SHANGHAI JUHUI INSTRUMENT MANUFACTURING CO.,LTD

Catalogue

1 Overview............................................................................................................................................. 3

1.1 Product features................................................................................................................. 3

1.2 Main purpose and scope of application.................................................................................. 4

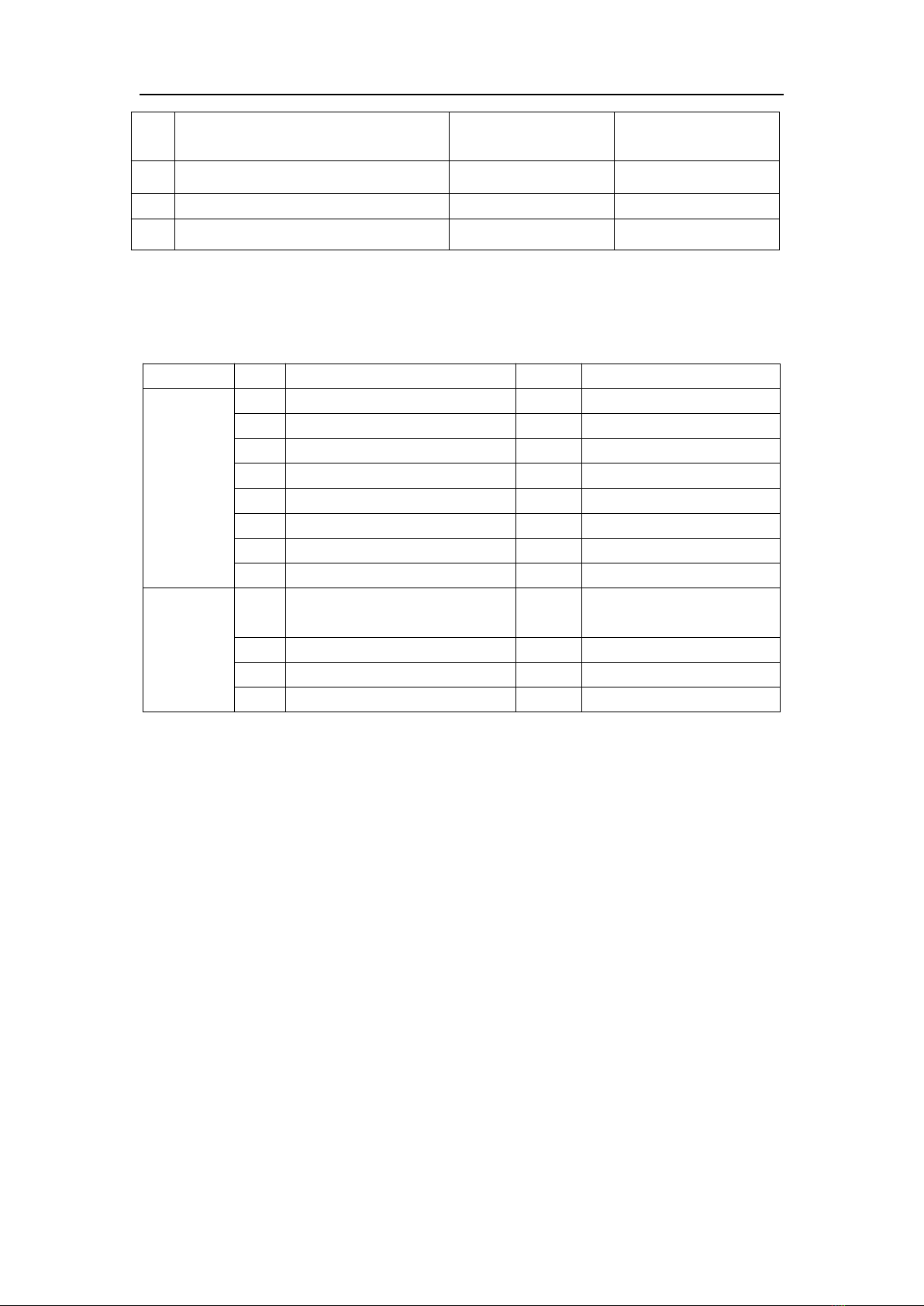

1.3 Specifications......................................................................................................................6

1.4 Working condition.............................................................................................................11

2. Structure characteristics and working principle...................................................................................... 11

2.1 Structure features.................................................................................................................... 11

2.2 Working principle.....................................................................................................................13

3 Technical characteristics.......................................................................................................................14

3.1 Technical parameters................................................................................................................ 14

3.2 Size Weight............................................................................................................................. 15

4 Using.................................................................................................................................................15

4.1 Prepare and check before use.................................................................................................... 15

4.2 Measurement..........................................................................................................................16

5 Special tips.........................................................................................................................................19

6 Detailed operation.............................................................................................................................. 19

6.1Start........................................................................................................................................19

6.2 Shutdown............................................................................................................................... 20

6.3 Measurement..........................................................................................................................20

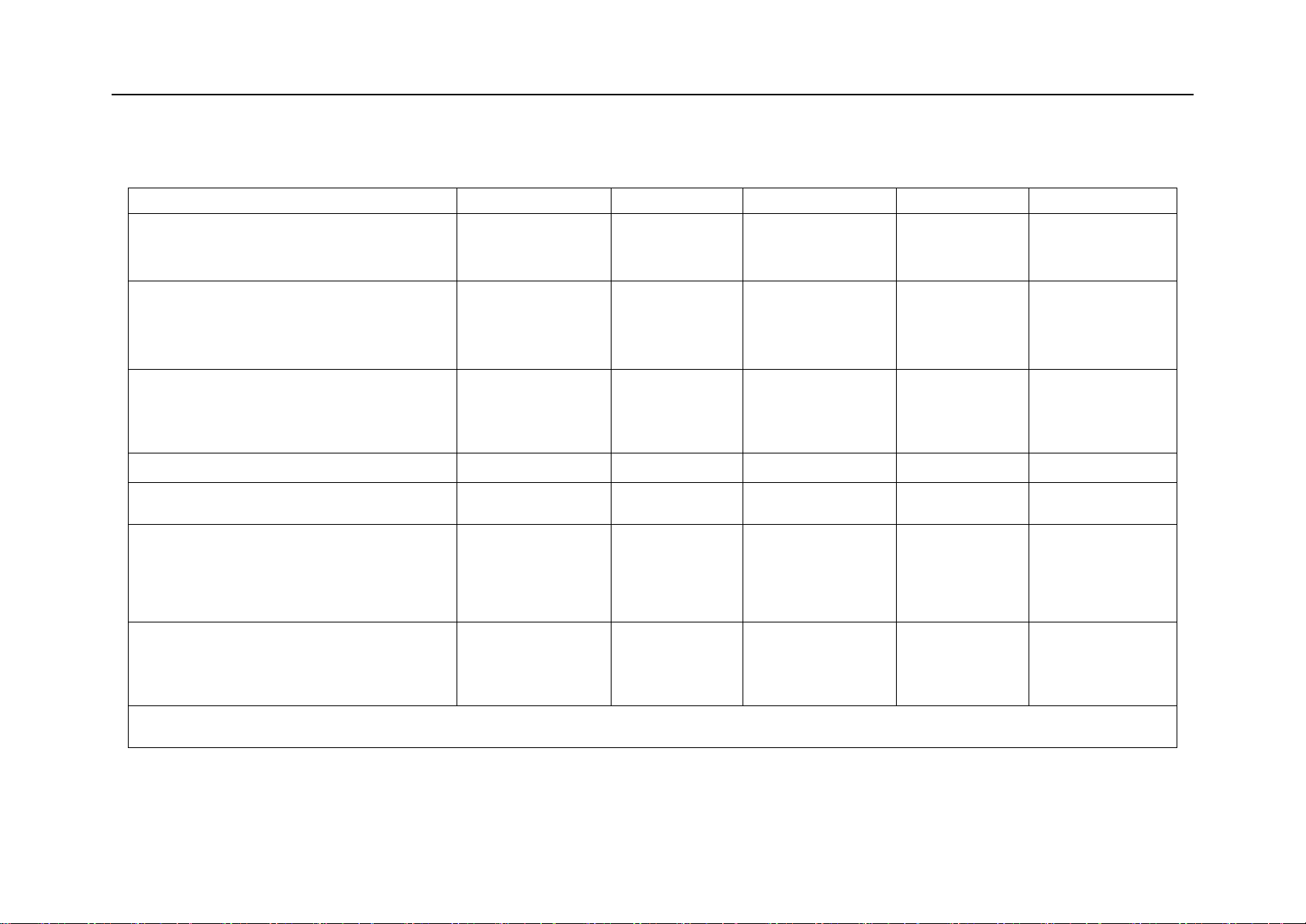

6.4 Menu structure........................................................................................................................22

6.5 Measurement condition............................................................................................................23

6.6 Print Function..........................................................................................................................26

6.7. Storage Manager.....................................................................................................................28

6.8 Browse interface...................................................................................................................... 30

6.9 System Settings........................................................................................................................31

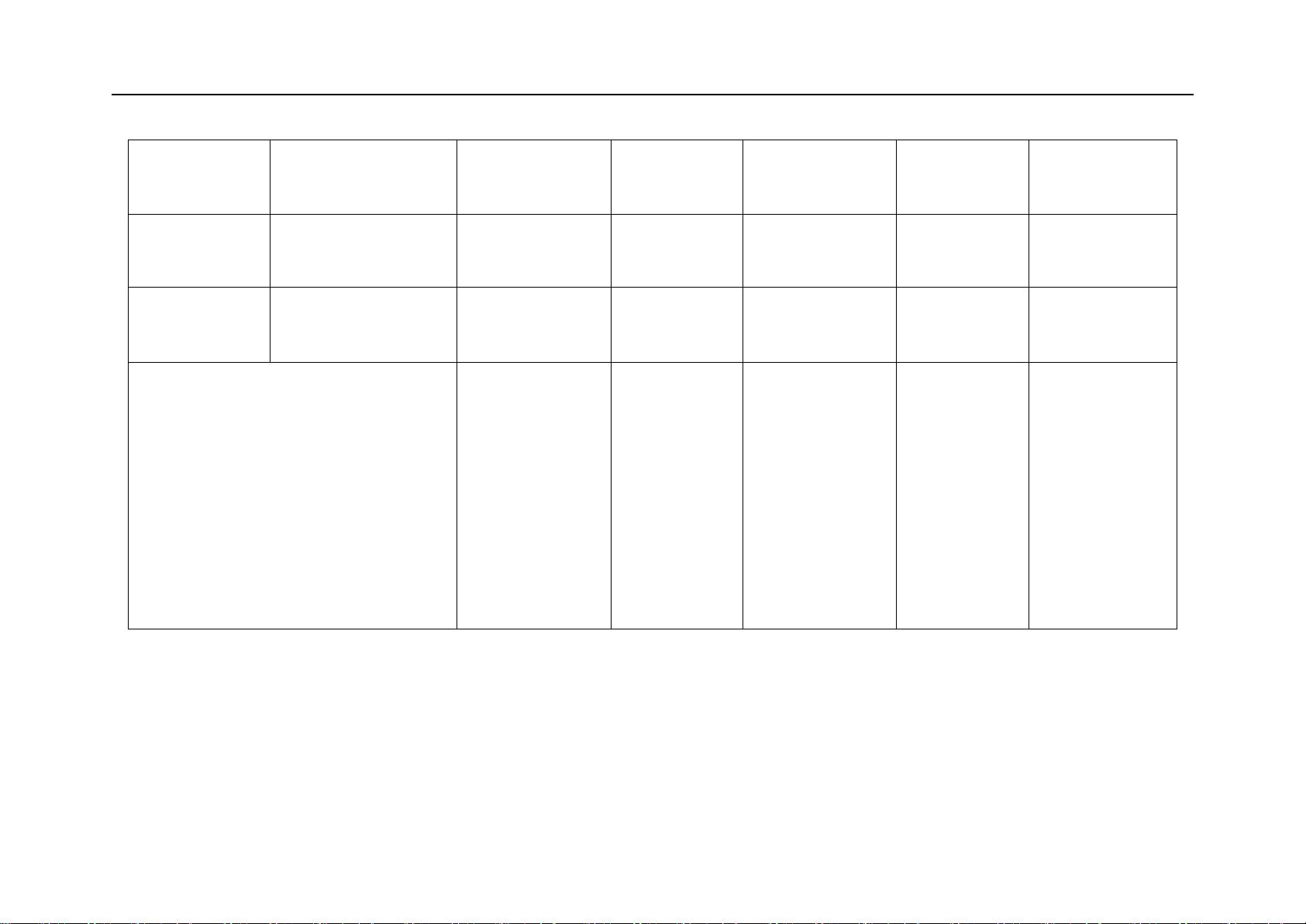

6.10 Software Information..............................................................................................................32

6.11 Software calibration................................................................................................................33

6.12 Backlight............................................................................................................................... 33

6.13 Auto power-off...................................................................................................................... 34

6.14 Battery replacement............................................................................................................... 34

7 Fault analysis and elimination...............................................................................................................34

8. Maintenance..................................................................................................................................... 34

8.1 Impact device.......................................................................................................................... 34

8.2 Normal maintenance program................................................................................................... 35

8.3 Non warranty device.................................................................................................................35

9 Verification cycle.................................................................................................................................35

10 User instructions...............................................................................................................................35

11 Storage condition, transportation and notice........................................................................................ 36