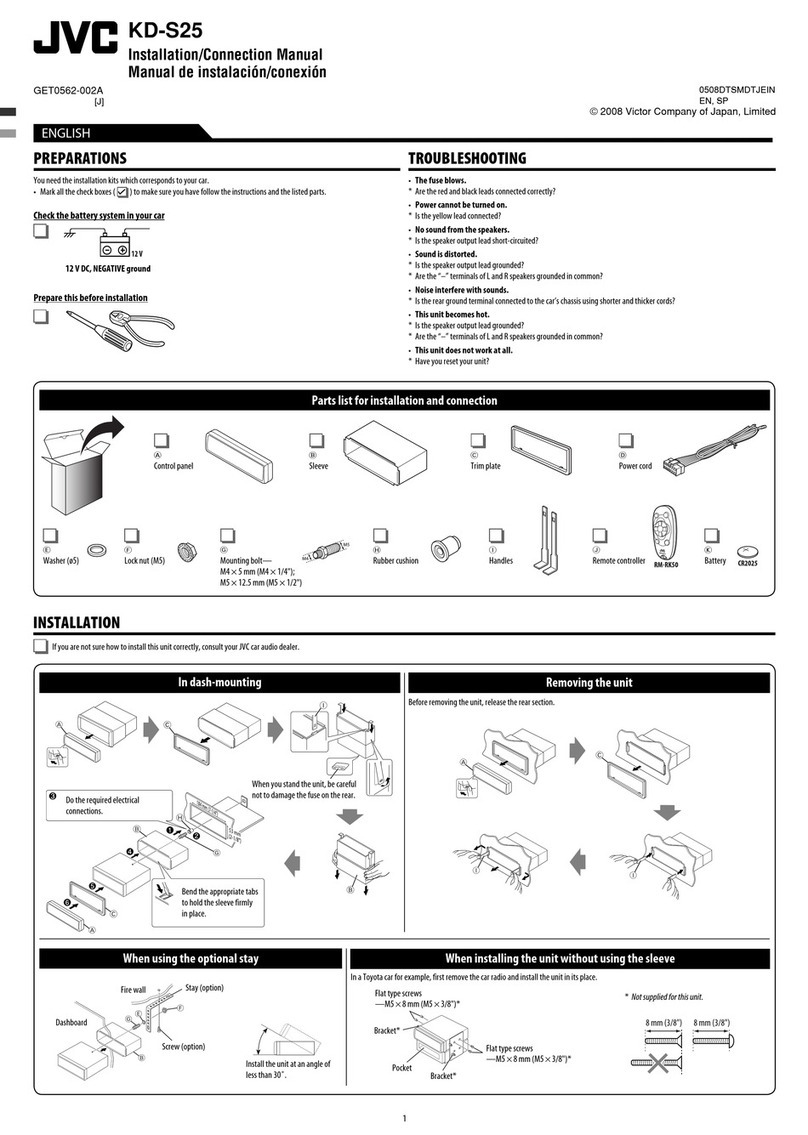

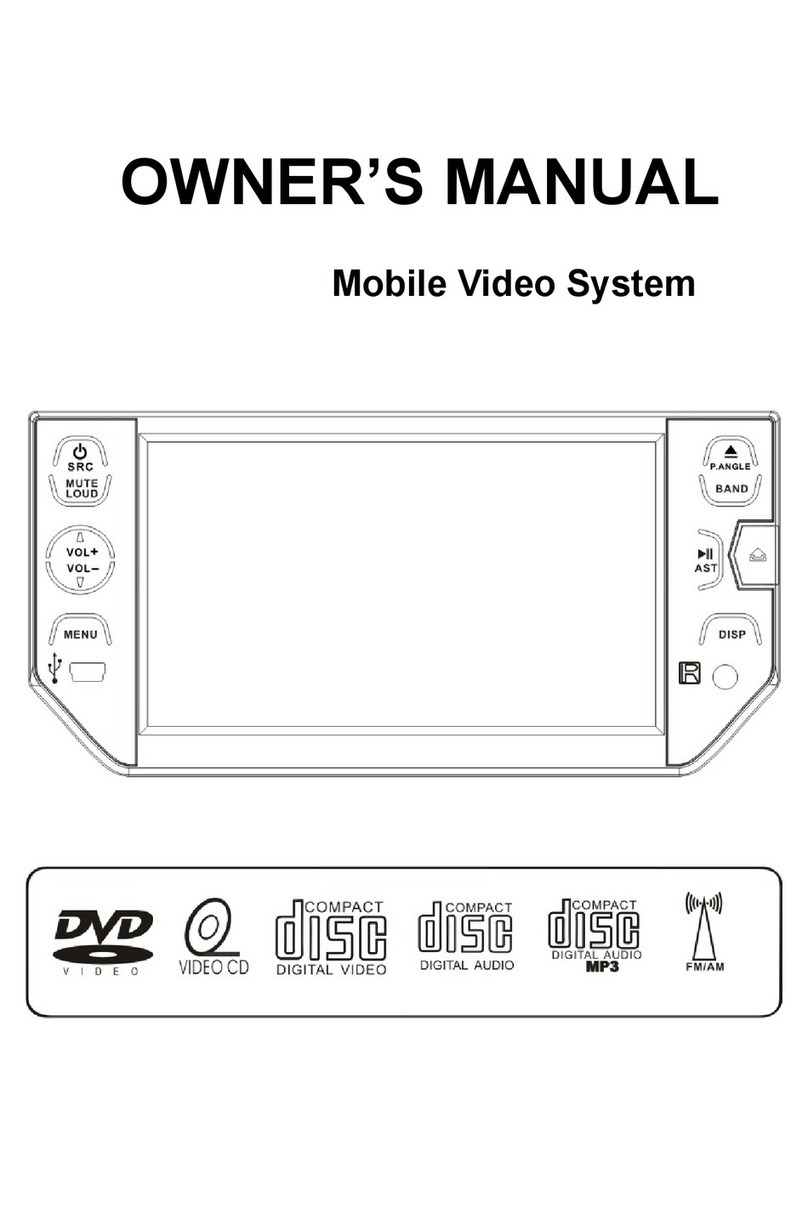

Fig. 7

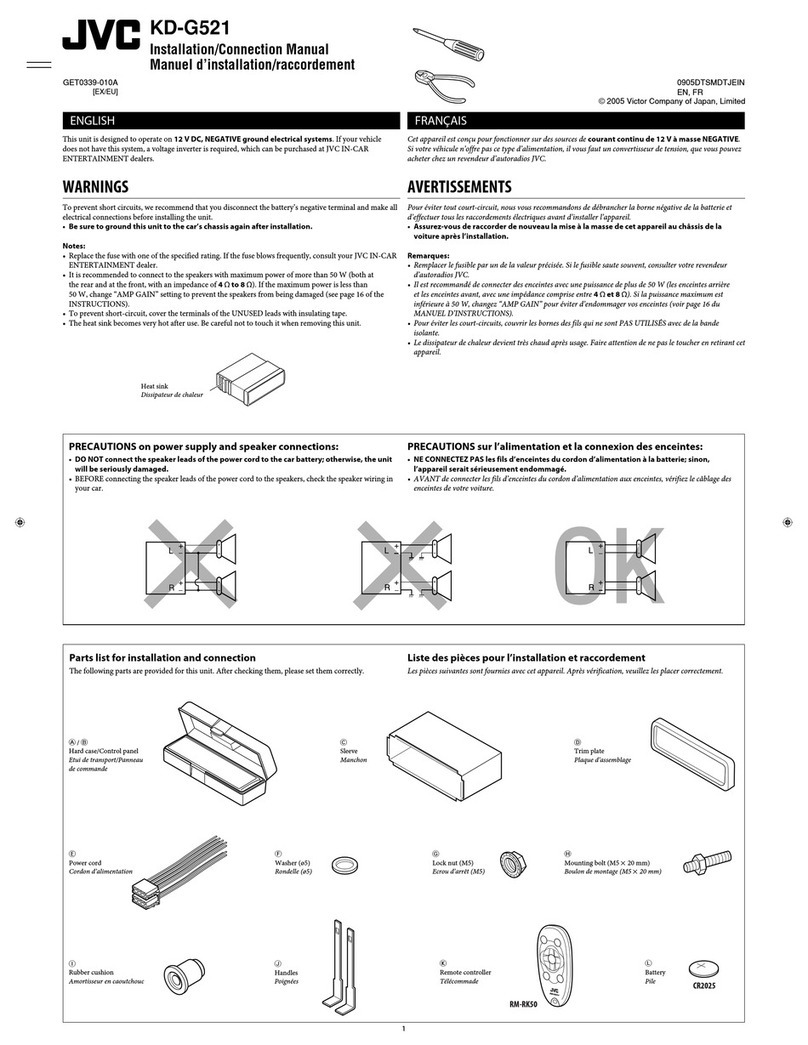

Fig. 10

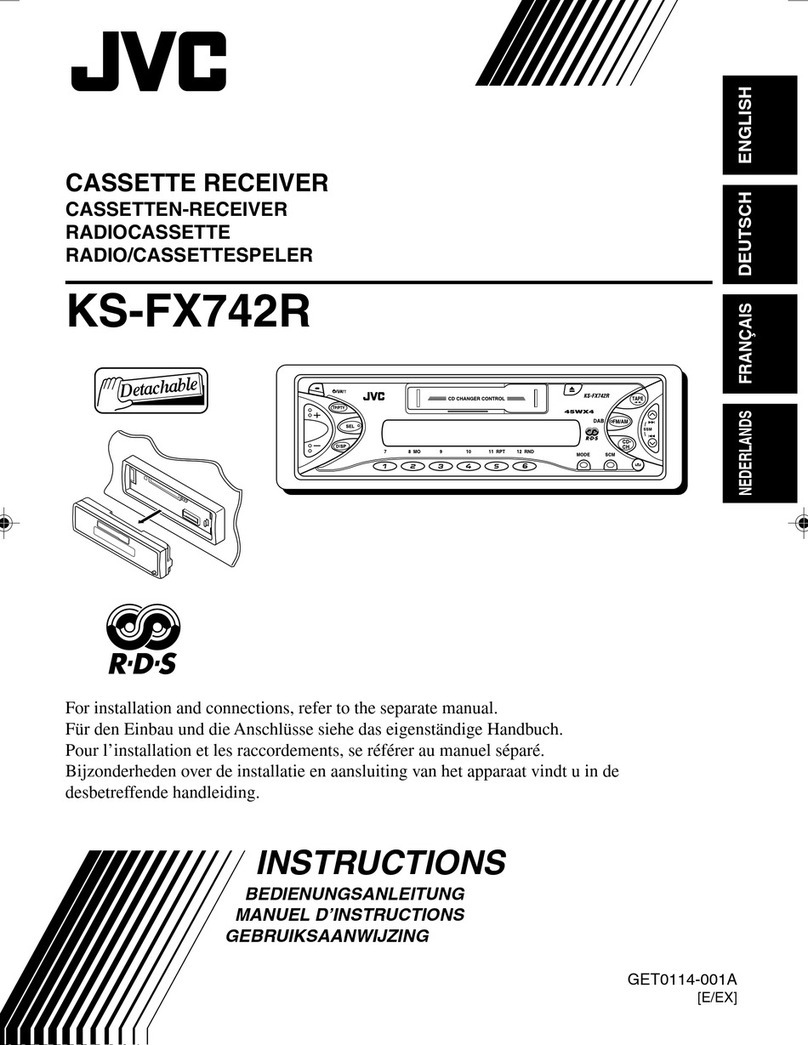

Fig. 9

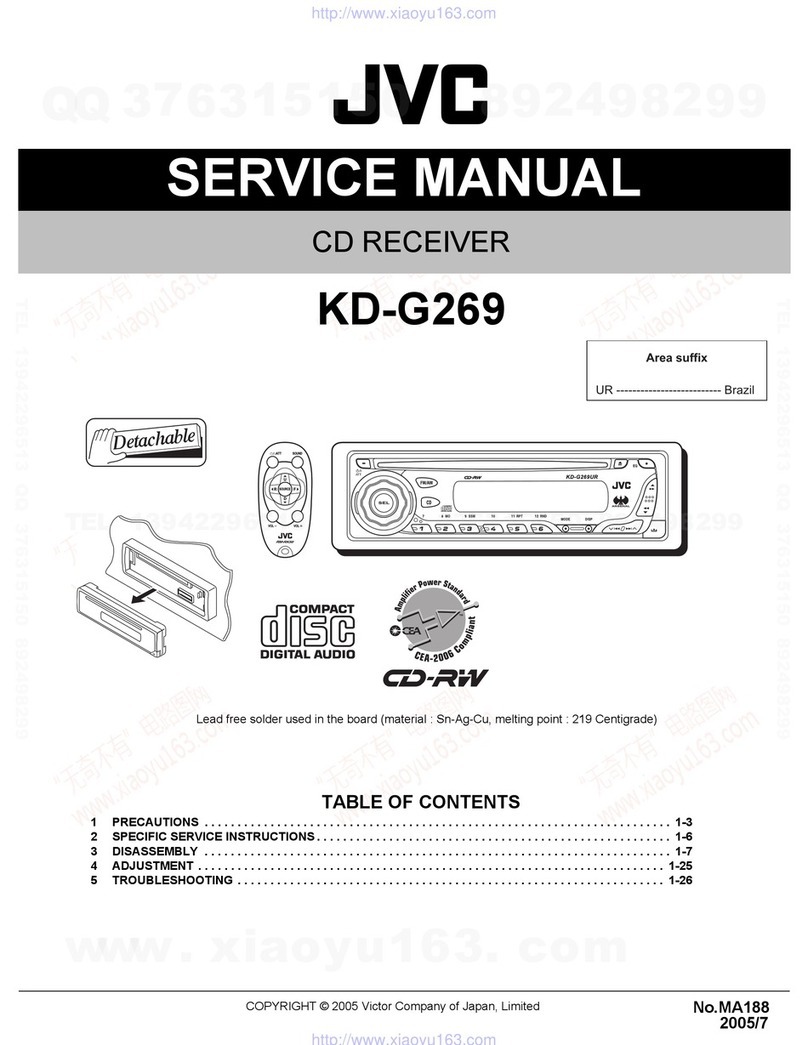

Fig. 8

Removing the Pinch-Roller assembly ( See Fig. 7)

1. Remove the two E Washers 3retaining the pinch-roller shaft.

2. Remove the P.Arm spring (F) from the chassis.

3. Remove the P.Arm spring (R) from the chassis.

4. Pull out the pinch-roller(F,R) assemblies from the left

and right sides.

Note : The P.arm spring (F) and P.arm spring (R) are different.

Note : The Pinch-roller (F) and Pinch-roller(R)assemblies

are different.

Removing the Playback Head ( See Fig. 7 )

1. Remove the one fixed screw 4retaining the playback head.

2. Remove the C Washer 5to pull the FF roller out .

3. Remove the S. support plate to remove the A.arm springs

(A,B) and playback head.

Note : The A. arm spring (A) and A. arm spring (B) are different.

Removing the Motor Assembly ( See Fig. 8 )

1. Remove the main belt and sub-belt from the back side unit.

2. Remove the two screws 6retaining the motor assembly.

Changing the Sub-Belt ( See Fig. 8 )

1. Remove the main belt from the back side unit..

2. Remove the sub-belt from the motor pulley.

3. Remove the four screws 7, 8retaining

the reel base assembly.

4. Lift up the reel base assembly slightly to

change the belt.

Removing the Reel Base Assembly ( See Fig. 8-10)

1. Remove the selector link (B) from the front unit by turning

the selector link (B) near the pinch-roller as shown

in the figure 9.

3. Remove the four screws 7, 8retaining the reel base

assembly.

4. Remove the reel base assembly carefully.

Note : Service for the reel base assembly is not available.

P. arm spring(F)

P. arm spring(R)

33

E Washer E Washer

Pinch-roller

shaft Pinch-roller shaft

Pinch-roller (R)

assembly

Pinch-roller (R)

assembly

Pinch-roller (F)

assembly

A.arm

spring(A)

A.arm

spring(B)

Remove the P. arm spring (F)

from the chassis.

S. support plate

Main belt Sub belt

Reel base assembly

Motor assembly

Motor pulley

Selector link (B) Turn the selector link (B)

disengage this one.

Back side view of the reel base assembly