2

Safe Operation Practices for Walk-Behind Snow Throwers

IMPORTANT: This snow thrower is capable of amputating hands and feet and throwing objects. Failure to observe the

following safety instructions could result in serious injury.

(d) Neverfillcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainers

ontheground,awayfromyourvehicle,before filling.

(e) When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment

on a trailer with a portable container, rather than

from a gasoline dispenser nozzle.

(f) Keep the nozzle in contact with the rim of the fuel

tankorcontaineropening atalltimes,until refueling

is complete. Do not use a nozzle lock-open device.

(g) Replace gasoline cap securely and wipe up spilled

fuel.

(h) If fuel is spilled on clothing, change clothing im-

mediately.

5. Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive motors

or electric starting motors.

6. Never attempt to make any adjustments while the

engine (motor) is running (except when specifically

recommended by manufacturer).

7. Always wear safety glasses or eye shields during op-

eration or while performing an adjustment or repair to

protect eyes from foreign objects that may be thrown

from the machine.

8. Letengineand machineadjusttooutdoor temperatures

before starting to clear snow.

Training

1. Read, understand and follow all instructions on the

machine and in the manual(s) before operating this

unit. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

2. Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

3. Keep the area of operation clear of all persons, par-

ticularly small children.

4. Exercise caution to avoid slipping or falling, especially

when operating the snow thrower in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is

to be used and remove all doormats, sleds, boards,

wires, and other foreign objects.

2. Ensure the control bar is released before starting the

engine.

3. Donotoperatetheequipmentwithoutwearingadequate

winter garments. Avoid loose fitting clothing that can

get caught in moving parts. Wear footwear that will

improve footing on slippery surfaces.

4. Handle fuel with care; it is highly flammable

(a) Use an approved fuel container.

(b) Never add fuel to a running engine or hot engine.

(c) Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors.

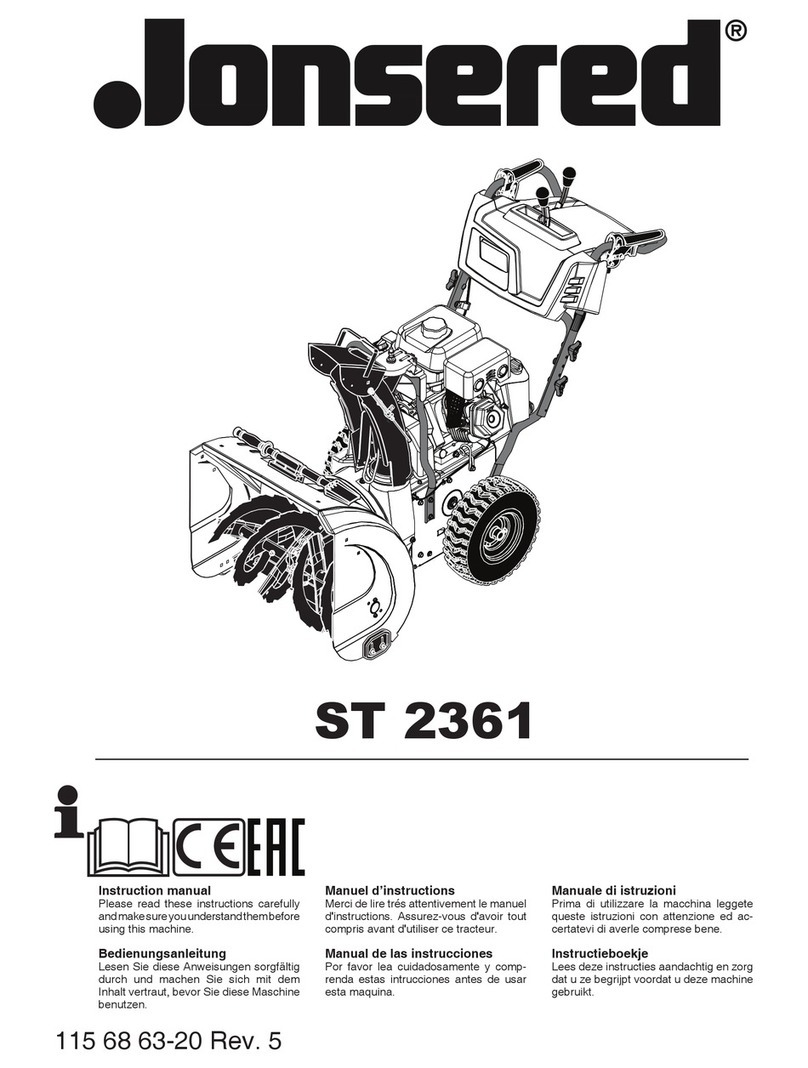

CONGRATULATIONS on your purchase of a new snow thrower. It has been designed, engineered and manufactured to

give best possible dependability and performance.

Should you experience any problem you cannot easily remedy, please contact your nearest authorized service center. We

have competent, well-trained technicians and the proper tools to service or repair this unit.

Please read and retain this manual. The instructions will enable you to assemble and maintain your snow thrower properly.

Always observe the “SAFETY RULES”.

Look for this symbol to point out important

safety precautions. It means CAUTION!!! BE-

COME ALERT!!! YOUR SAFETY IS INVOLVED.

WARNING: Always disconnect spark plug wire

and place it where it cannot contact plug in order

to prevent accidental starting when setting up,

transporting, adjusting or making repairs.

WARNING: This snow thrower is for use on

sidewalks,drivewaysandotherground level sur-

faces. Caution should be exercised while using

on sloping surfaces. Do not use snow thrower

on surfaces above ground level such as roofs

of residences, garages, porches or other such

structures or buildings.

WARNING: Engine exhaust, some of its constitu-

ents, and certain vehicle components contain or

emit chemicals known to the State of California

to cause cancer and birth defects or other repro-

ductive harm.

CAUTION: Muffler and other engine parts be-

come extremely hot during operation and remain

hot after engine has stopped. To avoid severe

burns on contact, stay away from these areas.

WARNING:Snow throwershaveexposedrotating

parts,whichcancausesevereinjury fromcontact,

orfrommaterialthrown fromthedischargechute.

Keep the area of operation clear of all persons,

small children and pets at all times including

startup.