Important Safety Precautions

INSTRUCTIONS

1. DISASSEMBLY

1.1 BEFORE ASSEMBLY AND DISASSEMBLY ......................... 1-1

1.1.1 Precautions ..................................................................... 1-1

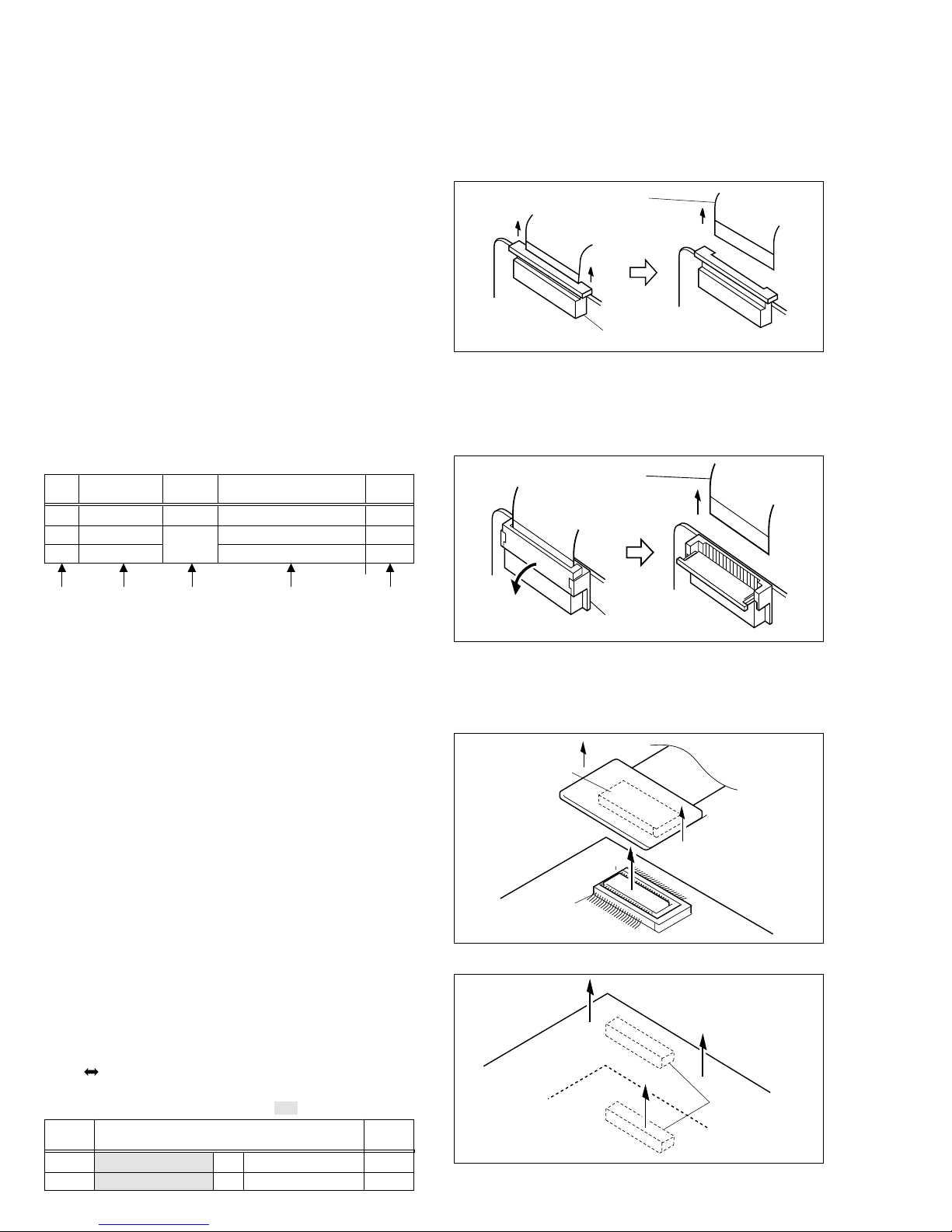

1.1.2 Assembly and disassembly ............................................ 1-1

1.1.3 Destination of connectors ............................................... 1-1

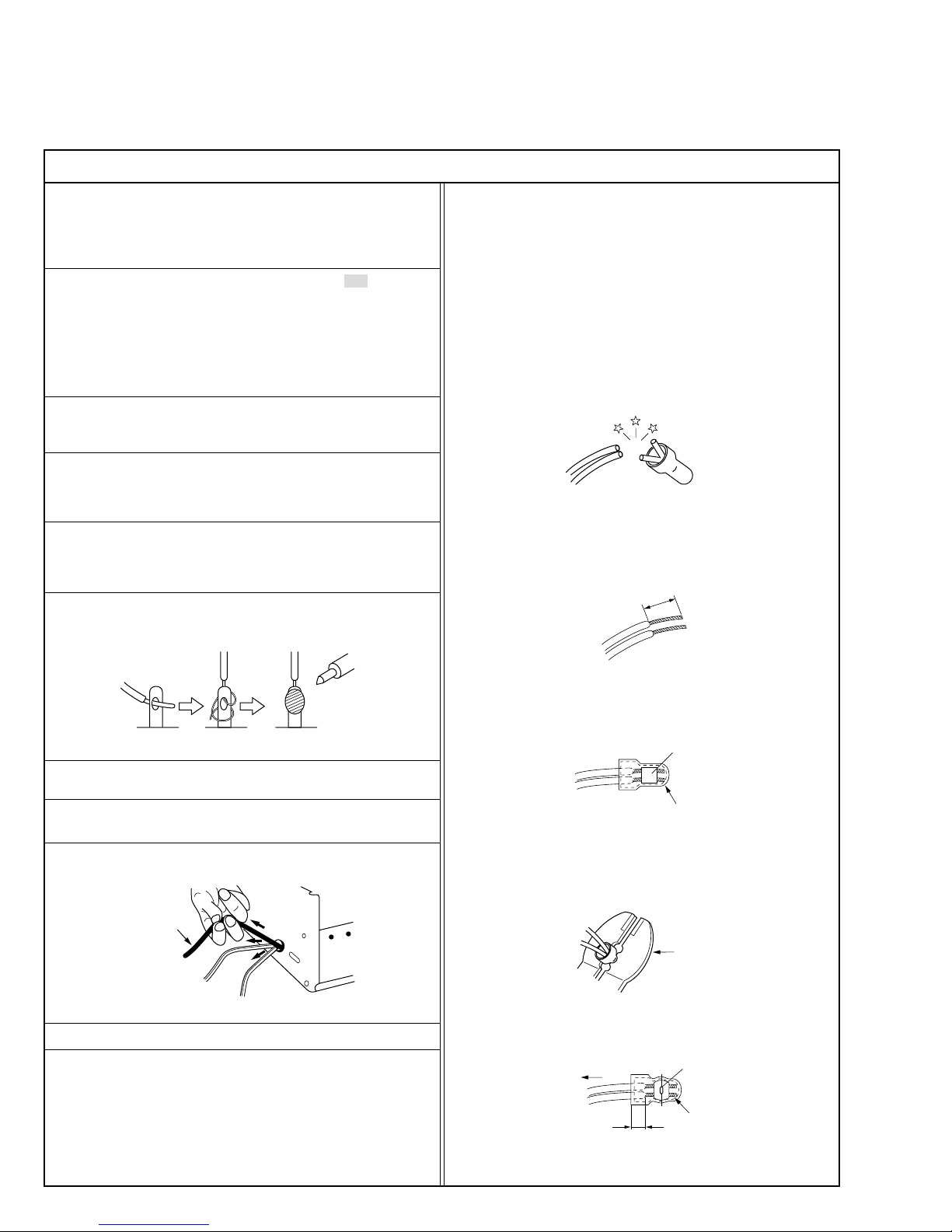

1.1.4 Disconnection of Connectors (Wires) ............................. 1-1

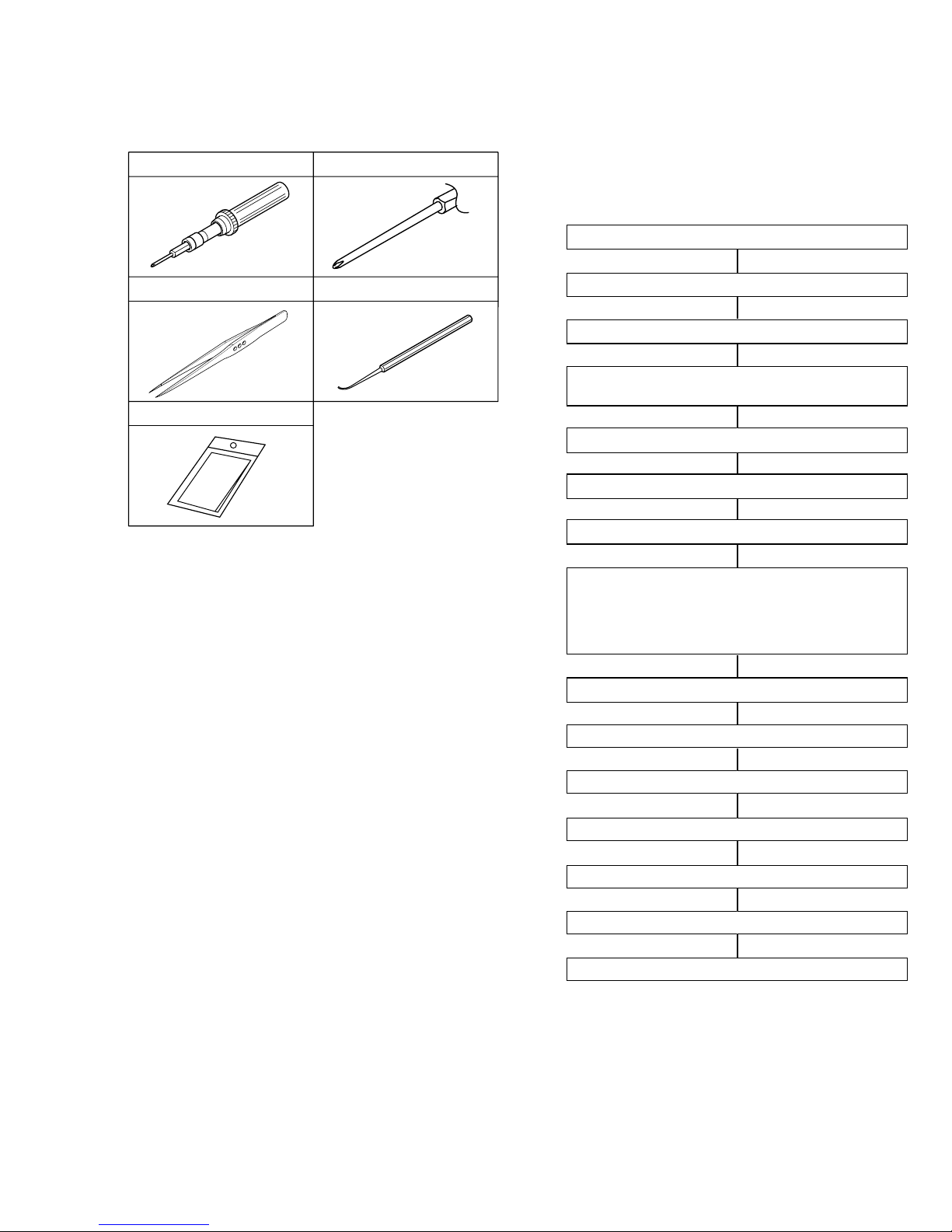

1.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY,

ASSEMBLY AND ADJUSTMENT ......................................... 1-2

1.2.1 Tools required for adjustments ........................................ 1-2

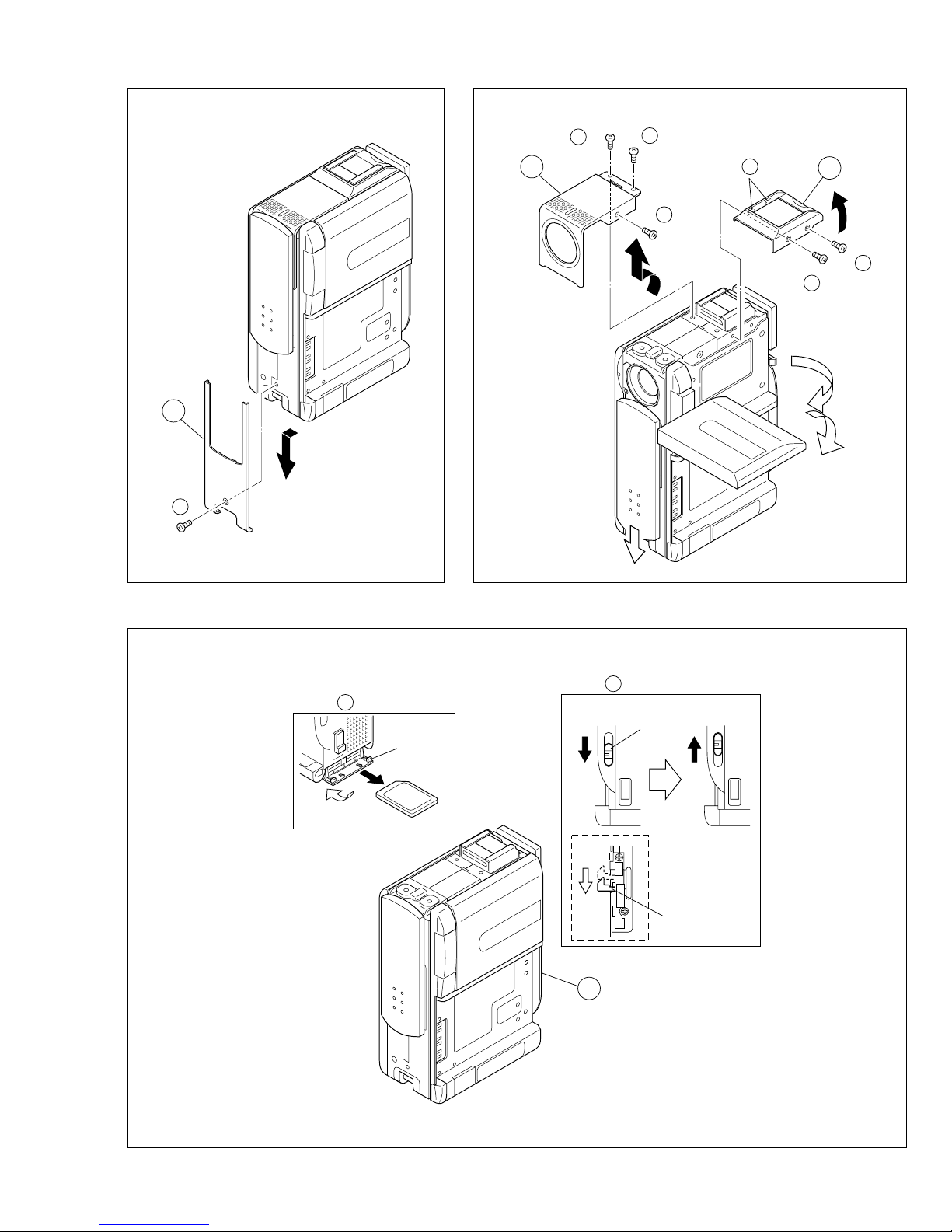

1.3 DISASSEMBLY/ASSEMBLY OF CABINET PARTS AND

BOARD ASSEMBLY ............................................................. 1-2

1.3.1 Disassembly flow chart ................................................... 1-2

1.3.2 Disassembly method ...................................................... 1-3

1.4 DISASSEMBLY OF 5MONITOR ASSEMBLY ..................... 1-8

1.4.1 5Monitor assembly/Hinge assembly ............................. 1-8

1.4.2 Hinge assembly .............................................................. 1-8

1.5 DISASSEMBLY OF @OP BLOCK ASSEMBLY/CCD

BOARD ASSEMBLY ............................................................. 1-9

1.5.1 Precautions ..................................................................... 1-9

1.5.2 How to remove @OP block assembly and CCD board

assembly ......................................................................... 1-9

1.5.3 How to install @OP block assembly and CCD board

assembly ......................................................................... 1-9

1.5.4 Replacement of service parts ......................................... 1-9

1.6 DISASSEMBLY OF #E. VF ASSEMBLY ............................ 1-10

1.6.1 #E. VF assembly ......................................................... 1-10

1.7 EMERGENCY DISPLAY ..................................................... 1-11

1.8 SERVICE KNOW-HOW ....................................................... 1-12

1.9 SERVICE NOTE .................................................................. 1-14

2. MECHANISM ADJUSTMENT

2.1

PRELIMINARY REMARKS ON ADJUSTMENT AND REPAIR ..

2-1

2.1.1 Precautions ..................................................................... 2-1

2.1.2 Notes on procedure for disassemby/assembly ............... 2-1

2.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY,

ASSEMBLY AND ADJUSTMENT ......................................... 2-2

2.2.1 Tools required for adjustments ........................................ 2-2

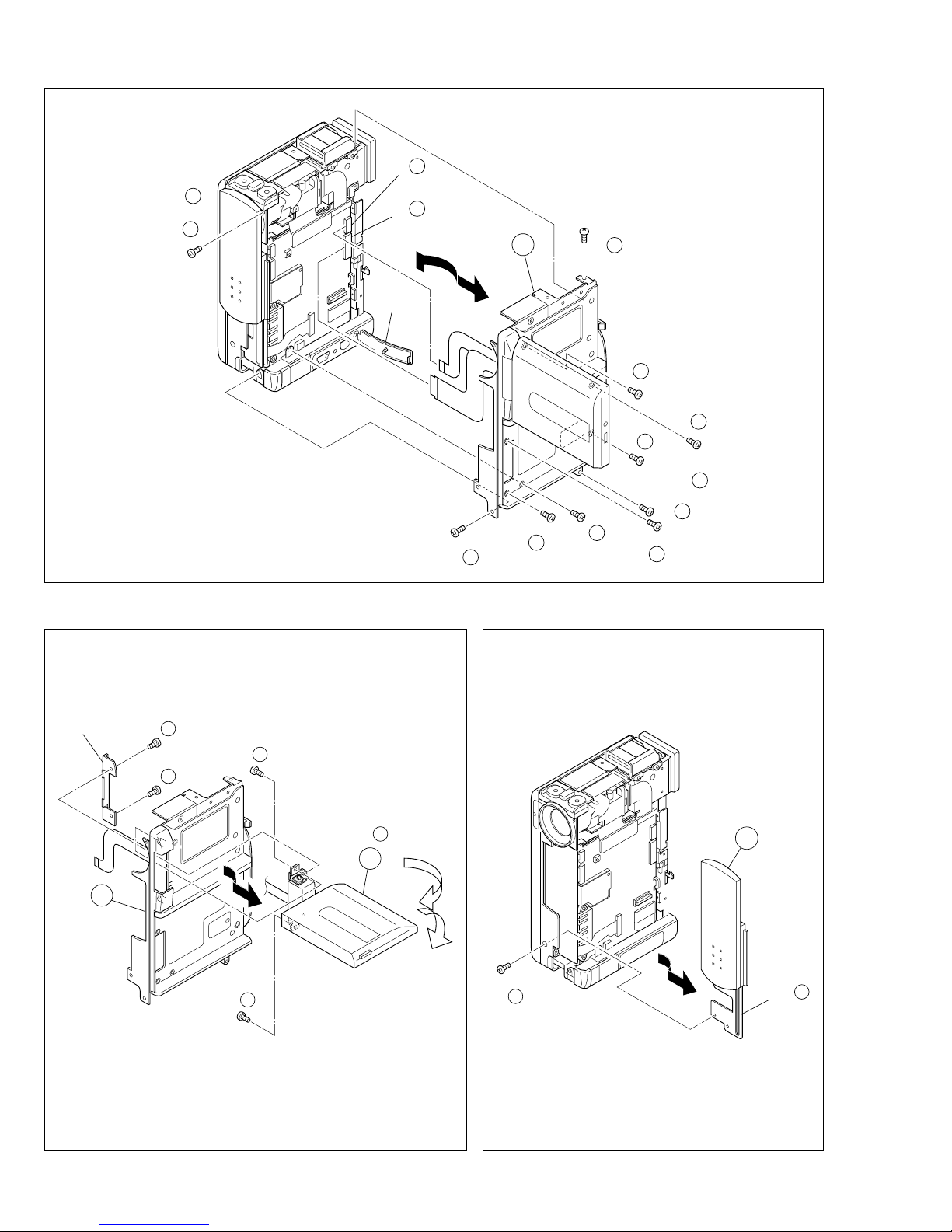

2.3 DISASSEMBLY/ASSEMBLY OF MECHANISM ASSEMBLY 2-3

2.3.1 General statement .......................................................... 2-3

2.3.2 Explanation of mechanism mode ................................... 2-3

2.3.3 Mechanism timing chart .................................................. 2-4

2.4 DISASSEMBLING PROCEDURE TABLE ............................. 2-5

2.4.1 Disassembly/assembly ................................................... 2-7

2.4.2 List of procedures for disassembly ............................... 2-13

2.5

CHECKUP AND ADJUSTMENT OF MECHANISM PHASE .

2-14

2.6 MECHANISM ADJUSTMENTS .......................................... 2-15

2.6.1 Adjustment of the slide guide plate ............................... 2-15

2.6.2

Adjustment of the Tension Arm and Pad Arm Assemblies ..

2-16

2.6.3 Adjustment of the Slide Lever 2 .................................... 2-16

2.7 SERVICE NOTE .................................................................. 2-17

2.8 COMPATIBILITY ADJUSTMENT ........................................ 2-19

2.8.1 Jig connector cable connection .................................... 2-19

2.8.2 Tape pattern check ....................................................... 2-19

TABLE OF CONTENTS

Section Title Page Section Title Page

3. ELECTRICAL ADJUSTMENT

3.1 PRECAUTION ....................................................................... 3-1

3.2 SETUP .................................................................................. 3-2

4. CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM .......................................... 4-1

CIRCUIT BOARD NOTES ........................................................... 4-2

4.1 BOARD INTERCONNECTIONS ........................................... 4-3

4.2

SYSCON-CPU SCHEMATIC DIAGRAM .................................... 4-5

4.3 SERVO SCHEMATIC DIAGRAM ................................................ 4-7

4.4 MDA SCHEMATIC DIAGRAM .................................................... 4-9

4.5 AUDIO AD/DA SCHEMATIC DIAGRAM ................................... 4-11

4.6 MAIN AUDIO SCHEMATIC DIAGRAM ..................................... 4-13

4.7 DV MAIN SCHEMATIC DIAGRAM ........................................... 4-15

4.8 PRE/REC SCHEMATIC DIAGRAM .......................................... 4-17

4.9 VIDEO I/O SCHEMATIC DIAGRAM ......................................... 4-19

4.10 CDS/AD SCHEMATIC DIAGRAM .......................................... 4-21

4.11 CAM.DSP SCHEMATIC DIAGRAM ....................................... 4-23

4.12 TG/VDR SCHEMATIC DIAGRAM .......................................... 4-25

4.13 REGCON SCHEMATIC DIAGRAM ........................................ 4-27

4.14 REG SCHEMATIC DIAGRAM ................................................ 4-29

4.15 VF MAIN SCHEMATIC DIAGRAM ......................................... 4-31

4.16 MONITOR MAIN SCHEMATIC DIAGRAM ............................. 4-33

4.17 DSC SCHEMATIC DIAGRAM ................................................ 4-35

4.18 USBDRV SCHEMATIC DIAGRAM ......................................... 4-37

4.19 SD SCHEMATIC DIAGRAM ................................................... 4-39

4.20 WBSEN/SW SCHEMATIC DIAGRAM .................................... 4-41

4.21 OPDRV SCHEMATIC DIAGRAM ........................................... 4-43

4.22 BOTTOM SCHEMATIC DIAGRAM ........................................ 4-45

4.23 MONITOR SCHEMATIC DIAGRAM ....................................... 4-47

4.24 W/B AND CCD SCHEMATIC DIAGRAMS ............................. 4-49

4.25 EJECT AND VF BL SCHEMATIC DIAGRAMS ...................... 4-50

4.26 MAIN CIRCUIT BOARD ......................................................... 4-51

4.27 OP MDA CIRCUIT BOARD .................................................... 4-57

4.28 BOTTOM CIRCUIT BOARD ................................................... 4-59

4.29 MONITOR, CCD, EJECT AND VF BL CIRCUIT BOARDS .... 4-61

4.30 VOLTAGE CHARTS ............................................................... 4-63

4.31 POWER SYSTEM BLOCK DIAGRAM ................................... 4-67

4.32 VIDEO SYSTEM BLOCK DIAGRAM ...................................... 4-69

5. PARTS LIST

5.1 PACKING AND ACCESSORY ASSEMBLY <M1> ............... 5-1

5.2 FINAL ASSEMBLY <M2> ..................................................... 5-3

5.3 MECHANISM ASSEMBLY <M3> ......................................... 5-6

5.4 ELECTRONIC VIEWFINDER ASSEMBLY <M4> ................ 5-8

5.5 MONITOR ASSEMBLY <M5> .............................................. 5-9

5.6 ELECTRICAL PARTS LIST ................................................. 5-10

MAIN BOARD ASSEMBLY <01> ............................................. 5-10

OP MDA BOARD ASSEMBLY <02> ........................................ 5-19

BOTTOM BOARD ASSEMBLY <03> ....................................... 5-20

MONITOR BOARD ASSEMBLY <04> ..................................... 5-20

CCD BOARD ASSEMBLY <05> .............................................. 5-21

EJECT BOARD ASSEMBLY <06> .......................................... 5-21

VF BL BOARD ASSEMBLY <07> ............................................ 5-21