TABLE OF CONTENTS

Section Title Page Section Title Page

Important Safety Precautions

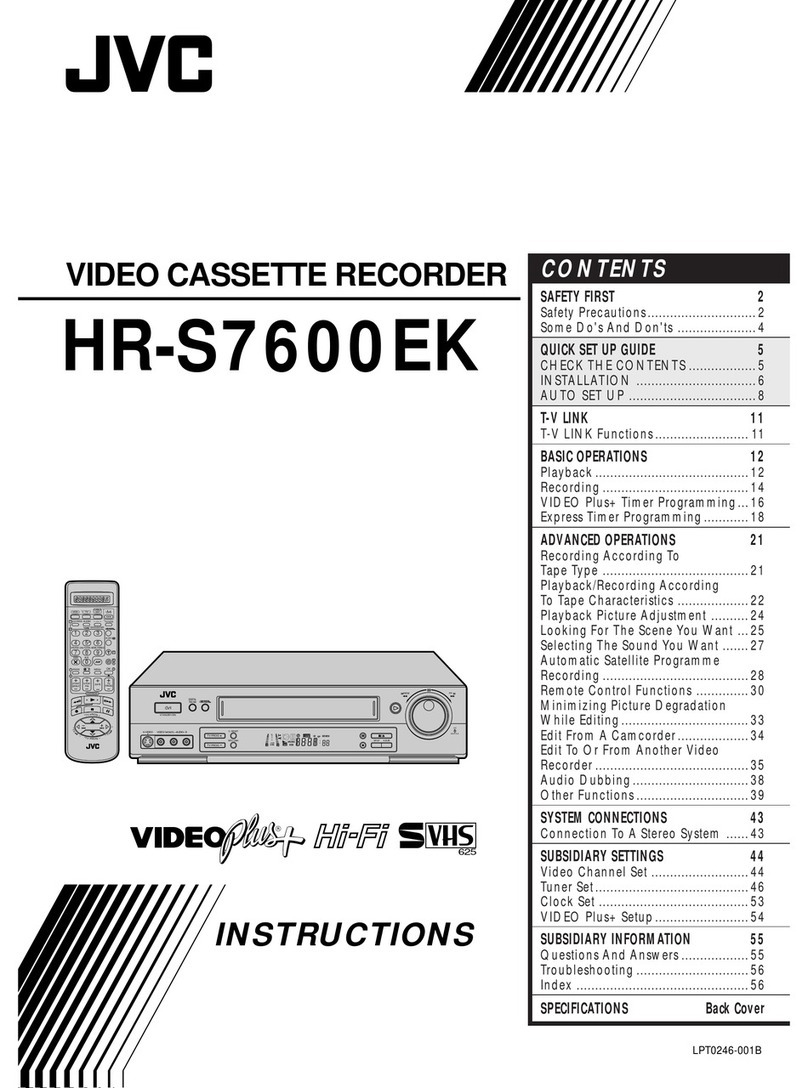

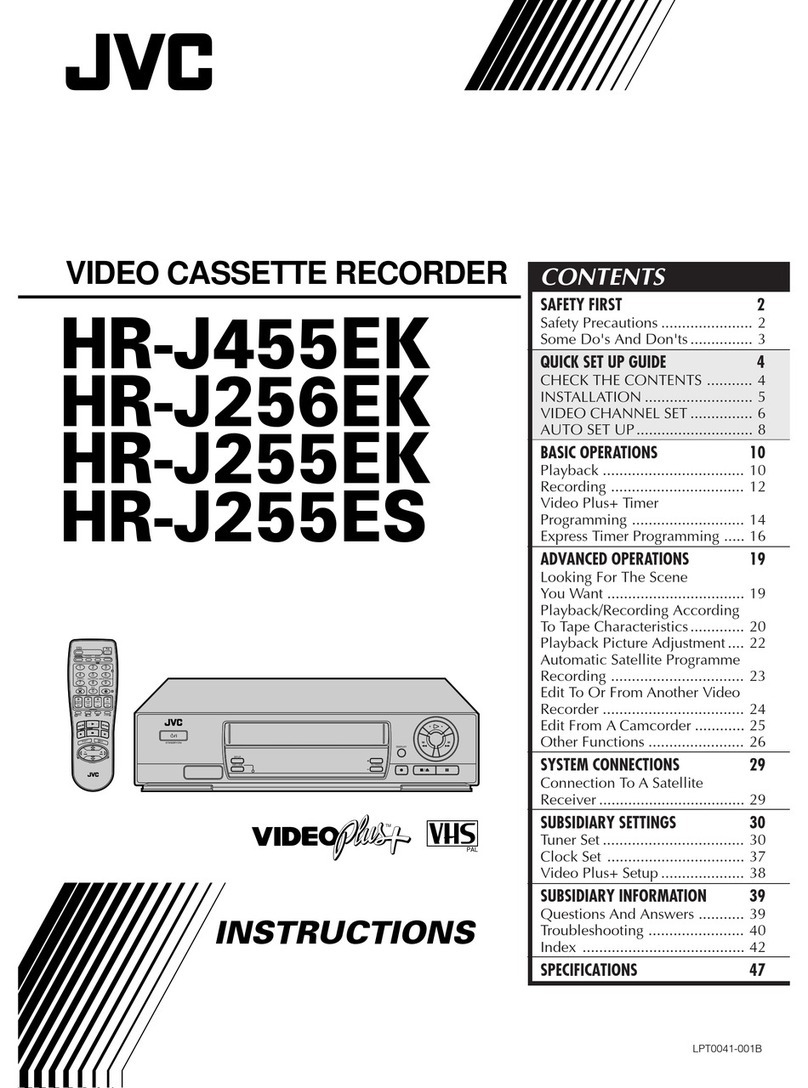

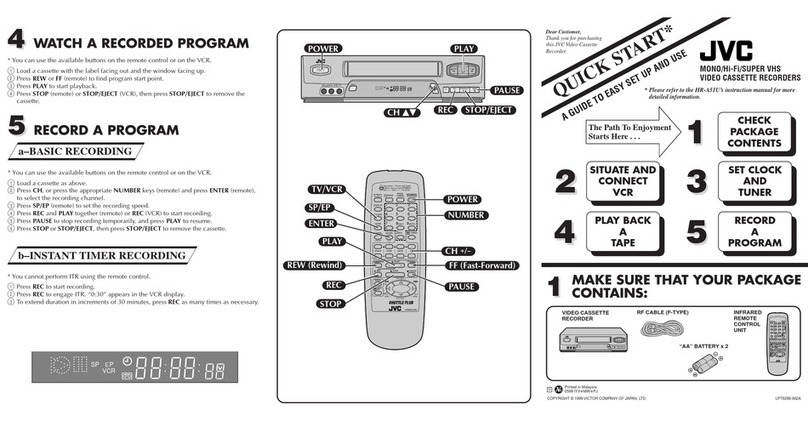

INSTRUCTIONS

DISASSEMBLY INSTRUCTION

1.REMOVAL OF MECHANICAL PARTS AND

P.C.BOARDS ..................................................................1-1

1-1 TOP CABINETAND FRONT CABINET ..................1-1

1-2 FLAP .......................................................................1-1

1-3 DECK CHASSIS .....................................................1-1

1-4 SYSCON PCB.........................................................1-1

2.REMOVAL OF DECK PARTS .........................................1-2

2-1 TOP BRACKET .......................................................1-2

2-2 CASSETTE HOLDER ASS’Y ..................................1-2

2-3 CASSETTE SIDE L/R .............................................1-2

2-4 LINK UNIT ...............................................................1-2

2-5 LINK LEVER/FLAP LEVER.....................................1-2

2-6 LOADING MOTOR/WORM .....................................1-3

2-7 TENSION ASS’Y .....................................................1-3

2-8 T BRAKE ARM/T BRAKE BAND .............................1-4

2-9

S REEL/T REEL/IDLERARM ASS’Y/IDLER GEAR ........

1-4

2-10 CASSETTE OPENER/PINCH ROLLER

BLOCK/P5 ARM ASS’Y...........................................1-5

2-11 A/C HEAD ...............................................................1-5

2-12 FE HEAD(RECORDER ONLY) ...............................1-5

2-13 AHC ASS’Y/CYLINDER UNIT ASS’Y......................1-5

2-14 CAPSTAN DD UNIT ................................................1-6

2-15

MAIN CAM/PINCH ROLLER CAM/JOINT GEAR ............

1-6

2-16

LOADING GEAR S/T UNIT..............................................

1-6

2-17

CLUTCH ASS’Y/RING SPRING/

CLUTCH LEVER/CLUTCH GEAR ...................................

1-7

2-18

CASSETTE GUIDE POST/

INCLINED BASE S/T UNIT/P4 CAP ................................

1-7

3.

REMOVALAND INSTALLATION OF FLAT PACKAGE IC ........

1-8

REMOVAL........................................................................1-8

INSTALLATION ................................................................1-9

KEY TO ABBREVIATIONS .............................................1-10

PREVENTIVE CHECKS AND SERVICE INTERVALS....1-12

CLEANING......................................................................1-12

SERVICE MODE LIST.....................................................1-13

SERVICING FIXTURES AND TOOLS.............................1-13

MECHANISM ADJUSTMENT PARTS LOCATION GUIDE.......

1-13

MECHANICAL ADJUSTMENTS

TAPE REMOVAL METHODAT NO POWER SUPPLY ....1-14

1.CONFIRMATION AND ADJUSTMENT .........................1-14

1-1 CONFIRMATION AND ADJUSTMENT OF

TENSION POST POSITION .................................1-14

1-2 CONFIRMATION OF PLAYBACK TORQUEAND

BACK TENSION TORQUE DURING PLAY BACK..1-14

1-3 CONFIRMATION OF VSR TORQUE ....................1-14

1-4 CONFIRMATION OF REEL BRAKE TORQUE .....1-15

2.CONFIRMATION AND ADJUSTMENT OF

TAPE RUNNING MECHANISM ....................................1-15

2-1 GUIDE ROLLER ...................................................1-15

2-2 CONFIRMATION AND ADJUSTMENT OF

AUDIO/CONTROL HEAD .....................................1-16

2-3

TAPE RUNNING ADJUSTMENT(X-VALUE ADJUSTMENT) ...

1-16

ELECTRICAL ADJUSTMENTS

1.BASIC ADJUSTMENT ..................................................1-17

1-1 SWITCHING POINT..............................................1-17

ELECTRICALADJUSTMENT PARTS LOCATION GUIDE ........

1-17

IC DESCRIPTIONS .........................................................1-18

SERVO TIMING CHART .................................................1-21

MECHANISM TIMING CHART........................................1-22

TROUBLESHOOTING GUIDE

POWER DOES NOT TURN ON ..............................................

1-23

POWER SHUTS OFF ....................................................1-24

CYLINDER NOT ROTATING DURING PLAYBACKAND RECODRDING..

1-26

CASSETTE IN AND DOWN, UNIT HAS NO FUNCTIONS .....

1-26

FF/REW DO NOT WORK ..............................................1-27

AUDIO SHAKES ............................................................1-27

CASSETTE TAPE IS NOT ACCEPTED.........................1-28

WHEN INSERTING CASSETTE, IT EJECTS IMMEDIATELY ..

1-30

TAPE LOADING IS OK, BUT UNLOADS IMMEDIATELY..

1-32

CAPSTAN DD MOTOR NOT ROTATING ......................1-33

PLAYBACK PICTURE JITTERS HORIZONTALLY ........1-34

PLAYBACK PICTURE SHAKES ....................................1-34

AUTO TRACKING DOES NOT OPERATE ....................1-35

WHEN PLAYBACK, FAST FORWARD OR REWIND MODE ISACTIVATED,

UNIT STOPS IMMEDIATELY

.....................................................1-35

PLAYBACK PICTURE JITTERS VERTICALLY .............1-36

NO PLAYBACK PICTURE .............................................1-37

NO PICTURE DURING PLAYBACK ..............................1-38

NO COLOR DURING SELF RECORDING AND PLAYBACK .

1-38

PLAYBACK PICTURE NOISY(EVEN AFTER CLEANING HEADS) ...

1-39

NO NORMALAUDIO ON PLAYBACK ...........................1-40

AUDIO CAN NOT BE RECORDED ...............................1-41

RECORDING MECHANISM WORKS,

BUT NO VIDEO RECORDED FROM INPUTJACK OR TUNER ..

1-42

NO E-E(NO VIDEO FROM TUNER)..............................1-43

NO E-E AUDIO(MONO) .................................................1-44

NO TUNER AUDIO(MONO)...........................................1-45

CHARTS AND DIAGRAMS

INTERCONNECTION DIAGRAM [HR-J3009UM]..............2-1

Y/C/AUDIO/CCD/HEADAMP SCHEMATIC DIAGRAM [HR-J3009UM] ...

2-3

SYSTEM CONTROL/SERVO SCHEMATIC DIAGRAM [HR-J3009UM]...

2-5

POWER SCHEMATIC DIAGRAM [HR-J3009UM] .............2-7

TUNER SCHEMATIC DIAGRAM

[HR-J3009UM] ................ 2-9

OPERATION SCHEMATIC DIAGRAM

[HR-J3009UM] ......... 2-11

SYSCON CIRCUIT BOARD(INSERTED PARTS) [HR-J3009UM] ..

2-13

SYSCON CIRCUIT BOARD(CHIP MOUNTED PARTS) [HR-J3009UM] ...

2-15

WAVEFORMS [HR-J3009UM] .........................................2-18

Y/C/AUDIO/HEAD AMP BLOCK DIAGRAM [HR-J3009UM] ...

2-19

SYSTEM CONTROL/SERVO BLOCK DIAGRAM [HR-J3009UM] ...

2-21

TUNER BLOCK DIAGRAM [HR-J3009UM] .....................2-23

OPERATION BLOCK DIAGRAM [HR-J3009UM] ............2-25

INTERCONNECTION DIAGRAM [HR-J4009UM]............2-27

Y/C/AUDIO/CCD/HEADAMP SCHEMATIC DIAGRAM [HR-J4009UM]

2-29

SYSTEM CONTROL/SERVO SCHEMATIC DIAGRAM [HR-J4009UM]

2-31

POWER SCHEMATIC DIAGRAM [HR-J4009UM] ...........2-33

TUNER SCHEMATIC DIAGRAM

[HR-J4009UM] .............. 2-35

OPERATION SCHEMATIC DIAGRAM

[HR-J4009UM] .........2-37

SYSCON CIRCUIT BOARD(INSERTED PARTS) [HR-J4009UM] ..

2-39

SYSCON CIRCUIT BOARD(CHIP MOUNTED PARTS) [HR-J4009UM] ...

2-41

WAVEFORMS [HR-J4009UM] .........................................2-44

Y/C/AUDIO/HEAD AMP BLOCK DIAGRAM [HR-J4009UM] ...

2-45

SYSTEM CONTROL/SERVO BLOCK DIAGRAM [HR-J4009UM] ...

2-47

TUNER BLOCK DIAGRAM [HR-J4009UM] .....................2-49

OPERATION BLOCK DIAGRAM [HR-J4009UM] ............2-51

PARTS LIST

3.1 PACKING AND ACCESSORY ASSEMBLY <M1> .....3-1

3.2 FINALASSEMBLY <M2> [HR-J3009UM].................3-2

3.3 FINALASSEMBLY <M2> [HR-J4009UM].................3-3

3.4 MECHANISM ASSEMBLY <M4>...............................3-4

3.5 ELECTRICAL PARTS LIST [HR-J3009UM]...............3-7

SYSCON BOARD ASSEMBLY <03> [HR-J3009UM] ...

3-7

3.6 ELECTRICAL PARTS LIST [HR-J4009UM].............3-10

SYSCON BOARD ASSEMBLY <03> [HR-J4009UM] ..

3-10

Reference..........................................................................4-1

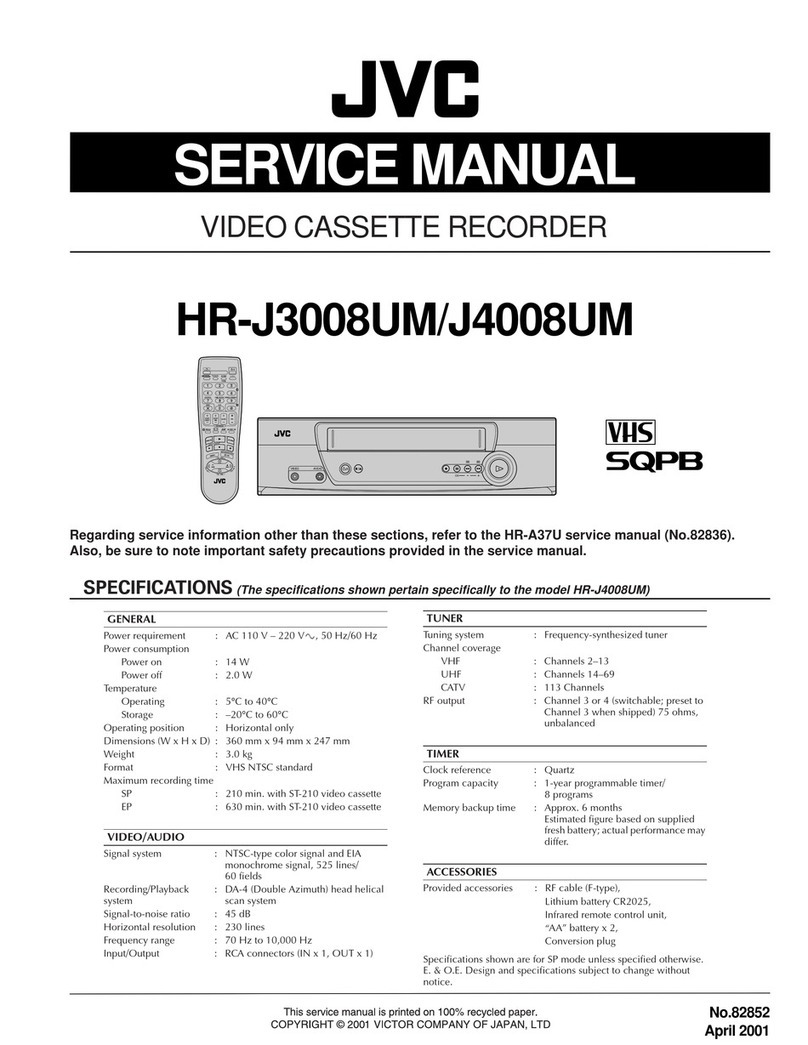

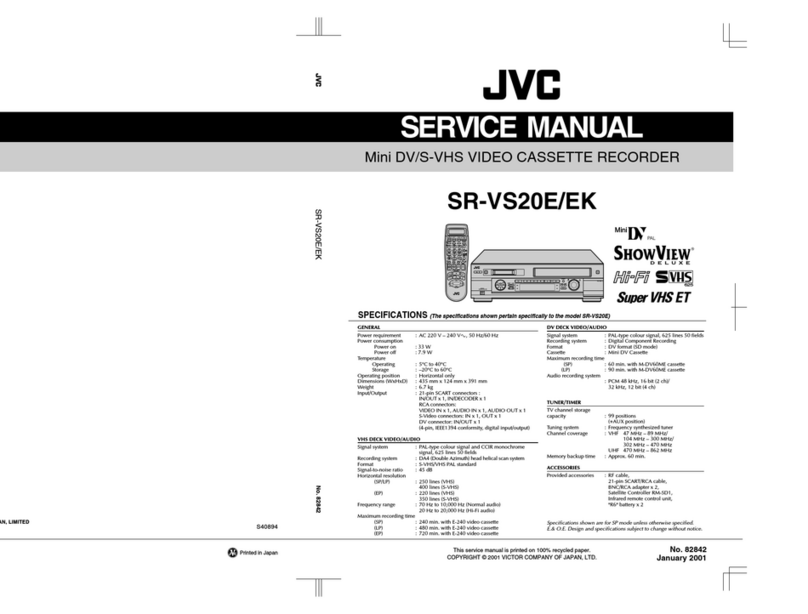

GENERAL SPECIFICATIONS [HR-J3009UM] ..................4-1

GENERAL SPECIFICATIONS [HR-J4009UM] ..................4-7

HR-J3009UM HR-J4009UM

POWER VOLTAGE 120 V 60 Hz 110-220 V 50/60 Hz

TIMER BACK-UP (at Power off mode) 5 second 18 Hours

The following table lists the differing points between Models HR-J3009UM and HR-J4009UM.

MODEL

ITEM