Important for laser products

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

VARNING : Osynlig laserstrålning är denna del är öppnad

och spårren är urkopplad. Betrakta ej strålen.

VARO : Avattaessa ja suojalukitus ohitettaessa olet

alttiina näkymättömälle lasersäteilylle.Älä katso

säteeseen.

ADVARSEL : Usynlig laserstråling ved åbning , når

sikkerhedsafbrydere er ude af funktion. Undgå

udsættelse for stråling.

ADVARSEL : Usynlig laserstråling ved åpning,når

sikkerhetsbryteren er avslott. unngå utsettelse

for stråling.

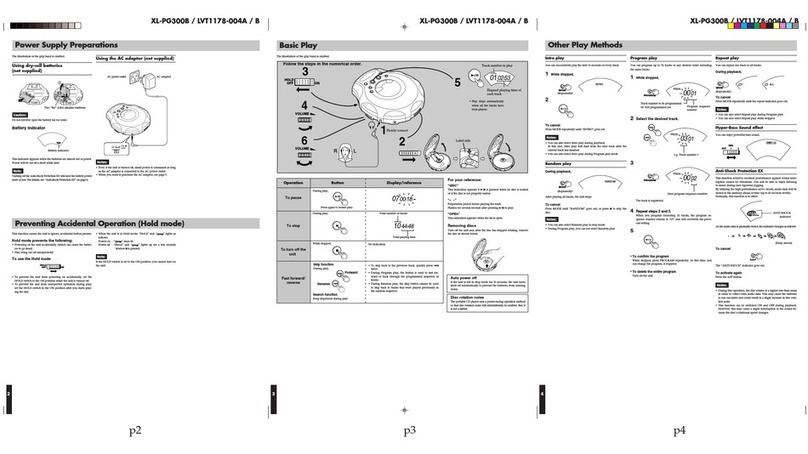

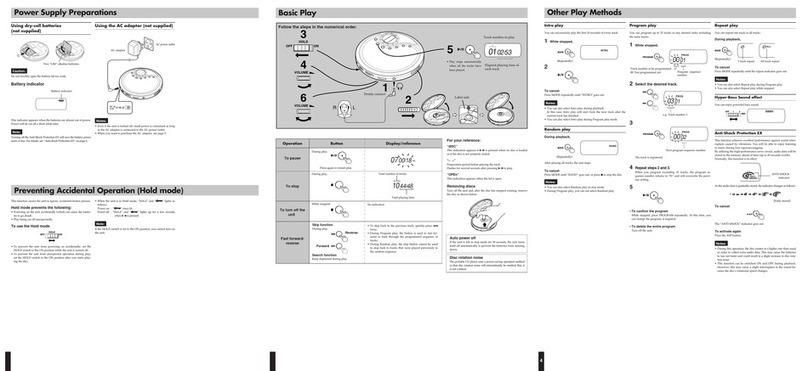

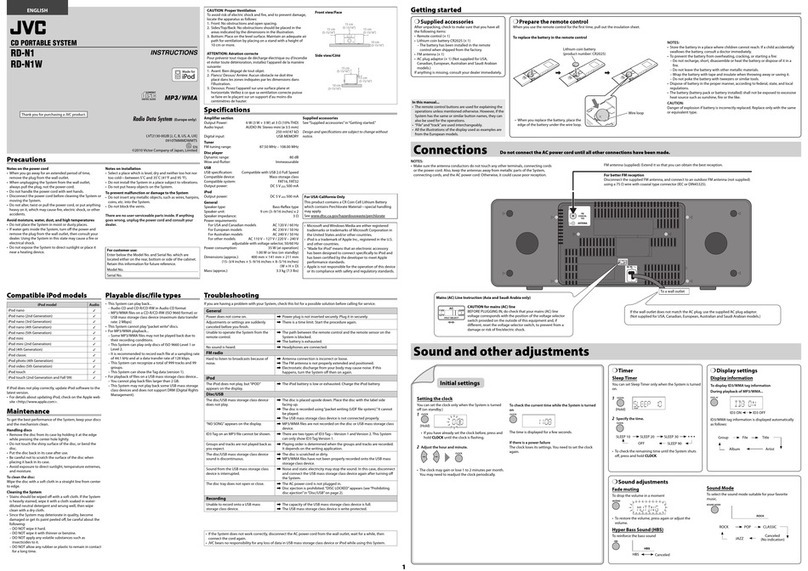

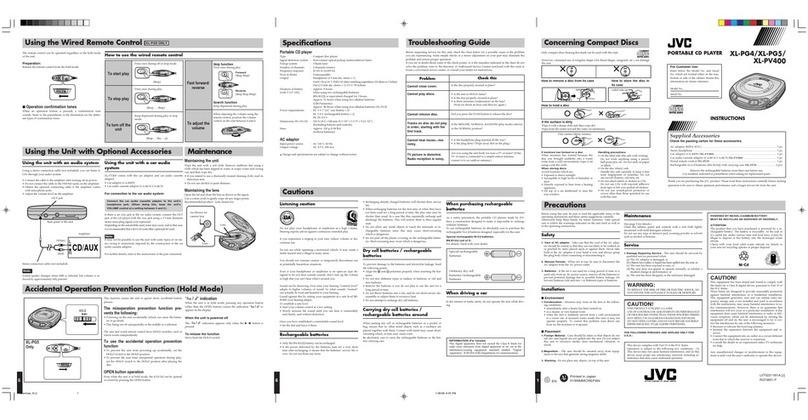

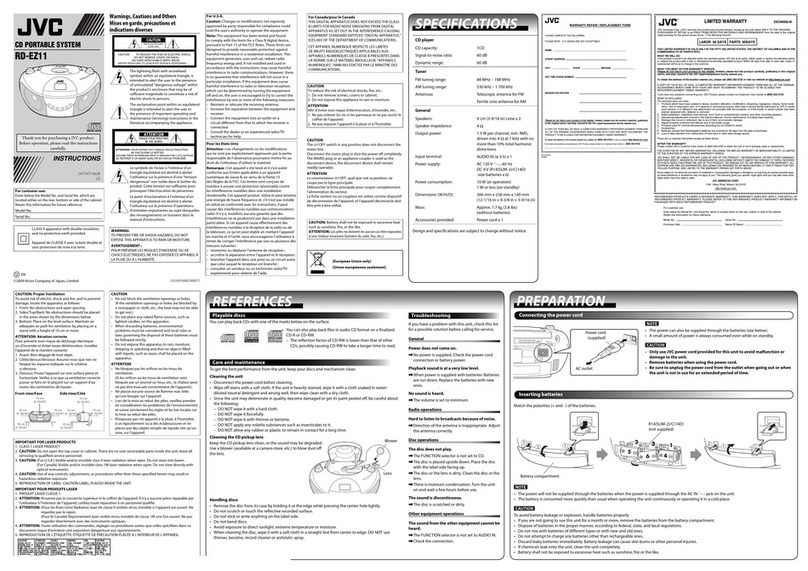

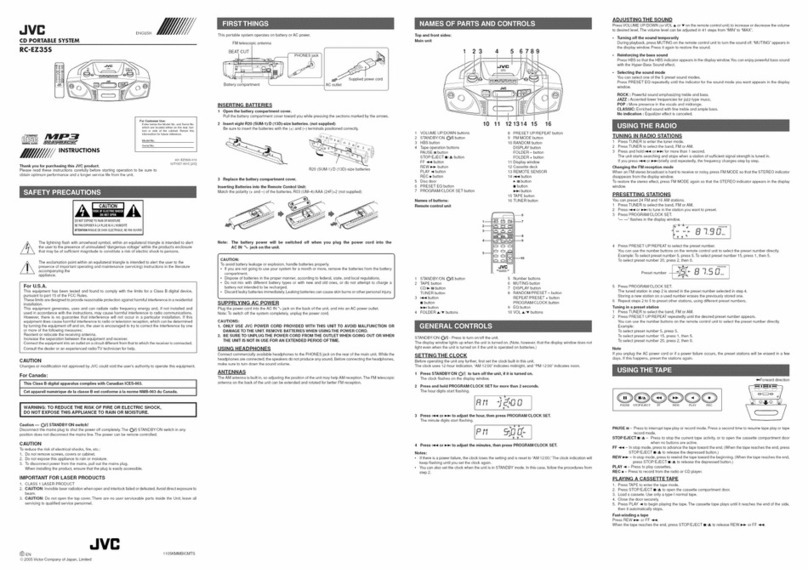

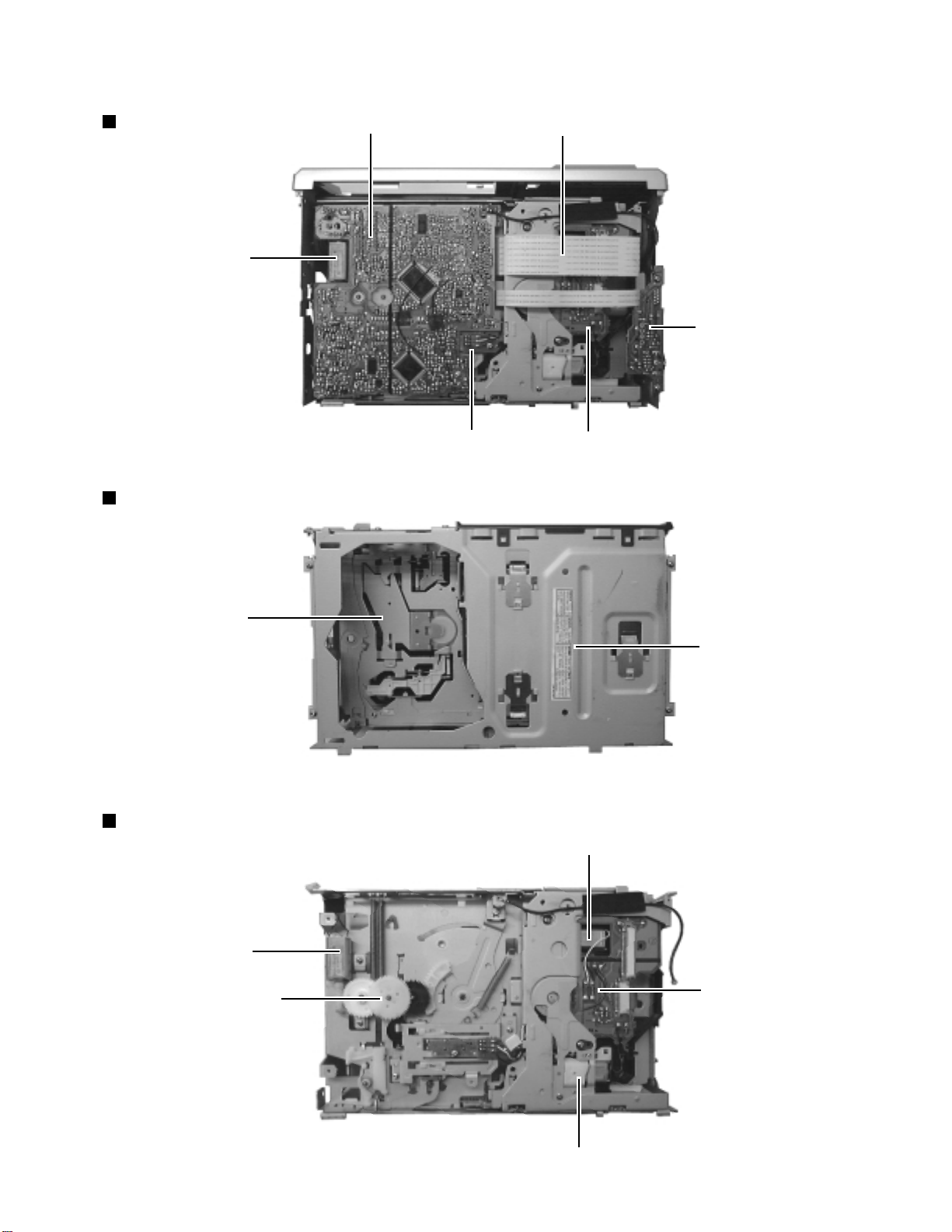

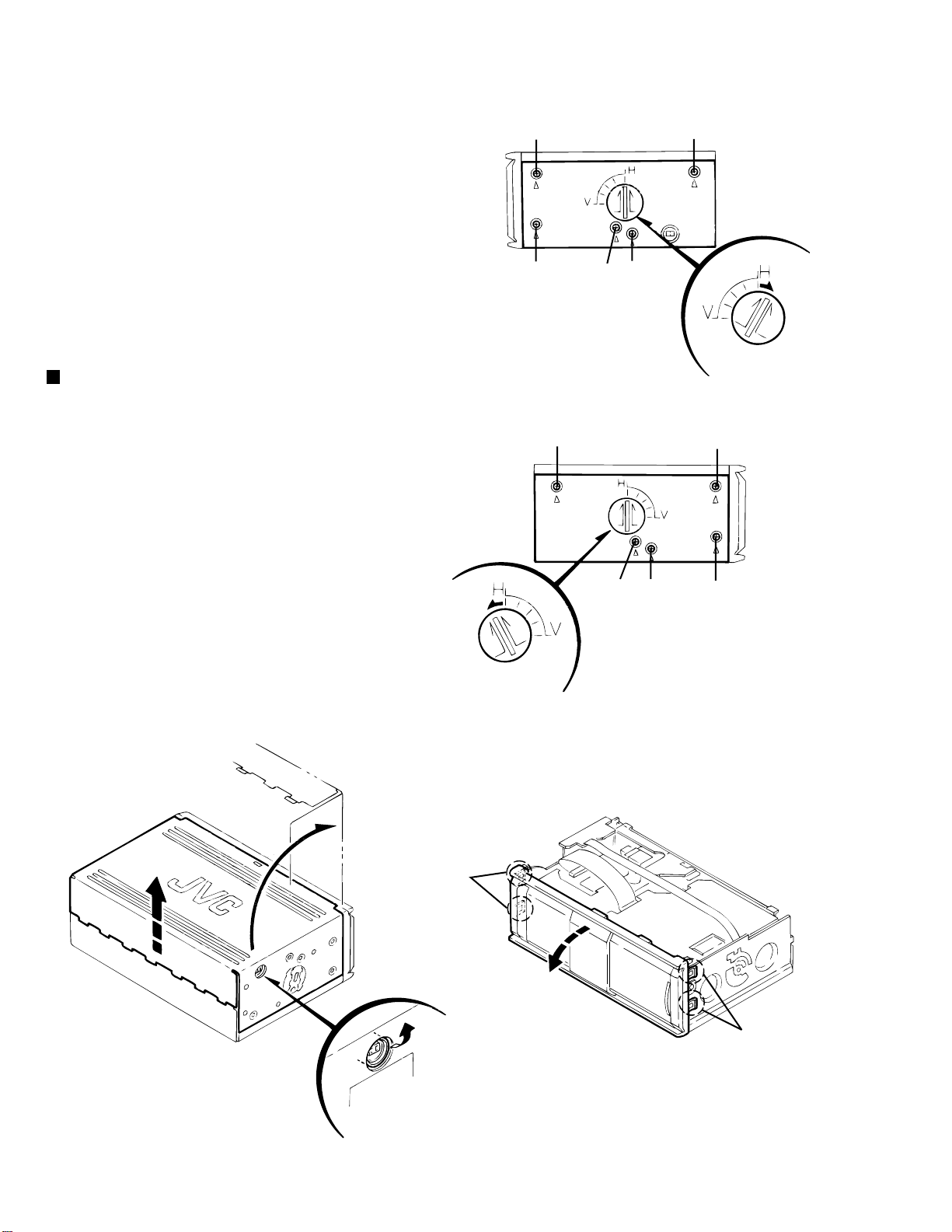

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

DANGER : Invisibie laser radiation

when open and interlock or

defeated.

AVOID DIRECT EXPOSURE TO

BEAM (e)

VARNING : Osynlig laserstrålning är

denna del är öppnad och spårren är

urkopplad. Betrakta ej strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettaessa olet alttiina

näkymättömälle lasersäteilylle.Älä

katso säteeseen. (d)

ADVARSEL :Usynlig laserstråling

ved åbning , når

sikkerhedsafbrydere er ude af

funktion. Undgå udsættelse for

stråling. (f)

!

CAUTION

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

Caution.

This production

contains laser

component

of higher laser class

than Class 1.

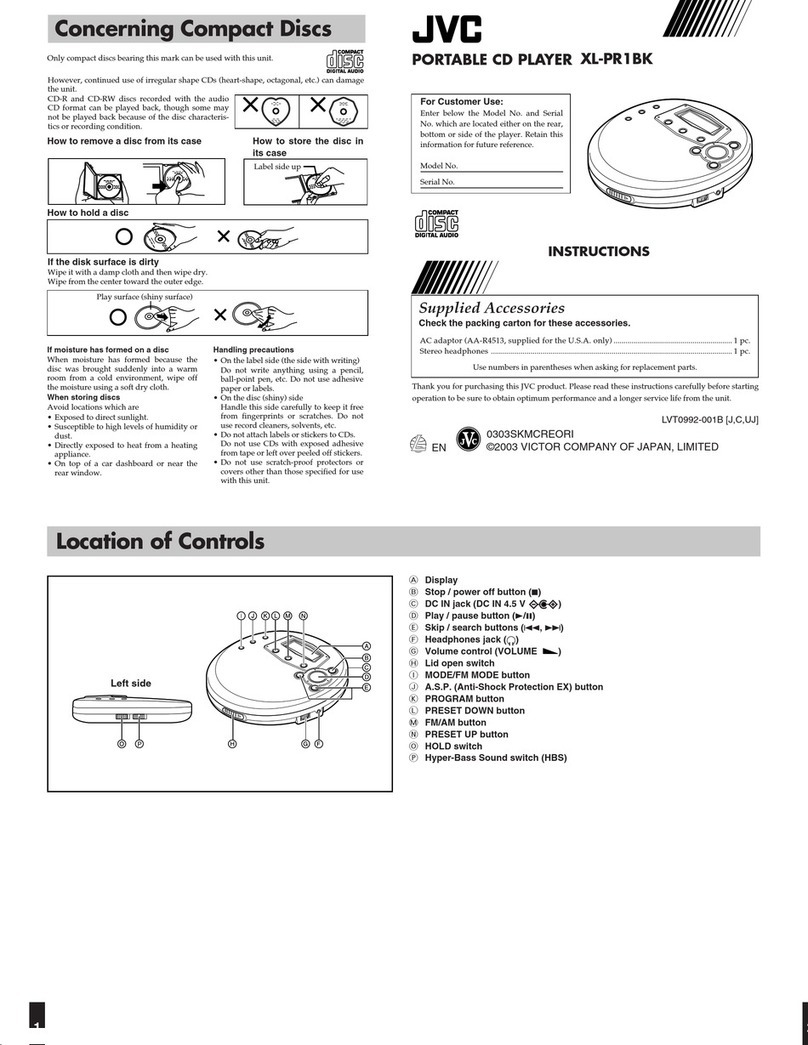

Top panel of the unit

Gerateoberseite

Panneau superieur de l"appereil

1-3