34

Safety information contains in this section must be observed at all times when working

on or with batteries. For safety, installers are responsibility to familiarize themselves with

this manual and all warnings before installation.

2.1 Basic Security

The PACK has been designed and tested in strict rules with international safety

certification requirements. Read all safety instructions carefully before any work and

obey the rules at all times when working on or with the PACK. Jinko shall not be liable for

any consequence caused by the violation of the following:

ŸDamage occurred during transportation.

ŸIncorrect transportation, storage, installation and use, or customer fails to convey the

correct information about transportation, storage, installation and use to terminal

customers.

ŸNon-professional installation.

ŸFailure to obey the rules of this operation instructions and safety precautions in this

document.

ŸUnauthorized modifications or removal of the software package.

ŸPACK tamper label is damaged or product with any part missing (except the authorized

dissemble parts).

ŸOperation in extreme environments which are not allowed in this document.

ŸRepair, disassemble, or change PACKs without authorization and cause failure.

ŸDamage to shell labels or modifies date of production.

ŸPACK fail to be charge for more than six months.

ŸDamages due to force majeure (such as lightning, earthquakes, fire, and storms).

ŸWarranty expiration.

2.2 Safety Precautions

2.2.1 Environment Requirements

Do not expose the battery to temperature above 50℃ or heat sources.

Do not install or use the battery in wet locations, moisture , corrosive gases or liquids,

such as bathroom.

Do not expose the battery to direct sunlight for extended periods of time.

Place battery in safe place away from children and animals.

Battery power terminals shall not touch conductive objects such as wires.

Do not dispose the batteries in fire, which may cause an explosion.

PACK shall not come in contact with liquids.

2 Safety 2.2.2 Operation Precautions

Do not touch the PACK with wet hands.

Do not disassemble the PACK without permission.

Do not crush, drop or puncture the PACK and battery.

Dispose the batteries according to local safety regulations.

Store and recharge battery in accordance with this manual.

Ensure the connection of ground wire reliable.

Remove all metal objects such as watches and rings that could cause a short-circuit

before installation, replacement and maintenance.

The Pack shall be repaired, replaced or maintained by skilled personal that has been

recognized.

When storing or handling batteries ,do not stack batteries without package.

Do not broke the battery, the released electrolyte may be toxic and is harmful to skin and

eyes.

Packaged batteries should not be stacked more than specified number stipulated on the

packing case.

Do not use damaged, failed or deformed batteries, which may lead to high temperature

or even dangerous accidents. Continued operation of damaged battery may result in

electrical shock, fire or even worse.

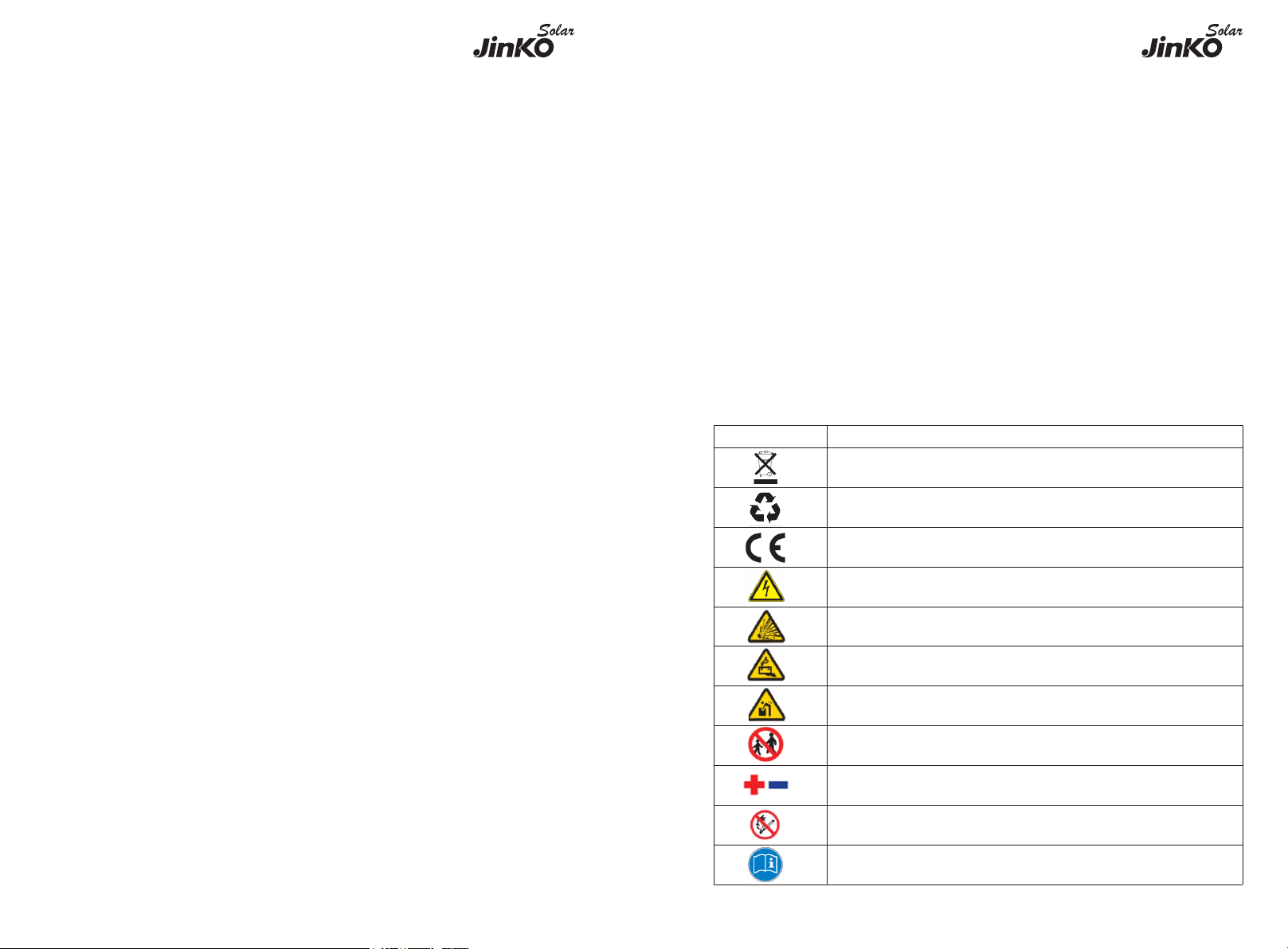

2.3 Warning Labels

Lithium ion battery can be recycled

Certification in European union area

Heavy enough to cause severe injury

Keep the Pack away from children

Make sure the battery polarity well connected