4

Section 1: Welcome to the OBD II System Tester

1-1 Overview

OBD II (On-Board Diagnostic, second generation) systems are designed to meet or

exceed a set of standards and regulations designed to im rove air quality. The

Environmental Protection Agency (EPA), in conjunction with California Air Research

Board (CARB), issued these standards and regulations through the Clean Air Act

of1990. OBD II systems are required to monitor the erformance of emission related

systems and their com onents. The ability to detect hard and intermittent faults are

further requirements of an OBD II com liant system. The Society of Automotive

Engineers (SAE) defined several standards for OBD II systems. These standards

include criteria for the diagnostic link connector, communication, Diagnostics trouble

codes (DTCs), descri tor names, and other re air information.

This OBD II System Tester will work on OBD II com liant cars and light trucks. If you

use a vehicle service manual along with the tester, you will be able to diagnose and

re air many automotive-related roblems. Before roceeding, make sure you have

read and fully understand the material in this Manual.

1-2 The OBD II System Tester

KAL Equi s OBD II System Tester was develo ed by ex erts in the automotive

service industry to hel diagnose todays vehicles and assist in troubleshooting

rocedures. When a roblem occurs in the vehicle, its com uter will store a record of

the event and take corrective action to adjust the circuit at fault. The OBD II System

Tester will allow you to monitor these vehicle events and read DTCs from the

com uters memory to in oint roblem areas. The OBD II System Tester will

inter ret the com uter signals and rovide you with a real time readout of vehicle

data. In addition, the Code Looku feature allows you to reference code descri tions

without having to age through an instruction manual. A detailed descri tion of the

functions are rovided in Section 2: Diagnosing with the Tester.

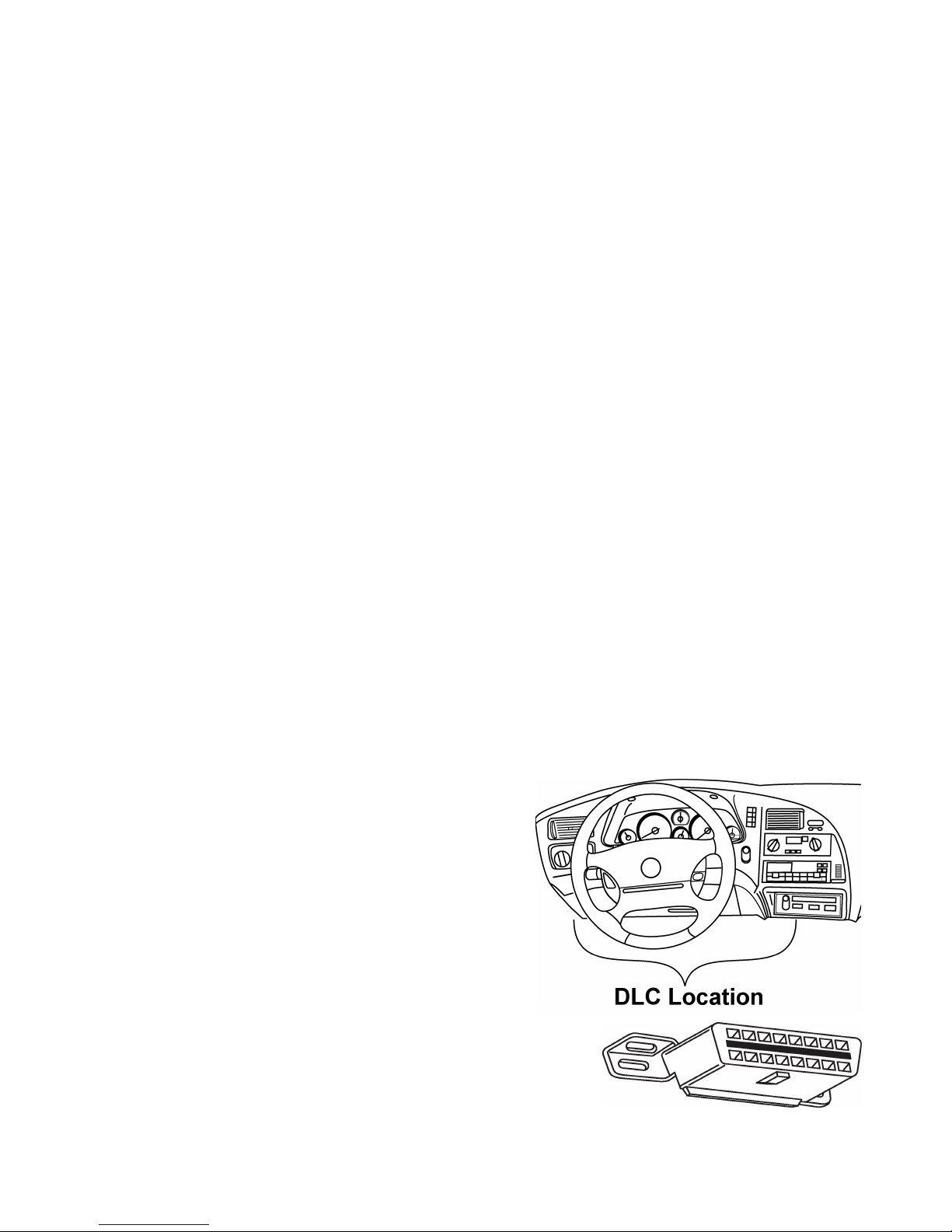

1-3 Diagnostic Connector and Location

The OBD II System Tester communicates with

the vehicle via a diagnostic link connector (DLC).

OBD II S ecification J1962 defines the DLCs

hysical and electrical ro erties. The DLC is

known as the J1962 connector. The S ecification

J1962 was introduced by the SAE (Society of

Automotive Engineers) to make all com liant

vehicles use the same DLC with the generic link

information available on the same ins, no

matter what make of vehicle. In addition to the

connector s ecification, there is a guideline on

where to locate the DLC or J1962 connector, which

states it should be located under the dashboard on the

drivers side of the vehicle. Even with this guideline, not

all OBD II DLCs are located under the dash on the

drivers side. If the DLC is not located in the s ecified area, then a note will be laced

where the DLC should be informing the user of the location. If you cannot find the

DLC, see the vehicle service documentation for its location.