1.1 General Description

Depending on the size of the Rooftop unit, there are two models of energy recovery system, with renewal

airflow in accordance with the following table:

Model Airflow rate

[m3/h]

017 / 022 1000 ‑ 1400 ‑ 1800 ‑ 2200

032 / 040 1800 ‑ 2200 ‑ 2800 ‑ 3400

The renewal airflow required must be indicated at the time the order is placed.

Otherwise, the energy recovery is supplied adjusted to the following airflows:

• 017: 1800 m3/h

• 022: 2200 m3/h

• 032: 2800 m3/h

• 040: 3400 m3/h

NOTE

These renewal airflows correspond to a 46 ÷ 53 % of the rated airflow of the Rooftop unit (see tables in

section Tempered air (TA) and indoor coil entering air (EA) temperatures, see on page 24).

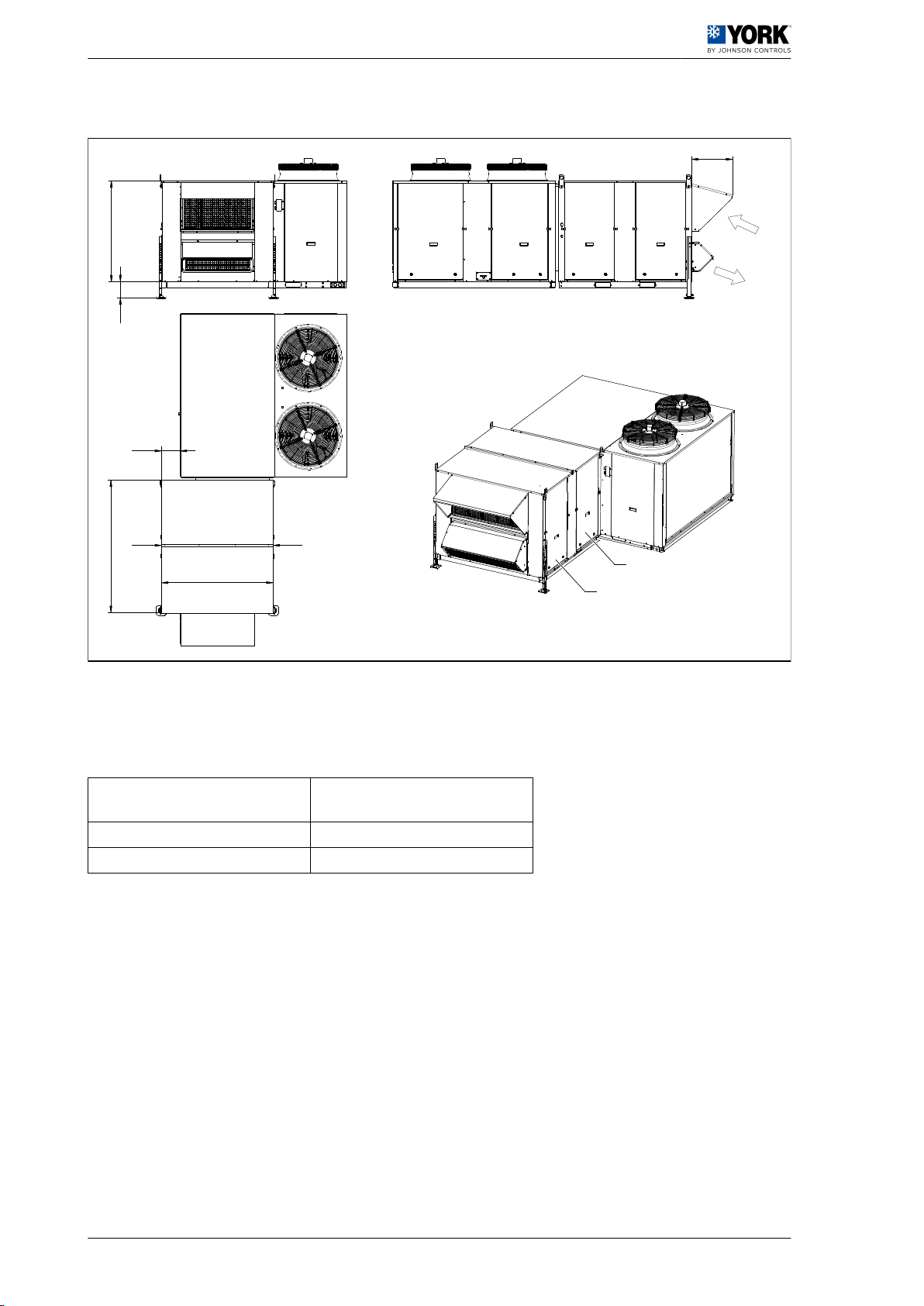

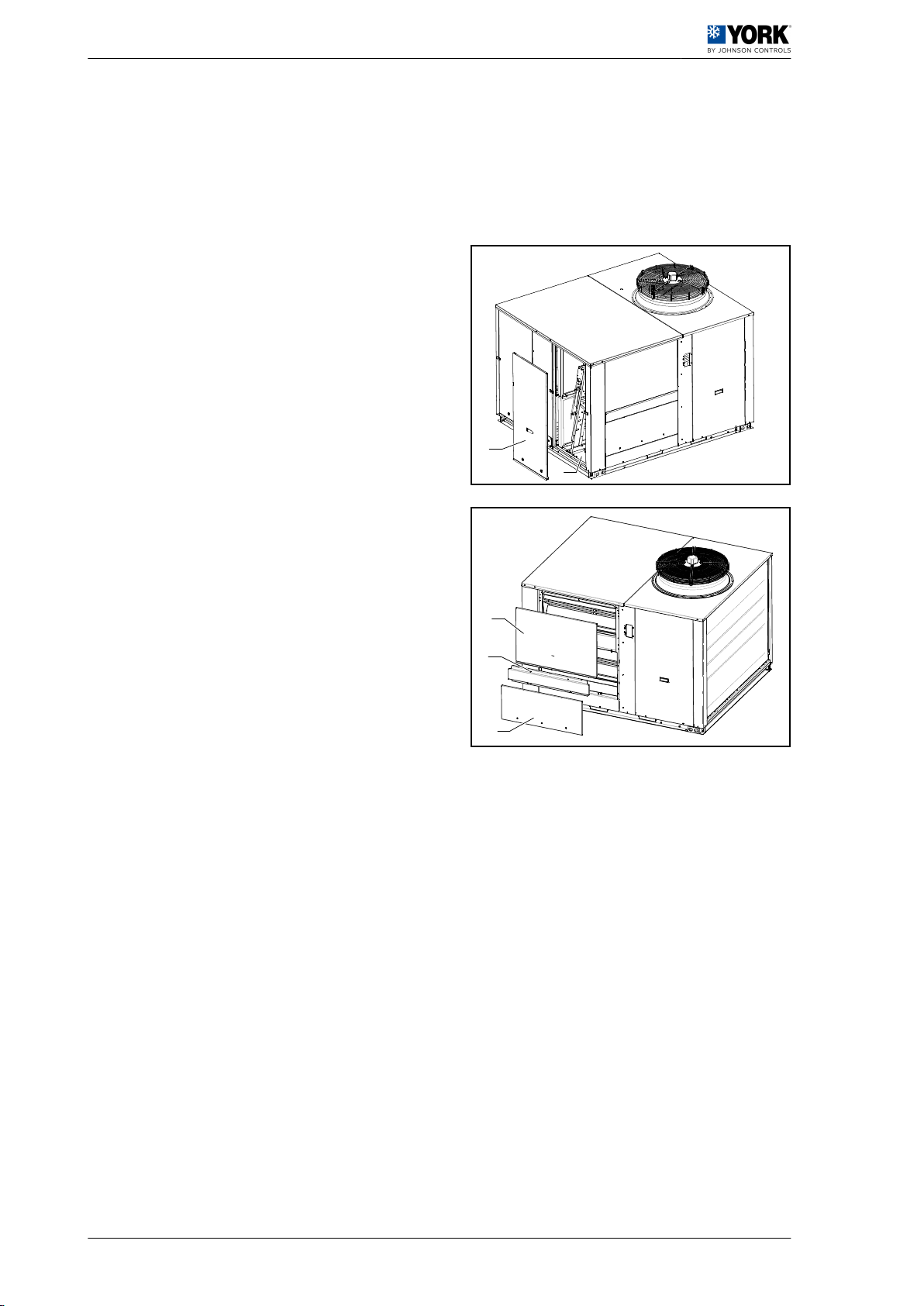

The energy recovery system is used directly coupled to the side of the Rooftop Activa units and includes

the Economiser and indoor air quality probe options.

NOTE

Only the vertical return air duct can be connected, at the bottom of the Rooftop unit.

Features:

• Rotating sectorised enthalpy wheel energy recovery system and rated diameter 30" (Models 017 /

022) and 36" (Models 032 / 040).

• Radial centrifugal fan, motor with integrated EC technology, controlled by differential pressure probe,

ensuring a constant renewal flow.

• Motor protection rating IP54 and insulation class F.

• Bypass damper for economiser mode operation.

• Rain protection (Rainhood) with drip filters on the air intake.

• Barometric damper on the exhaust air.

• G4 air filters, as standard on both sides of the enthalpy wheel. F6 and F7 optional.

• Height-adjustable support legs.

• All cabinet panels are fitted with heat insulation on the inside.

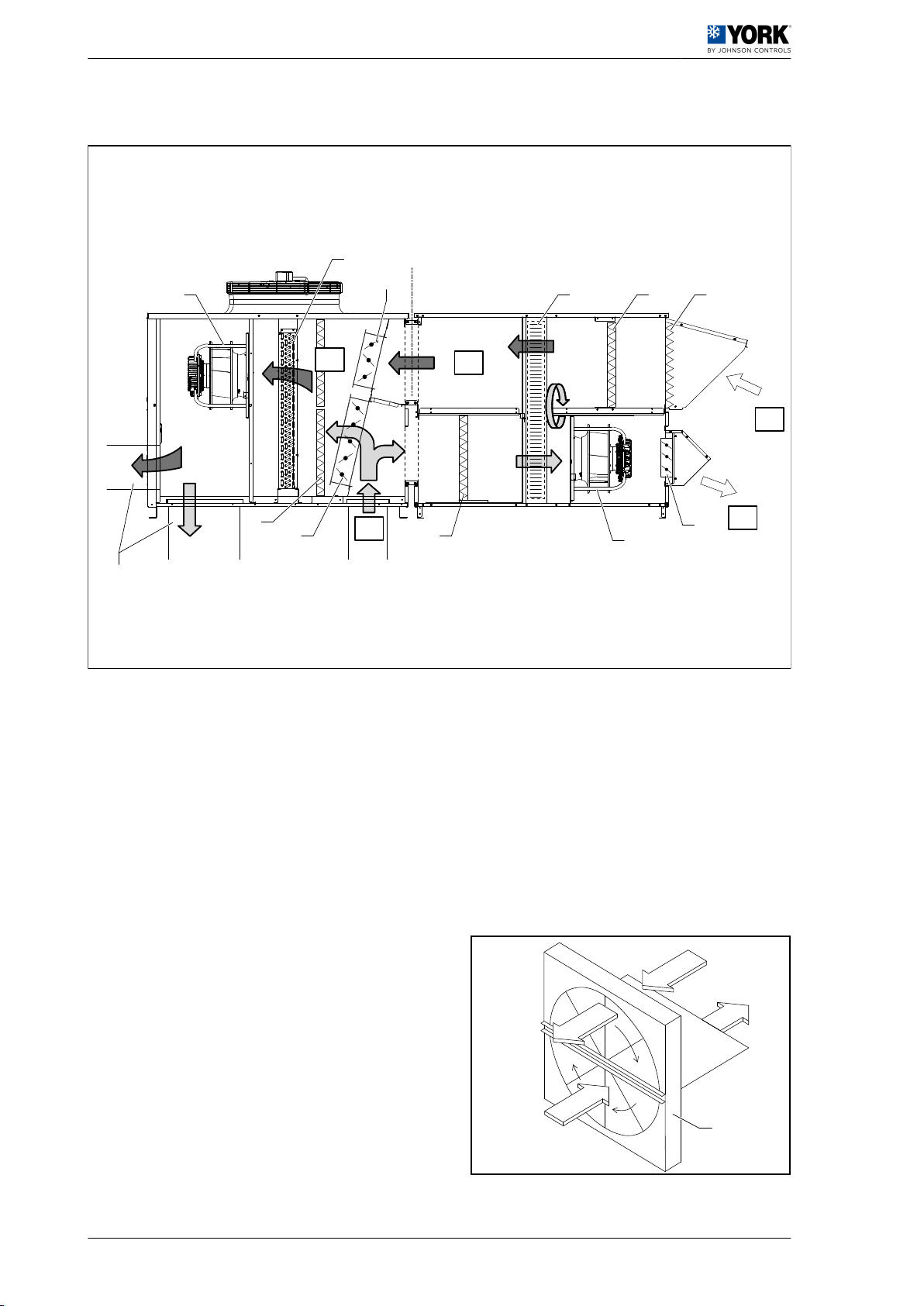

The enthalpy wheel provides substantial savings by reducing the demand for energy. It is ideal for areas

with high or low temperatures and areas with a high level of humidity. Also for areas with a very low level

of humidity, in buildings with a humidifying system, as the humidity is recovered from the exhaust air and

re-introduced into the building.

Air leakage and bleed sector

Many rotating recovery systems are fitted with a bleed sector when this is often not necessary. The bleed

sector minimises leaks between the exhaust airflow to that of the intake airflow by diverting a portion of

the latter to the exhaust flow through the separator between the two.

This is only necessary in cases of industrial applications where the exhaust air carries contaminants. As

a result, the air volume to be moved is 15-20% higher to ensure the required renewal flow, with the

subsequent increase in power required in the fan motor.

In residential air conditioning, the renewal air maintains an acceptable air quality and there are no

concentrated contaminants to be taken into account.

1Energy recovery system for ROOFTOP ACTIVA 017 / 040

1.1 General Description

2