-8-

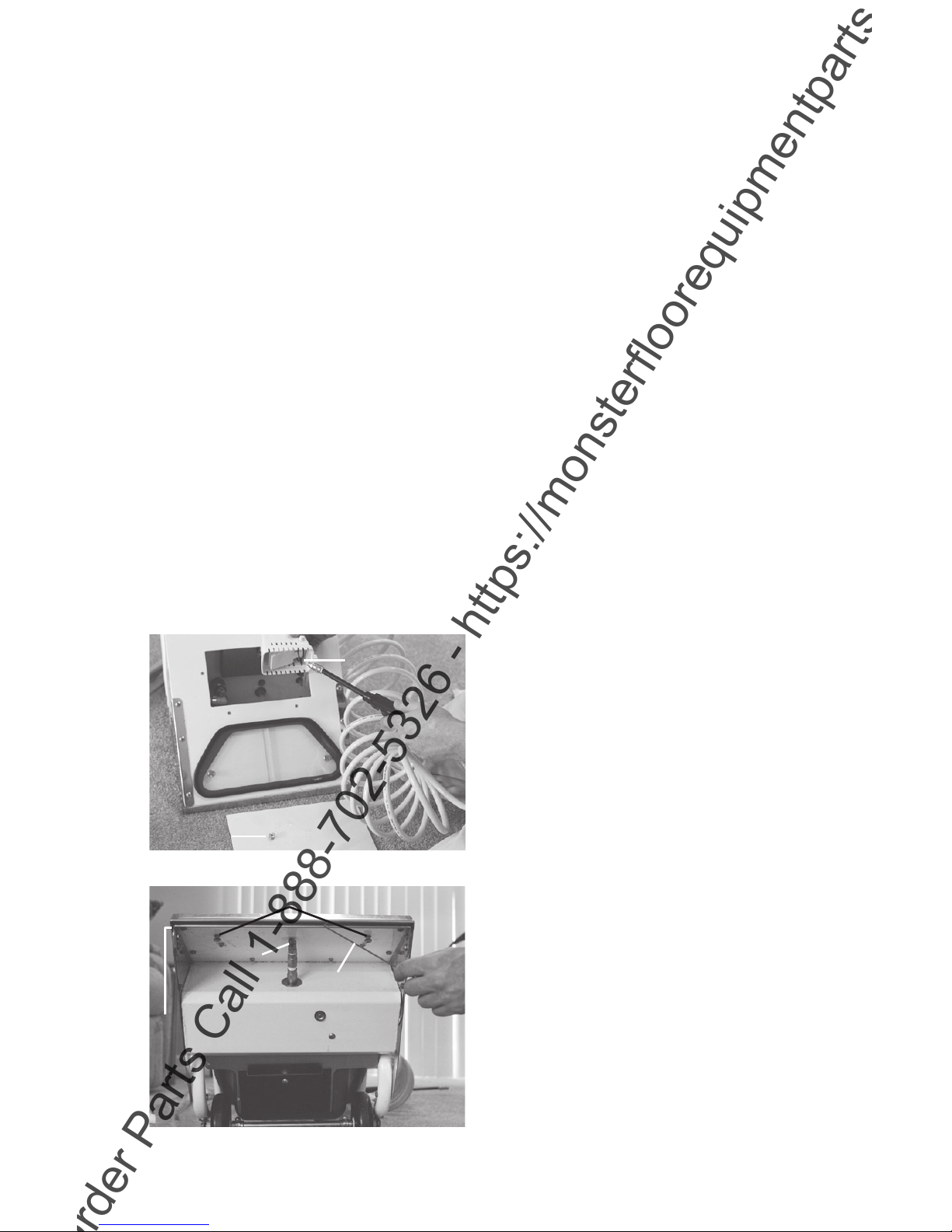

Figure 26: Cleaning Vacuum Shoe

4. Clean Air Filter (figure 23). At least

once or twice a month the air filter

should be removed and cleaned. Be-

gin by removing the wingnut, nylon

washer and the middle brace, then

pull out the air filter (figure 23). Thor-

oughly clean the air filter. When re-

placing the air filter, make sure it is

positioned properly around the black

plastic baffle. Then as you are retight-

ening the wingnut, push up on the

middle brace to make sure it seats flat

against the inside of the recovery tank.

Do not operate the machine without

the air filter. Doing so will dramati-

cally reduce the life and performance

of your vacuum motor.

5. Clean Float Switch (figure 25). Un-

screw brass thumbnut (figure 24) and

lift up the float switch. Use your

spray wand to spray out any debris

that may have collected inside the

plastic housing.

6. Remove drain plug and spray out bot-

tom of recovery tank with prespray

wand.

7. Remove and clean water channel by

removing thumbnuts from underside

of machine (figures 25 and 26).

8. Clean vacuum shoe with shoe hook

(figure 26).

9. Replace drain plug, float switch, wa-

ter channel and water filter. (Make

sure the water filter sits flat on the

bottom of the recovery tank before

tightening its garden hose swivel nut).

10. Watch for any hair and lint build up

between axle and wheel bearings.

11. Clean machine exterior with a damp

cloth and window cleaner.

IMPORTANT: A powder coating cov-

ers the marine-grade aluminum shell of

the machine. Over time, this coating will

chip or flake off, especially in areas such

as the inside of the recovery tank. A

spray paint such as Rustoleum may be

used to touch up the finish.

12. Plug machine back in and start

vacuum motor to remove any mois-

ture that may have entered it during

the cleaning process. Leave vacuum

motor on for about a minute; then

unhook machine.

VII. Hoses

A. To remove regular 50 foot hose

assembly from machine:

1. Unscrew machine’s drain valve assem-

bly from the drain line hose whip

swivel fitting (figure 27).

2. Unplug electrical connection.

3. Unscrew the pressure line’s garden

hose swivel nut from the prespray

assembly.

IMPORTANT: a garden hose screen

washer is located within this swivel nut.

Water Channel Thumb Nuts

Side Vacuum Slot

Lip Hook

Spray Jet

Figure 25: Cleaning the Float Switch

Thumb Nut

Float Switch

Water Channel

ToOrderPartsCall1-888-702-5326-https://monsterfloorequipmentparts.com