MODEL 753 Operator’s Manual

20195 South Diamond Lake Road, STE 100

Rogers, MN 55374

2

Table of Contents

1 Introduction................................................................................................................................................4

1.1 ....Application............................................................................................................................................................4

1.2 ....Navigating This Manual .................................................................................................................................4

1.3....Operation References/Terminology..........................................................................................................4

1.4 ....Owner Assistance ...............................................................................................................................................5

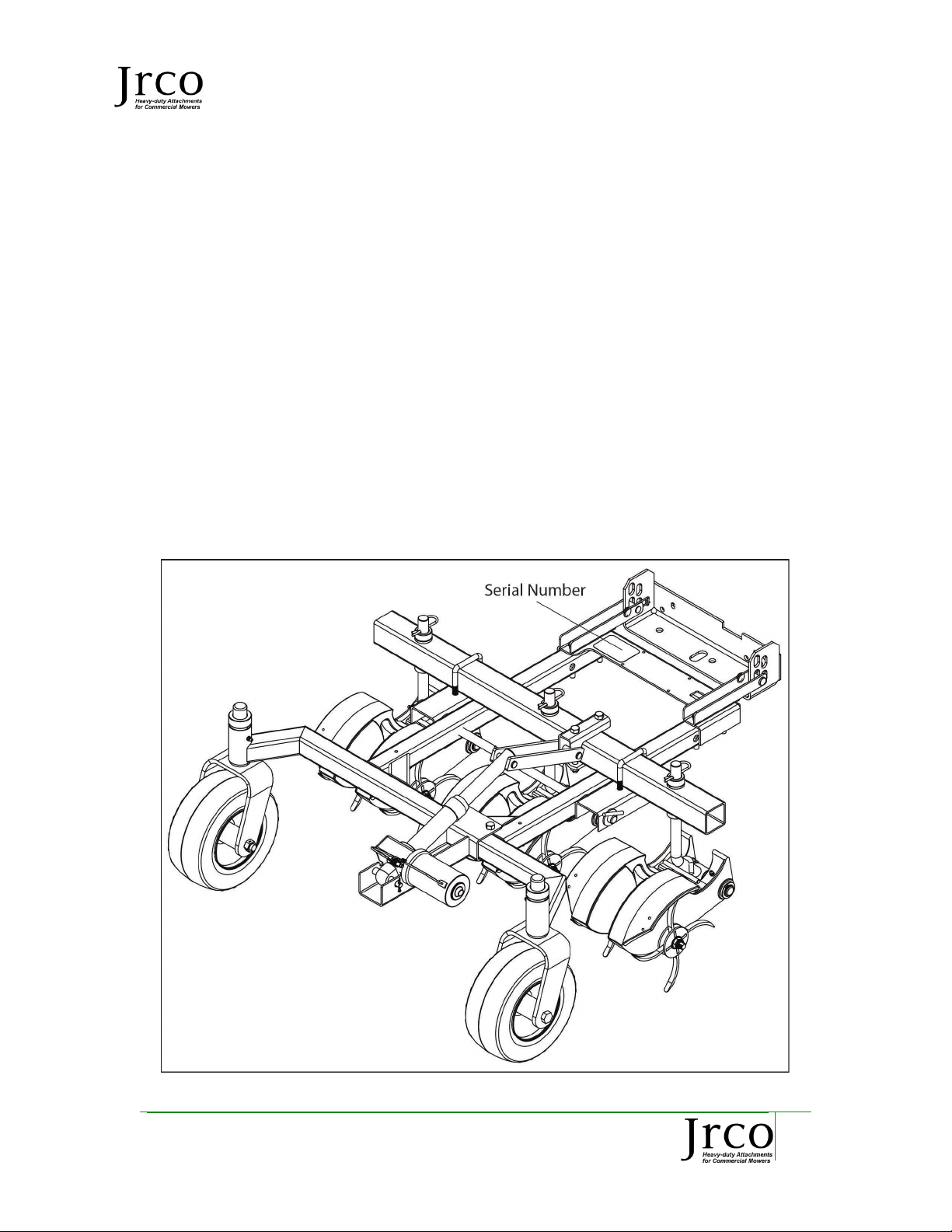

1.5 ....Model Identification .........................................................................................................................................5

1.6 ....Further Assistance.............................................................................................................................................6

2 Assembly and Set-up ...............................................................................................................................7

2.1 ....Frame Assembly Parts .....................................................................................................................................7

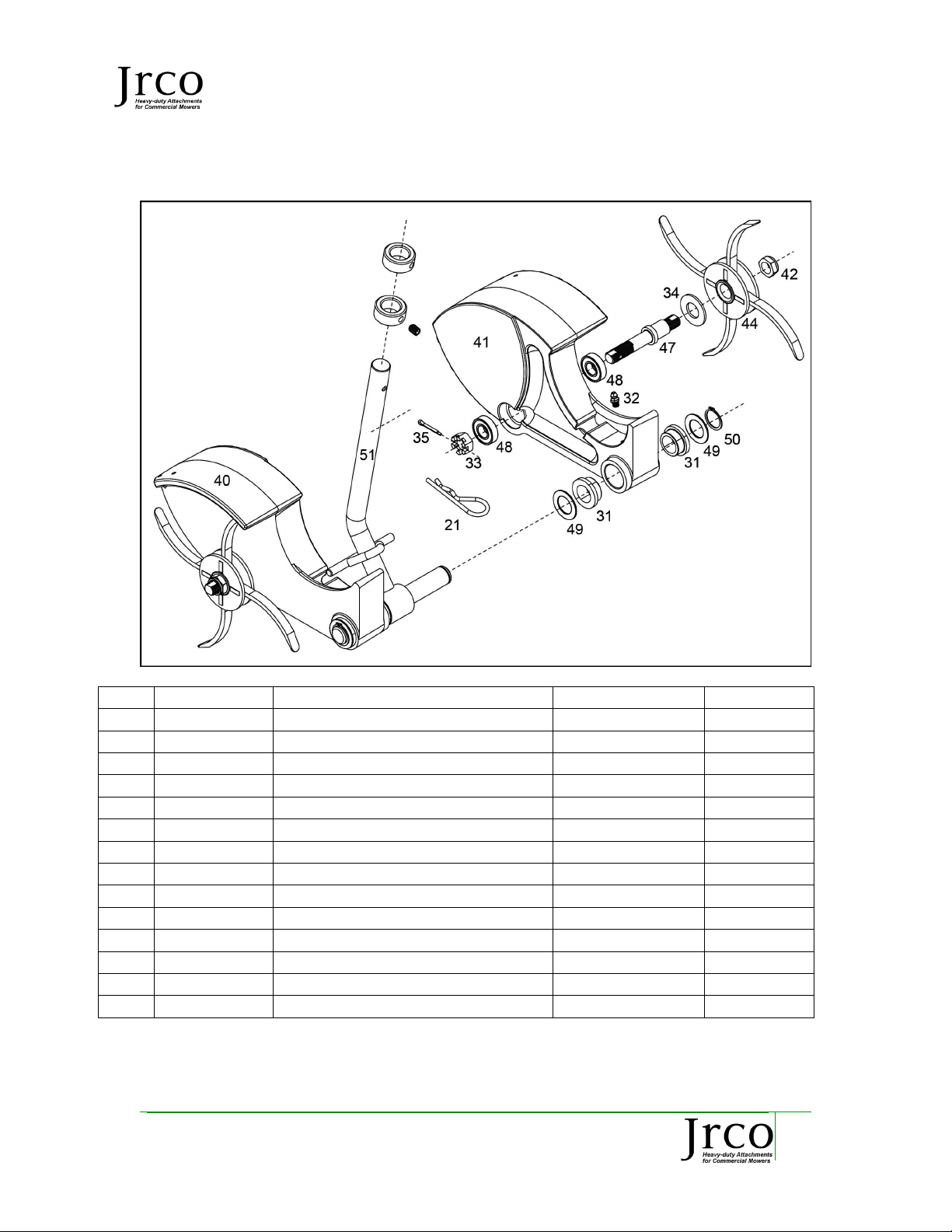

2.2 ....Caster Head Assembly Parts .........................................................................................................................9

2.3 ....Tools Required..................................................................................................................................................10

2.4 ....Power Unit Requirements...........................................................................................................................10

2.5 ....Unpacking Your Attachment.....................................................................................................................10

2.6 ....Torque Requirements ...................................................................................................................................10

2.7 ....General Assembly............................................................................................................................................10

2.8 ....Stabilizer Frame to Tow Tongues Assembly ......................................................................................11

2.9 ....Pivot Arms to Actuator Mount to Extension Harness Assembly................................................11

2.10..Wheels to Yokes Assembly ..........................................................................................................................11

2.11..Caster Bar to Top Pivot Assembly ...........................................................................................................12

2.12..Connecting Actuator .....................................................................................................................................12

2.13..Aerator Heads Assembly..............................................................................................................................12

2.14..Mount Hitch to Tow Vehicle.......................................................................................................................13

2.15..Connecting Power Wire to Vehicle Battery ........................................................................................13

2.16..Aerator to Hitch...............................................................................................................................................13

2.17..Battery Harness to Switch ..........................................................................................................................13

3 Operation Instructions ........................................................................................................................ 14

3.1 ....Before Operation.............................................................................................................................................14

3.2 ....Operator Safety................................................................................................................................................14

3.3 ....Operation............................................................................................................................................................15