i

CONTENTS

1. SAFETY PRECAUTIONS........................................................................................................ 1

1-1. Precautions to be taken when installing or adjusting the laser...............................................3

1-2. Precautions to be taken when using the laser...........................................................................4

2. MAINTENANCE ...................................................................................................................... 5

2-1. Care for the lens ...........................................................................................................................6

3. ELECTRICAL SAFETY ........................................................................................................... 9

3-1. Circuit diagrams ...........................................................................................................................9

4. INSTALLATION ..................................................................................................................... 10

4-1. Installing the laser power supply ..............................................................................................10

5. OPERATION.......................................................................................................................... 18

5-1. Tune ON the power .....................................................................................................................18

5-2. Starting the air supply................................................................................................................18

5-3. Temporary measures..................................................................................................................19

5-4. Use of the cooling system .........................................................................................................20

5-5. Adjusting the laser......................................................................................................................21

5-6. Using the laser ............................................................................................................................25

5-7. Adjusting the air volume of the fan...........................................................................................26

5-8. Editing / setting the patterns, setting the layer, and setting the speed.................................27

6. PRECAUTIONS TO BE TAKEN WHEN USING THE EQUIPMENT IN WINTER OR AT A

COLD REGION .................................................................................................................. 33

7. IDENTIFICATION AND HANDLING OF FAILURES IN GENERAL...................................... 34

7-1. High-tension ignition and electric discharge...........................................................................34

7-2. Breakage / rupture of the laser tube .........................................................................................34

7-3.

Cause of occurrence of high-pressure discharge and breakdown phenomenon ...................... 35

7-4. Attenuation of output .................................................................................................................36

7-5. Power fault inspection while the laser is in use ......................................................................36

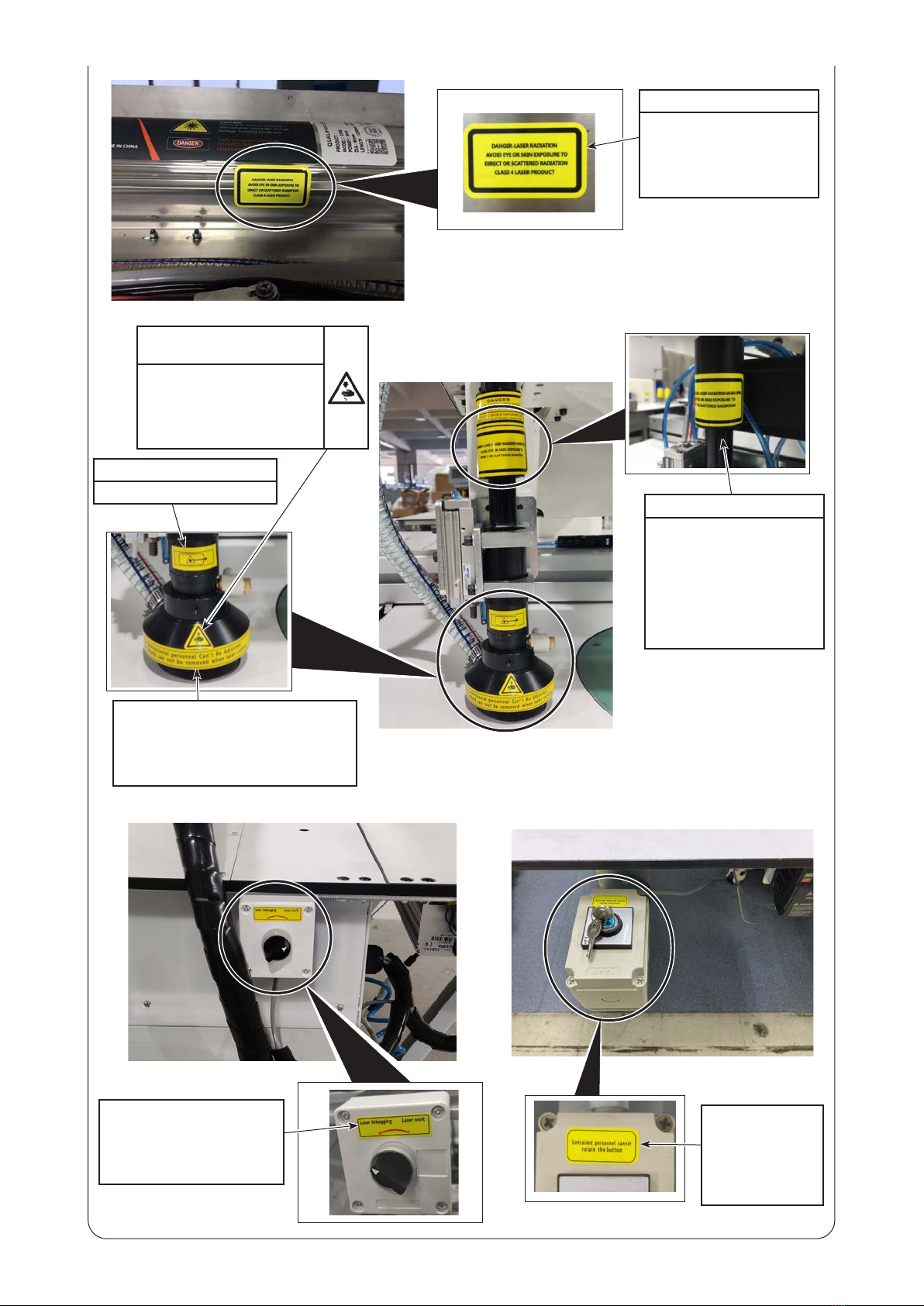

If any control device or program other than those specified in this Instruction Manual is

used, or if the adjustment method and usage specified in this Instruction Manual are not

followed, the maintenance person or user of this product can be exposed to hazardous

irradiation from the laser. If the human body or cornea is exposed to direct laser-irradia-

tion, health hazard such as burn of cornea, burn of retina, conjunctivitis, visual loss, burn

of skin, etc. and the fire can be caused.