2

Allvis – Manual (EN 2021-05-25)

Allvis – Manual Measuring System

Index

1 Introduction........................................................................................................................................ 3

1.1 General .......................................................................................................................................... 3

1.2 Maintenance ................................................................................................................................. 5

1.3 Liability .......................................................................................................................................... 6

1.4 Warranty........................................................................................................................................ 7

2 Allvis Measuring System..................................................................................................................... 8

2.1 General Description....................................................................................................................... 8

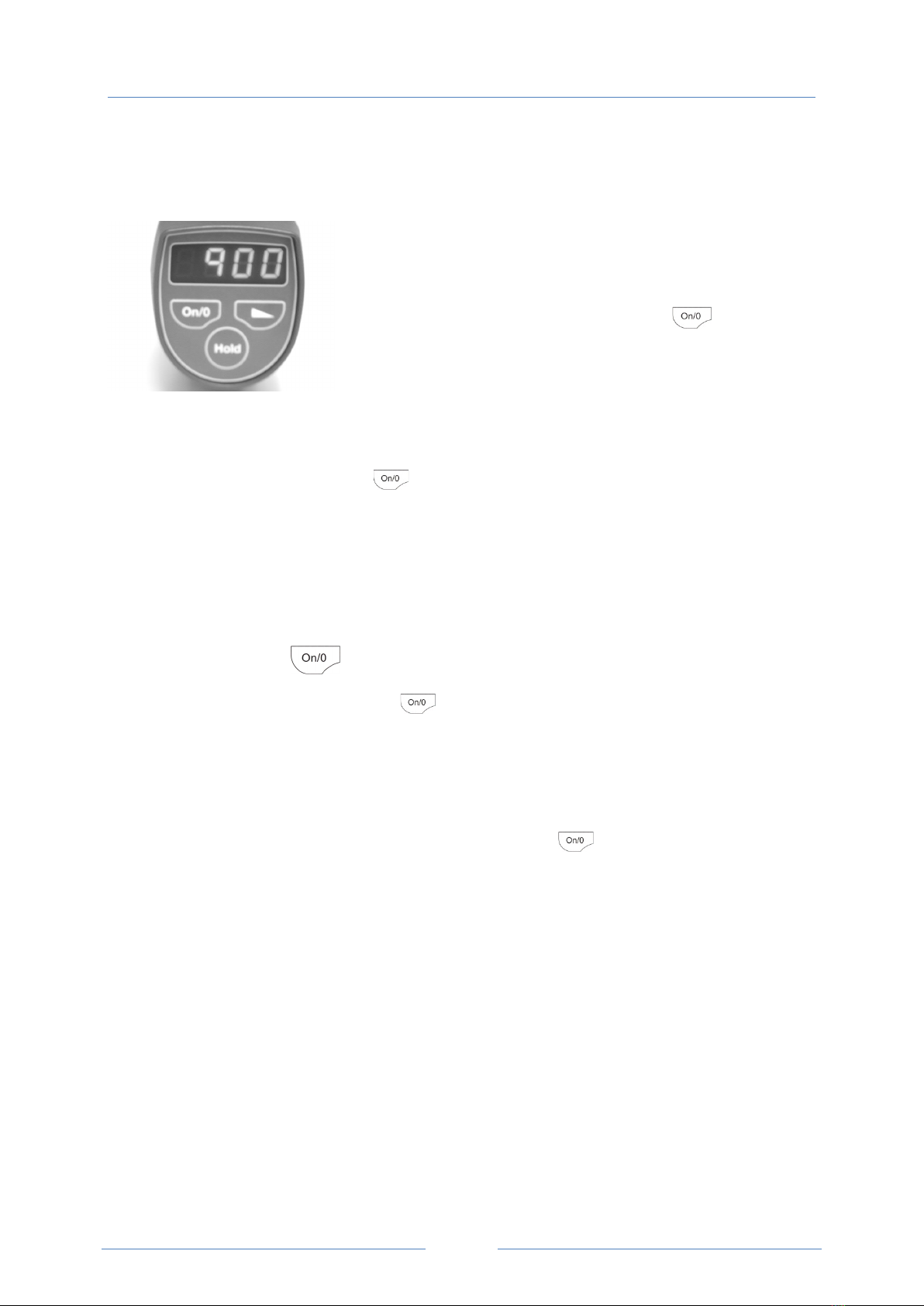

2.2 Display Functions........................................................................................................................... 9

2.3 Height Calibration Rods............................................................................................................... 11

2.4 Magnetic Attachment.................................................................................................................. 11

2.5 Datum Height Rods ..................................................................................................................... 11

2.6 ADJUSTABLE LEVEL ...................................................................................................................... 11

2.7 Measuring Sockets and Tips ........................................................................................................ 12

2.8 Short Measures ........................................................................................................................... 12

2.9 Replace Batteries......................................................................................................................... 13

2.10 Technical Specification .............................................................................................................. 14

3 Creating vehicle Dimension Data Sheets.......................................................................................... 15

3.1 General ........................................................................................................................................ 15

3.2 Liability ........................................................................................................................................ 16

4 Measuring......................................................................................................................................... 17

4.1 Mounting the Magnet Attachment ............................................................................................. 17

4.2 Using Level to Calibrate Height Plane ......................................................................................... 18

4.3 Length Measuring........................................................................................................................ 20

4.4 Symmetry Measuring (Cross-measuring) ................................................................................... 21

4.5 Height Measuring ........................................................................................................................ 23

4.6 Position of the Vehicle................................................................................................................. 25

5 Quick Guide ...................................................................................................................................... 26

5.1 Quick Guide without Data ........................................................................................................... 26

5.2 Quick Guide without Vehicle Dimension Data ............................................................................ 28

6 Adapters ........................................................................................................................................... 29

6.1 Adapters ...................................................................................................................................... 29

6.2 How to use AVA 111.................................................................................................................... 29

6.3 Choose Socket/Adapter............................................................................................................... 30

7 Technical Notes ................................................................................................................................ 31

7.1 Drawing and Article Numbers ..................................................................................................... 31

7.2 Explanations model codes........................................................................................................... 31

8 Declaration of Conformity ................................................................................................................ 33