2.3 Requirement of operating site

This machine is designed for operating on the site:

- Voltage The steady-state AC power supply is 0.9~1.1 times of the rated value.

- Frequency 0.99~1.01 times of rated frequency (continuous working)

0.98~1.02 times of rated frequency(short period working)

- Harmonics The sum of 2nd-5th distorted harmonic must not exceed 10% of RMS of voltage, maximum

2% of RMS of line voltage is allowed to add to the sum of 6th-30th harmonic.

- Unbalanced voltage of 3-phase power supply

Negative sequence component are not allowed to exceed 2% of the positive sequence component.

- Short-circuited protection and incoming line

The machine shall have short-circuited protective device at the power supply end by the end-user, the

rated current shall be 5A, and the diameter of the incoming line of the power supply must not be less

than 1.5mm2 (single phase) and 1.5mm2 (PE).

- Overvoltage protection

Overvoltage protection device shall be provided in the power supply line by the end user.

- The height above sea level of the machine installation doesn’t exceed 1000m;

- The ambient temperature range of air is 5℃~40℃.

- The relative humidity doesn’t exceed 50% at a maximum temperature of +40 ℃ .

Higher relative humidity may be permitted at lower temperature (e.g.90% at 20℃)

- Lighting of the work zone should be at least 500lux(provide by end user).

- The installation site of the machine shall be away from undesirable vibration, shock or bump.

3 Description of machine

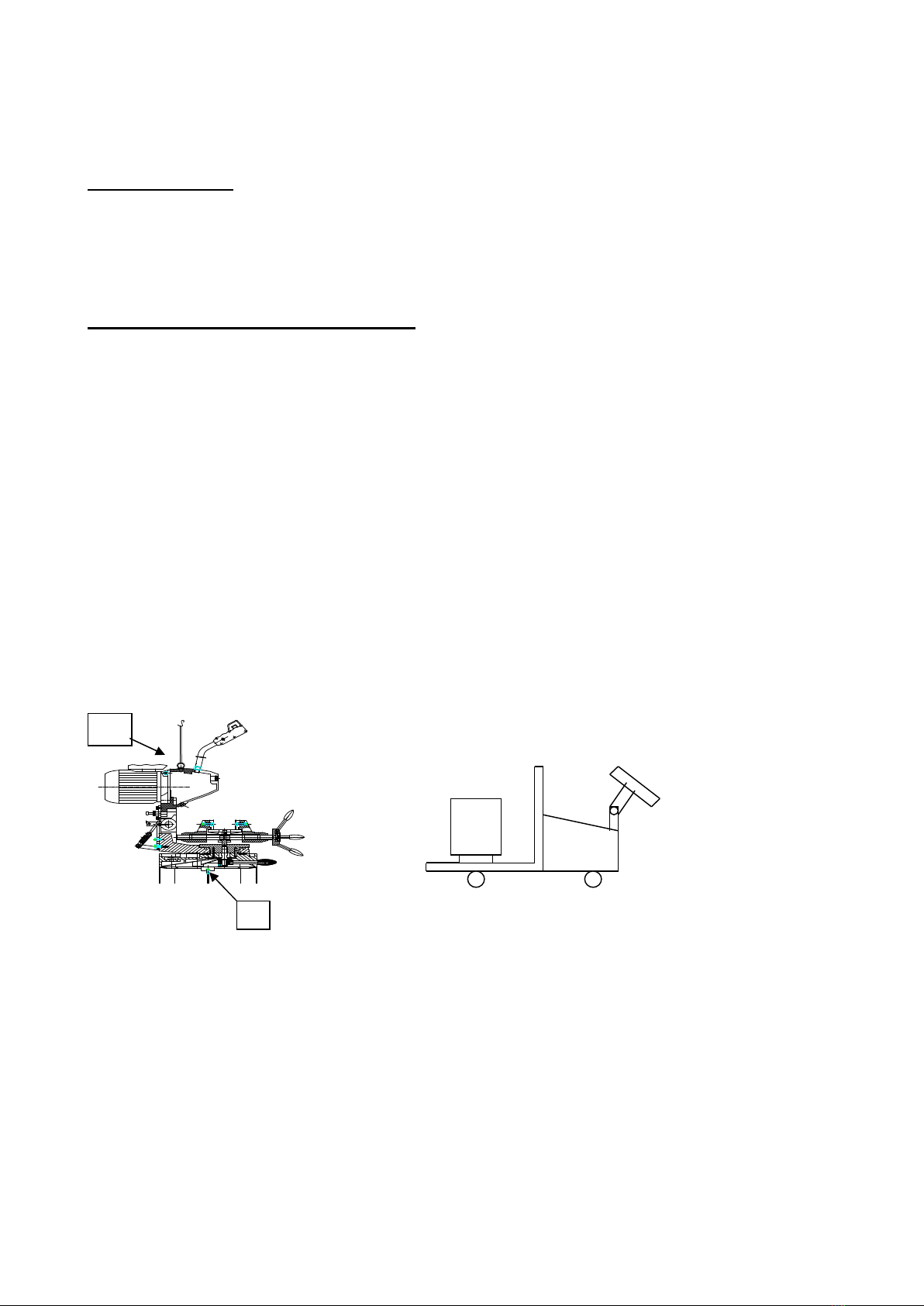

3.1 Description

Circular Saw consists of 6 models which have the same construction and each of which meets the same

high quality requirements.

The constructive differences apply to the application and the specific wishes of the user.

All versions are standardly equipped with a machine based with incorporated cutting oil tank and pump.

All versions are fitted with a tolerance-free long-life worm and worm wheel. The worm gear runs in an oil

bath case and is virtually maintenance-free.

All versions are fitted with a double, self-centring material vice.

The machine can mitre, slot and cut recessed corners in both directions. For this !ast form of operation it

is of special importance that the saw unit as a whole can turn around its axis.

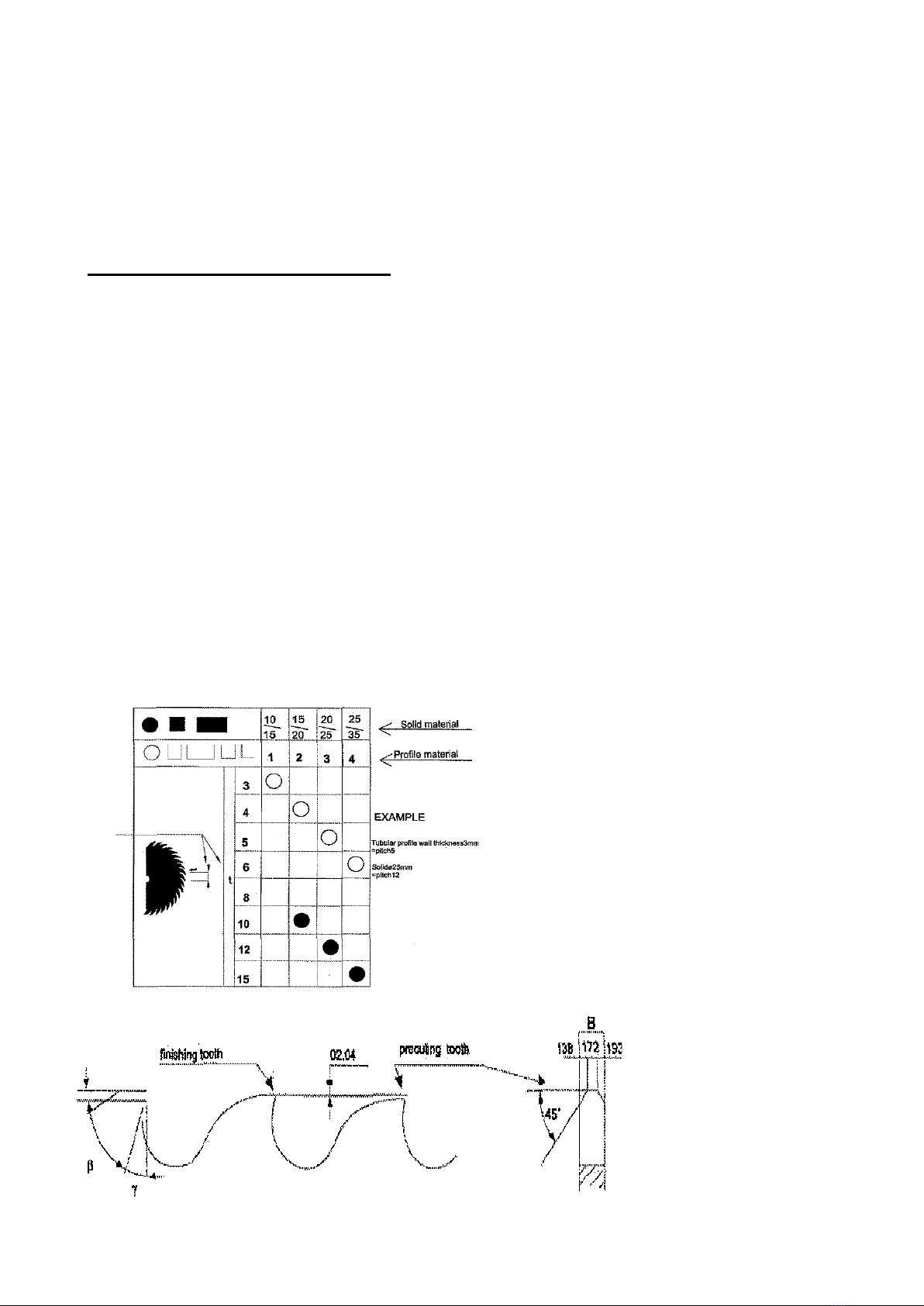

The machine can saw various profiles in various dimensions and cross-sections. A survey of these can

be found in chapter 5,3 "Sawing capacity",

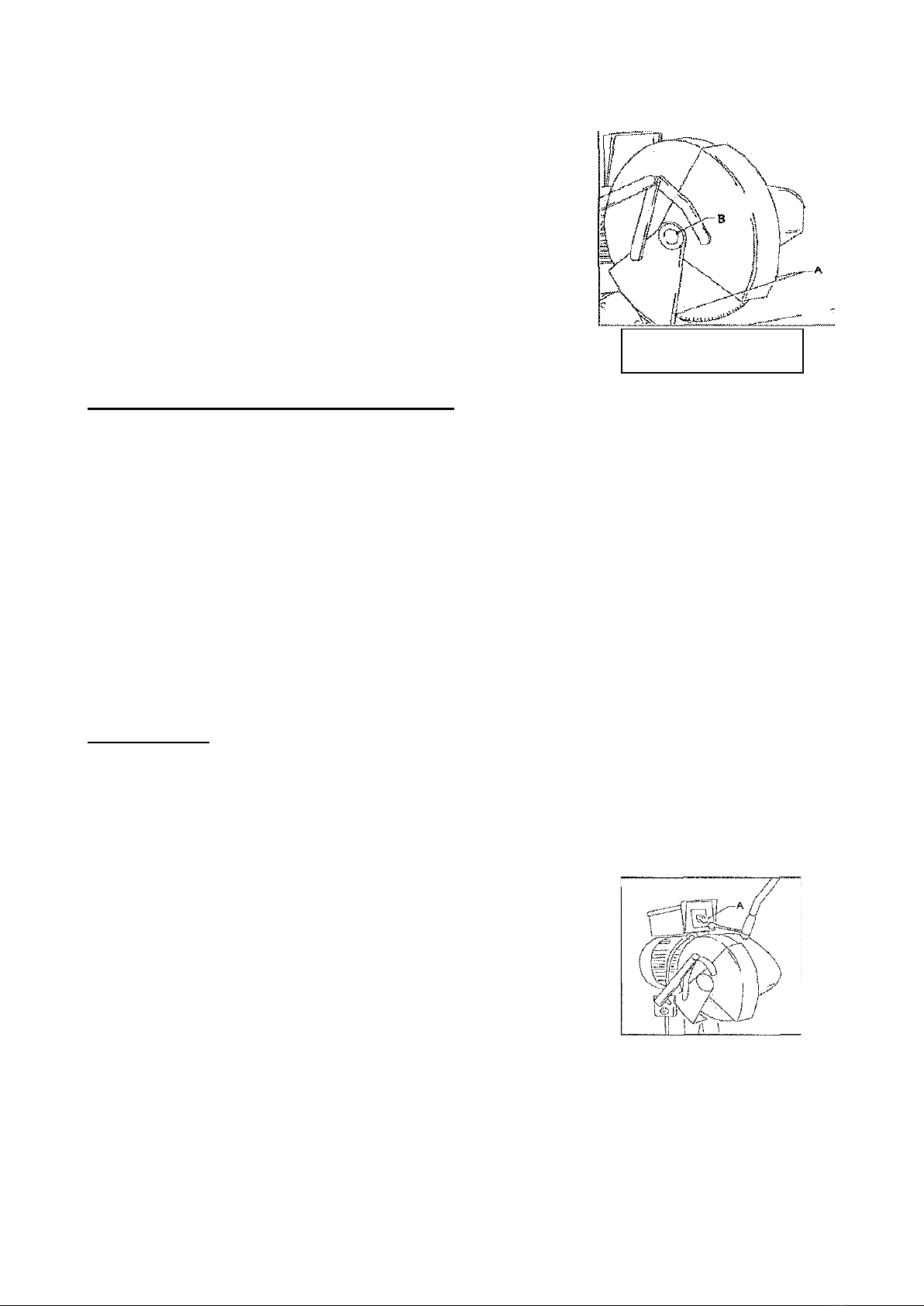

The patented protective guard opens and closes automatically. The saw blade can easily be exchanged.

The machine as standard is equipped with an adapter for the saw blade (see technical data). If ordered a