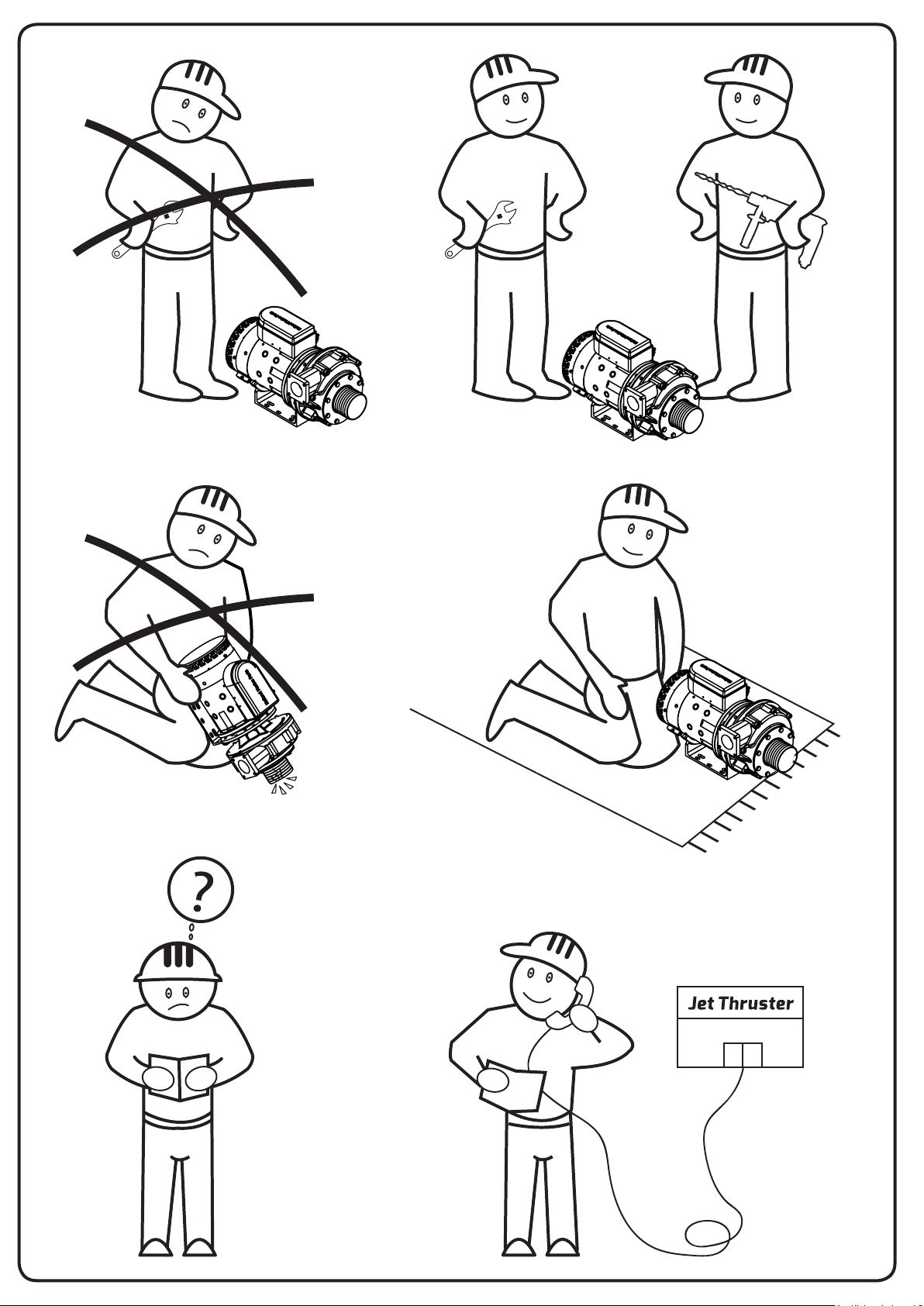

Jet Thruster D-010-07 User manual

This is a short manual for a

Jet Thruster installaon.

For more detailed informaon

see installaon manual D-010-07

Keep this manual and the D010-07 always on board

QUICK START

D-105-00

:

Modified date

:

Modified by

:

:

Checked by

Drawn date

Drawn by

0.20.20.20.03

0.03

UNLESS OTHERWISE SPECIFIED: DIMENSIONS ARE IN MILLIMETERS

ANGLES IN DEGREES - TOLERANCES ±0.2mm ±0.5º - BREAK ALL EDGES

Ra 3.2

:

Weight in kg

Material/Size

:

Customer

Part No./Note

:

:

Reference

:

Do

NOT

Scale

A3

Scale:

1:10

: 16-11-2015

JT-90 position 2

:

Modified date

:

Modified by

:

:

Checked by

Drawn date

Drawn by

0.20.20.20.03

0.03

UNLESS OTHERWISE SPECIFIED: DIMENSIONS ARE IN MILLIMETERS

ANGLES IN DEGREES - TOLERANCES ±0.2mm ±0.5º - BREAK ALL EDGES

Ra 3.2

:

Weight in kg

Material/Size

:

Customer

Part No./Note

:

:

Reference

:

Do

NOT

Scale

A3

Scale:

1:10

: 16-11-2015

JT-90 position 2

:

Modified date

:

Modified by

:

:

Checked by

Drawn date

Drawn by

0.20.20.20.03

0.03

UNLESS OTHERWISE SPECIFIED: DIMENSIONS ARE IN MILLIMETERS

ANGLES IN DEGREES - TOLERANCES ±0.2mm ±0.5º - BREAK ALL EDGES

Ra 3.2

:

Weight in kg

Material/Size

:

Customer

Part No./Note

:

:

Reference

:

Do

NOT

Scale

A3

Scale:

1:10

: 16-11-2015

JT-90 position 2

+31786174968

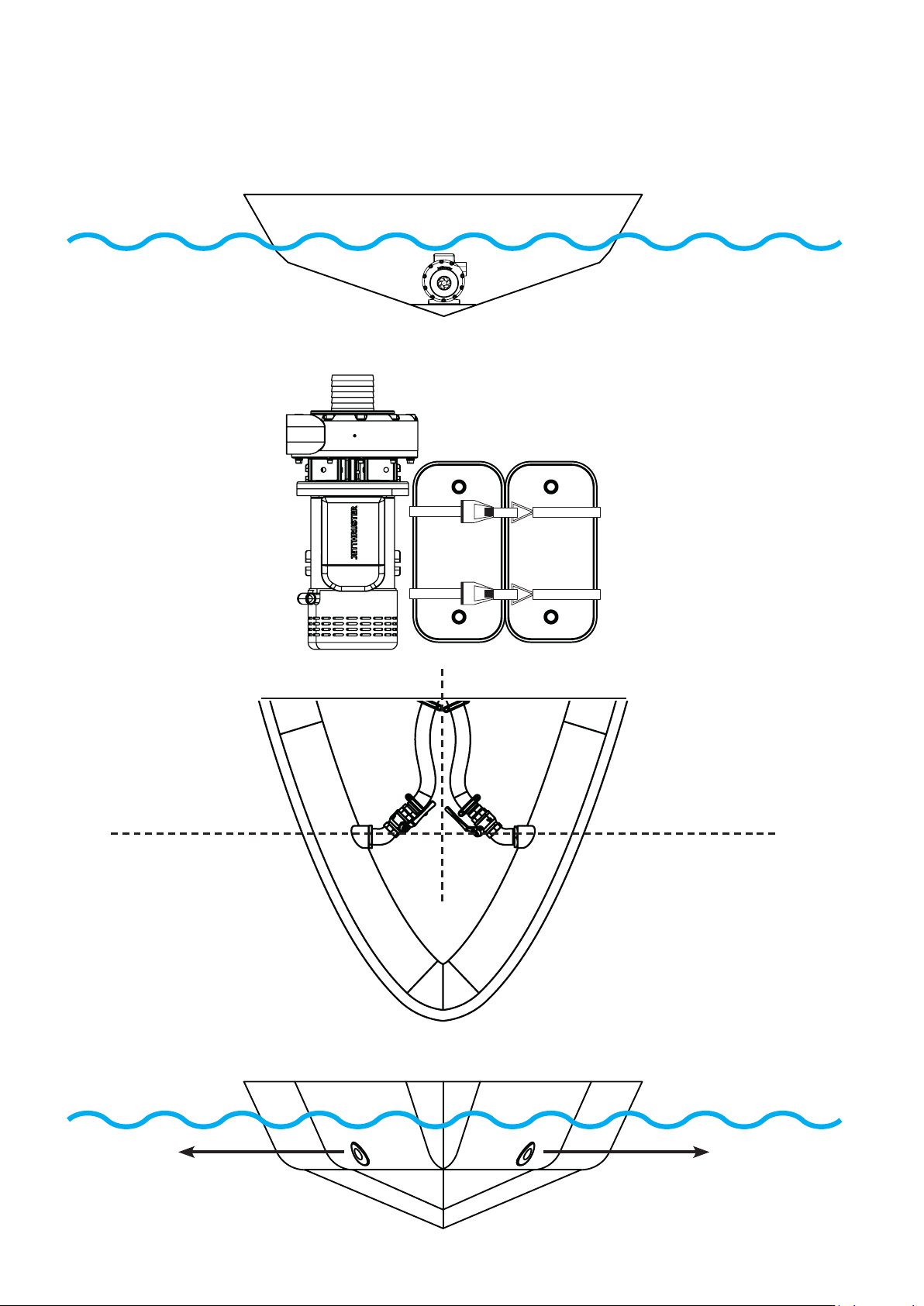

The foundaon for a proper installaon:

- Correct Nozzle posion

- Pump under waterline

- Baeries adjacent to the pump

- Smooth hose roung

- Very short baery cables

Installaon preparaon

- Determine pump posion, nozzle posion & hose roung throughout the ves-

sel

-Clean all stainless steel & composite parts thoroughly with acetone or Brake

cleaner. Make sure all grease is removed from parts.

-Use Polyurethane Marine sealant (for example Sikaex 291i) for all connecons

Check the shelf life!

-Prevent damaging of stainless steel parts by ferro items (Tools)

Nozzle’s position needs

to be 90° to Center line of

boat.

Nozzle’s position 7-10 cm

below waterline & Parallel to

waterline

Batteries directly next to pump

Most Crical steps to meet!

See all other steps and meet them as well

Pump must be below waterline

1: Pump always under the waterline

- Prevent contact with bilge water

- Install pump- zinc- anode

- Keep space behind pump unit (Venlator cap)

- Ensure space besides the pump for baeries

2: Baeries directly next to pump

- Use Opma Yellowtop baeries

- Install baeries on waterproof plywood and install baeries and secure safely

- When necessary: install series-parallel switch on top the baeries

- Keep cable length to absolute minimum. Take notes of cable length for evaluaon

- Connect negave of baery 1 with negave of service baery. (Common ground)

- Use proper baery pole clamps

- Use proper and good-ng terminals

- Install baery pole caps

3: Nozzle posion

- Nozzles as far forward (or in the stern) of the vessel

- Topside Nozzle tube 7-10cm under the waterline

- Installaon of Nozzle horizontal

- Nozzle 90 degrees to be installed to center-line of the vessel

- Nozzle can be located slightly forward and a of each other (staggered)

- Use 45-degrees elbow only in case of a small bow secon

- For a wide bow: do not use 45-degree elbows but curve the hose instead

- Install and connect the zinc anode with the stainless steel parts

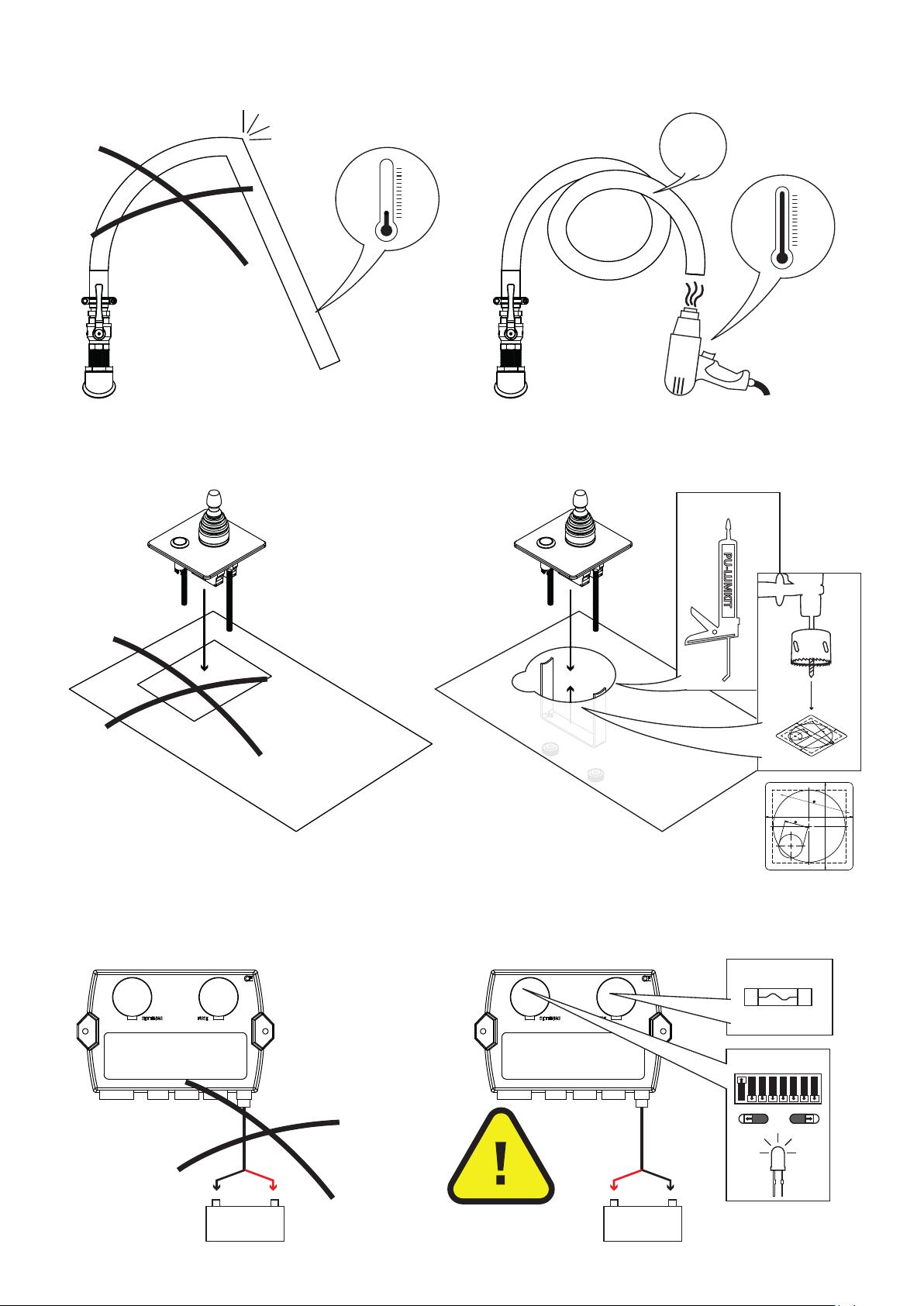

4: Clean all threaded parts before using PU sealant

7 CM

15-20 cm

90�

90�

7 cm

125˚C

85

85

23

70

85

85

23

70

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

+ -

+ -

>25˚C

Hose max 60˚C

7 CM

15-20 cm

90�

90�

7 cm

125˚C

85

85

23

70

85

85

23

70

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

+ -

+ -

>25˚C

Slang max 60˚C

7 CM

15-20 cm

90�

90�

7 cm

125˚C

85

85

23

70

85

85

23

70

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

+ -

+ -

>25˚C

Hose max 60˚C

Step 1

Step 2

Step 3

- Clean all threaded parts with brake cleaner, dry it o with a clean paper towel

- Apply a good amount of PU sealant on both threaded parts before connecng them

- make sure the complete surface of thread is covered in PU sealant

- Remove any le over PU Sealant with the special wet wipes in the round can

- Aenon, the wet wipes are for removing aerwards the le over sealant. Do not clean upfront the

threaded parts with the wet wipes. This will cause the sealant not to bond and will cause leakage!!!

5: Water inlet and acces to shut o valve

- Ball valve must be easily accessible

- Inlet hose max 1 meter long, shorter always possible

- Installaon of water inlet may be possible from the side of the vessel

- Water inlet below waterline. Posion higher than pump is allowed

- Remove anfouling under ange

- Use supplied Stainless steel tool to twist water inlet into 90-degrees turn

6: Hose clamps and connecon:

- Use grease on the bolts

- Prevenon against corrosion (Vaseline spray)

7: Hose roung

7 CM

15-20 cm

90�

90�

7 cm

125˚C

85

85

23

70

85

85

23

70

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

+ -

+ -

>25˚C

Hose max 60˚C

7 CM

15-20 cm

90�

90�

7 cm

125˚C

85

85

23

70

85

85

23

70

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

+ -

+ -

>25˚C

Hose max 60˚C

Step 4

Step 5

Step 6

7 CM

15-20 cm

90�

90�

7 cm

125˚C

85

85

23

70

85

85

23

70

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

+ -

+ -

>25˚C

Slang max 60˚C

- Hoses may be above waterline

- Heat up hose with a electrical heat gun to be able to make a nice steady curve

- Cut hose to appropriate length with a sharp knife (do not saw). Cut coiled wire with pliers

- Prevent kinks of dents in hose

- Prevent damaging the hose (sharp parts in vessel)

- Aach hose to hull with bonding fasteners

8: Control panel in helm staon

- Use drilling template for installing control panel

- Glue front plate panel onto dashboard with exible marine sealant

9: Controller

- Preferably install controller near the switch panel

- Use the length of the valve cable (10m) and pump cable (5m)

- Connect controller with 12V Service baery (via switch panel)

- DO NOT change polarity of connecon cable! (will cause serious damage!)

- Check if connecters click with audible click

- Check dip-switch sengs for Single or Combi funcon (see next page)

7 CM

15-20 cm

90�

90�

7 cm

125˚C

85

85

23

70

85

85

23

70

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

+ -

+ -

>25˚C

Slang max 60˚C

7 CM

15-20 cm

90�

90�

7 cm

125˚C

85

85

23

70

85

85

23

70

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

+ -

+ -

>25˚C

Slang max 60˚C

7 CM

15-20 cm

90�

90�

7 cm

125˚C

85

85

23

70

85

85

23

70

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

Jet Thruster controller

Controls Pump unit Valve bow Valve Stern 12V

+ -

+ -

+ -

>25˚C

Slang max 60˚C

Step 7

Step 8

Step 9

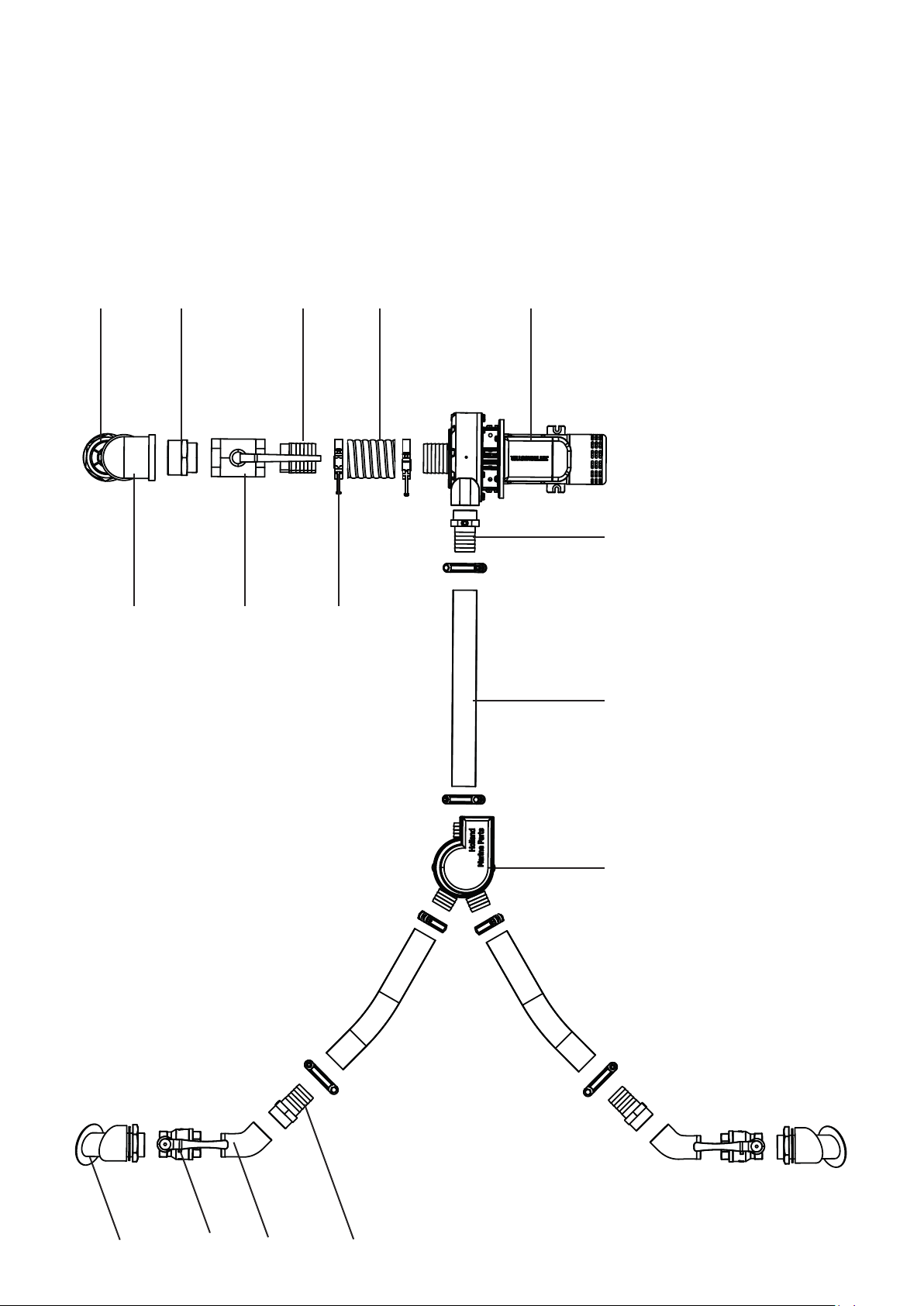

I-115-58I-330-00 I-316-00I-321-00

V-100-58

P-115-58

I-302-00

I-307-00

I-308-00

I-105-00

I-113-58

I-310-00

I-331-00

I-312-00

JT-30-50

JT-50-50

JT-50 example setup

I-267-00

I-268-01

I-269-GF

I-271-00

I-213-00

CP-050-00

V-200-50

I-275-01

I-330-00 I-215-00I-321-00

I-270-01

I-331-00

P-259-00

JT-70-50

JT-90-50

JT-90 example setup

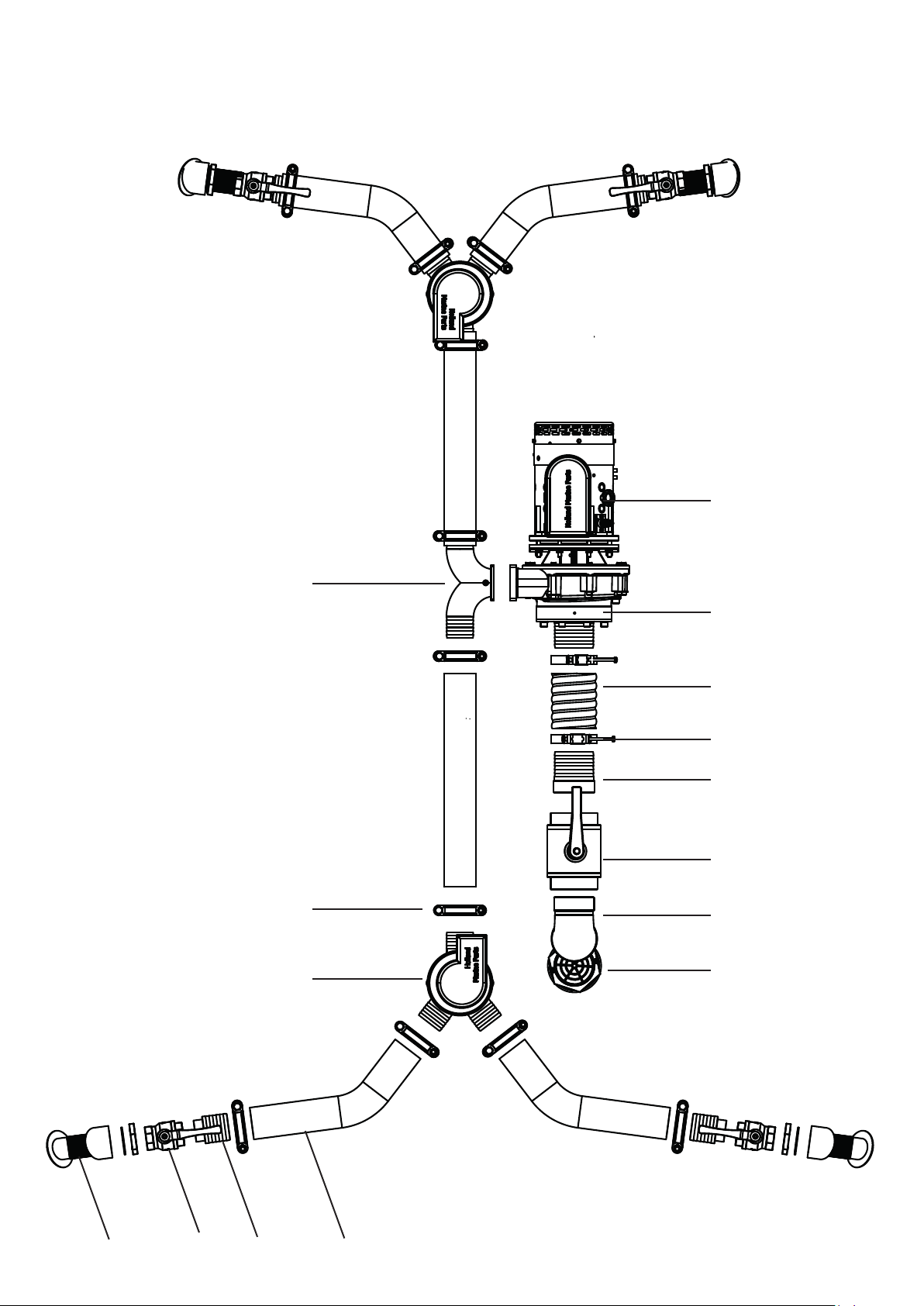

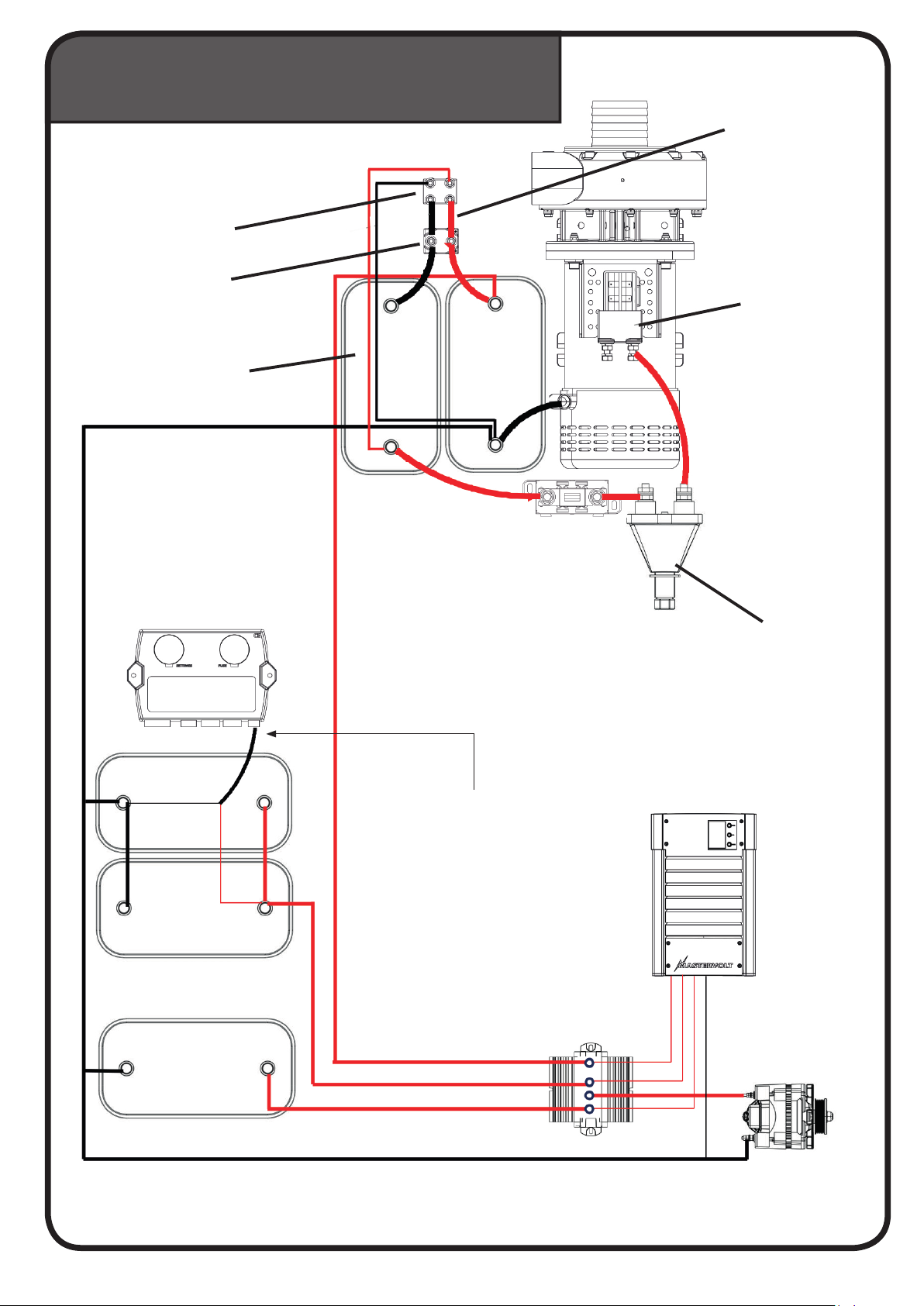

JT-30 12V

Charged 12V

Contactor

Main switch

Fuse

Opma baery

Controller

Service baeries

Start baery

Charger 12V

Alternator

Baery isolator

Do not extend this

power cable

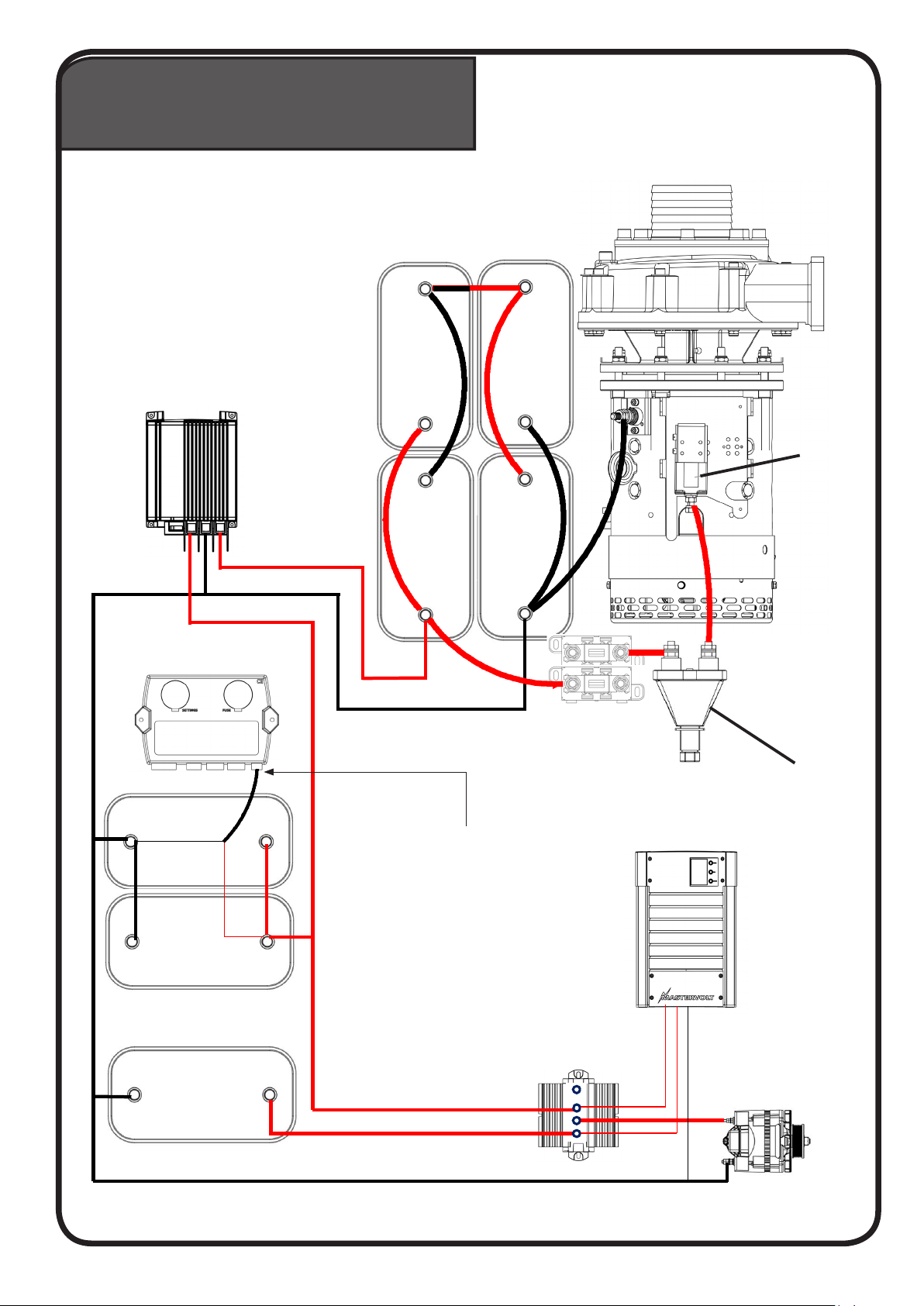

JT-50 24V

Charged 12V Step up charger

Contactor

Main switch

Fuse

Opma baeries

Controller

Service baeries

Start baery

Charger 12V

Alternator

Mac plus 12-24V

DC charger

Baery isolator

Do not extend this

power cable

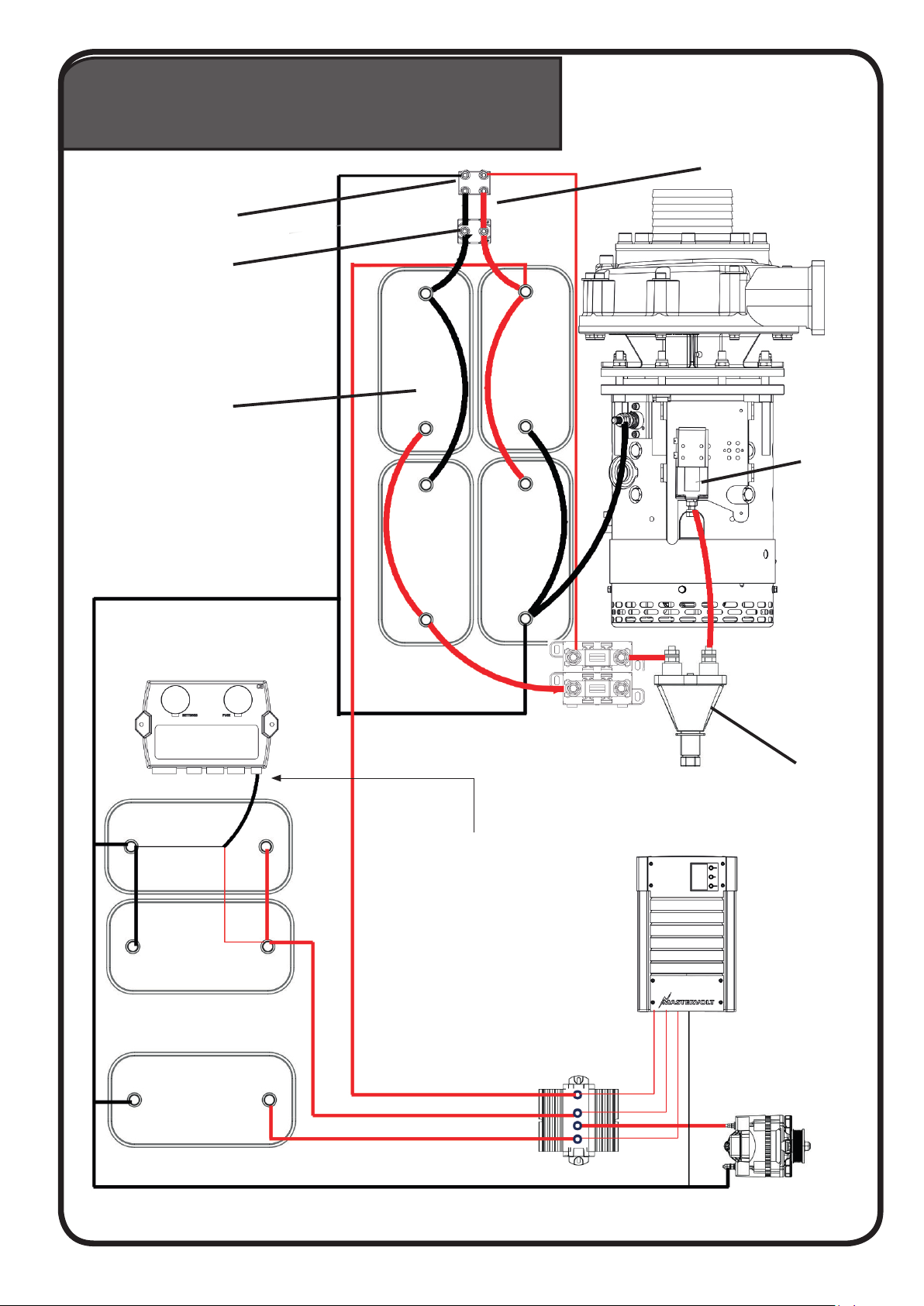

JT-50 24V

Charged with 12V + series parallel switch Strips factory mounted

Parallel switch

Boom side

Parallel switch

Top side

Contactor

Main switch

Fuse

Controller

Service baeries

Start baery

Baery isolator

Charger 12V

Alternator

Opma baeries

Do not extend this

power cable

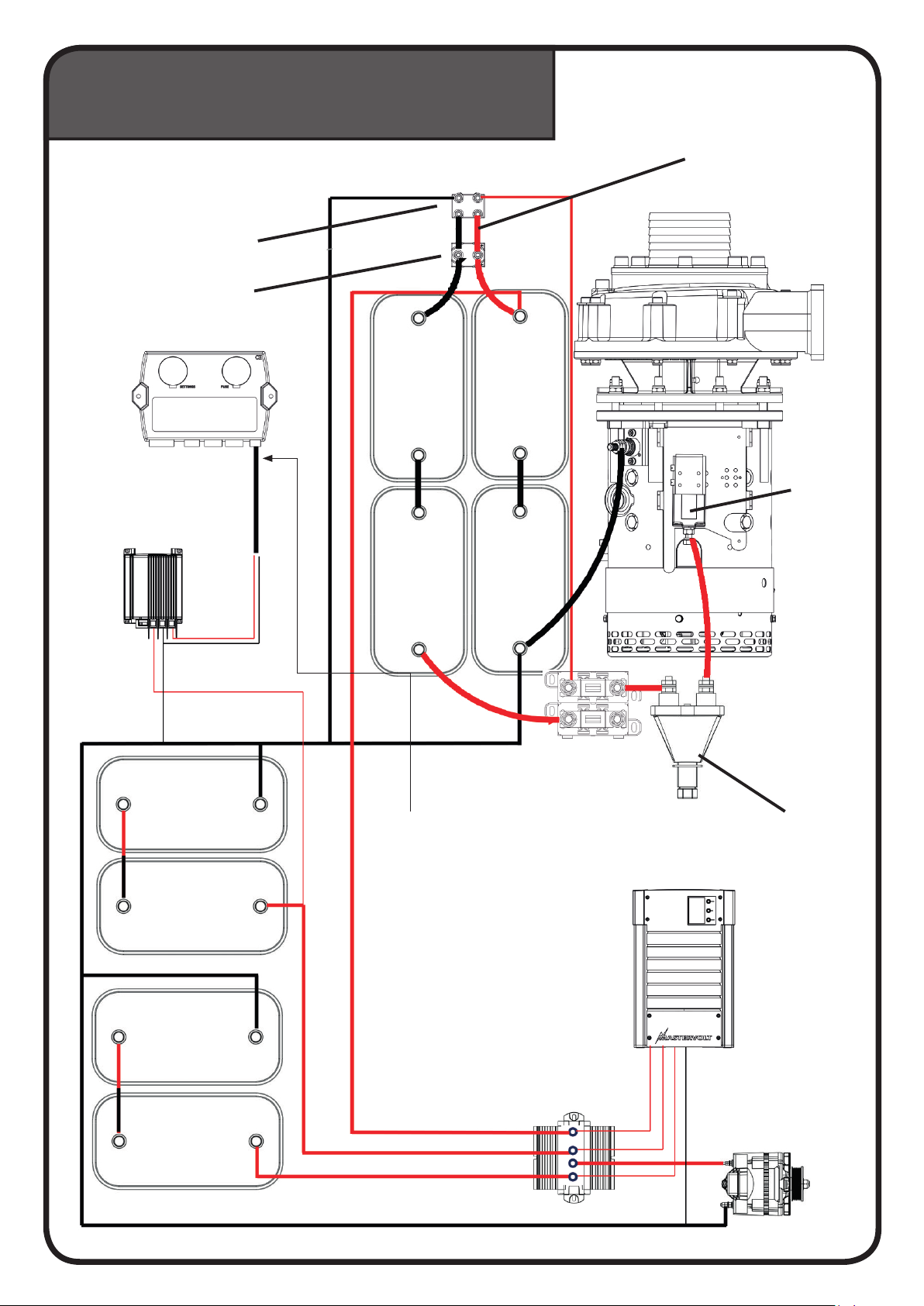

JT-90 24V

On a 24V board circuit

Main switch

Fuse

Contactor

2a

2b

1b

1a

Controller

Dc-Dc converter

24-12 20A

Service baeries

Start baery

Charger 24V

Alternator

Baery isolator

Do not extend this

power cable

JT-90 24V

Charged 12V Step up charger

Controller

Service baeries

Start baery

Charger 12V

Alternator

Mac plus 12-24V

DC charger

Contactor

Main switch

2a

2b

1b

1a

Fuse

Opma baeries

Baery isolator

Do not extend this

power cable

JT-90 24V

Charged with 12V + series parallel switch

Contactor

Main switch

Strips factory mounted

Controller

Service baeries

Start baery

Charger 12V

Alternator

Parallel switch

Boom side

Parallel switch

Top side

2a

2b

1b

1a

Fuse

Opma baeries

Baery isolator

Do not extend this

power cable

JT-90 48V

On a 24V board circuit

Strips factory mounted

Parallel switch

Boom side

Parallel switch

Top side

2a

2b

1b

1a

Controller

Service baeries

Start baery

Charger 24V

Alternator

Dc-Dc converter

24-12 20A

Fuse

Main switch

Contactor

Baery isolator

Do not extend this

power cable

Table of contents

Popular Boat manuals by other brands

Boston Whaler

Boston Whaler 180 Dauntless owner's manual

Hallberg-Rassy

Hallberg-Rassy MONSUN 31 instructions

Grady-White Boats

Grady-White Boats BIMINI 306 owner's manual

Sea Ray

Sea Ray 175 Sport owner's manual

Robalo

Robalo 2008 Walk Around Owner's and operator's manual

Malone

Malone MPG318 installation instructions