1-10 (No.YF100)

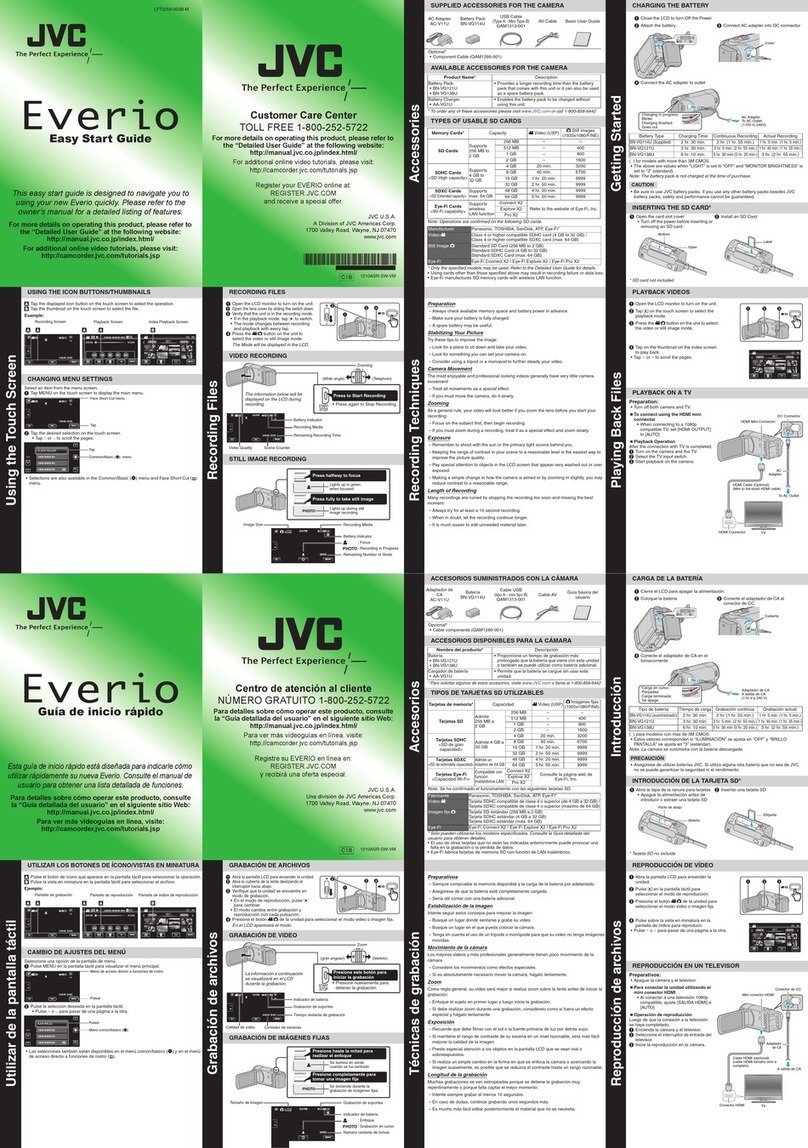

2.4.3 Precautions on handling Microdrives

Main causes of failures in hard disks including Microdrives are

listed as follows.

(1) Failures caused by shocks

(2) Failures caused by static electricity

(3) Failures caused by power cut during the operation

2.4.3.1 Failures caused by shock

One of the causes of the Microdrive failures is a crash between

the disk and the head caused by falls or shocks. The results of

the crash are listed as follows.

• The scratch on the surface of the disk (crash scar) disables

reading/ writing of the damaged part.

• The magnetic material that came off by the crash (disk frag-

ment) causes head reading failure.

• The head distortion deteriorates the read/ write attribute.

• The change in the space between the head and the disk dis-

ables the normal read/ write.

Stronger shocks result in the motor axis distortion, causing axial

runout and deterioration in performance such as disabling the

trace of normally recorded signal.

Pay extra caution not to drop or give shocks to the Microdrive

while servicing, and make sure to store the Microdrive in a pro-

vided plastic case.

NOTE:

The shock of 200G(G:Gravity), a maximum impact value in

operation, is equivalent of the impact of dropping from 20-

30cm above the hard floor. The shock of 2000G, a maximum

impact value in non-operation, is equivalent of the impact of

dropping from 75 - 100cm above the hard floor.

2.4.3.2 Failures caused by static electricity

Microdrives are designed to tolerate static electricity up to 15kV

approx. However, head destruction or boot failure will occur as a

result of high static electricity given to the magnetic head of a Mi-

crodrive that is very vulnerable to static electricity.

As same as handling other electronic parts, make sure not to

take charge of static electricity before touching a Microdrive for

checking or repairing. In addition, make sure to store the Micro-

drive in a provided plastic case when it is not in use.

The voltage of 15kV has enough power to break Microdrives de-

stroying heads etc. Errors in Microdrives may occur with lower

voltage. Asking the customers about the recording condition:

whether it was inside the car in winter, right after getting off the

car or in the carpeted area of a hotel etc., is recommended to in-

vestigate failures with poor reproducibility.

2.4.3.3 Failures caused by power cut during the operation

When the power is cut off while writing the data on the Micro-

drive, writing failure occurs in the writing sector (512 byte). As a

result, an error will occur while reading the data.

The effects on the system, given by the bad writing sector, de-

pend on the types of the written files on the sector.

If it is user data, the recorded movie may not be replayed.

To prevent failure in writing, do not insert/ remove the Microdrive

or cut off the power unless otherwise indicated or needed.

2.4.4 Microdrive backup

Unlike the information on tapes, customers' information on Micro-

drives can become unreadable in an instant.

Taking into account the personal information management, do not

perform Microdrive backup basically. If backup is needed during

the procedure, refer to the followings to carry out the backup.

hard disk

2GB 4GB 80GB

Model name Microdrive 3K4-2 Microdrive 3K4-4 Travelstar 4K80-80

Model number HMS360402D5CF00 HMS360404D5CF00 HTS428080F9AT00

Capacity 2 GB 4 GB 80 GB

Interface

CompactFlash Type

Τ

CompactFlash Type

ΤATA ATA-6

Form factor 1inch 1inch 2.5inch

System type Consumer electronics Consumer electronics Laptop

Cache buffer 128 KB 128 KB 8 MB

Disks / Heads 1/1 1/2 2/4

Rotational speed (RPM) 3,600 (RPM) 3,600 (RPM) 4,200 (RPM)

Media transfer rate 97.9 Mb/sec max 97.9 Mb/sec max 351 Mb/sec max

Interface transfer rate

33 MB/sec max 33 MB/sec max 100 MB/sec max

Average seek (ms) 12 (ms) 12 (ms) 13 (ms)

Average latency (ms) 8.33 (ms) 8.33 (ms) 7.1 (ms)

Areal density 56.5 Gb/sq. inch 56.5 Gb/sq. inch 68.5 Gb/sq. inch

Typical idle acoustic (Bels) 㧙㧙2.4B

Operating shock (G) 200 G (2ms) 200 G (2ms) 250 (2ms)

Non-operating shock (G) 2000 G (1ms) 2000 G (1ms) 800 (1ms)

Operating ambient temperature ()0㨪70 ()0㨪70 ()5㨪55 ()

Non-operating ambient temperature ()

-40 㨪70 () -40 㨪70 () -40 㨪70 ()

Microdrive

4GB(Old goods) 4GB(New case goods) 6GB

Model name Microdrive 3K4-4 Microdrive 3K6-4 Microdrive 3K6-4

Model number HMS360404D5CF00 HMS360604D5CF00 HMS360606D5CF00

Capacity 4 GB 4 GB 6 GB

Interface

CompactFlash Type

Τ

CompactFlash Type

Τ

CompactFlash Type

Form factor 1inch 1inch 1inch

System type Consumer electronics Consumer electronics

Consumer electronics

Cache buffer 128 KB 128 KB 128 KB

Disks / Heads 1/1 1/2 1/2

Rotational speed (RPM) 3,600 (RPM) 3,600 (RPM) 3,600 (RPM)

Media transfer rate 97.9 Mb/sec max 125 Mb/sec max 125 Mb/sec max

Interface transfer rate

33 MB/sec max 33 MB/sec max 33 MB/sec max

Average seek (ms) 12 (ms) 12 (ms) 12 (ms)

Average latency (ms) 8.33 (ms) 8.33 (ms) 8.33 (ms)

Areal density 56.5 Gb/sq. inch 78 Gb/sq. inch 78 Gb/sq. inch

Typical idle acoustic (Bels) 㧙㧙㧙

Operating shock (G) 200 G (2ms) 200 G (2ms) 200 G (2ms)

Non-operating shock (G) 2000 G (1ms) 2000 G (1ms) 2000 G (1ms)

Operating ambient temperature ()0㨪70 ()0㨪70 ()0㨪70 ()

Non-operating ambient temperature ()

-40 㨪70 () -40 㨪70 () -40 㨪70 ()

Microdrive

Head

㧔0.03um㧕

Head floating height

Disk

Disk

Disk fragment

Head

Crash scar

Microdrive

2.5 inch HDD

3.5 inch HDD

200

2500

2000

1500

1000

500

0

200

55

2000

Operation Non-operation

1000

300

Impact value (G)

(G):Gravity

50 100 150 200 250 300 350

Disk

shift

Read

error

Operation

Operation/ Non-operation

Shocks(G)

Read error

Normal

1400 1600 1800 2000 2200 2400 2600

Shocks(G)

Performance

deterioration

Normal

Model:HMS360404D5CF00SERIES

Shock

Crash

between

the head

and the

disk

Crash scar

on the disk

Disk

fragment

Excessive

power is

generated

in the

mechanism

Performance

deterioration

(G):Gravity