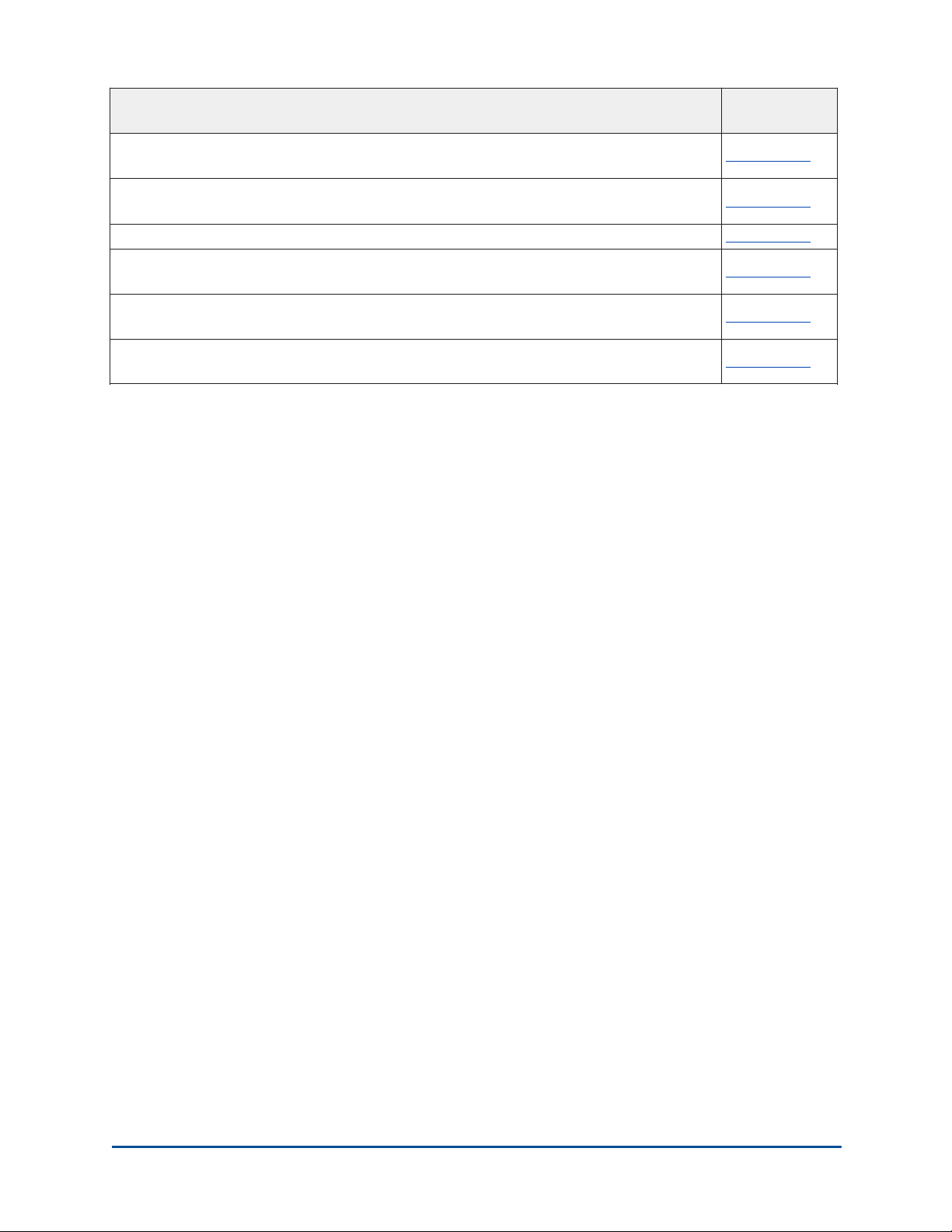

Contents

ContentsGeneral safety guidelines.............................................................................................................................. 5

Safety symbols..................................................................................................................................... 5

Changeability of this document......................................................................................................... 6

Revision notes...................................................................................................................................... 6

Associated literature........................................................................................................................... 6

Conditioned based maintenance...................................................................................................... 7

Nomenclature...................................................................................................................................... 8

Description of system and fundamentals of operation............................................................................ 9

System operation description............................................................................................................ 9

Capacity control................................................................................................................................. 10

System operating procedures.................................................................................................................... 11

Oil heaters.......................................................................................................................................... 11

Oil heater operation.......................................................................................................................... 11

Checking the oil level in the oil reservoir....................................................................................... 11

Start-up............................................................................................................................................... 12

Chiller operation................................................................................................................................ 12

Condenser water temperature control........................................................................................... 13

Operating log sheet.......................................................................................................................... 13

Operating inspections....................................................................................................................... 14

Need for maintenance or service.................................................................................................... 16

Stopping the system......................................................................................................................... 16

Prolonged shutdown......................................................................................................................... 16

System components description................................................................................................................ 17

Compressor........................................................................................................................................ 17

Capacity control................................................................................................................................. 17

Compressor lubrication system....................................................................................................... 17

Oil pump............................................................................................................................................. 18

Oil heater............................................................................................................................................ 20

Motor driveline.................................................................................................................................. 21

Heat exchangers................................................................................................................................ 21

Refrigerant flow control.................................................................................................................... 21

Optional service isolation valves..................................................................................................... 22

Optional hot gas bypass................................................................................................................... 22

OptiView™ Control Center................................................................................................................ 22

Solid state starter (optional)............................................................................................................ 22

Variable speed drive (optional)........................................................................................................ 23

Operational maintenance........................................................................................................................... 24

Oil return system............................................................................................................................... 24

Changing the dehydrator................................................................................................................. 24

The oil charge.................................................................................................................................... 25

Model YK (Style H), R-134a and R-513A 3