Compatibility

Use the Johnson Controls DP150 transducers with air or

nonconducting gases.

Note: Use with liquids or corrosive gases will

damage the unit.

The operating temperature limits of the DP150 are as

follows:

• Operating temperature: 32°F to 122°F (0°C to 50°C)

• Compensated temperature range: 32°F to 122°F (0°C to

50°C)

Mounting

About this task:

Mount and calibrate the DP150 in a vertical position for

quick and easy installation on ducts, walls, or ceilings

and in control rooms. The DP150 comes calibrated as if

mounted to a wall or a perpendicular surface to the floor

or ceiling. If you mount the DP150 in another orientation,

the unit may show a slight zero shift. See Zero adjustment

to correct the zero shift.

Installation

About this task:

The DP150 has a removable terminal block for easy

wiring. For CE compliance, you require a shielded cable

with both ends correctly grounded.

To install the DP150 transducer, complete the following

steps:

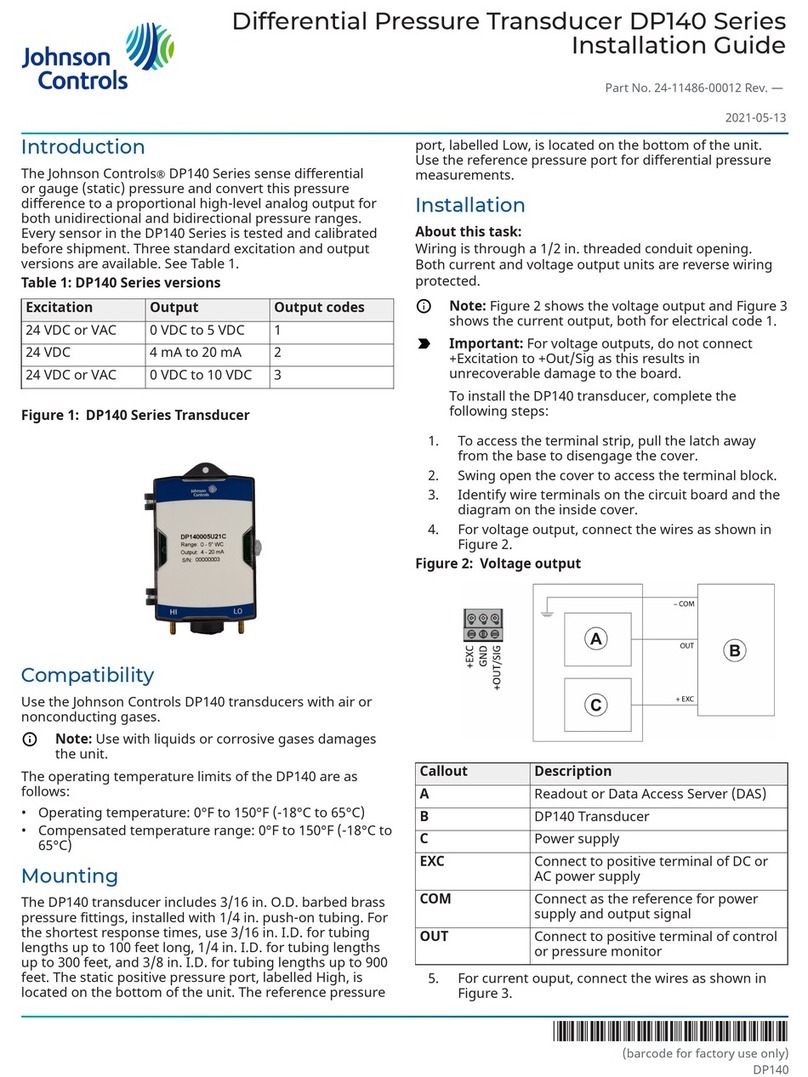

1. Wire and turn on the unit. See Figure 2 for 2-wire

configuration and Figure 3 for 3-wire configuration.

2. After you complete wiring requirements, turn on

the DP150.

3. Turn on the LCD unit. Display toggles through all

existing setup parameters.

4. The display indicates the pressure. Units are either

in inches of WC or Pa.

5. Select pressure range. Use the slide switch

multiplier and JMP4 jumper to set the appropriate

full-scale range. See Figure 4.

Note: A to D is WC, E to H is Pa. LCD will

indicate the selected range. To select E-H

position, move JMP to Pa position.

Figure 2: DP150 2-wire configuration

Callout Description

APower supply, 13 V to 30 V

B24 VAC, DC only, nominal excitation

CMulti-sense current, 2-wire, 4 mA to 20 mA

configuration

D250 ohm sense resistor for 1 V to 5 V output

measurement

ECurrent monitor

Figure 3: DP150 3-wire configuration

Callout Description

APower supply, 13 V to 30 V

B24 VAC or 24 VDC, nominal excitation

CMulti-sense current, 3-wire, 0 VDC to 5 VDC or

0 VDC to 10 VDC configuration

DVoltage monitor

6. Select unidirectional or bi-directional mode.

7. Select current, mA, or voltage: 0 VDC to 5 VDC or 0

VDC to 10 VDC output range. See Figure 4.

Note: If you use 0 VDC to 5 VDC or 5 VDC to

10 VDC outputs, set the mA/volt switch to volt

position.

Figure 4: DP150 range specifications

8. While at zero pressure, press and hold the zero

button until you see 0. Release the zero button to

automatically reset the output to zero.

Optional configuration

About this task:

For optional configuration of the DP150 transducer,

complete the following steps:

1. Press and hold the zero or config button, until you

see 0.

2. Hold down for 7 secs until you see the Conf screen.

3. Release button and screen reads Filt.

4. Hold down button until Filt flashes. Filt is a

sampling filter with 4 options: Nor (normal), SLo

(slow), FAS (fast), and Off (no filter). See Table 2.

5. Press the zero or config button to cycle through the

options.

Differential Pressure Transducer Multi-Range DP150 Series Installation Guide2