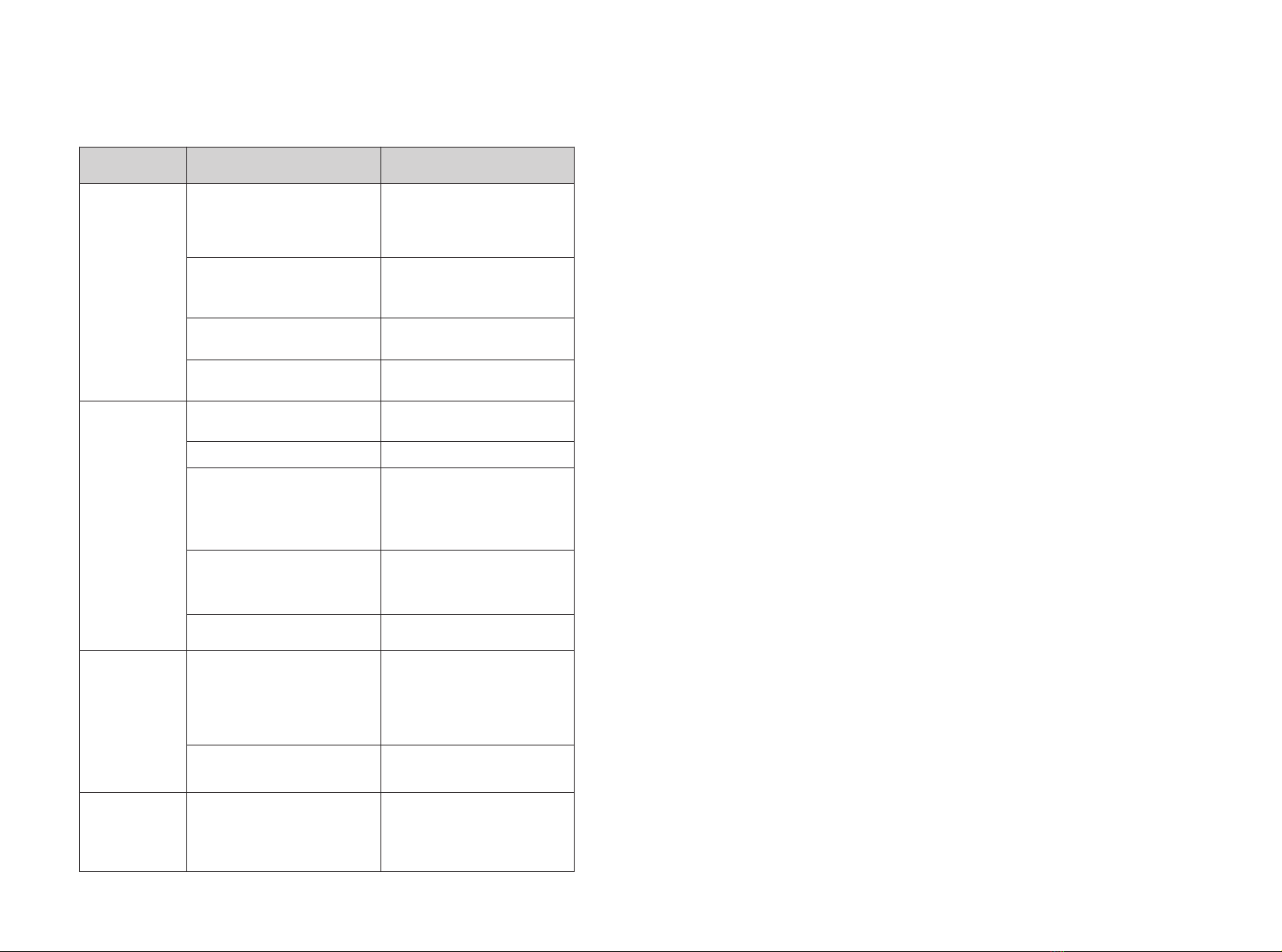

Troubleshooting Guide

Air ttings are loose.

Air ttings are too tight and

the gasket or seal is crushed

and damaged.

The component connected

to the nozzle is loose.

Check if the black hose on

the rear of the nozzle is

pulled and reconnected.

Test spray charge with the

multimeter. If there are

charges, the bulb needs to

be replaced.

Check the built-in lter

screen of liquid bottle to see

if any jam exists, replace it if

necessary.

Check for damaged wires

and replace if necessary.

The position of the bottle is

too high compared to the

nozzle, and the water

pressure is not enough.

Raise the bottle to reduce the

height dierence between

the nozzle and the bottle.

Check for leaks in

components. Apply soapy

water to air connections –

tighten ones that bubble.

Check the air assembly for

damage and replace

damaged seals.

Fasten loose connection

hoses.

The hose connection is not

reliable.

Check for leaking trachea

and replace it.

Clean nozzle according to

instructions.

The hose is worn or has an

opening.

Nozzle is blocked.

low liquid level in the bottle. Rell bottle.

Trigger is disengaged.

Light bulb damaged.

Damaged wire.

Clogged liquid Filter.

Make sure trigger is engaged.

Air pressure

of spray

appears low

The spray

from nozzle is

erratic

Charging

indicator

(LED) is out

The nozzle

uid ow is

low

Symptom Possible Problem(s) Corrective Action

Failure to present the corresponding purchase order or invoice;