EN

400400400

2 Description

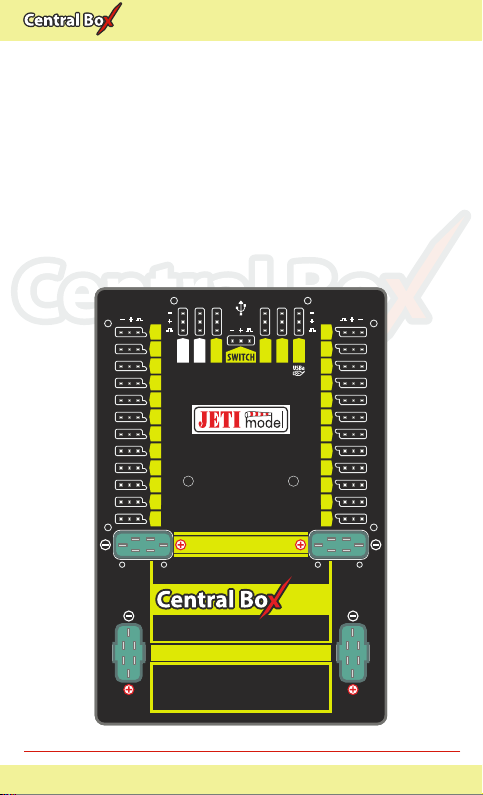

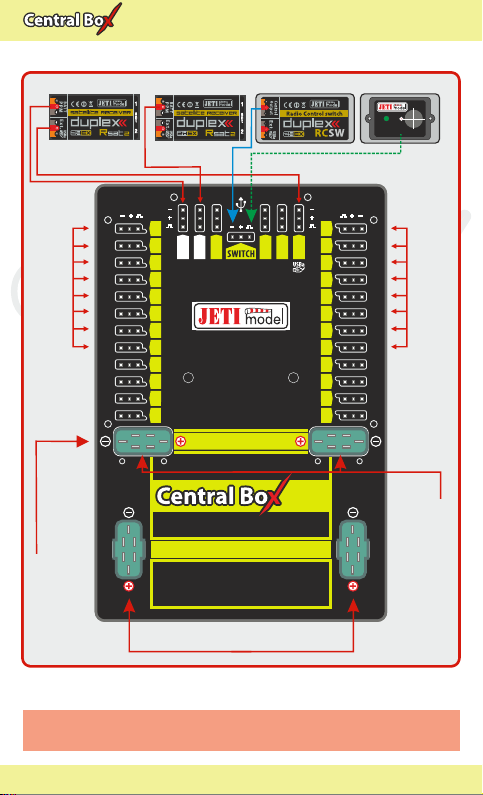

Central Box 400 has 24 outputs for servos with individual

overload protection. More over, outputs Y17-Y24 can be

configured as:

servo output

logical input

logical output

Control signals generated by the Central Box to servos are 5V. This

solution ensures reliable servo signal transfer for longer distances.

Ext1 - Ext4 ports can be configured for use as:

inputs for telemetry sensors

EX Bus expanders - used for connecting devices which support the

EX Bus protocol (the Central Box, a sensor,...)

Ext4 - slot is also used as an output to connect a JETIBOX to

configure the Central Box and for the firmware update connection

Rx1 - primary input for connecting receivers with serial output (EX,

PPM, UDI)

Rx2 - secondary (backup) input for connecting receivers with serial

output (EX bus, PPM, UDI)

Switch slot is reserved for connecting magnetic switch or RC Switch

BEC output serves as the output for stabilized voltage to power

supply other Central Boxes that can be power supplied from the

Central Box 400. The voltage at the output has the same level as the

voltage for supplying the servos. Voltage for the servo outputs is

adjustable from 5-8V with 0.1V steps.

For more safety, the Central Box 400 contains two BEC regulators

connected in parallel. Information about the correct power supply

and a faultless condition of the individual branches is indicated by

green LED and also by telemetry. It is not recommended to use the

BEC outputs for direct power supply of servos or receivers with

servos. These devices are not individually protected. If one element

of the branch supplied from the BEC output is overloaded, the

5 EN