CAUTION Damage to the product.

Note This information makes the product easier to use.

General safety instructions

• Use the product correctly. Injury or death is a

possible result of incorrect use. Only use the product

for the tasks found in this manual. Do not use the

product for other tasks.

• Obey the instructions in this manual. Obey the safety

symbols and the safety instructions. If the operator

does not obey the instructions and the symbols,

injury, damage or death is a possible result.

• Do not discard this manual. Use the instructions to

assemble, to operate and to keep your product in

good condition. Use the instructions for correct

installation of attachments and accessories. Only

use approved attachments and accessories.

• Do not use a damaged product. Obey the

maintenance schedule. Only do the maintenance

work that you find an instruction about in this

manual. An approved service center must do all

other maintenance work.

• This manual cannot include all situations that can

occur when you use the product. Be careful and use

your common sense. Do not operate the product or

do maintenance to the product if you are not sure

about of the situation. Speak to a product expert,

your dealer, service agent or approved service

center for information.

• Disconnect the spark plug cable before you

assemble the product, put the product into storage or

do maintenance.

• Do not use the product if it is changed from its initial

specification. Do not change a part of the product

without approval from the manufacturer. Only use

parts that are approved by the manufacturer. Injury

or death is a possible result of incorrect

maintenance.

• Do not breathe in the fumes from the engine. Long

term inhalation of the engine's exhaust fumes is a

health risk.

• Do not start the product indoors or near flammable

material. The exhaust fumes are hot and can contain

a spark which can start a fire. Not sufficient airflow

can cause injury or death because of asphyxiation or

carbon monoxide.

• When you use this product the engine makes an

electromagnetic field. The electromagnetic field can

cause damage to medical implants. Speak to your

physician and medical implant manufacturer before

you operate the product.

• Do not let a child operate the product. Do not let a

person, without knowledge of the instructions

operate the product.

• Make sure that you always monitor a person, with

decreased physical capacity or mental capacity, that

uses the product. A responsible adult must be there

at all times.

• Lock the product in an area that children and

unapproved persons cannot access.

• The product can eject objects and cause injuries.

Obey the safety instructions to decrease the risk of

injury or death.

• Do not go away from the product when the engine is

on.

• The operator of the product is responsible if an

accident occurs.

• Before and while you walk rearward, look behind and

down for small children, animals or other risks that

can cause you to fall.

• Make sure that parts are not damaged before you

use the product.

• Make sure that you are at a minimum 15 m (50 ft)

away from other persons or animals before you use

the product. Make sure that a person in adjacent

area knows that you will use the product.

• Refer to national or local laws. They can prevent or

decrease the operation of the product in some

conditions.

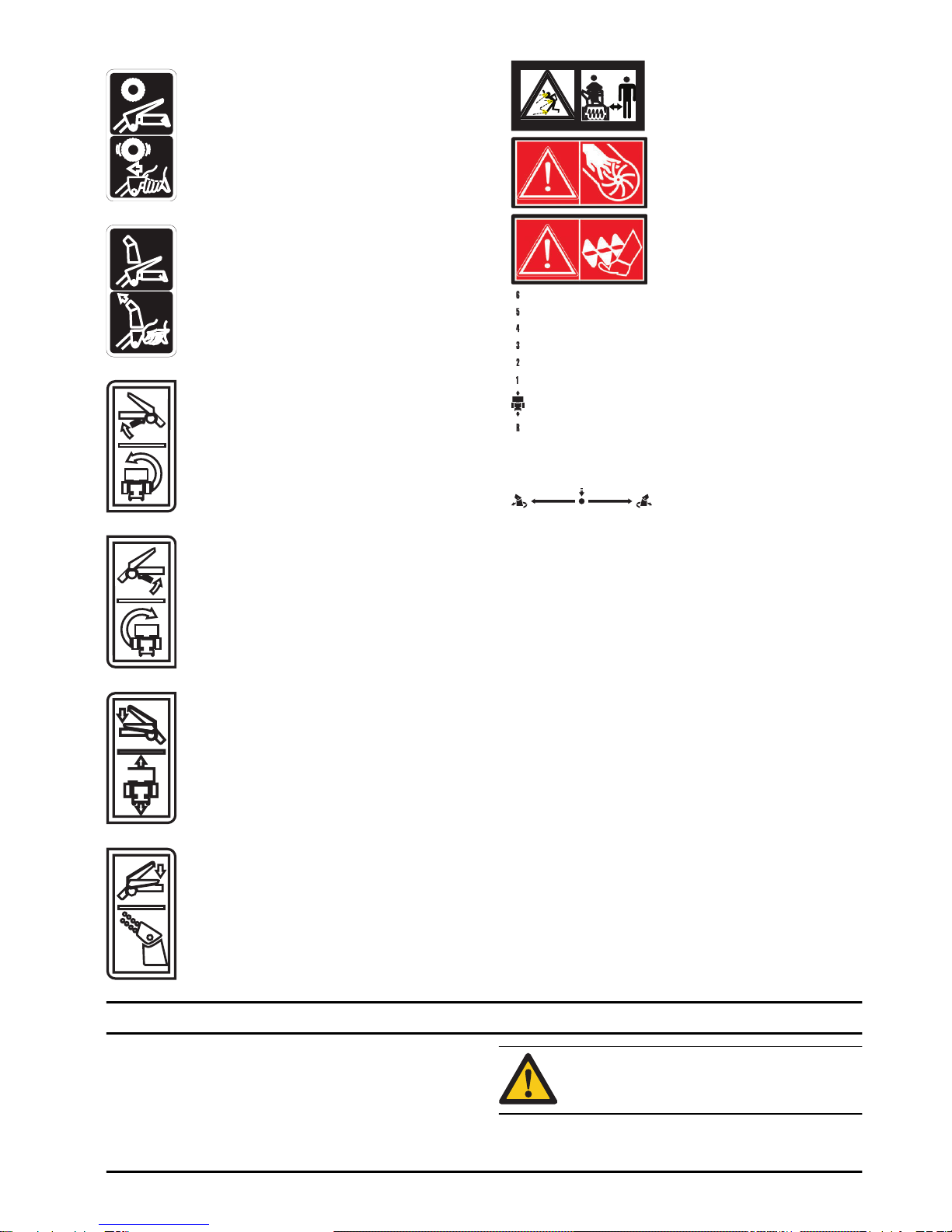

Safety instructions for operation

• Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

• Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traffic.

• After striking a foreign object, stop the engine

(motor), remove the wire from the spark plug,

disconnect the cord on electric motors, thoroughly

inspect the product for any damage, and repair the

damage before restarting and operating the product.

• If the product starts to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

• Stop the engine (motor) whenever you leave the

operating position, before unclogging the auger

housing or chute deflector, and when making any

repairs, adjustments or inspections.

• When cleaning, repairing or inspecting the product,

stop the engine and make certain the augers and all

moving parts have stopped. Disconnect the spark

plug wire and keep the wire away from the plug to

prevent someone from accidentally starting the

engine.

• Do not run the engine indoors, except when starting

the engine and for transporting the product in or out

of the building. Open the outside doors; exhaust

fumes are dangerous.

• Exercise extreme caution when operating on slopes.

• Never operate the product without proper guards,

and other safety protective devices in place and

working.

6797 - 001 -