English

READ THIS INSTRUCTION SHEET AND THE SAFETY WARNINGS CAREFULLY BEFORE INSTALLING AND SAVE IT FOR FUTURE USE

VA-747x Series - Electronic Terminal Unit Valve Actuator1

This document is subject to change without notice

General Features

The VA-747x Series provides floating or proportional control in HVAC

applications.

This actuator is designed for field mounting onto VG6000 terminal unit valves.

Figure 1: Dimensions in mm

(a). Cable length 1.5 m

Mounting

Figure 2: Mounting actuator on the valve

Figure 3: Mounting positions

When mounting the actuator on a valve, please follow the instructions below:

• It is recommended that the valves be mounted upright or at angles not

greater than 90° in an easily accessible location.

• Do not mount the actuator upside down to avoid dripping water, which

could enter the housing and damage the mechanism or motor.

• Do not cover with insulating material.

• Sufficient clearance must be allowed for actuator removal (refer to the

dimension drawings).

• The valve must be installed so that the plug seats against the flow, as

indicated by the arrows on the valve.

Installation and Adjustment

Figure 4: Cover for jumper selection

Remove this cover for jumper selection

(removable only for VA-7472-9001 models)

Wiring

Wiring Diagrams

Figure 5: VA-7470-1001 Floating Model Wiring

Figure 6: VA-7472-1001 and VA-7472-9001 Proportional Models Wirings

Led Indication

After 2 minutes the motor is running, an internal timer switches off the motor.

When the signal is 0% or 100%, the timer switches on the motor every 2

hours for 2 minutes, in the signal direction.

Anti-sticking cycle (only VA-7472 models)

Every 24 hours, the actuator runs one complete cycle up and down and

returns to the control position.

Check out procedure

Before leaving the installation observe at least three complete operating

cycles to be sure that all components are functioning correctly. If not, contact

your supplier.

Autozero cycle (only on VA-7472 models)

Each time the power is switched on, the actuator performs one complete

stroke time down and after that it reaches the control position.

Repair and replacement

Field repair is not possible. If the actuator is not working properly and all

wiring is correct, the actuator should be replaced. Please check with your

nearest supplier.

IMPORTANT: the actuator stem is in completely up position from the factory.

If the actuator is powered when not mounted on the valve, be sure to return

the spindle to completely up position before mounting onto the valve.

WARNING: The electrical connections for the actuators must be

executedinaccordancewiththerelevantlegalrequirements.

In order to avoid any personal injury or damage to the

equipment or other property, always isolate the power supply

before commencing any work on the electrical wiring. In order

to avoid danger to property, it is important for the equipment to

be used solely for which it is intended.

WARNING: The integrated circuits in the actuator are sensitive

to static electricity. Take suitable precautions.

IMPORTANT: Use the Actuator only to control equipment under normal

operating conditions. Where failure or malfunction of the electric actuator

could lead to personal injury or property damage to the controlled

equipment or other property, additional precautions must be designed into

the control system. Incorporate and maintain other devices such as

supervisory or alarm system or safety or limit controls intended to warn of,

or protect against, failure or malfunction on the electric actuator.

On Power line present

Off Power line not present

Double Blinking Actuator performs an end-of-stroke

confirmation cycle or an anti-sticking cycle

Blinking The motor is running

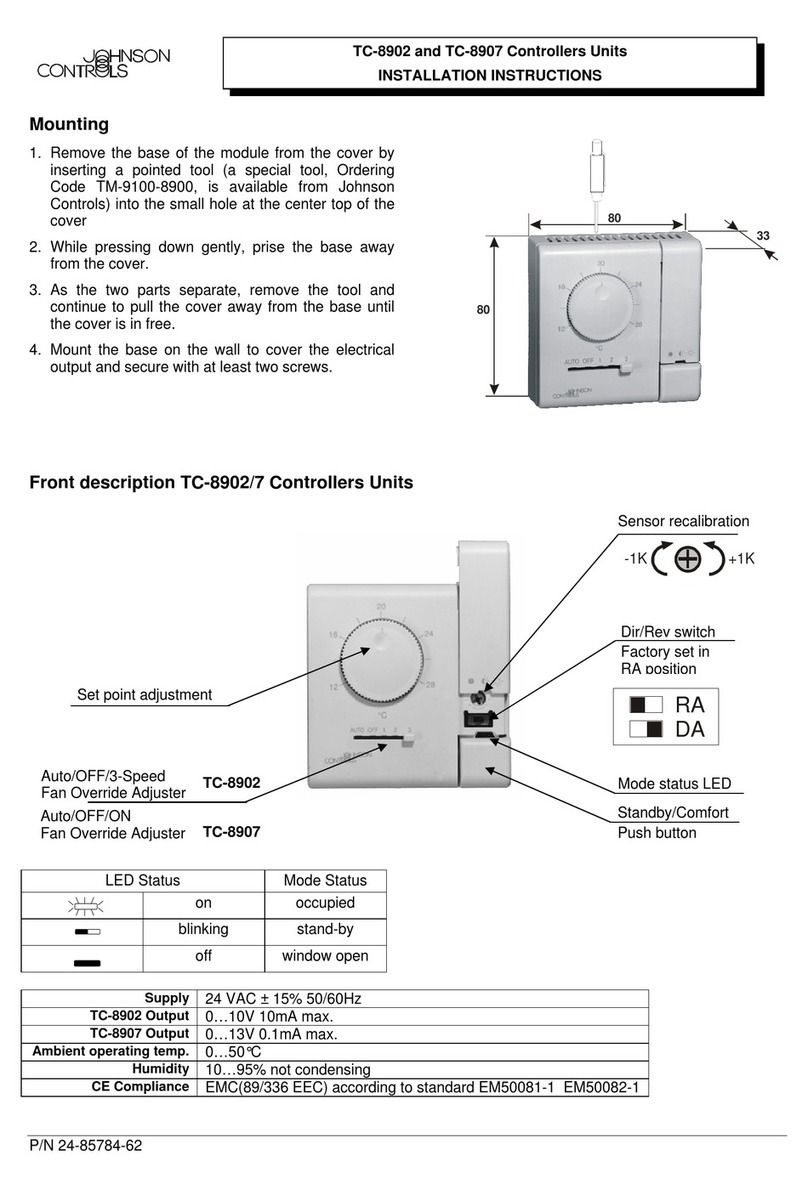

Adjustments (jumper settings) of proportional models

VA-7472-9001 is configurable.

This is how the jumpers are positioned on the board:

Jumper in place:

Jumper removed:

Function Jumper No.

VA-7472-9001 (adjustable)

Factory setting Alternative setting

Anti-sticking 1 enabled disabled

Input control

signal 20...10 V 5...10 V 0...5 V

3

No Function 4 No function ---

Action 5 Direct (DA) Reverse (RA)

No Function 6 No function ---