Preface

Sensor-enabled fifth wheel couplings are parts that

must comply with very high safety requirements.

This repair manual is designed to act as a guide to

completing repair work on our sensor set.

The use of JOST spare parts is essential. Changes

or modifications of any kind invalidate any warranty

claims and will lead to the component type approval

being forfeited.

Operation and installation are described separately

in dedicated publications.

Explanation of symbols

WARNING!

Means that death, serious physical injury

or significant material damage can occur if

the relevant safety instructions are not fol-

lowed.

ATTENTION!

Means that slight physical injury or mater-

ial damage can occur if the relevant safety

instructions are not followed.

ADVICE!

Contains additional important information.

Contents

1 Safety instructions...................................... 3

2 Intended use................................................ 4

2.1 Use...................................................... 4

3 General......................................................... 5

4 Standard/special tools and auxiliary

materials....................................................... 6

4.1 Standard tools..................................... 6

4.2 Special tools........................................ 6

4.3 Auxiliary materials............................... 6

5 Sensor function test.................................... 7

6 Repair work.................................................. 8

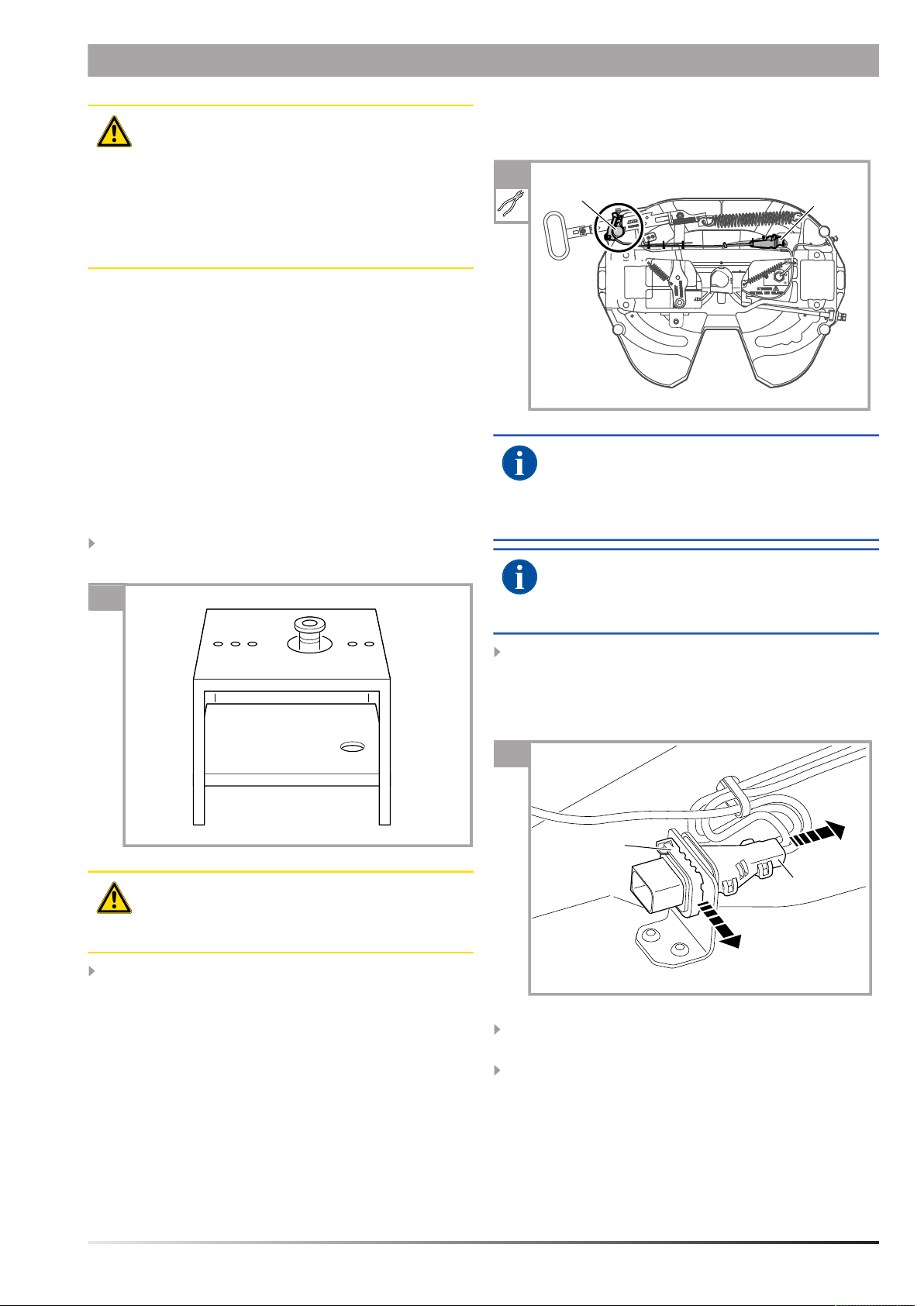

6.1 Preparing the fifth wheel coupling....... 8

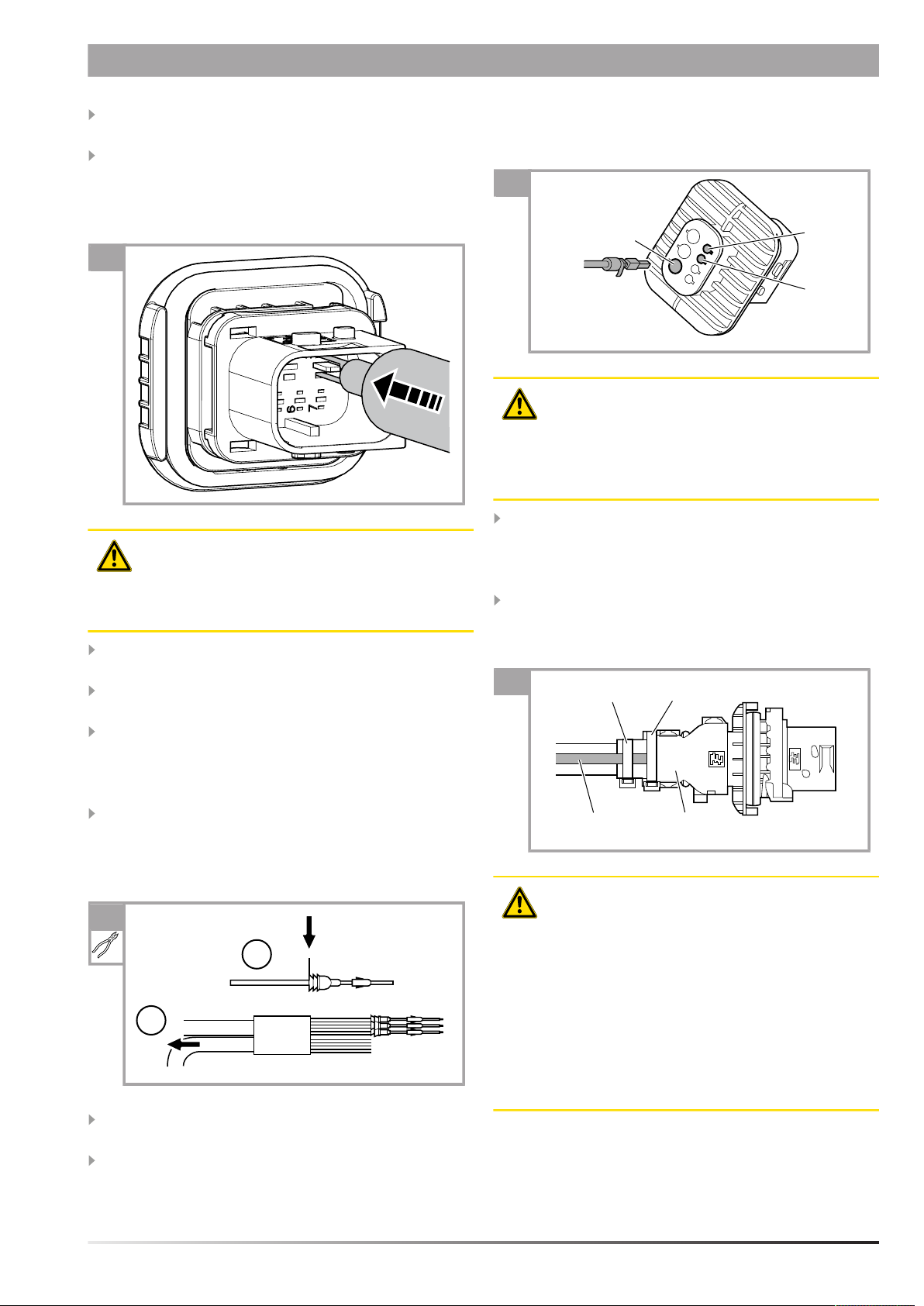

6.2 Removing cable fastenings and con-

nectors................................................. 8

6.3 Removing the locking sensor.............. 9

6.4 Removing contacts.............................. 9

6.5 Installation........................................... 10

6.5.1 Installing contacts................ 10

6.5.2 Installing the connector........ 11

7 Disposal instructions.................................. 12

REP 007 005 EN- (REV--) 11/2019 2