FAA APPROVED INSTALLATION MANUAL FOR THE EGT-701 Report 103

INSTALLING THE EGT-701 SCANNER® 1/20/09 Rev-E Page 3 of 30

1) INSTALLING THE INDICATOR Installation

Should Be Done In Accordance With Advisory Circular AC43.13-1A. All Models have the same basic

Part No. EGT-701 ( ).

EDM-700/800 Model :A steel template supplied with the installation kit is used as a guide for drilling two button holes

in the instrument panel. Align and Mount the Template into the instrument panel hole. First drilling a 0.125 hole.

Remove the template and check the instrument alignment, if OK redrill with a 0.147 drill. Buttons can be removed by

pulling off. The EGT-701 mounts in a standard 2.25” or 3 1/8” instrument hole. The instrument configures itself

automatically for 4 to 9 cylinders, 14/28 volt aircraft. The instrument is 7.5” deep less connectors and is 2.6 square

behind the panel.

TO PREVENT DISPLAY DAMAGE IT IS ESSENTIAL THAT THE FOUR MOUNTING SCREWS NOT PENETRATE

THE INSTRUMENT MORE THAN .12 INCHES.

DAMAGE OF THIS NATURE IS NOT COVERED UNDER WARRANTY.

EDM-730/830 Model: Mounts in a standard 3.1/8” instrument hole. First place the mounting bracket on the

instrument and tighten the clamp hex screw until you can just remove the instrument from the bracket. The Mounting

bracket is then placed behind the instrument panel hole and screwed (6-32 x ½” screws) in place using the existing

holes. Three screws should be used leaving one hole vacant on either side of the hex screw. Locate the hex screw in

a location that you can easily get to from the rear of the panel. The body of the instrument is 3.0 inches and 2.0 inches

deep less connectors. The body of the instrument is 3.0 inches and 2.0 inches deep less connectors.

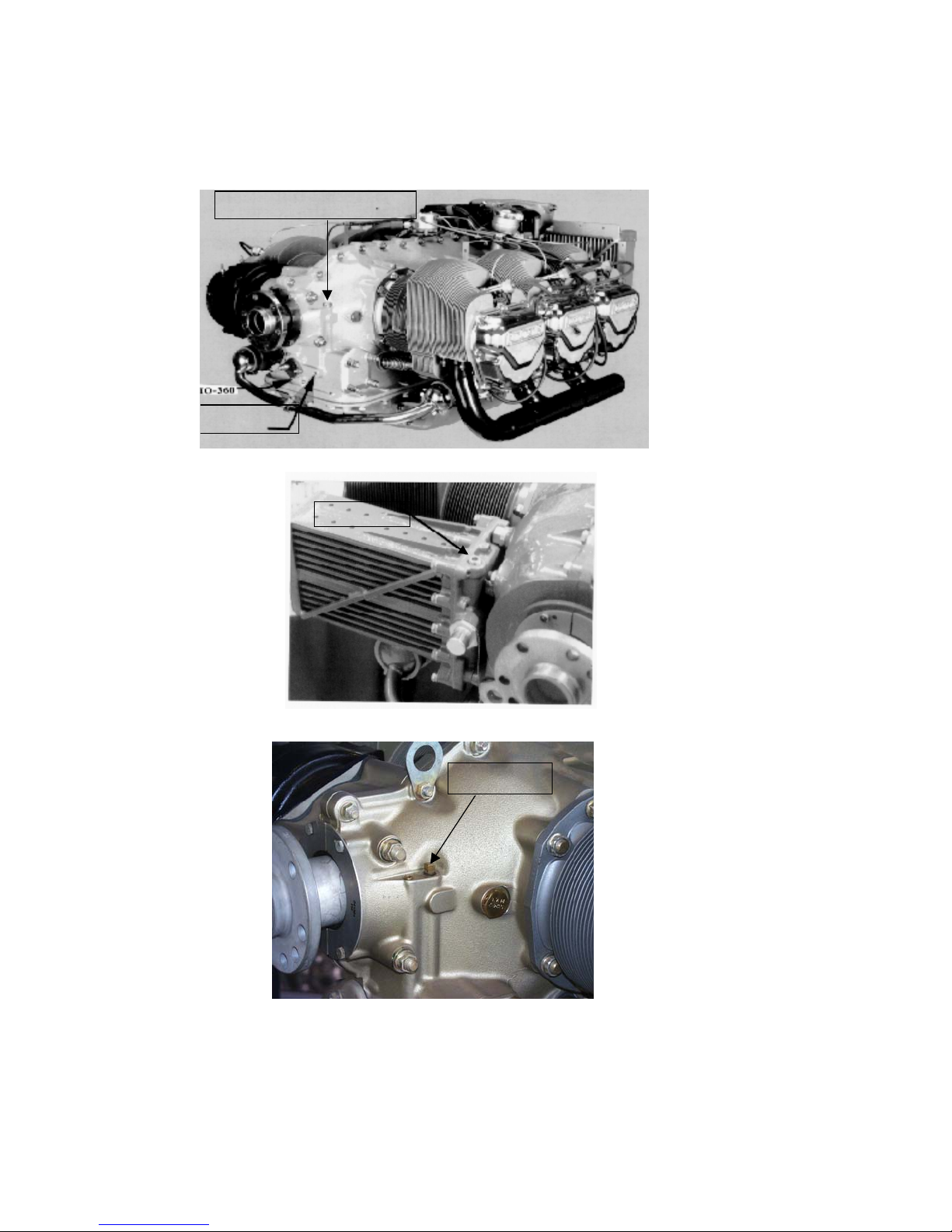

2) EXHAUST GAS TEMPERATURE PROBE (EGT)

The Model M-111 Probe will fit any existing holes in the exhaust stack in any engine having the diameter of 1/8" to

1/4". If no hole exists, it will require the drilling of a 1/8" diameter hole and ream to fit. It is important that each probe

be mounted a uniform distance from the exhaust stack flange. A nominal distance of 2 to 4 inches from the exhaust

flange is recommended. (See fig-2). If the recommended distance is impractical because of obstructions, slip joints or

bends in the exhaust system then position the probes a uniform distance from the flange as space permits. Be

certain to locate all holes BEFORE drilling to ensure that nothing interferes with the probe, clamp, clamp screw or wire.

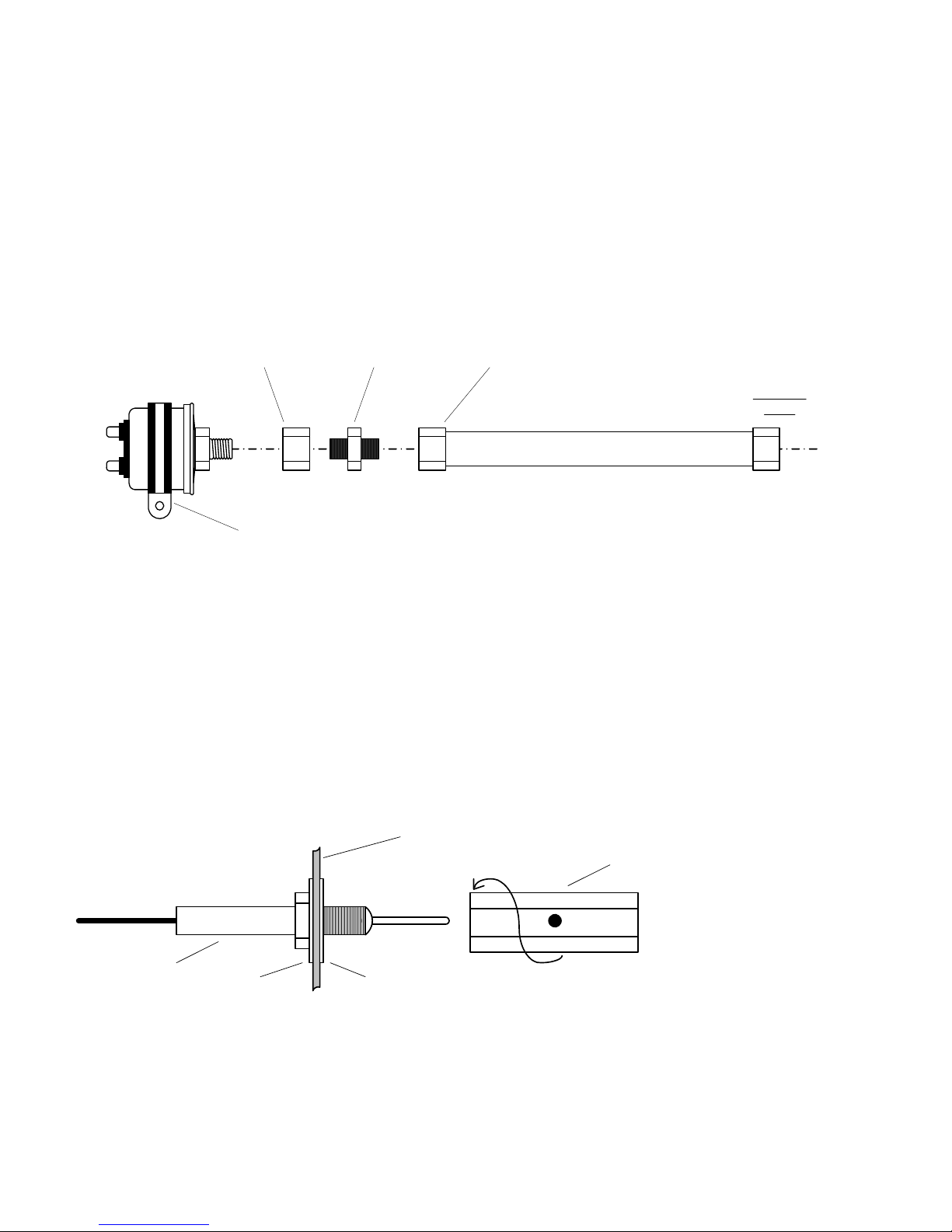

Careful matching of probe position will provide best temperature readings. Insert the probe in the exhaust or

previously drilled hole (see fig-3) so that the tip of the probe is in the center of the exhaust stream. Tighten the

stainless steel clamp to a torque of 45 in/Lbs. Cut off the excess strap close to the screw. Probe warranty is void if

mounted in a slip-joint of any kind.

RADIAL ENGINES , EGT

Radial engine exhaust, require a larger EGT clamp (supplied) to fit the 2.5 inch exhaust pipe. The EGT probe is

installed in the same fashion as a Lycoming or Continental engine and should be placed between the exhaust pipe

flange and the accumulator at a distance of 2 to 3 inches form the engine exhaust flange. Cylinder head temperatures

are measured with a spark plug gasket type probe placed under the front sparkplugs. Refer to the engine

manufactures red line and set the EDM-700 appropriately. Front spark plugs will read 15 to 20 degrees cooler than

the rear plugs. Do not route the EGT/CHT harness in with the ignition harness. Do not extend the yellow

thermocouple leads with copper wire.

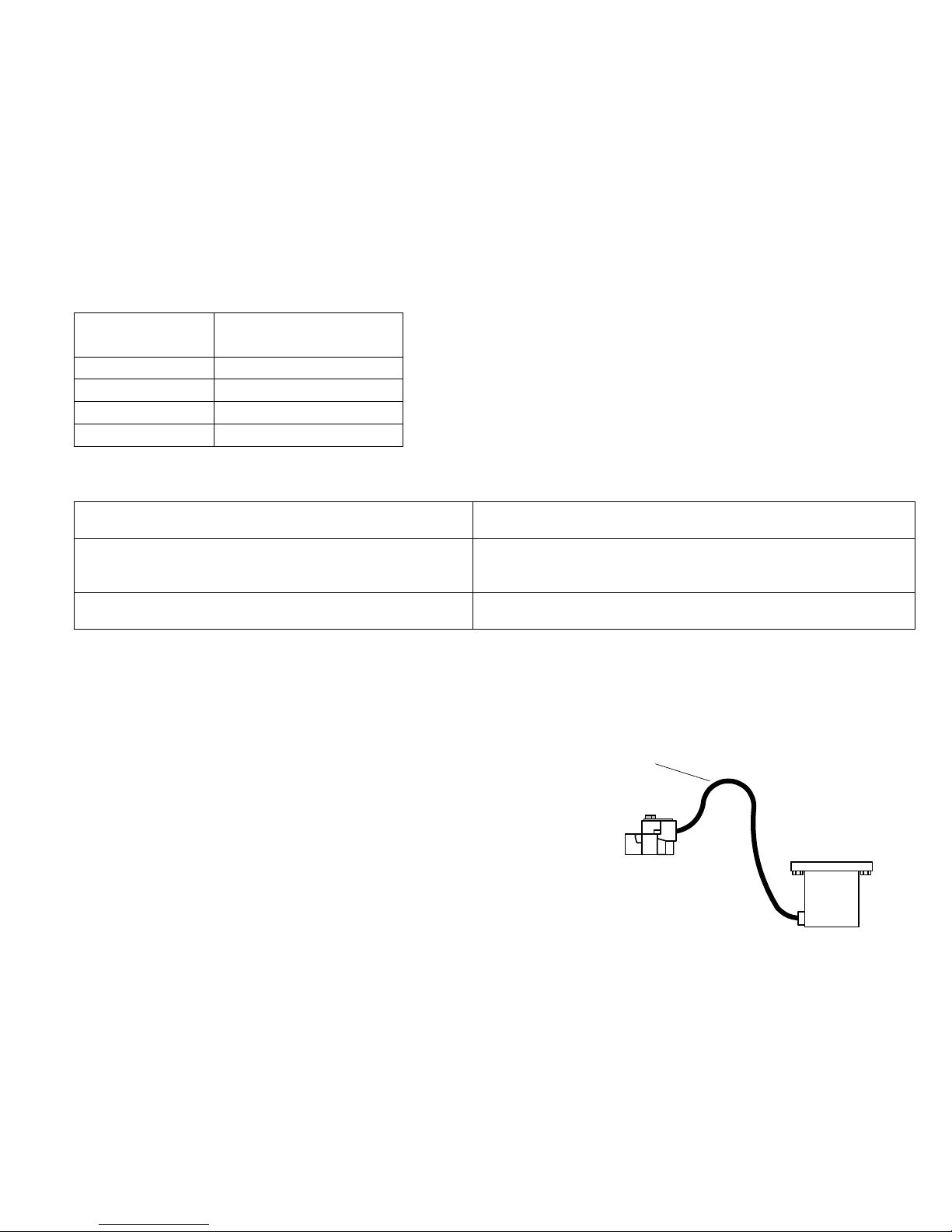

3) TURBINE INLET TEMPERATURE PROBE (TIT)

The standard TIT probe P/N M-111-T with a special clamp is placed in the exhaust stack accumulator to a maximum

depth of 1/2 inch and approximately four (4) inches from the Turbine inlet if possible, on the wastgate side of the

turbine. TIT will appear as the seventh column “T “and the expression “1650 TIT” will be seen when the dot is in place

over it. The EDM-700 input is also compatible with the aircraft’s factory TIT and may be piggy backed.

The EDM-700 TIT cable may be connected in parallel (piggyback) at the TIT probe (preferred), or at the ship's TIT

gage. Check the TIT readings between the EDM and the ships TIT gage in flight, then do the following calibration

procedure. (This may be done in flight or on the ground.)