Jetter JVM-206-K00-O21 Installation and operating instructions

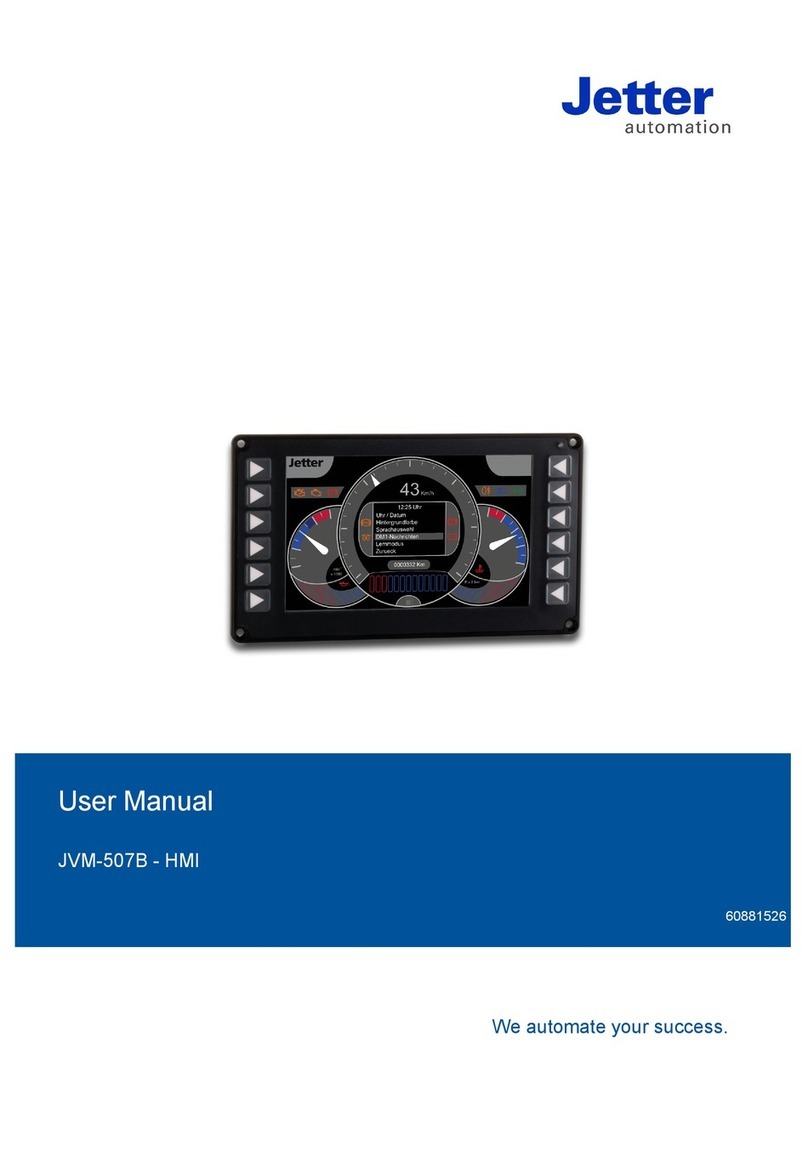

User Manual

JVM-206-K00-O21

Display

We automate your success.

60886309_00

Jetter AG

Graeterstrasse 2

71642 Ludwigsburg

Germany

Phone

Switchboard +49 7141 2550-0

Sales +49 7141 2550-531

Technical Hotline +49 7141 2550-444

E-mail

Technical Hotline [email protected]

Sales [email protected]

Translation of the original User Manual

Revision 1.00.1

Date of issue 8/2/2021

This document has been compiled by Jetter AG with due diligence, and based on the known

state of the art. Revisions and further development of our products are not automatically

mentioned in a reviewed document. Jetter AG shall not be liable for errors in form or content,

or for missing updates, as well as for damages or disadvantages resulting from such failure.

Jetter AG Table of contents

JVM-206-K00-O21 User Manual iii

Table of contents

1 Introduction ......................................................................................................................................... 5

1.1 Information on this document .......................................................................................................5

1.2 Typographical conventions...........................................................................................................5

2 Safety ................................................................................................................................................... 6

2.1 General information......................................................................................................................6

2.2 Purpose ........................................................................................................................................6

2.2.1 Usage other than intended ...............................................................................................6

2.3 Warnings used in this document ..................................................................................................6

3 Product Description............................................................................................................................ 7

3.1 Design ..........................................................................................................................................7

3.2 Product Features..........................................................................................................................8

3.3 Nameplate ....................................................................................................................................8

3.4 Scope of delivery..........................................................................................................................8

4 Technical specifications..................................................................................................................... 9

4.1 Dimensions...................................................................................................................................9

4.2 Display..........................................................................................................................................9

4.3 Pushbuttons .................................................................................................................................9

4.4 Processor Kernel........................................................................................................................10

4.5 Mechanical specifications...........................................................................................................10

4.6 Environmental conditions ...........................................................................................................10

4.7 Electrical properties....................................................................................................................11

4.8 EMC values ................................................................................................................................11

4.9 Ports and interfaces ...................................................................................................................12

4.9.1 ISOBUS interface ...........................................................................................................12

4.9.2 USB interface .................................................................................................................12

4.10 Inputs/outputs according to ISO11786:1995 ..............................................................................13

4.11 Acoustic signal generator ...........................................................................................................14

4.12 Real-time clock...........................................................................................................................14

5 Mechanical installation..................................................................................................................... 15

5.1 Allowed mounting orientations ...................................................................................................15

6 Electrical connection ........................................................................................................................ 16

6.1 8-pin M12 connector (male) .......................................................................................................17

6.2 8-pin M12 connector (female) ....................................................................................................17

7 Identification and Configuration...................................................................................................... 18

7.1 Operating System Update via USB ............................................................................................18

Jetter AG Table of contents

JVM-206-K00-O21 User Manual iv

7.2 Operating System Update via CAN............................................................................................19

8 Programming..................................................................................................................................... 20

8.1 System Menu .............................................................................................................................20

8.1.1 Reserved Object IDs ......................................................................................................20

8.1.2 Key Codes......................................................................................................................24

8.1.3 Physical keys (shortcuts)................................................................................................25

8.2 Updating the System Menu ........................................................................................................26

8.3 Font Selection in the System Menu............................................................................................26

9 Maintenance and repairs .................................................................................................................. 27

9.1 Maintenance, repairs and disposal.............................................................................................27

9.2 Storage and shipment ................................................................................................................27

10 Service ............................................................................................................................................... 28

10.1 Customer service .......................................................................................................................28

11 Spare parts and accessories ........................................................................................................... 29

11.1 Accessories ................................................................................................................................29

Jetter AG Introduction | 1

JVM-206-K00-O21 User Manual 5 / 32

1 Introduction

1.1 Information on this document

This document forms an integral part of the product and must be read and under-

stood prior to using it. It contains important and safety-related information for the

proper use of the product as intended.

Target groups This document is intended for specialists with appropriate qualifications.

Only competent and trained personnel is allowed to put this device into operation.

During the whole product life cycle, safe handling and operation of the device

must be ensured. In the case of missing or inadequate technical knowledge or

knowledge of this document any liability is excluded.

Availability of infor-

mation

Make sure this document is kept at the ready in the vicinity of the product

throughout its service life.

For information on new revisions of this document, visit the download area on our

website. This document is not subject to any updating service.

Start | Jetter - We automate your success.

For further information refer to the following information products:

■Version updates

Information about new versions of software products or of the operating sys-

tem of your device.

■JetSym software Online Help

Detailed description of software functions with application examples

1.2 Typographical conventions

This manual uses different typographical effects to support you in finding and

classifying information. Below, there is an example of a step-by-step instruction:

üThis symbol indicates requirements which have to be met before executing

the following action.

►This sign or a numbering at the beginning of a paragraph marks an action in-

struction that must be executed by the user. Execute the instructions one after

the other.

ðThe target after a list of instructions indicates reactions to, or results of these

actions.

INFO Further information and practical tips

In the info box you will find helpful information and practical tips about your prod-

uct.

Jetter AG Safety | 2

JVM-206-K00-O21 User Manual 6 / 32

2 Safety

2.1 General information

When placed on the market, this product corresponds to the current state of sci-

ence and technology.

In addition to the operating instructions, the laws, regulations and guidelines of

the country of operation or the EU apply to the operation of the product. The op-

erator is responsible for compliance with the relevant accident prevention regula-

tions and generally accepted safety rules.

2.2 Purpose

2.2.1 Usage other than intended

Do not use the device in technical systems for which a high level of fail-safety is

required.

Machinery Directive This device is no safety-related part as per Machinery Directive 2006/42/EC, and

must, therefore, not be used for safety-relevant applications. This device is NOT

intended for the purpose of personal safety, and must, therefore, not be used to

protect persons.

2.3 Warnings used in this document

DANGER High risk

Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING Medium risk

Indicates a potential hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION Low risk

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE Material damage

Indicates a situation which, if not avoided, could result in malfunctions or material

damage.

Jetter AG Product Description | 3

JVM-206-K00-O21 User Manual 7 / 32

3 Product Description

The entry-level HMI JVM-206-K00-O21 has a display that can be operated intu-

itively. Thanks to its Limited-ISOBUS-UT functionality it works together with

ISOBUS controllers. Communication takes place via the ISOBUS protocol.

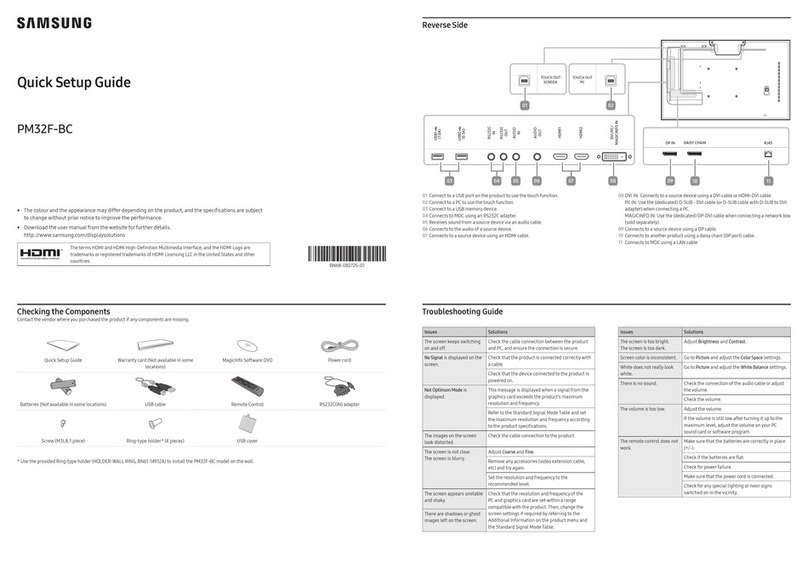

3.1 Design

8

1

23456

7

9

Fig.1: Design

1Power button 2ISB button

3Programmable softkey 4Home button to exit the current

menu

5ESC button to exit the edit mode 6Up/Down buttons for navigation

within the system menu

7OK button to open the edit mode 8F1 … F12

Programmable softkeys

9TFT touch display

Jetter AG Product Description | 3

JVM-206-K00-O21 User Manual 8 / 32

3.2 Product Features

■5" touch display, high resolution

■12 softkeys

■Navigation buttons, ISB and power button

■2 digital inputs for tractor speed

■1 digital rear PTO speed input

■1 three-point digital input

■1 three-point analog input

■1 digital input for ignition signal

■Real time clock (RTC), battery-backed

■Limited-ISOBUS-UT

■16 MB flash memory

■Limited TECU function

■Calibration function for tractor speed signal

■Limited FS function

■Update via USB

■System menu customizable

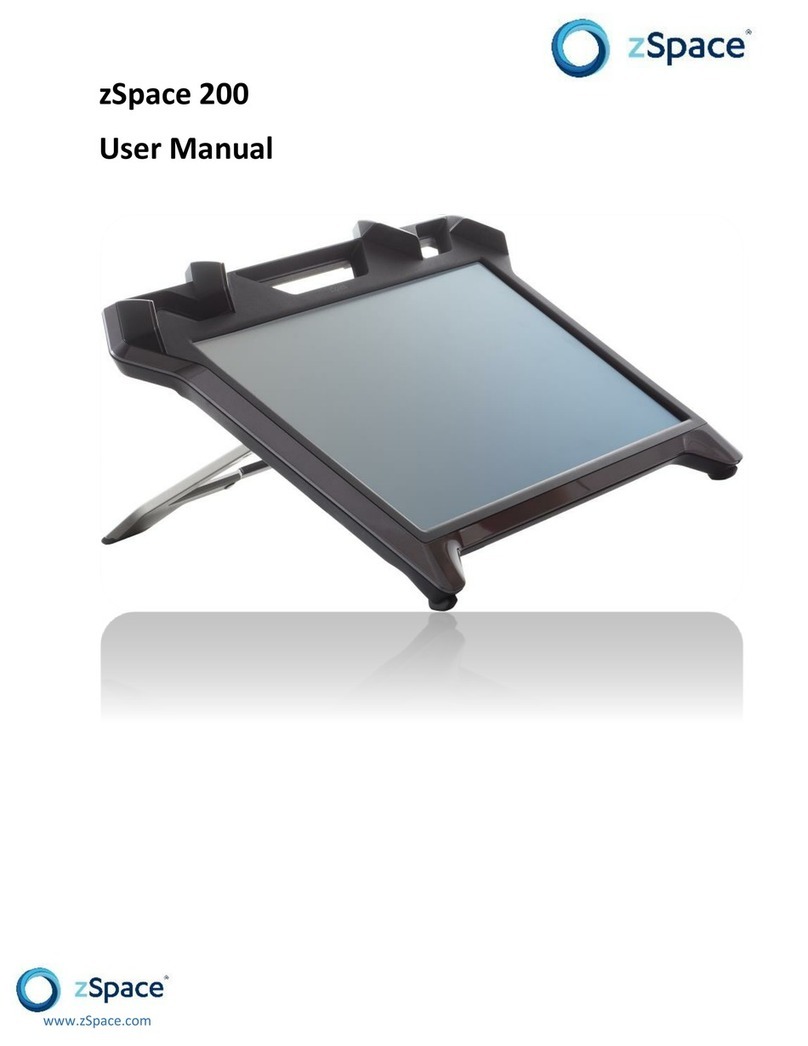

3.3 Nameplate

2

3

1

54

6

7

Fig.2: Nameplate

1Logo 2Barcode

3Serial number 4Type designation

5CE logo 6Revision number

7Part number

3.4 Scope of delivery

Scope of delivery Item number Quantity

JVM-206-K00-O21 10001905 1

Jetter AG Technical specifications | 4

JVM-206-K00-O21 User Manual 9 / 32

4 Technical specifications

This chapter contains information on electrical and mechanical data, as well as

on operating data of the JVM-206-K00-O21.

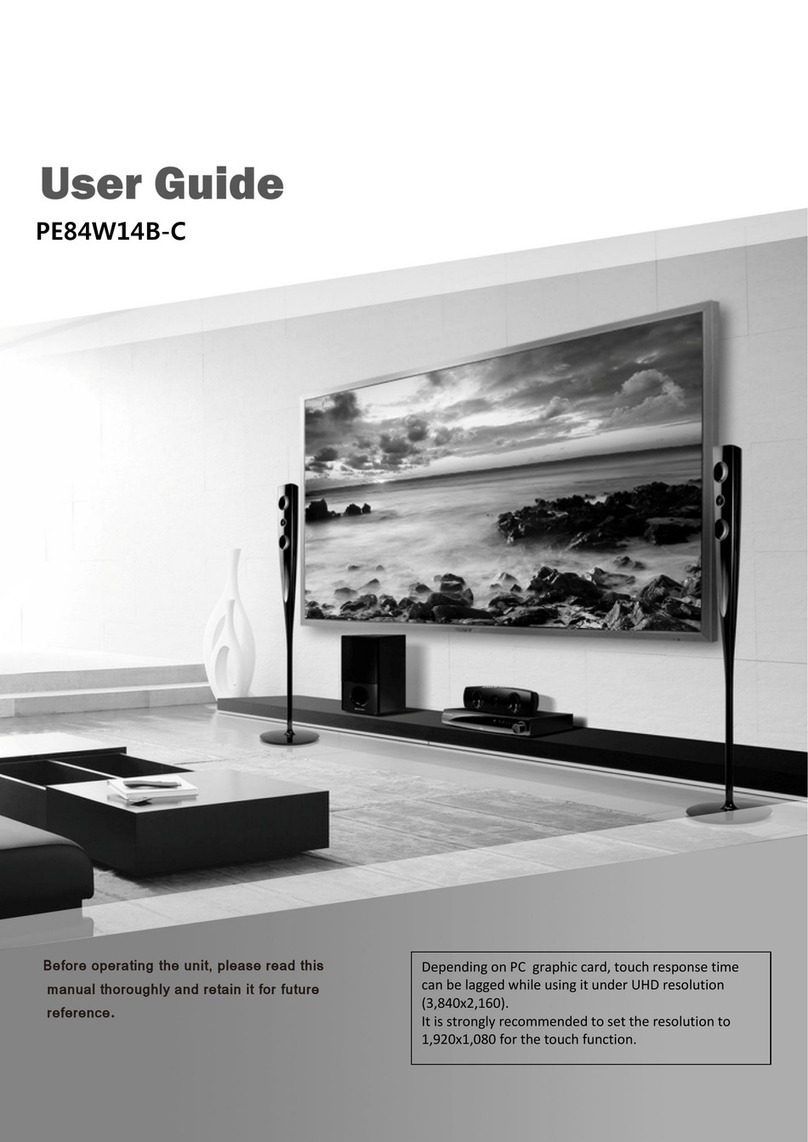

4.1 Dimensions

198

138

R6

37,7

43,2

Fig.3: Dimensions in mm

4.2 Display

Category Description

Type TFT screen with touch function

Resolution 800 x 480 pixels

Size 5"

Background lighting LED, typically 500 cd/m2, dimmable

Horizontal viewing angle In each direction 70°

Vertical viewing angle 50° from above, 70° from below

Tab.1: Technical data - Display

4.3 Pushbuttons

Category Description

Number of membrane

keys

19 keys + power key

Background lighting Dimmable

Adjustable between

0 ... 100%

Typical service life 1,000,000 operations

Tab.2: Technical data - Keyboard

Key Behaviour ■Power ON/OFF: Press and hold for one second to turn the device on/off.

■ISB: Press and hold for one second to send the ISB message.

Jetter AG Technical specifications | 4

JVM-206-K00-O21 User Manual 10 / 32

4.4 Processor Kernel

Parameter Description

CPU STM32F4

FLASH 16 MB

SDRAM 8 MB

Tab.3: Processor Kernel

4.5 Mechanical specifications

Parameter Description Standards

Weight

Enclosure specifications

Material Plastic

Vibration resistance 10 Hz ... 150 Hz, 6 h ISO 16750-3

Shock resistance

Type of shock Half-sine wave ISO 16750-3

Intensity and duration 50 g for 18 ms

Number and direction 10 shocks in the directions of all three spatial axes

Tab.4: Mechanical specifications

4.6 Environmental conditions

Parameter Description Standards

Operating temperature -20°C ... +70°C ISO 16750-4

Climatic conditions Humid heat

Storage temperature -30°C ... +70°C ISO 16750-4

DIN EN 60068-2-1

DIN EN 60068-2-2

Air humidity 5 … 95 %

Degree of protection IP65 with mating connector plugged in

IP20 without mating connector

Tab.5: Environmental conditions

Jetter AG Technical specifications | 4

JVM-206-K00-O21 User Manual 11 / 32

4.7 Electrical properties

Power supply

VBAT_ECU

Parameter Description

Rated voltage DC 8.5 V… DC 18 V

Permissible voltage range

VBAT_ECU

DC 8 V ... DC 28 V

Maximum current 2 A

Typical current consump-

tion logic circuit

(VBAT_ECU)

320 mA at DC 12 V

Power consumption Approx. 3 W

Integrated protective func-

tions

Reverse polarity protection, overvoltage, voltage

surges

Tab.6: Power supply VBAT_ECU

4.8 EMC values

The has CE approval in accordance with EN ISO 13766-1 for 12 V vehicle power

supply systems.

Pulses to ISO

7637-2

Test pulse Values Functional class

1 -450V C

2a +37V O

2b +20V C

3a -150V O

3b +150V O

4 Ua1: -12 V/50 ms

Ua2: -5 V/500 ms

B (24 V systems)

Tab.7: Pulses to ISO 7637-2

Pulses to ISO

16750-2

(12 V vehicle power

supply systems)

Test pulse Values Functional class

5b Load dump

70V/2Ω/350 ms

C

Tab.8: Pulses to ISO 16750-2 for 12 V vehicle power supply systems

Irradiation to ISO

11452

Immission to ISO 11452 Functional class

20 MHz ... 2 GHz 30 V/m O

20 MHz ... 2 GHz 100 V/

m

B

Tab.9: Irradiation to ISO 11452

Jetter AG Technical specifications | 4

JVM-206-K00-O21 User Manual 12 / 32

Emission to CISPR

25

Emission to CISPR 25 Limit

Narrowband emission

30 MHz ... 1000MHz

30 ... 75 MHz = 52 ... 42 dBµV/m (decreasing over

logarithm)

75 ... 400 MHz = 42 ... 53 dBµV/m (increasing over

logarithm)

400 ... 1000 MHz = 53 dBµV/m (constant)

Wideband emission

30 MHz ... 1000 MHz

30 ... 75 MHz = 62 ... 52 dBµV/m (decreasing over

logarithm)

75 ... 400 MHz = 52 ... 63 dBµV/m (increasing over

logarithm)

400 ... 1000 MHz = 63d BµV/m (constant)

Tab.10: Emission to CISPR 25

ESD EN 61000-4-2 ESD EN 61000-4-2 Functional class

Contact ±4 kV O

Air ±8 kV O

Tab.11: ESD EN 61000-4-2

4.9 Ports and interfaces

4.9.1 ISOBUS interface

Parameter Description

Baud rate 250 kBaud

Protocol ISOBUS

Terminating resistor Integrated

Cable specification CAN-compliant, twisted wires, unshielded

4.9.2 USB interface

Category Description

Supply unit 5 V, 500 mA max.

Data rate USB 1.1

Protocol USB host interface

Jetter AG Technical specifications | 4

JVM-206-K00-O21 User Manual 13 / 32

4.10 Inputs/outputs according to ISO11786:1995

Within the operating voltage range, all inputs are voltage-proof and overcurrent

protected.

Digital inputs for

tractor speed

Category Description

ISO11786 - Digital inputs for wheel speed and ground speed with two modes

Abbreviation IN_1 … IN_2

Quantity 2

Pull resistor 4.7 KOhm

H level Mode 1: ≥ 3.4 V

Mode 2: ≥ 6.2 V

L level Mode 1: ≥ 2.5 V

Mode 2: ≥ 1.5 V

Accuracy 2 %

System menu functions Mode and pull-up selec-

tion

Pulse/meter Calibration

Tab.12: Digital tractor speed inputs according to ISO11786:1995

PTO speed input

Category Description

ISO11786 - PTO speed

Abbreviation PTO_IN

Quantity 1

Pull resistor 4.7 KOhm Can be disabled

H level Mode 1: ≥ 3.4 V

Mode 2: ≥ 6.2 V

Default = Mode 1

L level Mode 1: ≥ 2.5 V

Mode 2: ≥ 1.5 V

Signal Up to 20%/80% duty cy-

cle

Tab.13: PTO speed according to ISO11786:1995

Hitch position (digi-

tal input)

Category Description

ISO11786 - Hitch position (digital input)

Abbreviation TP_DI_IN

Quantity 1

H level ≥ 6.2 V

L level ≥ 1.5 V

Source resistance 100 Ohm ± 10 Ohm

Input resistance > 3 kOhm

Tab.14: Hitch position - digital input according to ISO11786:1995

Jetter AG Technical specifications | 4

JVM-206-K00-O21 User Manual 14 / 32

Hitch position (ana-

log input)

Category Description

ISO11786 - Hitch position (analog input)

Abbreviation TP_AI_IN

Quantity 1

Voltage range 0 … 10 V

Input resistance > 3 kOhm

Tab.15: Hitch position - analog input according to ISO11786:1995

Ignition input/out-

put

Category Description

Ignition input/output

Abbreviation IGN_KEY

Quantity 1

Input

Power supply 12 V

Output

Max. output current 0.5 A

Tab.16: Ignition

4.11 Acoustic signal generator

Category Description

Type Piezo

Volume > 70 dB At resonant frequency

without mechanical at-

tenuation

Volume control Switched off,

10% ... 100%

Controlled via PWM

Frequency band 200 Hz ... 4 kHz

Tab.17: Acoustic signal generator

4.12 Real-time clock

Parameter Description

Battery type CR2032

Service life Approx. 10 years from

production

The battery life depends

on the environmental

conditions and may

therefore vary.

Jetter AG Mechanical installation | 5

JVM-206-K00-O21 User Manual 15 / 32

5 Mechanical installation

NOTICE Damages to material or functional impairment

Welding on the chassis may cause damages to material of the device, or impair

its functions.

►Before you start welding, disconnect all connections between the device and

the electric system of the vehicle.

►Protect the device from flying sparks and welding beads (splatter).

►Do not touch the device with the welding electrode or earth clamp.

NOTICE Dirt and moisture can affect the electrical connections.

►Plug unused pins with blanking plugs.

►Protect all electrical connections with appropriate single wire seals.

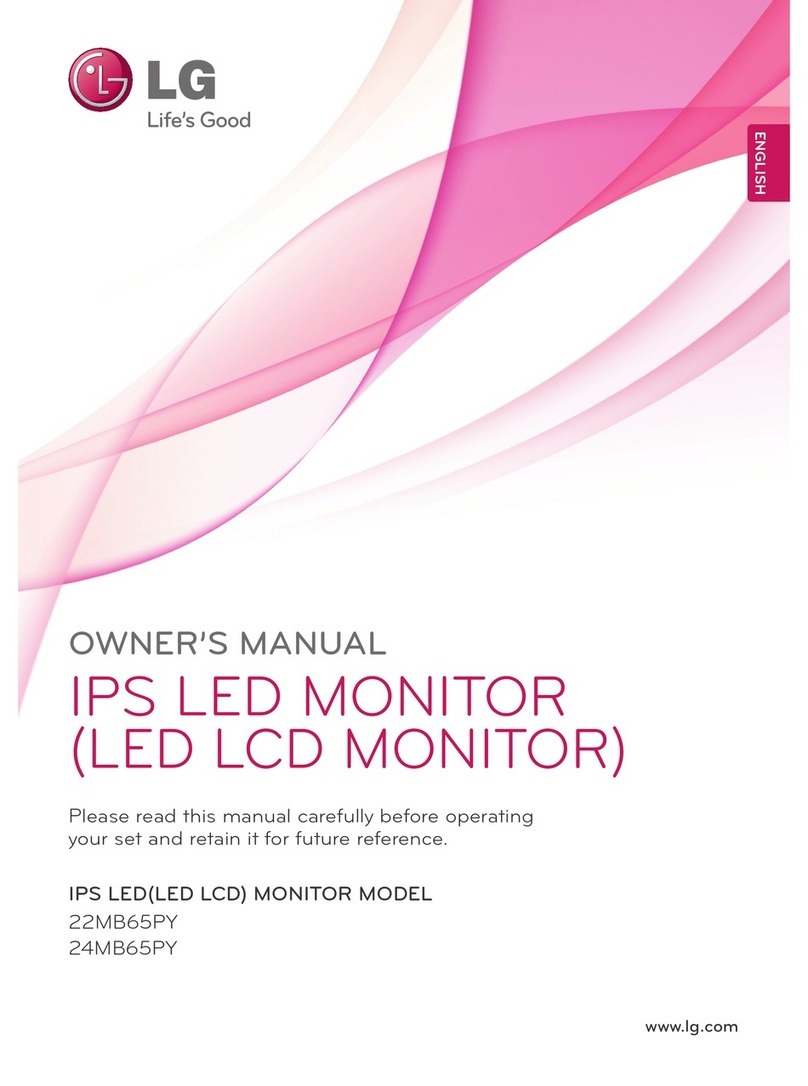

5.1 Allowed mounting orientations

The device has a RAM Mount ball adapter and can be installed accordingly in the

driver's cab.

Fig.4: Allowed mounting orientation

Jetter AG Electrical connection | 6

JVM-206-K00-O21 User Manual 16 / 32

6 Electrical connection

NOTICE Damages to material or functional impairment

Improper implementation of the wiring harness may cause mechanical stress.

►Protect the cables from bending, twisting or chafing.

►Install strain reliefs for the connecting cables.

NOTICE Surges resulting from missing protection or fusing

Surges may cause malfunctions or damage to the product.

►Protect the voltage inputs from surges according to the requirements.

►Ensure that the device is handled in accordance with ESD regulations.

Jetter AG Electrical connection | 6

JVM-206-K00-O21 User Manual 17 / 32

6.1 8-pin M12 connector (male)

2

1

7

5

6

4

3

8

Fig.5: 8-pin M12 connector (male)

1Power supply from terminal 30

(+12 V) 2USB data transfer +

3Ignition input/output (max. 0.5 A) 4USB data transfer -

5CAN-L 6Power supply from terminal 31

(GND)

7CAN H 8USB +5 V (USB_VBUS)

INFO A cable tee should be used to use the USB signal.

6.2 8-pin M12 connector (female)

1

2

3

5

4

6

7

8

Fig.6: 8-pin M12 connector, female

1n. c. 2Tractor speed: Wheel speed

3Tractor speed: Ground speed 3n. c.

5PTO speed input (RPM signal) 6Hitch position (digital)

7Power supply from terminal 31

(GND) 8Hitch position (analog)

Jetter AG Identification and Configuration | 7

JVM-206-K00-O21 User Manual 18 / 32

7 Identification and Configuration

7.1 Operating System Update via USB

The operating system of the JVM-206-K00-O21 can be updated via USB. An up-

date cable is required for the update (Accessories [}29]).

Preparing the Update Process

1. Unzip the firmware package "JVM-206-K00-O21_rev_x_x_x.zip" where

"x_x_x_x" stands for the firmware version.

2. Connect the update cable to the device.

3. Make sure that the device is switched off.

4. Connect the 12 V power supply.

Update via USB

This update variant requires an already installed operating system.

1. Copy the file “34434445.EDC“ to a USB flash drive.

2. Insert the USB flash drive into the USB A port of the update cable.

3. Switch the device ON.

4. Select the system settings:

5. Select "Update via USB":

Jetter AG Identification and Configuration | 7

JVM-206-K00-O21 User Manual 19 / 32

7.2 Operating System Update via CAN

The operating system of the JVM-206-K00-O21 can be updated via CAN. To up-

date the OS, A PEAK-P-CAN USB/CAN dongle is required.

The update can only be performed on a PC with Windows 10 Pro 64 operating

system.

For the necessary tool JV-206_CAN_updater_rev_1_0_0_2.zip, as well as

the system requirements, please contact Jetter support at

1. Insert the PEAK-P-CAN USB/CAN dongle into the USB slot of a Windows

computer

2. Unzip the file "JV-206_CAN_updater_rev_1_0_0_2.zip" into any direc-

tory.

3. Option: Replace the standard file "34434445.EDC" with an individualized file.

4. Connect the JVM-206-K00-O21 to the dongle.

5. Turn on the JVM-206-K00-O21.

6. Execute the file "JVM-206_updater.bat". Do not turn off the device during

the update.

ðThe device-specific firmware file (34434445.EDC) is loaded to the device

via CAN.

7. After successfully downloading the file, the device must be restarted. After the

restart, the new EDC contents are automatically used.

The device restarts automatically when the ignition input is used. If not, press

the power button on the device to restart it.

For a detailed "smallhmi_updater.py" Python script description, please con-

tact Jetter support at [email protected].

Jetter AG Programming | 8

JVM-206-K00-O21 User Manual 20 / 32

8 Programming

This chapter is intended exclusively for specialist personnel who are familiar with

ISOBUS visualizations.

The device already has a system menu for end users ex works.

8.1 System Menu

The system menu is described by a customer-specific IOP file that is downloaded

together with the firmware. Jetter provides the necessary tool for linking the two

files.

The system menu contains the general functions of the terminal. You can use

them without ECU visualization. The objects of the system menu are used sepa-

rately from the ECU objects, therefore it is not necessary to check for a possible

object collision.

To open the system menu during an ECU visualization, press the HOME button.

INFO The object description contains all system menu functions, but some functions

are not accessible for all device versions. For this reason, check the device-spe-

cific description before adjusting the system menu:

■The RTC values are synchronized with the real-time clock if the hardware ex-

ists.

■The UDS-related objects are accessible if the corresponding license is active

in the firmware.

■The hardware-specific objects are only active if the necessary hardware is

available:

■Speed channels

■PTO speed input functions

■Hitch position (digital)

■Hitch position (analog)

■Ignition output

■Physical keys

8.1.1 Reserved Object IDs

Data Mask

Objects

Object ID Description

1000 Home data mask

1001 … 1029 Data masks for settings

1030 IOP download

1031 USB update request

1032 Update via USB

1033 Update via UDS

1035 "Input Boolean" editor

1036 "Input Number" editor

1037 „Input String“ editor

1038 „Input List“ editor

1040 "The IOP cache has been cleared!"

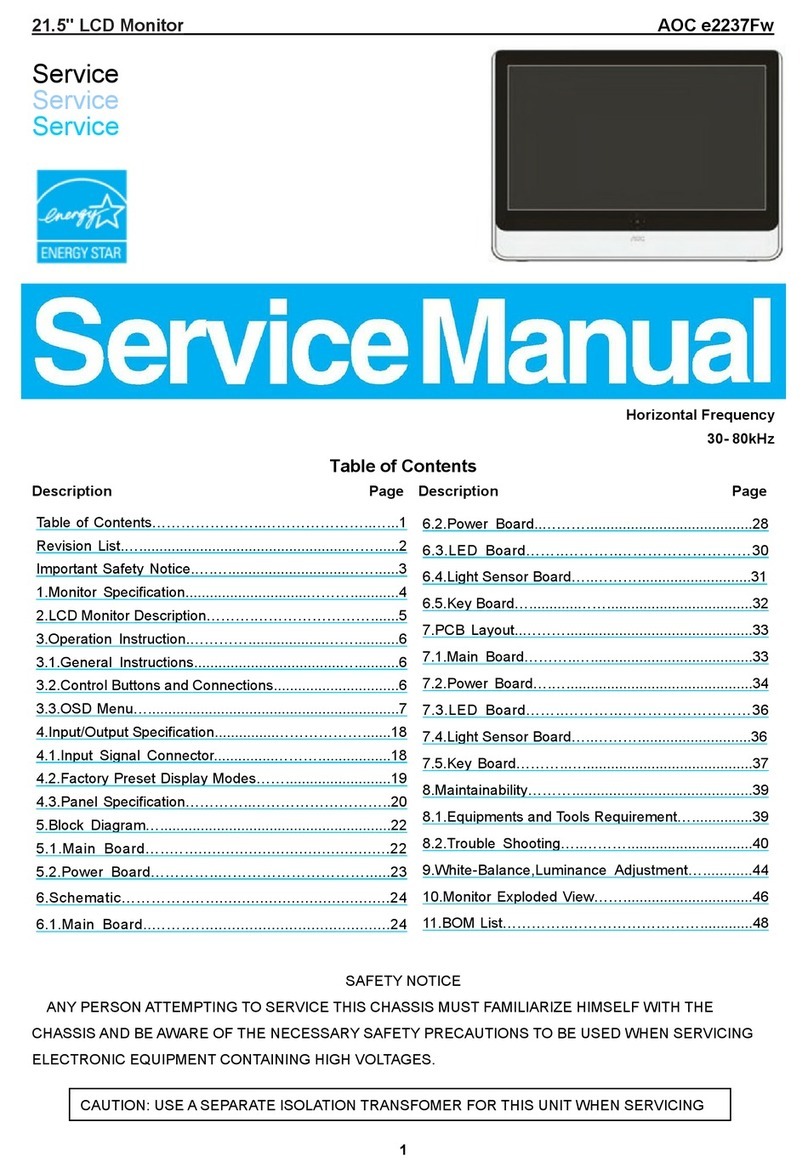

Table of contents

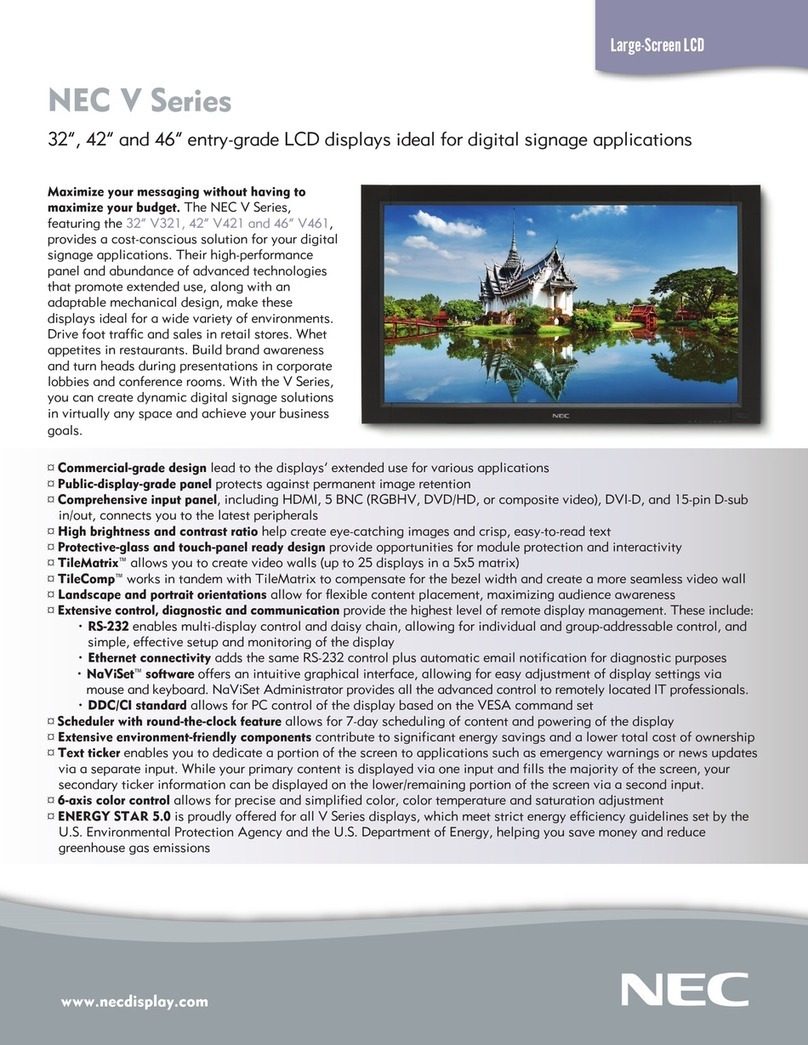

Other Jetter Monitor manuals