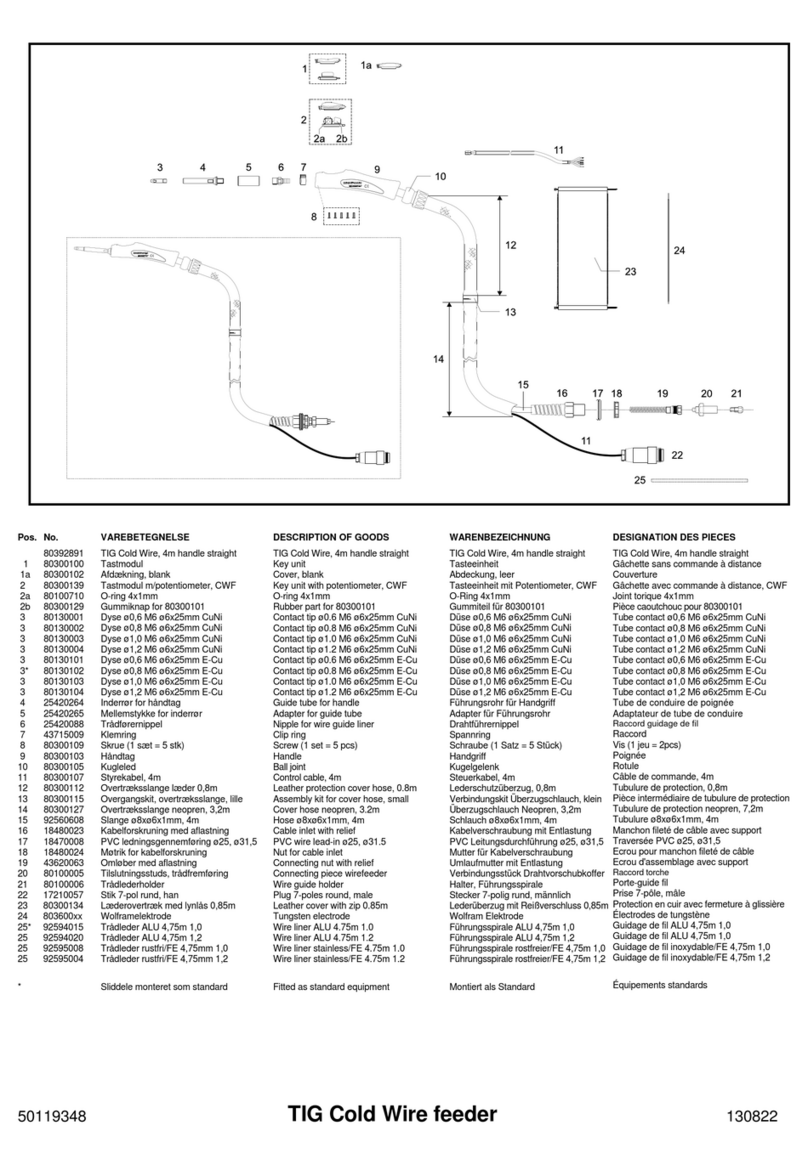

CWF-50 Cold Wire Feeder

- 4 -

“.... there is now a very large volume of scientic

ndings based on experiments at the cellular

level and from studies with animals and people

which clearly establish that low frequency

magnetic elds can interact with, and produce

changes in, biological systems. While most of

this work is of very high quality, the results are

complex. Current scientic understanding does

not yet allow us to interpret the evidence in a

single coherent framework. Even more frustrat-

ing, it does not yet allow us to draw denite

conclusions abut questions of possible risk or to

offer clear science-based advice on strategies to

minimize or avoid potential risks.”

To reduce magnetic elds in the work place, use

the following procedures:

1. Keep cables close together by twisting or

taping them.

2. Arrange cables to one side and away from

the operator.

3 .Do not coil or drape cables around the

body.

4. Keep welding power source and cables

as far away as practical.

5. Connect work clamp to workpiece as

close to the weld as possible.

About Pacemakers:

The above procedures are among those also

normally recommended for pacemaker wearers.

Consult your doctor for complete information.

I. Principal Safety Standards

Reference as applicable

Safety in Welding and Cutting, ANSI Standard

Z49.1, from American Welding Society, 550

N.W. LeJeune Rd, Miami, FL 33126

Safety and Health Standards, OSHA 29 CFR

1910, from Superintendent of Documents, U.S.

Government Printing Ofce, Washington, D.C.

20402

National Electric Code, NFPA Standard 70 from

National Fire Protection Association, Battery-

march Park, Quincy, MA 02269

Recommended Safe Practices for the Prepara-

tion for Welding and Cutting of Containers That

Have Held Hazardous Substances, American

Welding Society Standard AWS F4.1, from

American Welding Society, 550 N.W. LeJeune

Rd, Miami, FL 33126

Safe Handling of Compressed Gases in Cylin-

ders, CGA Pamphlet P-1, from Compressed Gas

Association, 1235 Jefferson Davis Highway,

Suite 501, Arlington, VA 22202

Code for Safety in Welding and Cutting, CSA

Standard W117.2, from Canadian Standards

Association, Standards Sales, 178 Rexdale Bou-

levard, Rexdale, Ontario, Canada M9W 1R3

Sales Practices for Occupation and Educational

Eye and Face Protection, ANSI Standard Z87.1,

from American National Standards Institute,

1430 Broadway, New York, NY 10018

Cutting and Welding Processes, NFPA Standard

51B, from National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269