5844973-UIM-A-0920

2 Johnson Controls Ducted Systems

Due to system pressure, moving parts, and electrical components,

installation and servicing of air conditioning equipment can be hazard-

ous. Only qualified, trained service personnel must install, repair, or ser-

vice this equipment. Untrained personnel can perform the basic

maintenance functions of cleaning coils and filters and replacing filters.

Observe all precautions in the literature, labels, and tags accompanying

the equipment when working on air conditioning equipment. Ensure to

follow all other applicable safety precautions and codes including ANSI

Z223.1 or CSA-B149.1 (latest edition).

Wear safety glasses and work gloves. Use quenching cloth and have a

fire extinguisher available during brazing operations.

SECTION III: MODEL NUMBER NOMENCLATURE

SECTION IV: INSTALLATION

INSTALLATION SAFETY INFORMATION

Read these instructions before continuing the unit installation. This is an

outdoor combination heating and cooling unit. Give the instructions to

the homeowner, and instruct the homeowner to retain them for future

reference.

Adhere to the following:

• Refer to the unit rating plate for the approved type of gas for this

product.

• Install the unit only in a location and position specified on page 4 of

these instructions.

• Never test for gas leaks with an open flame. Use commercially

available soap solution made specifically for the detection of leaks

when checking all connections, as specified on page 9 of these

instructions.

• Install the unit to operate within the unit's intended temperature

rise range with the duct system and within the allowable external

static pressure range, as specified on the unit name/rating plate

and in Table 7.

• Do not use this equipment for temporary heating of buildings or

structures under construction.

WARNING

Before performing service or maintenance operations on unit, turn off

main power switch to unit. Electrical shock could cause personal

injury. Improper installation, adjustment, alteration, service, or main-

tenance can cause injury or property damage. Refer to this manual.

For assistance or additional information consult a qualified installer,

service agency, or the gas supplier.

CAUTION

This system uses R-410A refrigerant, which operates at higher pres-

sures than R-22. No other refrigerant may be used in this system.

Gage sets, hoses, refrigerant containers, and recovery systems must

be designed to handle R-410A. If you are unsure, consult the equip-

ment manufacturer. Failure to use R-410A compatible servicing

equipment may result in property damage or injury.

!

!

WARNING

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury, or

loss of life.

Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

1. Do not try to light any appliance.

2. Do not touch any electrical switch; do not use any phone in

your building.

3. Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

4. If you cannot reach your gas supplier, call the fire depart-

ment.

Installation and service must be performed by a qualified installer,

service agency, or the gas supplier.

!

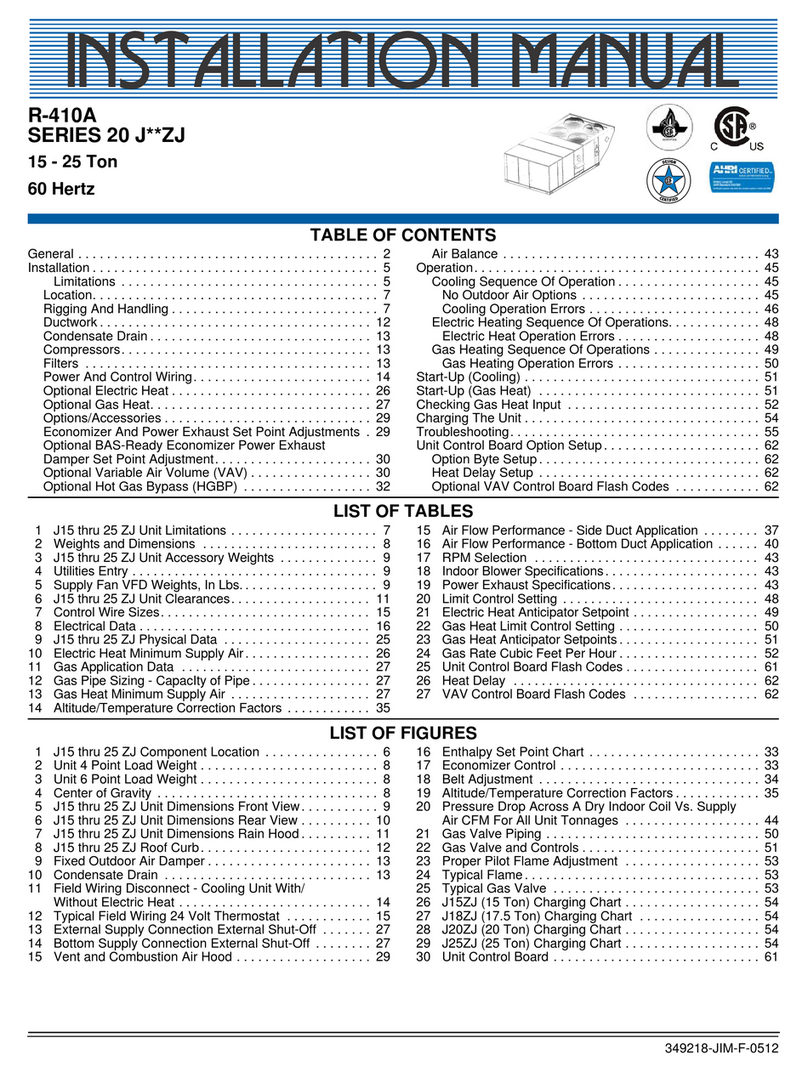

PCG 4 A 24 050 2 X 4 A

123456789

1. Model Family

PCG - packaged A/C with gas heat

PHG - packaged heat pump with gas heat

PCE - packaged A/C with electric heat

PHE - packaged heat pump with electric heat

5. Gas Heating Input BTU/Hr x 1000

050 = 50,000 BTU/Hr input, blank = electric heat

6. Voltage-Phase-Frequency

2 = 208/230-1-60, 3 = 208/230-3-60, 4 = 460-3-60

2. Nominal Cooling Efficiency

4 = 14 SEER, 6 = 16 SEER

7. NOx Approval

X = Low NOx, blank = not Low NOx

3. Cabinet Size

A = small 35.75 x 51.25, B = large 45.75 x 51.25

8. Generation Level

1 = first generation 2 = second generation

4. Nominal Air Conditioning Cooling Capacity BTU/Hr x 1000

24 = 24,000 BTU/Hr, 30 = 30,000 BTU/Hr

9. Revision Level

A = original release, B = second release

Example:

PCG4A240502X4A is a packaged A/C with gas heat, 14 SEER, small cabinet, 2 ton, single-stage heat, 50,000 BTU/Hr gas heat, 208/230 V, single-

phase, Low NOx model, fourth generation, original release.

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warning exactly could result in serious

injury, death, or property damage.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of leaks to

check all connections. A fire or explosion may result causing property

damage, personal injury, or loss of life.

!