TABLE OF CONTENTS

Section Title Page

Important Safety Precautions

INSTRUCTIONS

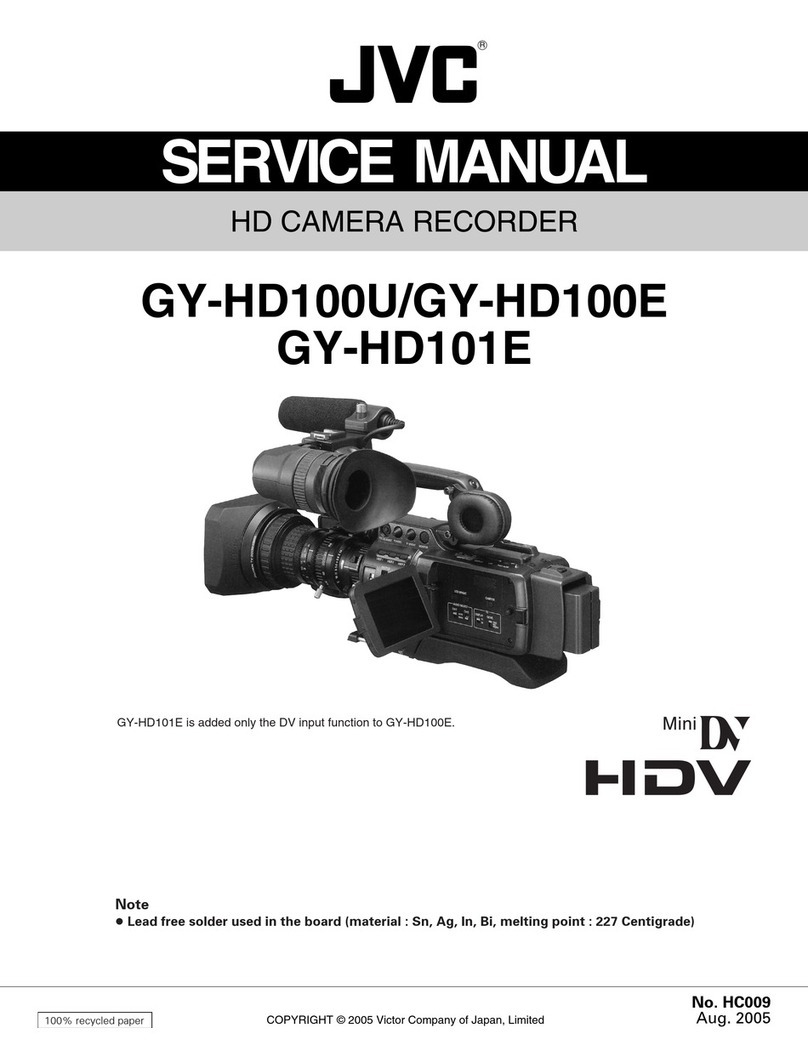

1. DISASSEMBLY

1.1 BEFORE ASSEMBLY AND DISASSEMBLY................................. 1-1

1.1.1 Precautions .......................................................................... 1-1

1.1.2 Assembly and disassembly ................................................. 1-1

1.1.3 Destination of connectors .................................................... 1-1

1.1.4 Disconnection of Connectors (Wires) .................................. 1-1

1.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY,

ASSEMBLY AND ADJUSTMENT ................................................. 1-2

1.2.1 Tools required for adjustments............................................. 1-2

1.3 DISASSEMBLY/ASSEMBLY OF CABINET PARTS AND

BOARD ASSEMBLY ..................................................................... 1-3

1.3.1 Disassembly flow chart ........................................................ 1-3

1.3.2 Disassembly method (I) ....................................................... 1-4

1.4 DISASSEMBLY OF 4MONITOR ASSEMBLY............................ 1-8

1.4.1 4Monitor assembly/Hinge assembly.................................. 1-8

1.4.2 Hinge assembly ................................................................... 1-8

1.5 DISASSEMBLY 0E VF ASSEMBLY ........................................... 1-9

1.5.1 0E. VF assembly ............................................................... 1-9

1.6 DISASSEMBLY OF 7OP BLOCK ASSEMBLY/CCD

BOARD ASSEMBLY ................................................................... 1-10

1.6.1 Precautions ........................................................................ 1-10

1.6.2 How to remove OP block assembly and CCD board

assembly............................................................................ 1-10

1.6.3 How to install OP block assembly and CCD board

assembly............................................................................ 1-10

1.6.4 Replacement of service parts ............................................ 1-10

1.7 HOW TO TAKE OUT CASSETTE TAPE MANUALLY ................ 1-11

1.8 SERVICE NOTE ......................................................................... 1-12

1.9 EMERGENCY DISPLAY............................................................. 1-13

2. MECHANISM ADJUSTMENT

2.1 PRELIMINARY REMARKS ONADJUSTMENTAND REPAIR ..... 2-1

2.1.1 Precautions .......................................................................... 2-1

2.1.2 Notes on procedure for disassembly/assembly................... 2-1

2.2 DISASSEMBLY/ASSEMBLY OF MECHANISM ASSEMBLY........ 2-2

2.2.1 General statement ............................................................... 2-2

2.2.2 Explanation of mechanism mode......................................... 2-2

2.2.3 Mechanism timing chart .......................................................2-3

2.2.4 Disassembly/assembly of mechanism assembly................. 2-4

2.2.5 Disassembly/assembly ........................................................ 2-7

2.2.6 List of procedures for disassembly .................................... 2-13

2.2.7 Checkup and adjustment of mechanism phase................. 2-14

2.2.8 Assembling slide deck assembly and main deck

assembly............................................................................ 2-15

2.2.9 Locating tension pole......................................................... 2-16

2.3 SERVICE NOTE ......................................................................... 2-17

2.4 JIG CONNECTOR CABLE CONNECTOR ................................. 2-19

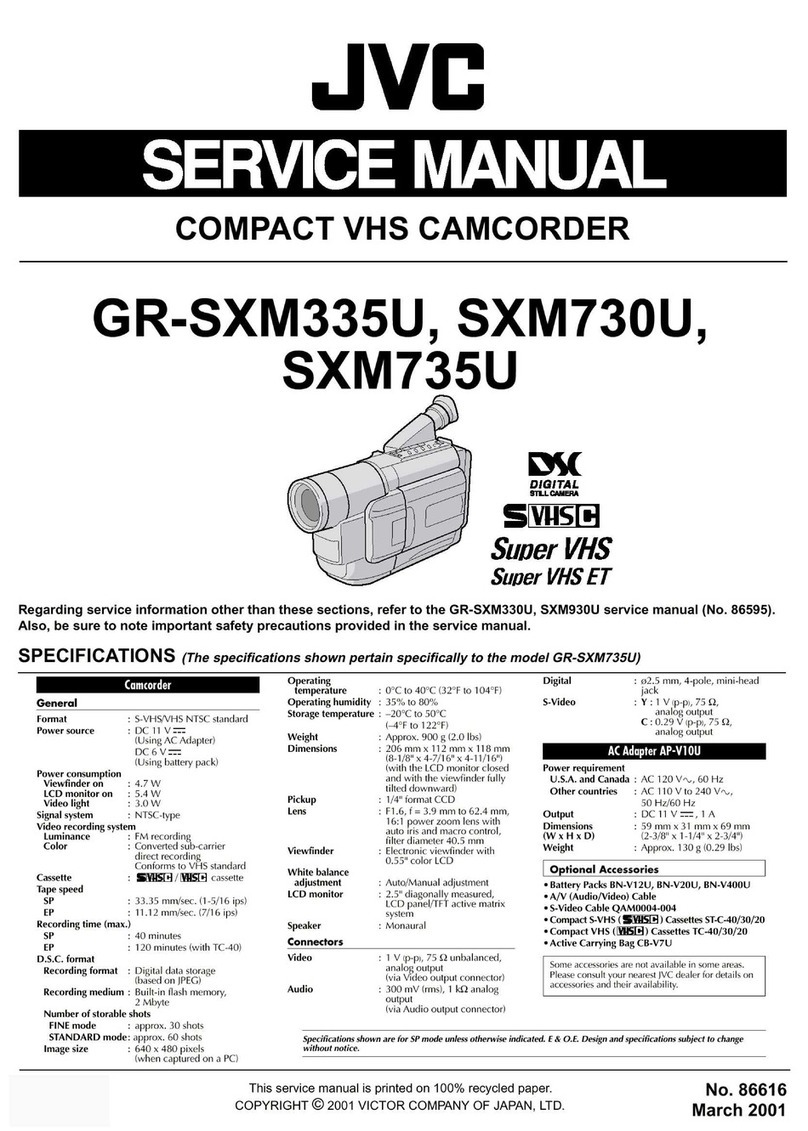

3. ELECTRICAL ADJUSTMENT

3.1 PREPARATION ............................................................................ 3-1

3.2 SETUP .......................................................................................... 3-1

3.3 FUSE LOCATION ......................................................................... 3-2

3.3.1 MAIN PWB (FOIL SIDE) ......................................................3-2

3.3.2 MAIN PWB (COMPONENT SIDE) ...................................... 3-2

3.3.3 MONITOR PWB (COMPONENT SIDE)............................... 3-3

4. CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM............................................ 4-1

CIRCUIT BOARD NOTES ............................................................ 4-2

4.1 BOARD INTERCONNECTIONS................................................... 4-3

4.2 CPU SCHEMATIC DIAGRAM ...................................................... 4-5

4.3 MSD CPU SCHEMATIC DIAGRAM ............................................. 4-7

4.4 A/HP SEL SCHEMATIC DIAGRAM .............................................. 4-9

4.5 DVMAIN SCHEMATIC DIAGRAM .............................................. 4-11

4.6 PHY SCHEMATIC DIAGRAM..................................................... 4-13

4.7 DVEQ/DVANA SCHEMATIC DIAGRAM ..................................... 4-15

4.8 PRE/REC SCHEMATIC DIAGRAM ............................................ 4-17

4.9 VIDEO SCHEMATIC DIAGRAM................................................. 4-19

4.10 CDS SCHEMATIC DIAGRAM .................................................... 4-21

4.11 DSP SCHEMATIC DIAGRAM ...................................................... 4-23

4.12 TG/VDR SCHEMATIC DIAGRAM .............................................. 4-25

4.13 REG CTLSCHEMATIC DIAGRAM............................................. 4-27

4.14 REGULATOR SCHEMATIC DIAGRAM ...................................... 4-29

4.15 STROBE SUB SCHEMATIC DIAGRAM ..................................... 4-31

4.16 DSC SCHEMATIC DIAGRAM .................................................... 4-33

4.17 AU DSP SCHEMATIC DIAGRAM .............................................. 4-35

4.18 B/W AND IR/TALLY SCHEMATIC DIAGRAMS.......................... 4-37

4.19 MDA SCHEMATIC DIAGRAMS .................................................. 4-39

4.20 IRIS &AF/ZOOM SCHEMATIC DIAGRAM ................................ 4-41

4.21 CCD SCHEMATIC DIAGRAM .................................................... 4-43

4.22 MONITOR A SCHEMATIC DIAGRAM ........................................ 4-45

4.23 MMC, W/B SENSAND EJECT SCHEMATIC DIAGRAMS......... 4-47

4.24 STROBE SCHEMATIC DIAGRAM ............................................. 4-49

4.25 AUDIOAD/DA SCHEMATIC DIAGRAM ..................................... 4-51

4.26 MAINAUDIO SCHEMATIC DIAGRAM ....................................... 4-53

4.27 AU NR SCHEMATIC DIAGRAM................................................. 4-55

4.28 VF A SCHEMATIC DIAGRAM .................................................... 4-57

4.29 JACK SCHEMATIC DIAGRAM ................................................... 4-59

4.30 CAMERAOPE UNIT, SUB OPE ASSY, ZOOM UNIT

AND DECK OPE UNIT SCHEMATIC DIAGRAMS .................... 4-61

4.31 MAIN CIRCUIT BOARD ............................................................. 4-63

4.32 MDAAND CCD CIRCUIT BOARD ............................................. 4-69

4.33 MONITOR CIRCUIT BOARD ..................................................... 4-71

4.34 MMCAND STROBE CIRCUIT BOARD...................................... 4-73

4.35 AUDIO VF CIRCUIT BOARD ..................................................... 4-75

4.36 JACK, W/BAND EJECT CIRCUIT BOARD................................ 4-77

4.37 POWER SYSTEM BLOCK DIAGRAM ....................................... 4-79

4.38 VIDEO SYSTEM BLOCK DIAGRAM.......................................... 4-81

4.39 REGULATOR SYSTEM BLOCK DIAGRAM ............................... 4-83

4.40 VOLTAGE CHARTS.................................................................... 4-85

5. PARTS LIST

5.1 PACKING ANDACCESSORY ASSEMBLY <M1> ........................ 5-1

5.2 FINAL ASSEMBLY <M2> .............................................................. 5-3

5.3 MECHANISMASSEMBLY <M3>.................................................. 5-6

5.4 ELECTRONIC VIEWFINDERASSEMBLY <M4> ......................... 5-8

5.5 MONITOR ASSEMBLY <M5>....................................................... 5-9

5.6 ELECTRICAL PARTS LIST ........................................................ 5-10

MAIN BOARDASSEMBLY <01>................................................ 5-10

MDABOARDASSEMBLY <02> ................................................. 5-20

CCD BOARDASSEMBLY <03> ................................................ 5-21

MONITOR BOARD ASSEMBLY <04> ........................................ 5-22

MMC BOARDASSEMBLY <06> ................................................ 5-23

STROBE BOARDASSEMBLY <07> .......................................... 5-23

AUDIO VF BOARDASSEMBLY <08> ........................................5-24

JACK BOARDASSEMBLY <09>................................................ 5-26

W/B BOARDASSEMBLY <11> ................................................. 5-26

EJECTBOARD ASSEMBLY <12>.............................................. 5-26

6. AC POWERADAPTER (AA-V51U)

6.1 CABINETASSEMBLY <MA> ........................................................ 6-1

6.2 SCHEMATIC DIAGRAM ............................................................... 6-2

6.3 CIRCUIT BOARD ......................................................................... 6-4

6.4 ELECTRICAL PARTS LIST .......................................................... 6-5

Section Title Page