35

EN

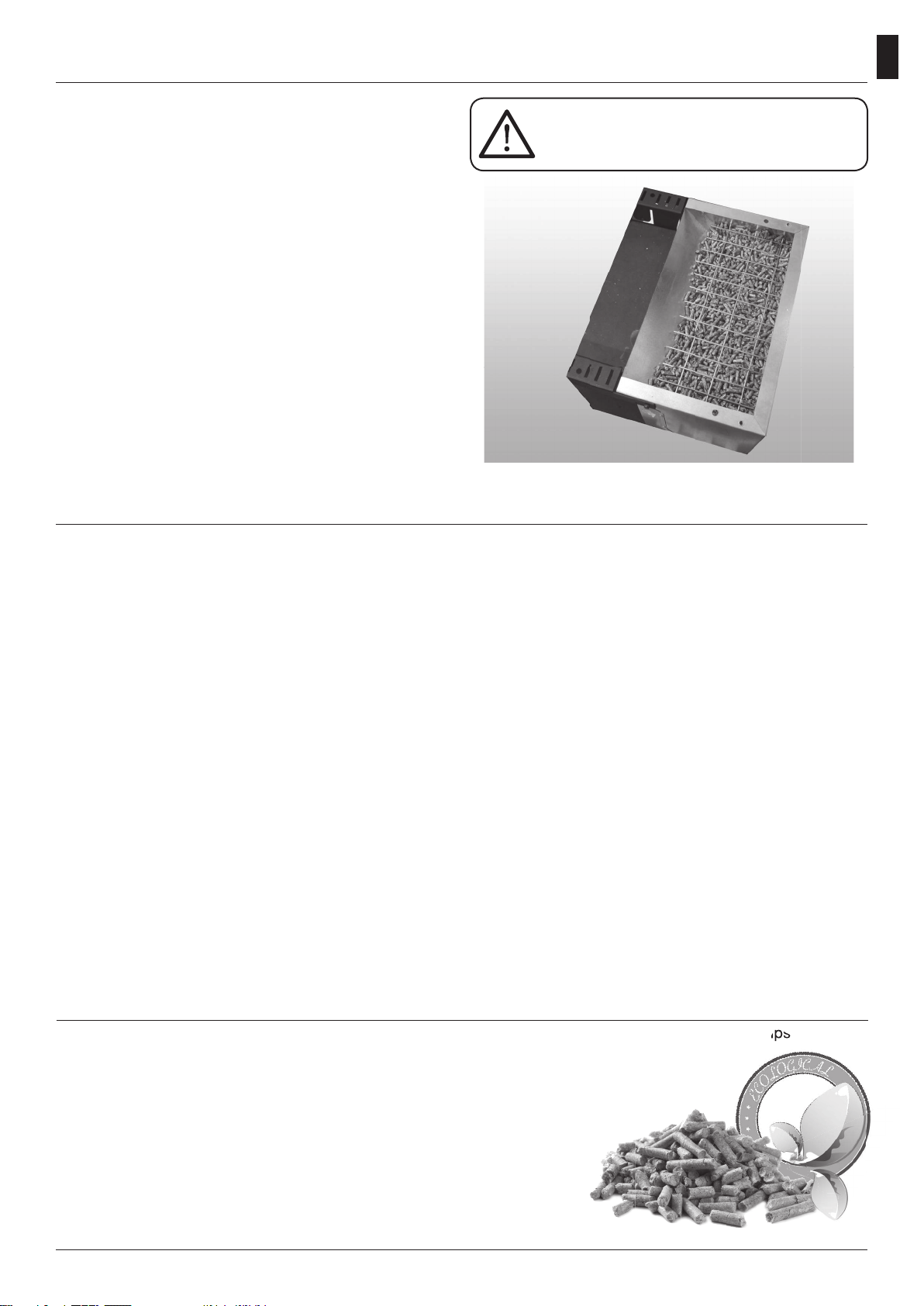

Charge pellet

Fuel is loaded from the upper part of the stove by opening

a door. Pour the pellets in the hopper.

This is easier if performed in two steps:

• Pour half of the contents of the bag into the hopper and

wait for the fuel to settle on the bottom.

• Then pour in the second half;

• Keep the cover closed , after loading the pellets , the lid

of the fuel tank;

The stove is a product by heating, presents the external

surfaces particularly hot. For this reason, we recommend

extreme caution when operating in particular:

• Do not touch the stove body and the various components,

do not approach the door , it could cause burns;

• Do not touch the exhaust fumes;

• Do not perform any type of cleaning;

• Do not dump the ashes;

• Do not open the ash tray;

• Be careful that children do not come near;

Never remove the protection grille in the

hopper. When lling, do not let the sack

of pellets touch any hot surfaces.

• The device can be used by children that are not less than

8 years old and people with reduced physical, sensory or

mental capabilities, or lack of experience or knowledge,

provided being under supervision of someone responsible

or after having received instructions relating to the safe

use of the device and to the understanding of the dangers

inherent to it. Children should not play with the device.

Cleaning and maintenance to be performed by the user

should not be made by children without supervision;

• Do not use the stove as a ladder or scaffold;

• Do not put clothes to dry on the stove.

Any clothes hangers and suchlike must be kept a suitable

distance from the stove. - Risk of re

• Carefully explain that the stove is made from material

subjected to high temperatures for the elderly , the

disabled, and in particular for all children, keeping them

away from the stove during operation

• Do not touch the stove with wet hands: the stove has

electrical components that could produce sparks if

handled incorrectly.

• Never open the glass door of the pellet stove while the

stove is in operation.• The stove must be connected to an

electrical system equipped with an earthing conductor in

accordance with regulations 73/23 and 93/98 EEC;

• The system must be of adequate electrical power

declared the stove;

• Do not wash the inside of the stove with water.

The water could damage the electrical insulation, causing

electric shock;

• Do not expose your body to hot air for a long time. Do

not overheat the room you are in and where the stove is

installed.

This can damage the physical conditions and cause

health problems;

• Do not expose to direct the ow of hot air plants or

animals;

• The pellet stove is not a cooking element;

• External surfaces during operation can become very

hot. Do not touch them except with the appropriate

protection.

• The plug of the device power cable must be connected

only after installation and assembly of the device and

must remain accessible after installation, if the unit is not

provided of a double-pole switch suitable and accessible.

• Do not lay objects, glasses, infusers, room perfumers

on the stove, they could be damaged or to damage the

stove (in this case de warranty does not respond).

Instructions for safe and efficient use

The pellets are cylinders of compressed wood, produced from sawdust and wood processing (chips and

sawdust), generally produced by sawmills and carpenters. The binding capacity of the lignin contained

in wood, allows to obtain a compact product without adding additives and foreign chemicals to the

wood, is therefore obtained a natural fuel with high yield.

The use of expired pellets or any other unsuitable material can damage parts of the

thermostove and impair proper operation: this can lead to the termination of the

guarantee, and its producer responsibility.

For our products use pellets diameter 6 mm, length 30 mm and a

maximum of 6% and A1 certied according to the UNI EN ISO 17225-2

standard. Keep the pellets away from heat sources and not in humid

environments or with explosive atmosphere.

Pellet

The pellets are cylinders of compressed wood, produced from sawdust and wood processing (chips