10

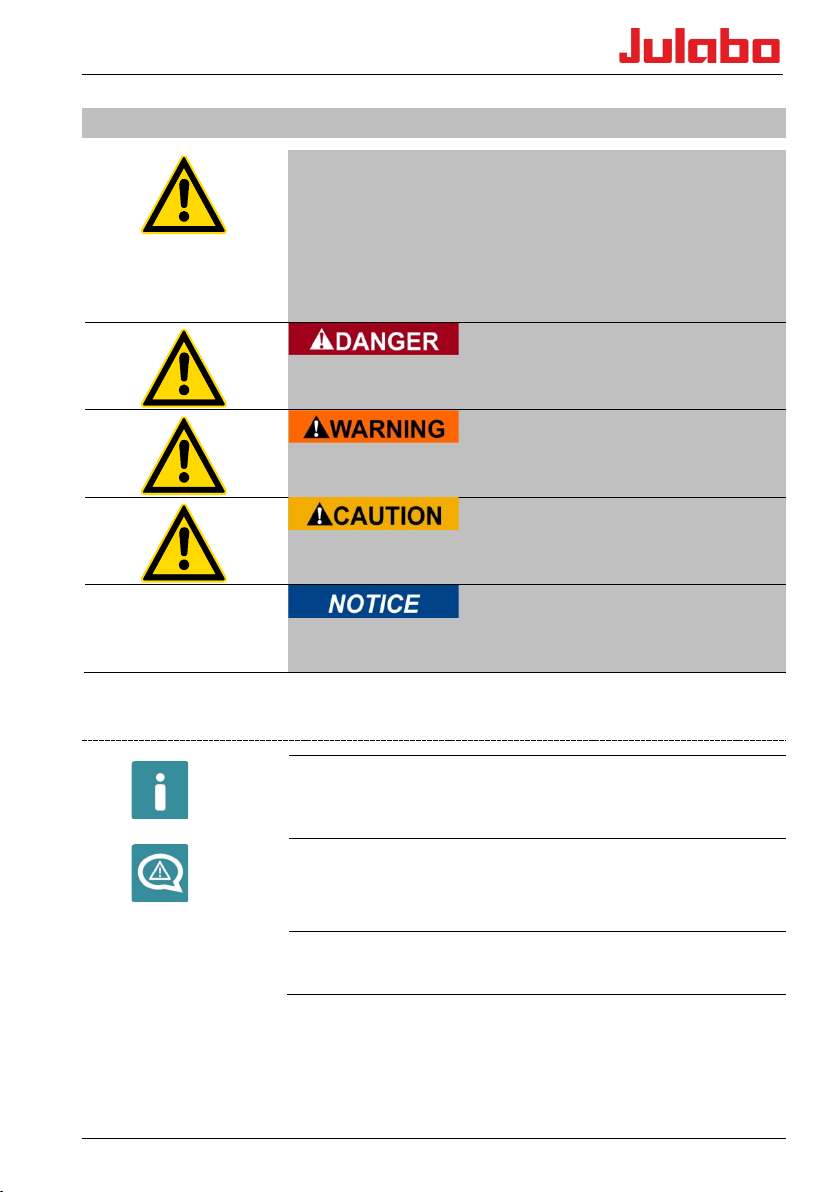

6Operator's responsibility - safety instructions

Products manufactured by JULABO GmbH ensure safe operation when

installed, operated and according to common safety regulations. This

section explains the potential dangers which may occur when operating

the unit and specifies the most important safety measures to prevent

these dangers as far as possible.

6.1 Requirements for the operating personnel

The operator is responsible for the qualifications of the personnel

operating the unit. Ensure that the personnel who operate the unit are

trained in the relevant work application by a trained person.

The operative must receive regular training about the dangers involved

with their work and about action to prevent such dangers.

Ensure that everybody involved with the operation, maintenance and

installation have read and understood the safety information and the

operating manual. The unit may only be configured, installed,

maintained and repaired by trained personnel.

If hazardous substances or substances which may become hazardous are

used, the unit may only be used by a person who is completely familiar

with these substances and the unit. This person must be able to assess

the possible dangers in full.

6.2 Operating and ambient conditions for using the unit

•Avoid impacts on the housing, vibrations, damage to the operative

keypad (keys and display) and heavy soiling.

•Ensure that the product is checked at regular intervals suitable for its

frequency of use to ensure that it is in perfect condition.

•Check the proper condition of the mandatory warning, prohibition,

and safety labels at least every 2 years.

•Ensure that the mains supply has a low impedance to prevent

influencing of other units powered in the same mains.

•The unit is designed for operation in a controlled electromagnetic

environment. This means that in an environment of this nature,

transmission equipment such as mobile phones should not be used

in the immediate vicinity.

•Other units with components which are susceptible to magnetic

fields may be influenced by magnetic radiation. We recommend to

maintain a minimum distance of 1 m.

•Permissible ambient temperature: max. 40 °C, min. 5 °C.

•The relative humidity should not exceed 50% (40°C).

•Do not store in an aggressive atmosphere. Protect from dirt.

•Protect from direct sunlight.