Johnson Controls DSH024B-120B User manual

Other Johnson Controls Air Conditioner manuals

Johnson Controls

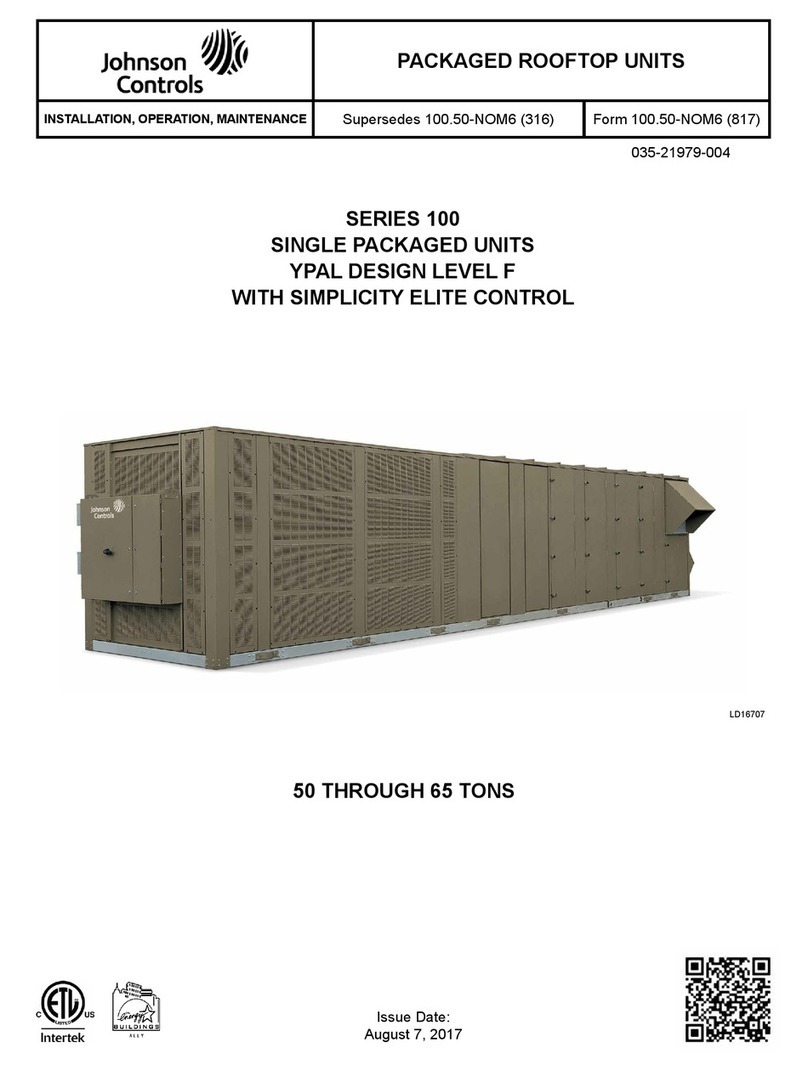

Johnson Controls 100 Series User manual

Johnson Controls

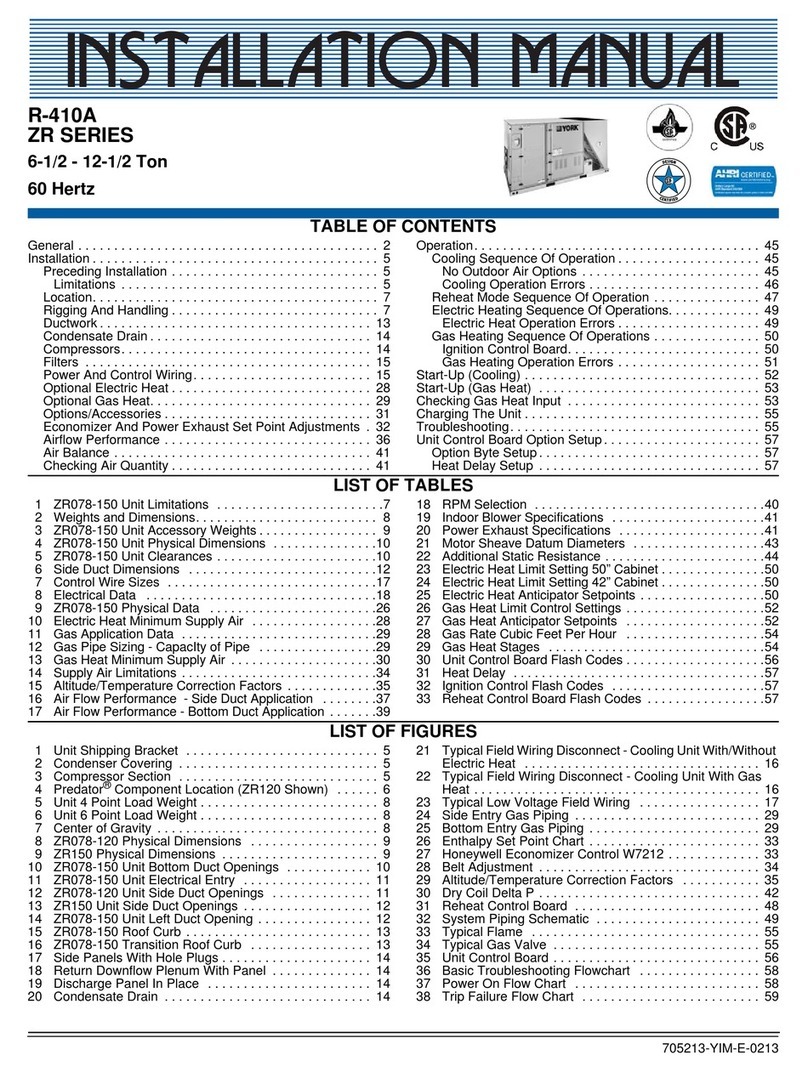

Johnson Controls ZR Series User manual

Johnson Controls

Johnson Controls DW-03 User manual

Johnson Controls

Johnson Controls 100 Series Owner's manual

Johnson Controls

Johnson Controls YORK EK Series User manual

Johnson Controls

Johnson Controls YORK YHUJYH024BARS-A-M User manual

Johnson Controls

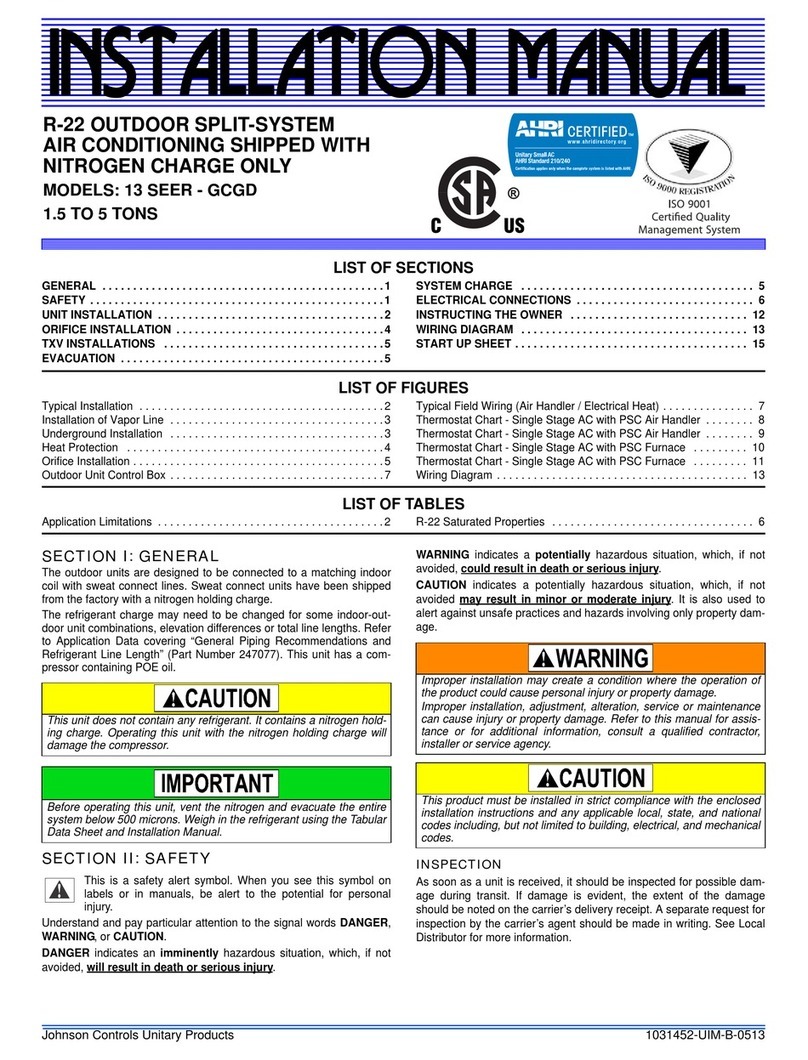

Johnson Controls 13 SEER - GCGD User manual

Johnson Controls

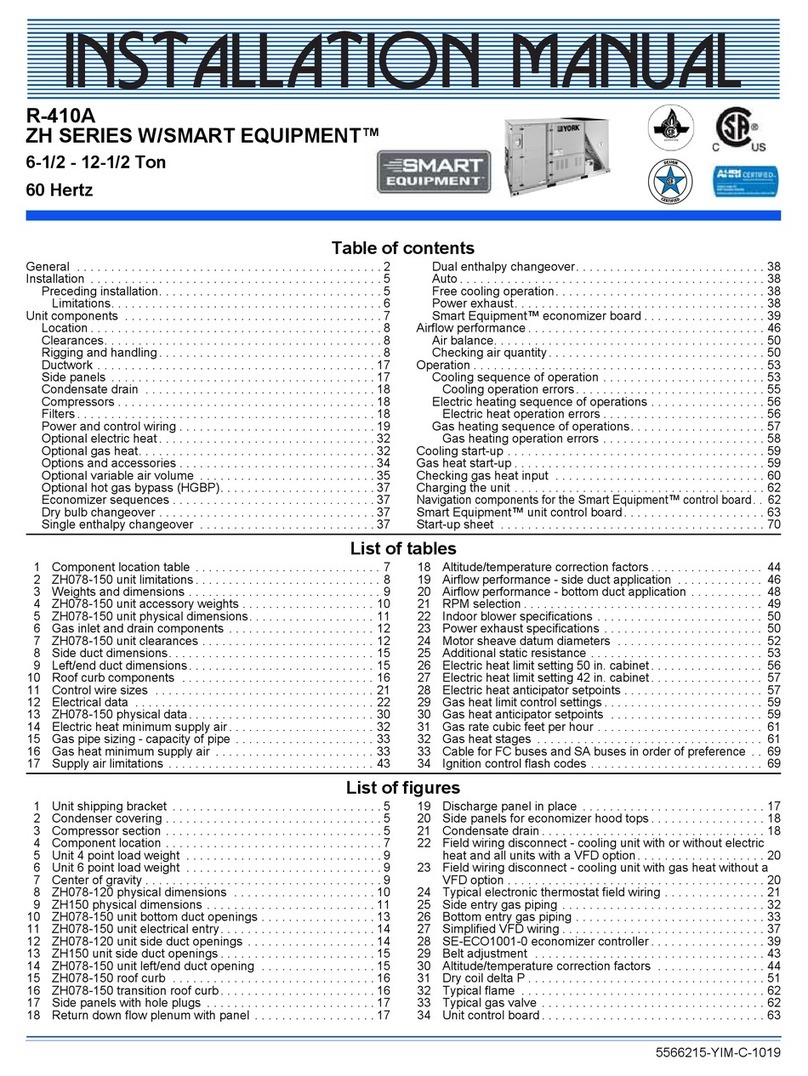

Johnson Controls ZH Series User manual

Johnson Controls

Johnson Controls 18 SEER CZH Series User manual

Johnson Controls

Johnson Controls Y Seroes Manual

Johnson Controls

Johnson Controls YC2D Series User manual

Johnson Controls

Johnson Controls York YH9FZH12-AFX User manual

Johnson Controls

Johnson Controls 341426-BIM-A-0108 User manual

Johnson Controls

Johnson Controls ZF Series User manual

Johnson Controls

Johnson Controls HICM008B21S User manual

Johnson Controls

Johnson Controls DHP09NWB21S User manual

Johnson Controls

Johnson Controls YC2E User manual

Johnson Controls

Johnson Controls 13 SEER - GCGD User manual

Johnson Controls

Johnson Controls DEZ Series User manual

Johnson Controls

Johnson Controls YJHJXH024BARR-FX User manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions

McQuay

McQuay MCK020A Technical manual

Webasto

Webasto Frigo Top 25 DS Instructions for use

Frigidaire

Frigidaire FAZ12ES2A installation instructions

Mitsubishi Electric

Mitsubishi Electric MSC-GE20VB operating instructions

Mitsubishi Electric

Mitsubishi Electric PLA-M100EA installation manual

Daikin

Daikin Split Sensira R32 Service manual