2

1 SAFETY INSTRUCTIONS

1.1 SAFETY RULES FOR ALL MACHINES WEAR PROPER APPAREL.

(1.) Always wear eyes protection. Also use face or dust mask if cutting operation is

dusty.

(2.) Wear proper apparel. Do not wear loose clothing, gloves, rings, bracelet etc., there

is hazard of entanglement.

(3.) Wear protective hair covering to contain long hair.

(4.) Keep proper footing and balance at all times. Non-slip footwear is recommended.

(5.) Keep children away from the machine. Serious injury could occur if the tool is

tipped or if the cutting machine is accidentally contacted.

(6.) Don’t leave machine until it comes to a complete stop.

(7.) Do not operate machine while under the influence of alcohol or any medication.

(8.) Make sure the plug is disconnected from power supply while making maintenance,

adjustment or repair.

(9.) Always keep hands and fingers away from the aiguille.

(10.) Do not force the machine. It will do the job better and safer at the ratings for which it

was designed.

(11.) Use clamps to hold work piece when operating.

(12.) Consult the operator’s manual for recommended accessories. The use of improper

accessories may cause hazard.

(13.) Avoid accidental starting. Always make sure the low/high speed switch is in ‘0’

position before plugging in power cord.

(14.) Grounding the machines. Always make sure your machine is well connected to the

earth. It may reduce electric shock hazards.

(15.) Do not install & use the machine in flammable, explosible or damp environment.

(16.) For your hearing health, we advise the operator to wear hearing protection when

necessary.

(17.) Do not start the machine until all safeguards are located to their position.

Hazards may occur when running with safeguards opened.

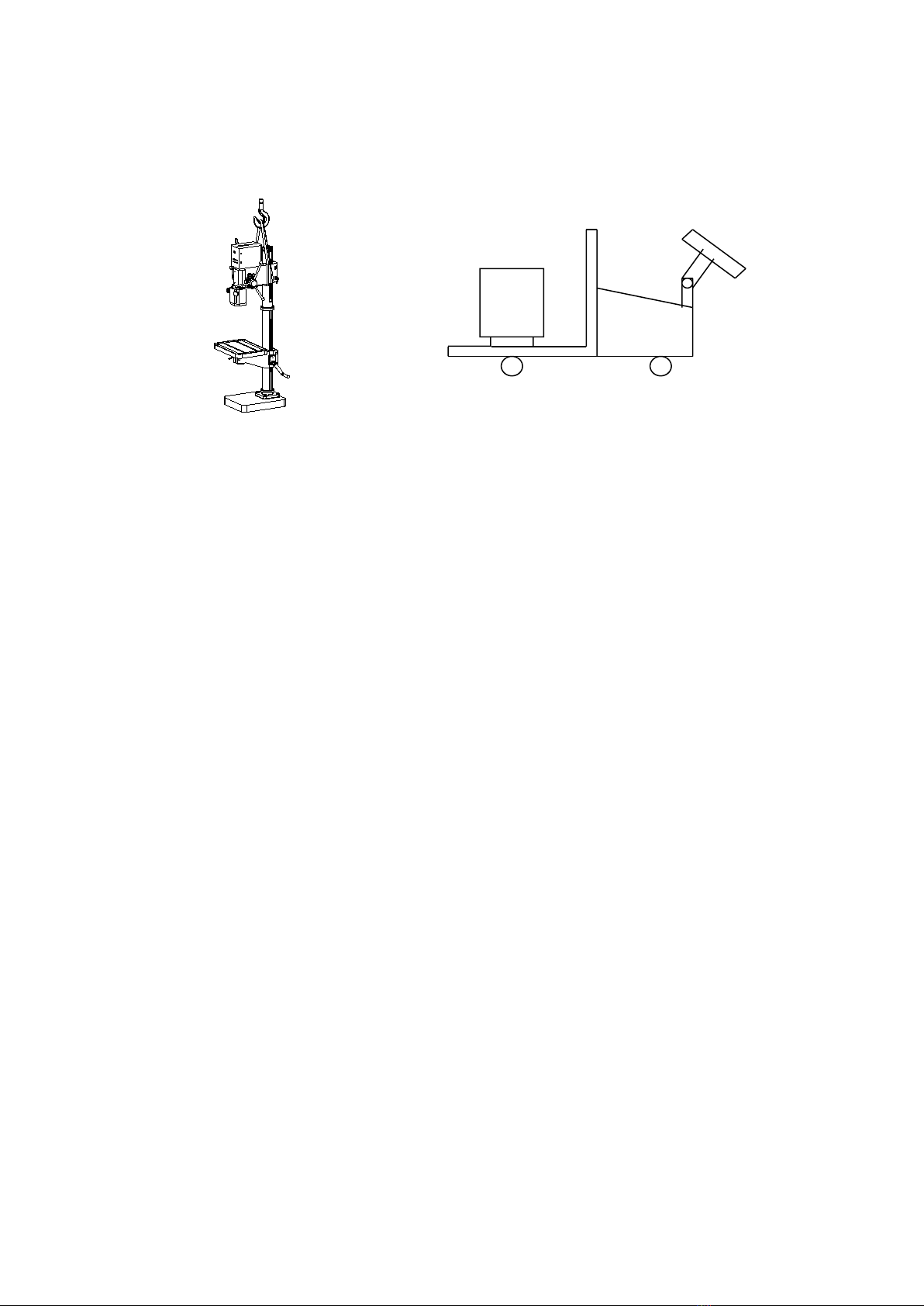

(18.) Fix the machine to the floor for enough stability when machining long and heavy

workpiece. Proper lifting equipment is required for workpieces over 10 kg in weight.

Provision shall be provided by the end user for installation and operation of lifting

equipment.

(19.) The speed adjustment must be done only when the machine stops.

(20.) The machine tool must only be used for the purpose it has been designed for. Never

use the machine tool without the limits established by the technical data.

(21.) Do not neglect regular inspections in accordance with the instructions for use.

(22.) Operation, setting and maintenance including shall be achieved by the required skill

level of operators.

(23.) It should use certain tools in case avoid being scalded for the hot blade tools after

drilling.

(24.) Don’t put the fingers on drilled hole in case to protect the safety of finger.

(25.) The swarf is sharp after drilling, it should use certain tool to clean in order to avoid

fingers being hurt.

(26.) Pay attention to the spindle rotation direction when take the first trial run, the direction

should be the same with the direction which indicated on front of the machine. When the

rotation is not right, you can change the rotaion in the plug conveniently.

(27.) Pay attention to the relationship between the diameter of drill and spindle speed. The spindle

speed must decrease with the increasing of drill diameter. When the diameter of drill is Φ25mm, the

spindle speed shall be lower than 600rpm; Only when drill diameter is Φ3mm, the maximum

spindle speed can be selected.