HBK AED 9101D User manual

AED

ENGLISH DEUTSCH

Operating Manual

Bedienungsanleitung

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.:

DVS: A05803 01 X00 00

11.2021

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

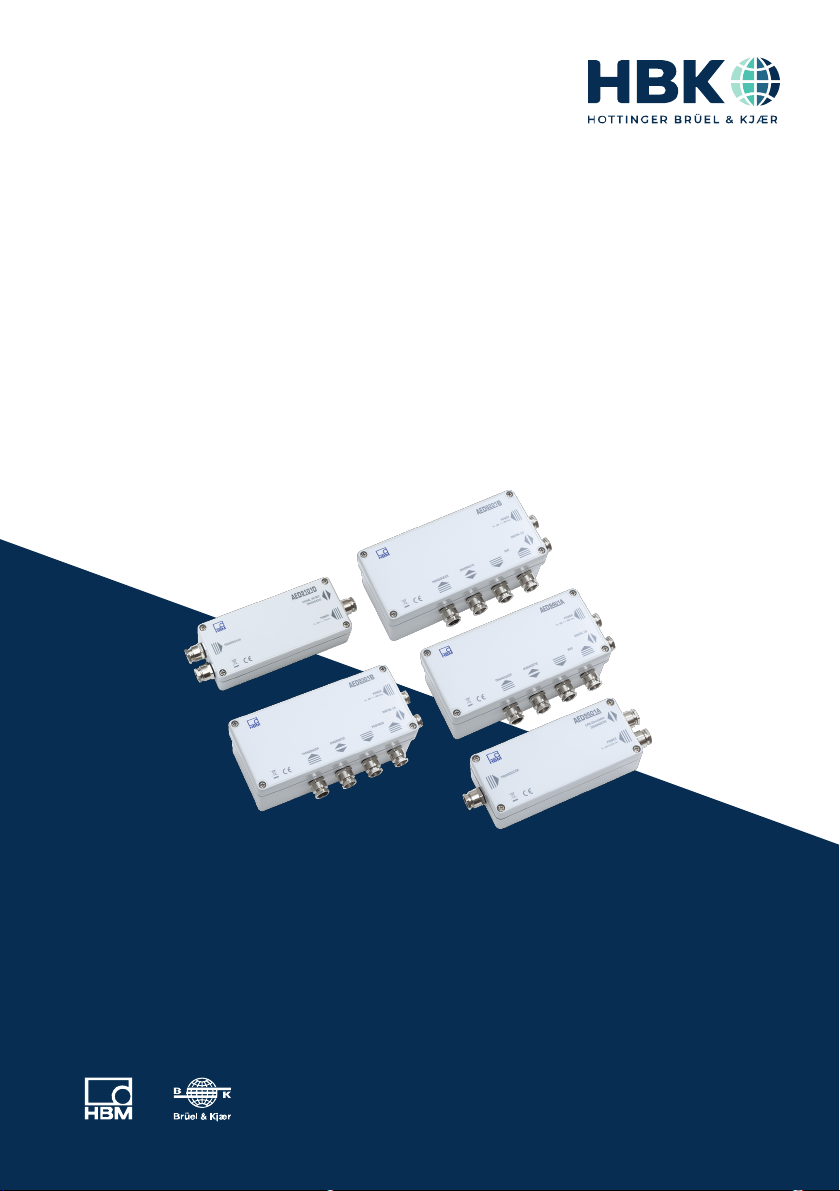

AED

Transducer Electronics 9101D, 9201B, 9301B,

9401A and 9501A

ENGLISH DEUTSCH

Operating Manual

AED

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety Instructions 4................................................

2 Markings used 7....................................................

2.1 Markings used in this document 7.....................................

2.2 Symbols on the device 8.............................................

3 Overview 9.........................................................

3.1 Scope of supply 9...................................................

3.2 Method of operation and functions 9...................................

4 Mechanical construction 11...........................................

4.1 Mechanical construction of the AED9101D 11............................

4.2 Mechanical construction of the AED9201B 12............................

4.3 Mechanical construction of the AED9301B 13............................

4.4 Mechanical construction of the AED9401A 14............................

4.5 Mechanical construction of the AED9501A 15............................

5 Mechanical installation 16............................................

6 Electrical connection 17..............................................

6.1 Ground (GND) and shield wiring 17.....................................

6.2 Cable connection via the PG gland 19...................................

6.3 Transducer connection 20.............................................

6.3.1 6wire circuit (standard mode of operation) 20...........................

6.3.2 4wire circuit 20.....................................................

6.4 Connecting the supply voltage 23......................................

6.4.1 Power supply to AED9101D 23.........................................

6.4.2 Power supply to AED9201B 24.........................................

6.4.3 Power supply to AED9301B 24.........................................

6.4.4 Power supply to AED9401A 25.........................................

6.4.5 Power supply to AED9501A 25.........................................

7 Connecting interfaces and I/Os 26.....................................

7.1 Using several AEDs (bus mode) 26......................................

7.1.1 Connection variants with the RS-485 interface 26.........................

7.1.2 Connection to a CANopen/DeviceNet bus system 28......................

7.1.3 Connection to a PROFIBUS bus system 29...............................

7.1.4 Connection to the diagnostic bus 30....................................

3

AED

TABLE OF CONTENTS

7.2 AED9101D 31.......................................................

7.2.1 ConnectingRS-232, RS-422, RS-485 in a 2-wire or 4-wire configuration 31..

7.2.2 Connecting the diagnostic bus 32......................................

7.2.3 Connecting the digital input 33.........................................

7.3 AED9201B 34.......................................................

7.3.1 Connecting RS-232 or RS-485 in a 4-wire configuration 34................

7.3.2 Connecting the diagnostic bus 35......................................

7.3.3 Connecting digital inputs/outputs 35....................................

7.4 AED9301B 37.......................................................

7.4.1 Connection to the PROFIBUS 37........................................

7.4.2 Connecting the diagnostic bus 38......................................

7.4.3 Connecting digital inputs/outputs 38....................................

7.5 AED9401A 40.......................................................

7.5.1 Connecting CANopen or DeviceNet 40...................................

7.5.2 Connecting the diagnostic bus 41......................................

7.5.3 Connecting digital inputs/outputs 41....................................

7.6 AED9501A 43.......................................................

7.6.1 Connecting CANopen or DeviceNet 43...................................

7.6.2 Connecting the diagnostic bus 44......................................

7.6.3 Connecting the digital input 44.........................................

8 Technical Support 46.................................................

9 Maintenance 47.....................................................

10 Disposal and environmental protection 48...............................

AED

SAFETY INSTRUCTIONS

4

1 SAFETY INSTRUCTIONS

Intended use

The device is to be used exclusively for measurement tasks and directly related control

tasks within the operating limits detailed in the specifications. Use for any purpose other

than the above is deemed improper use.

Any person instructed to carry out installation, startup or operation of the device must

have read and understood the operating manual and in particular the technical safety

instructions.

In the interests of safety, the device should only be operated by qualified personnel and

as described in the Operating Manual. This also applies to the use of accessories.

The device is not intended for use as a safety component. Please also refer to the “Addi

tional safety precautions” section. Proper and safe operation requires proper transporta

tion, correct storage, siting and mounting, and careful operation.

Operating conditions

SProtect the device from direct contact with water.

SProtect the device from moisture and weather such as rain or snow. The protection

class of the device is IP65 (DIN EN 60529).

SDo not expose the device to direct sunlight.

SComply with the maximum permissible ambient temperatures and the specifications

regarding maximum humidity.

SThe design or safety engineering of the device must not be modified without our

express consent. In particular, any repair or soldering work on motherboards

(replacement of components) is prohibited. When exchanging complete modules, use

only genuine parts from HBM.

SThe device is supplied ex works with a fixed hardware and software configuration.

Changes can only be made within the range of possibilities described in the corre

sponding documentation.

SThe device is maintenance free.

SPlease note the following points when cleaning the housing:

-Disconnect the device from all current and voltage supplies.

-Clean the housing with a soft, slightly damp (not wet!) cloth. Never use solvent, as

this could damage the label or the housing.

-When cleaning, ensure that no liquid gets into the device or connections.

SOld equipment that can no longer be used must be disposed of separately from nor

mal household garbage, in accordance with national and local environmental protec

tion and material recycling regulations, see section 10, page 48.

5

AED

SAFETY INSTRUCTIONS

Qualified personnel

Qualified persons are individuals entrusted with the installation, fitting, startup and oper

ation of the product and with the relevant qualifications for their work.

This includes people who meet at least one of the three following criteria:

SThey have knowledge of the safety equipment and procedures of measurement and

automation systems, and are familiar with them as project personnel.

SThey are operating personnel of measurement or automation systems and have been

instructed on how to handle the machinery. They are familiar with the operation of the

equipment and technologies described in this document.

SAs a commissioning or service engineer, they have successfully completed training on

the repair of automation plants. Moreover, they are authorized to start up, ground and

label circuits and equipment in accordance with safety engineering standards.

Working safely

SThe device must not be directly connected to the power supply system. The supply

voltage must not exceed 30VDC .

SError messages should only be acknowledged once the cause of the error has been

eradicated and there is no further danger.

SAutomation equipment and devices must be designed to ensure adequate protection

or locking against inadvertent actuation (e.g. access control, password protection,

etc.).

SFor devices operating in networks, safety precautions must be taken in terms of both

hardware and software, so that an open circuit or other interruptions to signal trans

mission do not result in undefined states or loss of data in the automation device.

SFollowing work on settings or password-protected activities, make sure that any con

trols that may be connected remain in a safe condition until the switching behavior of

the device has been tested.

Additional safety precautions

Additional safety precautions must be taken in plants where malfunctions could cause

major damage, loss of data or even personal injury. You can find details e.g. in the acci

dent prevention regulations applicable to your particular application.

The performance and scope of supply of the device cover only a small proportion of test

and measuring equipment. Before starting up the device in a plant, first perform a project

planning and risk analysis, taking into account all the safety aspects of measurement

and automation engineering, to minimize residual risk. This particularly concerns the

protection of personnel and equipment. In the event of a fault, appropriate precautions

must produce safe operating conditions.

AED

SAFETY INSTRUCTIONS

6

General dangers of failing to follow the safety instructions

This is a state-of-the-art device that is safe to operate. However, there may be residual

risks if the device is installed or operated incorrectly.

7

AED

MARKINGS USED

2 MARKINGS USED

2.1 Markings used in this document

Importantinstructions for your safety are highlighted. Following these instructions is

essential in order to prevent accidents and damage to property.

Icon Meaning

NOTICE This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important This marking draws your attention to important in

formation about the product or about handling the

product.

Tip This marking indicates application tips or other

information that is useful to you.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

Device -> New Bold text indicates menu items, as well as dialog and

window titles in the user interfaces. Arrows between

menu items indicate the sequence in which the menus

and sub-menus are called up

Sample rate Bold text in italics indicates inputs and input fields in

the user interfaces.

uThis marking indicates an action in a procedure

AED

MARKINGS USED

8

2.2 Symbols on the device

CE mark

With the CE mark, the manufacturer guarantees that the product

complies with the requirements of the relevant EC directives (the

Declaration of Conformity can be found on the HBM website

HBM (www.hbm.com) under HBMdoc).

Statutory waste disposal marking

In accordance with national and local environmental protection

and material recovery and recycling regulations, old devices that

can no longer be used must be disposed of separately and not

with normal household garbage. Also see section 10 on page48.

9

AED

OVERVIEW

3 OVERVIEW

Make sure that you always use the version of the operating manual that is valid for your

device. You can always find the latest version on the HBM website in the Digital weighing

electronicsarea at: https://www.hbm.com/AED

.

3.1 Scope of supply

SQuick start guide

SAED transducer electronics (basic device)

3.2 Method of operation and functions

The AED digital transducer electronics (acronym from the German: AufnehmerElek

tronikDigital) digitally condition the signals from SG1) transducers and offer different

interfaces, depending on the version. This way, you can connect SG transducers to a PC

or PLC in a full bridge circuit and create complete measurement chains at little expense.

The basic AED device accommodates the AD103C amplifier board, which digitizes and

processes the signal from the transducer. It provides:

SMechanical protection (IP65)

SThe power supply for the amplifier board and transducer excitation voltage

SBridge excitation voltage for SG transducers with a total bridge resistance of 80 …

4000 Ω or 40 … 4000 Ω (AED9101D only)

SAn EMC-tested combination of basic device and AD103C amplifier board

SA diagnostic bus

SDepending on the version, serial interfaces RS‐422, RS‐485 or RS‐232 or industrial

bus systems CANopen®, DeviceNet®or PROFIBUS®.

Important

The AD103C amplifier board is not included in the scope of supply of the basic device,

and must be ordered separately.

The digital inputs and outputs enable you to do the following:

SControl processes using limit values (LIV …)

SStart measurements via triggers (MAV)

SControl a filling or dosing process.

Different numbers of inputs and outputs are available, depending on the version.

The PanelX PC software is available to facilitate parameter settings, display dynamic

measurement signals and for comprehensive system analysis. You can download the

1) Strain Gauge

AED

OVERVIEW

10

software free of charge from the HBM website and the Weighing technology area at:

https://www.hbm.com/AED. All commands from the AEDs and various bus systems are

described in this program’s online Help.

The DWS2103 digital indicator can be connected to all AEDs and supports all imple

mented functions.

Tip

All factory settings are stored in the amplifier, where they are power failsafe and cannot

be changed. You can restore the factory settings if necessary with the command TDD0;.

You can find further information in the online Help of the PanelX program.

11

AED

MECHANICALCONSTRUCTION

4 MECHANICAL CONSTRUCTION

The AD103C amplifier board is a plug-in board that is inserted into the carrier board of

the basic device via a plug connection. The basic device features terminals for connect

ing the transducers, for connecting the power pack and interface and, depending on the

version, setting options for the interface. The connection cables exit the housing via PG

glands on the side.

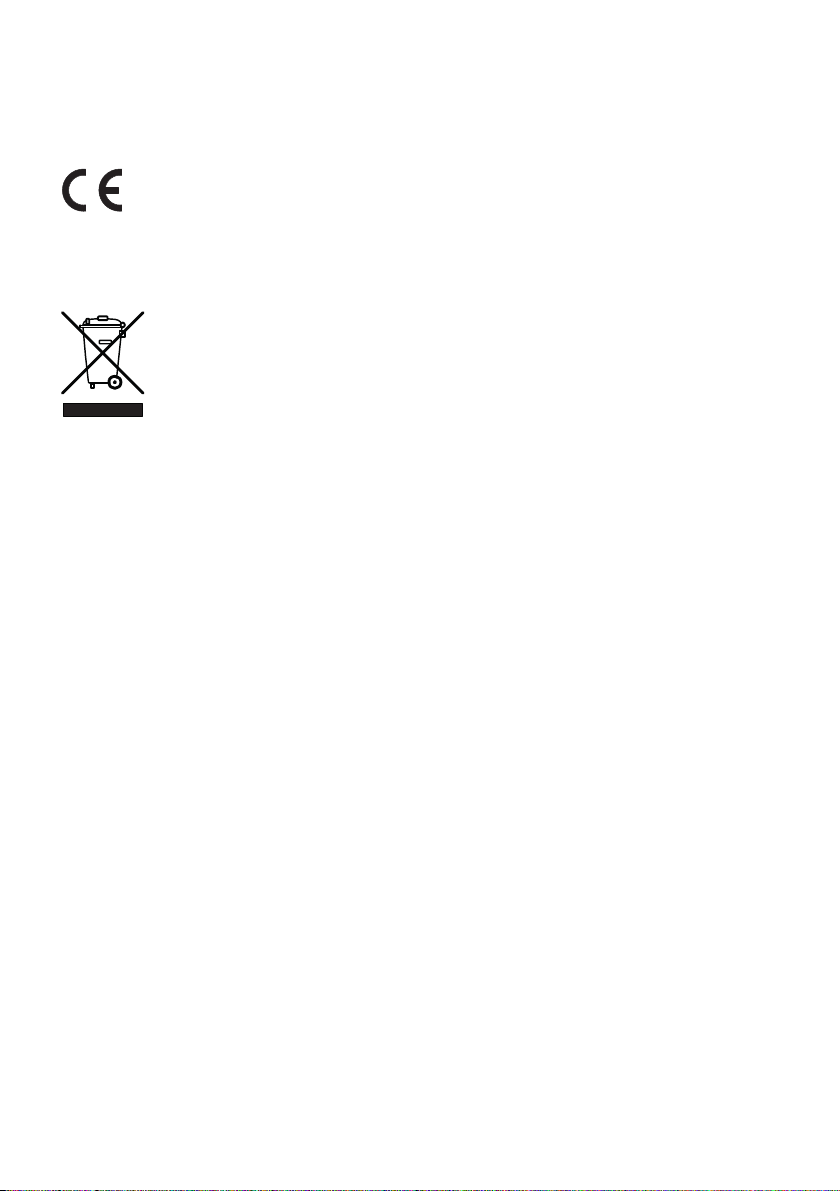

4.1 Mechanical construction of the AED9101D

1

1 Transducer connection

2 Interface setting (bus termination, type of interface)

3 RS‐485 bus termination

4 AD103C amplifier connection

5 Terminals for interface, supply voltage, trigger input and diagnostic bus

23

45

Fig. 4.1 Mechanical construction of the AED9101D

AED

MECHANICALCONSTRUCTION

12

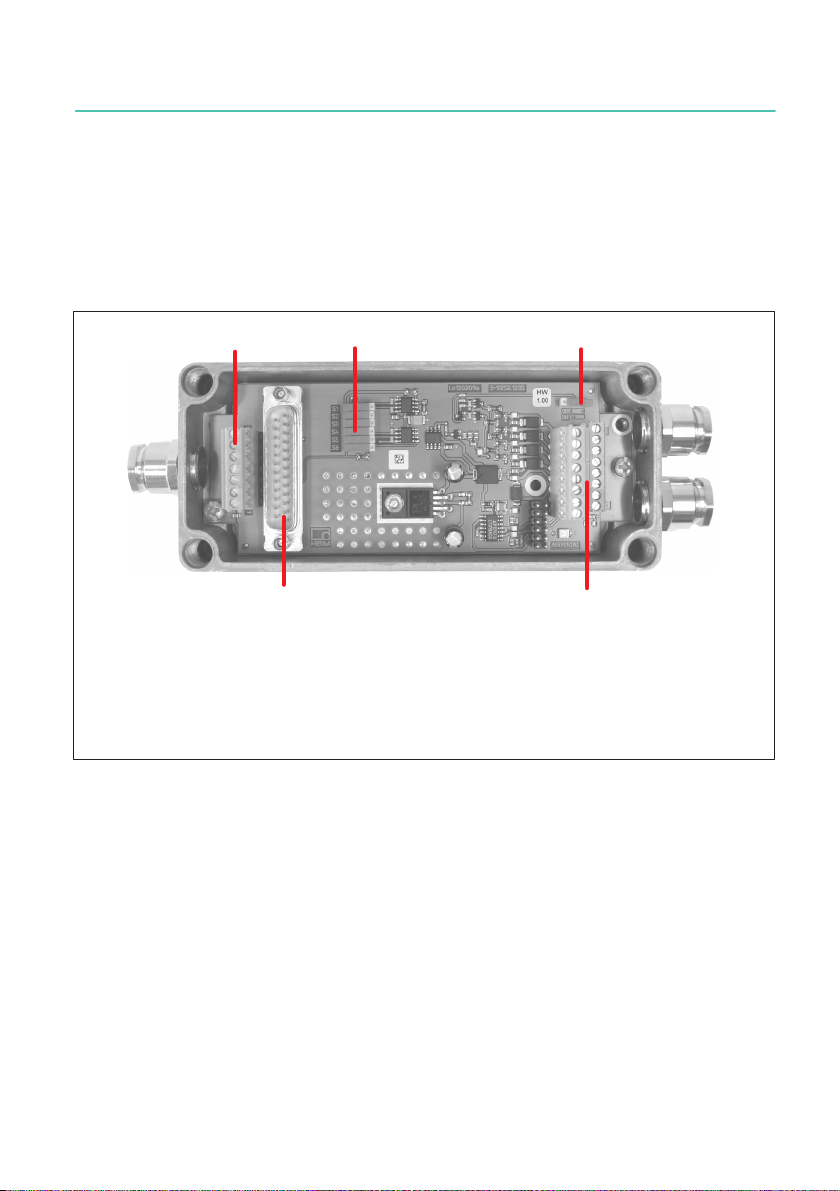

4.2 Mechanical construction of the AED9201B

12

45

3

1 Transducer connection

2 Interface setting (RS-232 or RS-485)

3 Power supply and interface connection (electrically isolated from AD103C)

4 AD103C amplifier connection

5 Digital I/O (electrically isolated from AD103C) and diagnostic bus

Fig. 4.2 Mechanical construction of the AED9201B

13

AED

MECHANICALCONSTRUCTION

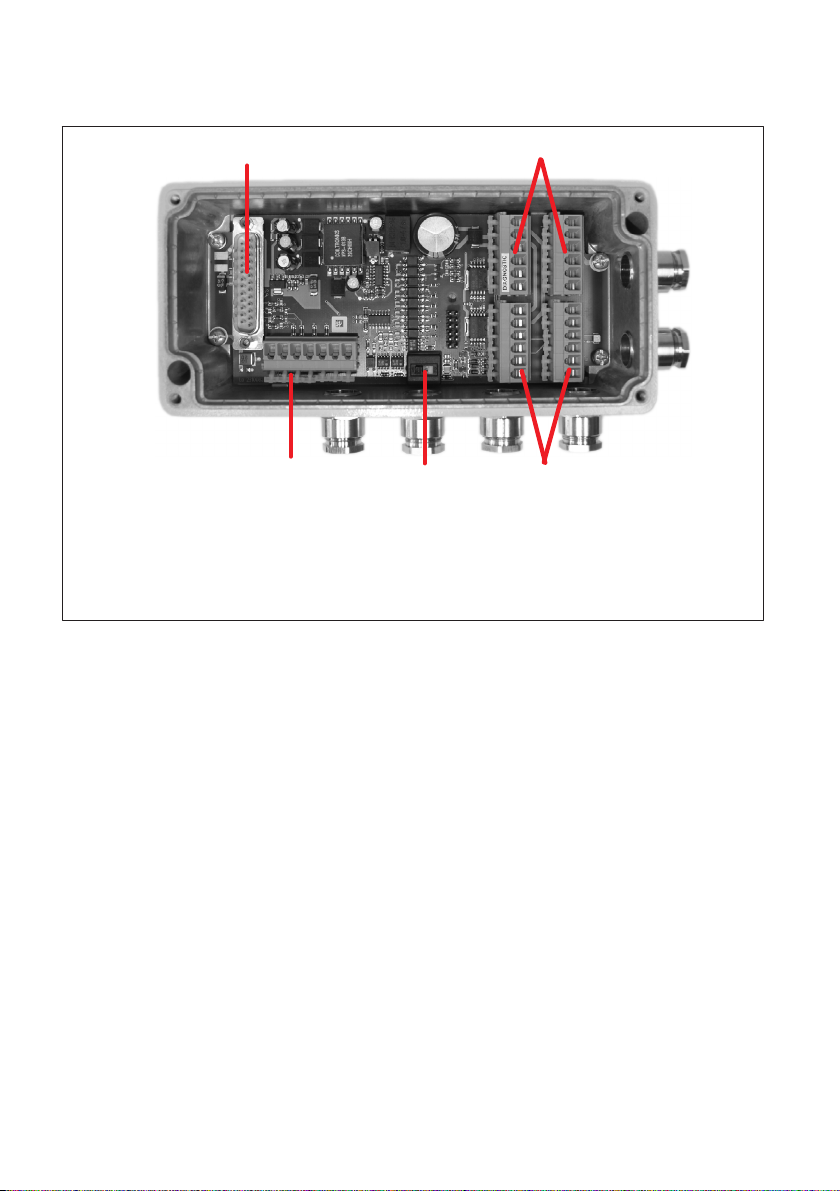

4.3 Mechanical construction of the AED9301B

1

LED4

3

2

LED3

LED2

LED1

456

1 AD103C amplifier connection

2 Power supply and digital I/Os (electrically isolated from AD103C and PROFIBUS)

3 Transducer connection

4 Address interface setting

5 PROFIBUS connection (electrically isolated)

6 Diagnostic bus

7 Bus termination (PROFIBUS) and PROFIBUS disconnection (for diagnosis)

7

Fig. 4.3 Mechanical construction of the AED9301B

LED Function Explanation

LED1

(green)

PROFIBUS power sup

ply

The LED lights up to indicate that there is a

supply voltage to the interface driver.

LED2

(green)

PROFIBUS

data exchange

Shows the status of the cyclical data exchange.

LED3

(yellow)

PROFIBUS diagnosis The LED lights up if there is an internal error.

The measurement data may be invalid.

LED4 (red) PROFIBUS error The LED lights up if there is an bus error.

Possible causes:

- Incorrect wiring (A and B transposed?)

- PROFIBUS master not (yet) working

AED

MECHANICALCONSTRUCTION

14

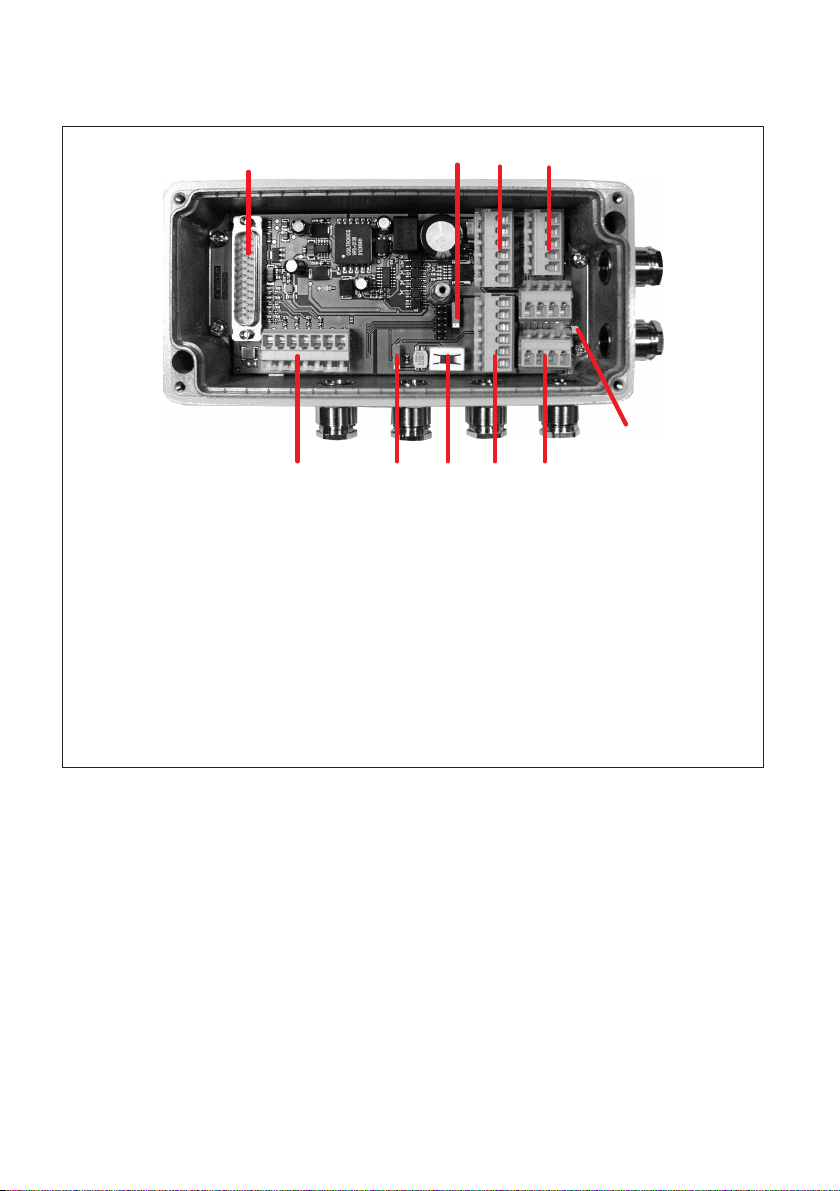

4.4 Mechanical construction of the AED9401A

3

1 AD103C amplifier connection

2 CAN bus or DeviceNet bus selection

3 Power supply and digital outputs (electrically isolated from AD103C)

4 Digital inputs (electrically isolated from AD103C)

5 Transducer connection

6 Bus termination

7 Disconnection of AED from the bus system

8 Diagnostic bus

9 CAN bus and DeviceNet (electrically isolated from AD103C)

10 LED power supply

124

56789

10

Fig. 4.4 Mechanical construction of the AED9401A

15

AED

MECHANICALCONSTRUCTION

4.5 Mechanical construction of the AED9501A

1 Transducer connection

2 Bus termination

3 CANopen and DeviceNet interfaces (electrically isolated from AD103C)

4 AD103C amplifier connection

5 CANopen or DeviceNet bus selection

6 Power supply and trigger input connections

1 2 3

456

Fig. 4.5 Mechanical construction of the AED9501A

AED

MECHANICALINSTALLATION

16

5 MECHANICAL INSTALLATION

Conditions at the installation site

SProtect the device from direct contact with water.

SProtect the device from moisture and weather such as rain or snow. The protection

class of the device is IP65 (DIN EN 60529).

SDo not expose the device to direct sunlight.

Mounting position

The device can be mounted in any position.

Installation

Mount the device with two bolts with an outside diameter of less than 4.4mm. Remove

the cover of the housing to reach the mounting holes.

Please also see section 6.2 starting on page 19, which explains correct connection via

one of the PG glands.

After cable installation, tighten the screws of the housing cover to a torque of approx.

1Nm to ensure the stated IP rating and the best possible EMC protection.

17

AED

ELECTRICAL CONNECTION

6 ELECTRICAL CONNECTION

Notice

Electroniccomponents are sensitive to electrostatic discharge (ESD). You must therefore

discharge your own static electricity before opening the device. We recommend wearing

an antistatic band (conductive wristband) and using a conductive base.

The required power supply is an extra-low voltage (max. 30 VDC ) with protective separa

tion from the mains.

6.1 Ground (GND) and shield wiring

Use shielded cables for the connecting cables to the transducers and interfaces. Connect

the shield fully to both sides of the housing of the devices or to metal connectors or met

alized connector housings, not to the measurement ground, GND or the power supply

0V. An example of cable shield, supply voltage and transducer wiring is shown in Fig. 6.1

on page 18. Adouble shielded cable is advantageous for improved EMC.

In this case, the cables for the supply voltage and digital I/Os only need to be shielded if

they are longer than 30m or are routed outside closed buildings (as per EN 61326 1).

For connection, please ensure that the cable wires do not project beyond the connection

terminals (risk of short circuit) and do not lie on the amplifier board (risk of interference

coupling). The correct connection of the cable shield to the PG gland is described in sec

tion 6.2 on page 19.

AED

ELECTRICAL CONNECTION

18

Interface(s)

Power

supply

Digital I/O

AED

24V 0 V

Power

supply

Optional

PC/master/

slave

Transducer

Optional

Fig. 6.1 Example of shield connection

Tip

A connection diagram is attached with adhesive inside the cover of the basic device.

Notice

For cables 30m long or more, there is a risk that individual bus nodes will have different

ground potentials. In this case, establish a potential equalization between the bus nodes

using a separate cable.

For potential equalization, the best choice is a flexible cable with a minimum conductor

cross-section of 10mm2.

Other manuals for AED 9101D

1

This manual suits for next models

4

Table of contents

Languages:

Other HBK Transducer manuals