DN082-02v02

JYE Tech - 5 - www.jyetech.com

Fig 7

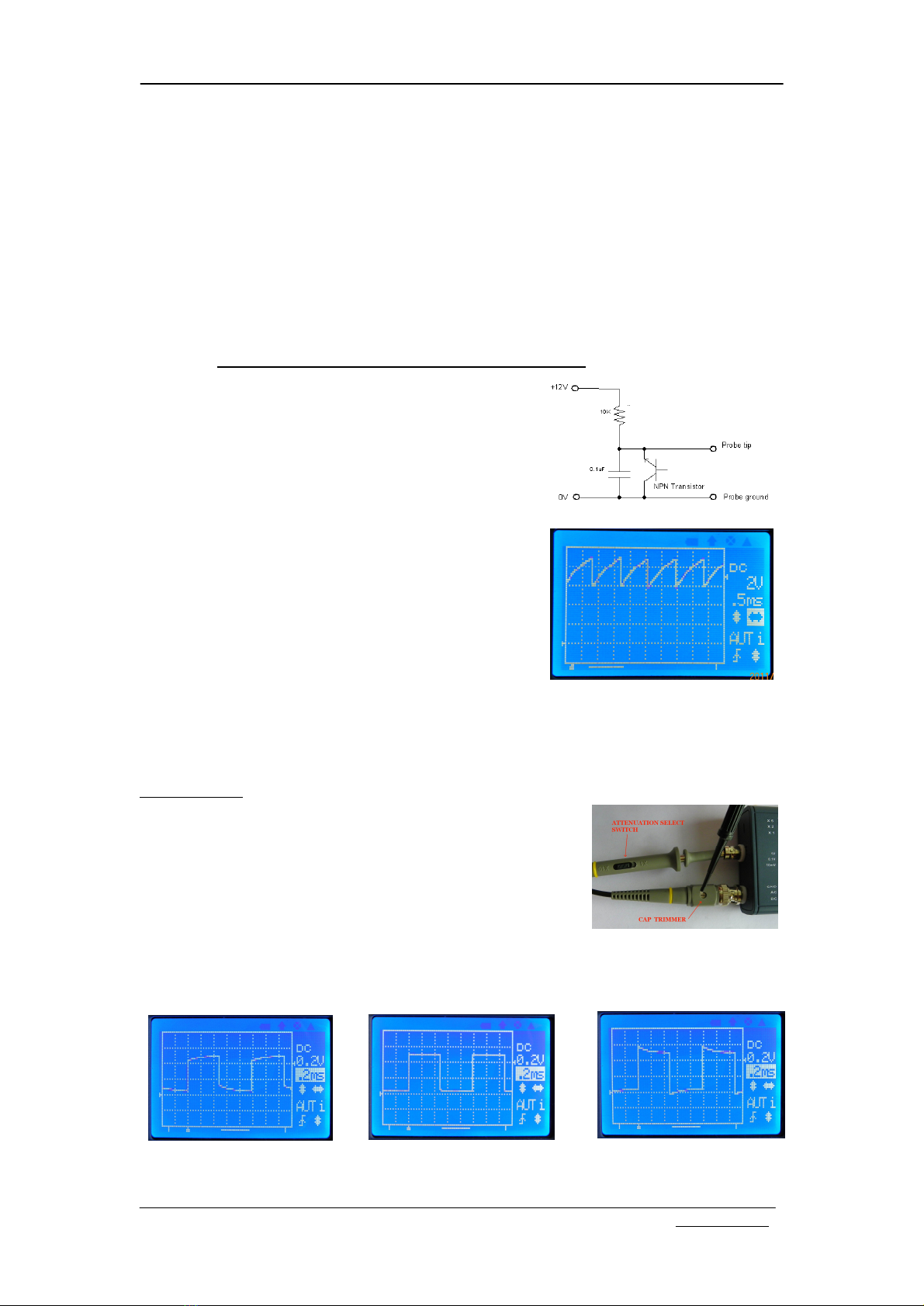

Fig 8

Vertical Position Zeroing

Sometimes you mayfind the vertical position indicator is not aligned to 0V level trace. This is caused bytwo

factors.

1) Component errors.

2) Interference fromthe ADC clock.

In order toreducethemisalignment a “VerticalPosition Zeroing”function was implemented as workaround on

the DSO082. What it actuallydoes is to add correction values to samples so that misalignment does not appear to

be that large. However,even withthiscorrection somemisalignment stillexists (varies depending on Time-base

settings between 1 3pixels,). This misalignment causes someinconvenience but will not affect the measurement

results. Users can use the VPos triangle as arough indicatoronly.Use where the 0V level is as areference point

and start measurements fromthere.

Touse the “Vertical Position Zeroing”function first set the coupling switch to the “GND”position. Then press

[VPOS]button and hold itdownfor about 3seconds.The VPos zeroing prompt screen will appear.Followthe

instructions on the screen to continue.

Please note thatvertical position zeroing isdependent upon theindividual Time-base setting. Thismeans that

for each Time-base setting there is aspecific correction value, which the zeroing process generates for that

individual Time-base. But 1ms/Div Time-base is special. Zeroing carried under 1ms/Div will set all corrections to

the samevalue. So for anewoscilloscopevertical position zeroing shouldbe first done to1ms/Div.Usuallyonce

zeroing under1ms/Div is doneVPos alignments for most ofthe rest Time-base settings are ok. Ifthe misalignment

is found too large for an individual Time-base, then you should carry out zeroing for that Time-base.

Rolling Display Mode

When Time-base is set to 0.1s/Divor slower DSO 082 uses adisplaymode called “Rolling”.In thismode the

trace shifts fromright to left, simulating time passing.

LCD Backlight ON/OFF

Pressing [MODE]and [LEVEL]at the sametimewill toggle the LCD backlight ON/OFF.This is useful when

the oscilloscope is running on batterypower.

PowerOff

Topower offthe oscilloscopepushdownthe adjustment knob and holditfor about 3seconds. The oscilloscope

will enter stand-bymode where most ofcircuits are powered off. Onlykeypad remains active.

6. Advanced Operations

Select Record Length

In normal running mode pushing and holding downthe [HPOS] button

will make the device enter the Record Length Selection screen (see Fig 7).

Use the adjustment knob to select the record length you want and press

[HOLD]to Exit and return to normal running mode.

Formost applicationsrecord length of2000 points isenough and is thus

recommended. This will allowthe oscilloscope response timeto be faster.If

alonger record length is selected the slower the response will be expected

because the device needs more timeload the buffer before starting anew

captured signal sample. Particularly,when the Time-base is set to 20ms/Div

or 50ms/Div and the record lengthof10000 or larger is selected; you will see

a significantlyslower displayupdate.

Change TriggerPosition

In normal running mode pushing and holding downthe [LEVEL] button

will make the device enter theTrigger Position selection screen (see Fig 8).

Use the adjustment knob toselect the trigger position you want and pressing

the [HOLD]button Exits and returns to normal running mode.

The Trigger position can beset to1/8, 1/4, 1/2, 3/4, or 7/8 in the captured

signal sample buffer (regardless ofrecord length setting). Ifthe trigger

position is setto 1/8 this means the first 1/8ofthebuffer keeps the sample

taken before trigger point, and 7/8 ofthe buffer keeps asample taken after

the trigger point. Ifthetrigger position is setto 1/2 this means buffer size

used tokeep samples before and after trigger point is halfand half.Apparently,

ifyou are more interested inwaveformsafter the trigger point you shouldset thetrigger position to a smaller value.

And ifyou are more interested in a signal before the trigger then a larger trigger position setting should be used.

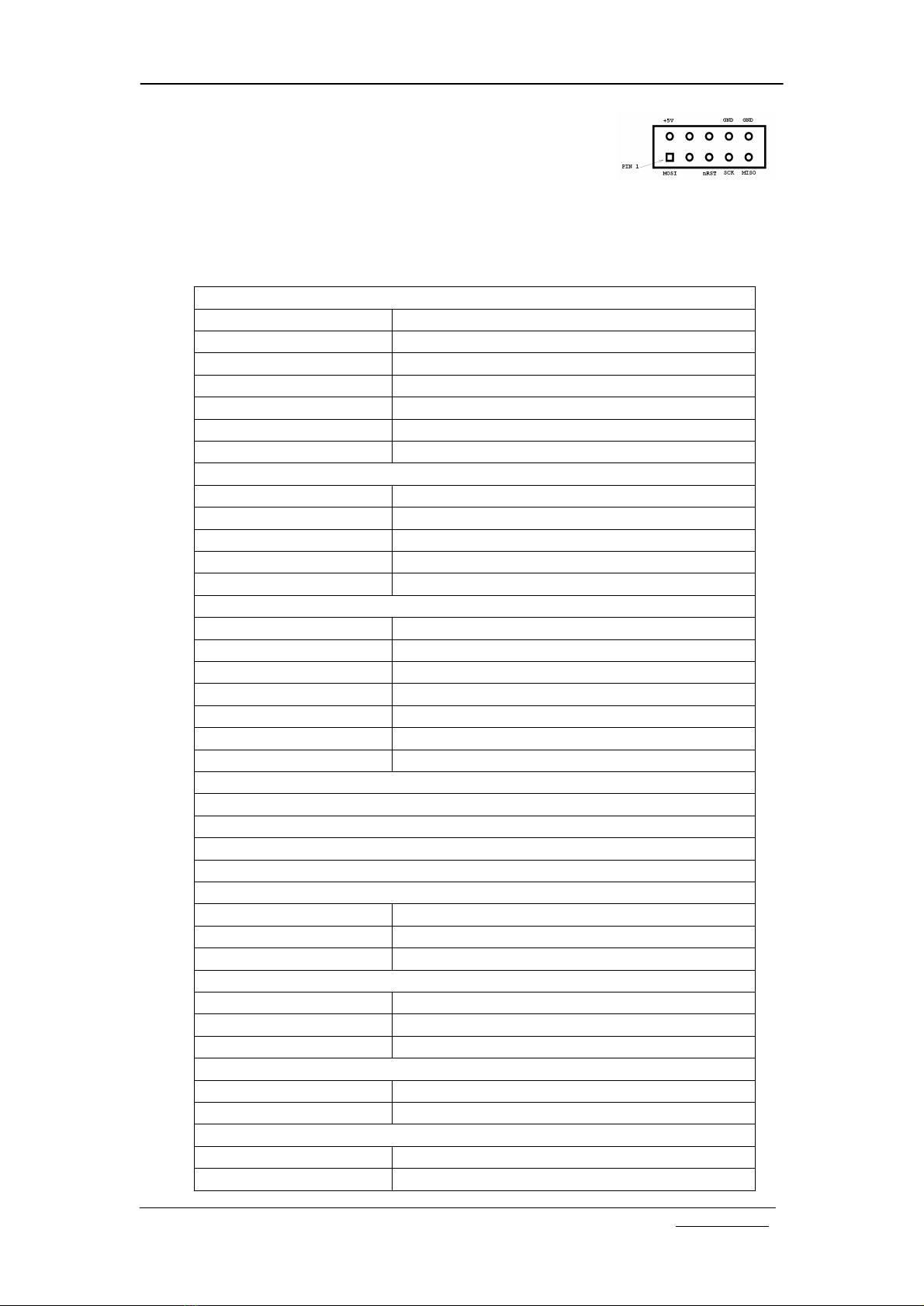

USBConnection

The USB connection used in082 is avirtual Uart portbased on the dedicated Uart-USB convert chip CP2102

fromSilicon Lab. Tousetheconnection, you need to installthe PC drivers. Drivers for Windowsand Linux can be

downloaded fromthe Silicon Lab’s web site.