4 DMPR-KC204, DMPR-KC205, and DMPR-KC206 Jackshafts Installation Bulletin

12. Attach each mounting bracket on the framework

using two 12-24 x 1/2 inch self-tapping screws

(item 10 in Figure 1) per mounting bracket.

13. Slide the jackshaft tubing (item 2 in Figure 1)

through one mounting bracket until it is almost to

the other mounting bracket.

14. Install one hose clamp (item 3 in Figure 1) onto the

tubing and position it against the first mounting

bracket.

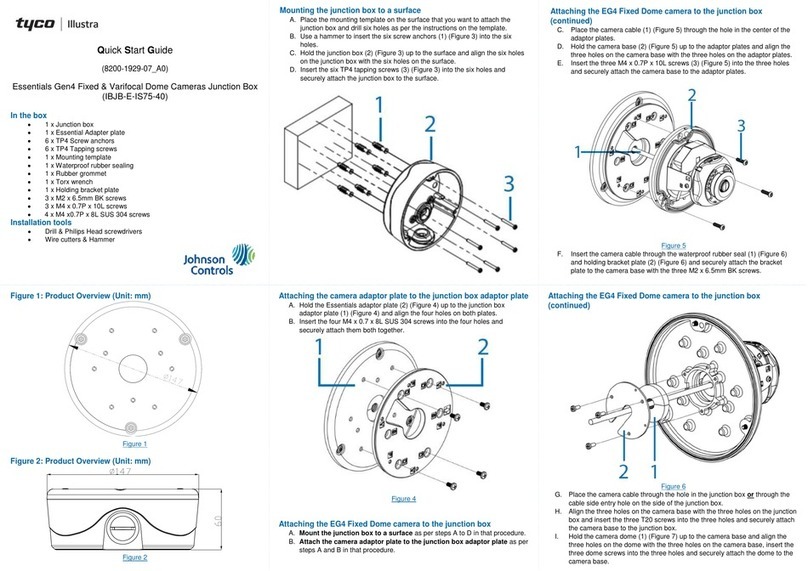

Figure 11: Installing Crank Arm

15. Install one crank arm (item 5 in Figure 1) onto the

jackshaft tubing. Do not tighten.

Note: Repeat Steps 13 through 15 if there are three

panels.

16. Install the second hose clamp on the inside edge

of the final mounting bracket, leaving enough room

to allow the tubing to be inserted through the other

mounting bracket.

17. When the tubing is through all mounting brackets,

position the two hose clamps against each

mounting bracket to prevent side-to-side

movement of the tubing. Make sure enough tubing

is available to install the final crank arm.

18. Secure the connection links (item 7 in Figure 1) to

each crank arm and blade arm using the clevis

pins (item 9 in Figure 1) and push nuts (item 8 in

Figure 1).

19. Slide the remaining crank arm onto the tubing and

connect it to the connection bracket using

connection link, clevis pins, and push nuts.

20. Install a 5/16-18 x 1-1/2-inch-long bolt (item 4 in

Figure 1) and No. 5/16-18 nut (item 6 in Figure 1)

to each crank arm. Refer to Figure 11.

Figure 12: Installing Drive Arm

21. Install the drive arm (item 11 in Figure 1) and

secure it with the U-bolts and nuts (item 13 in

Figure 1).

22. Manually rotate the jackshaft to check for proper

operation before attaching the actuators.

For application at conditions beyond these specifications, consult the local Johnson Controls representative. Johnson Controls, Inc. shall not be liable

for damages resulting from misapplication or misuse of its products.

Controls Group www.johnsoncontrols.com

507 E. Michigan Street

P.O. Box 423

Milwaukee, WI 53201 Printed in U.S.A.