4 7058-205K August 21, 2018

HEATILATOR ECO-CHOICE

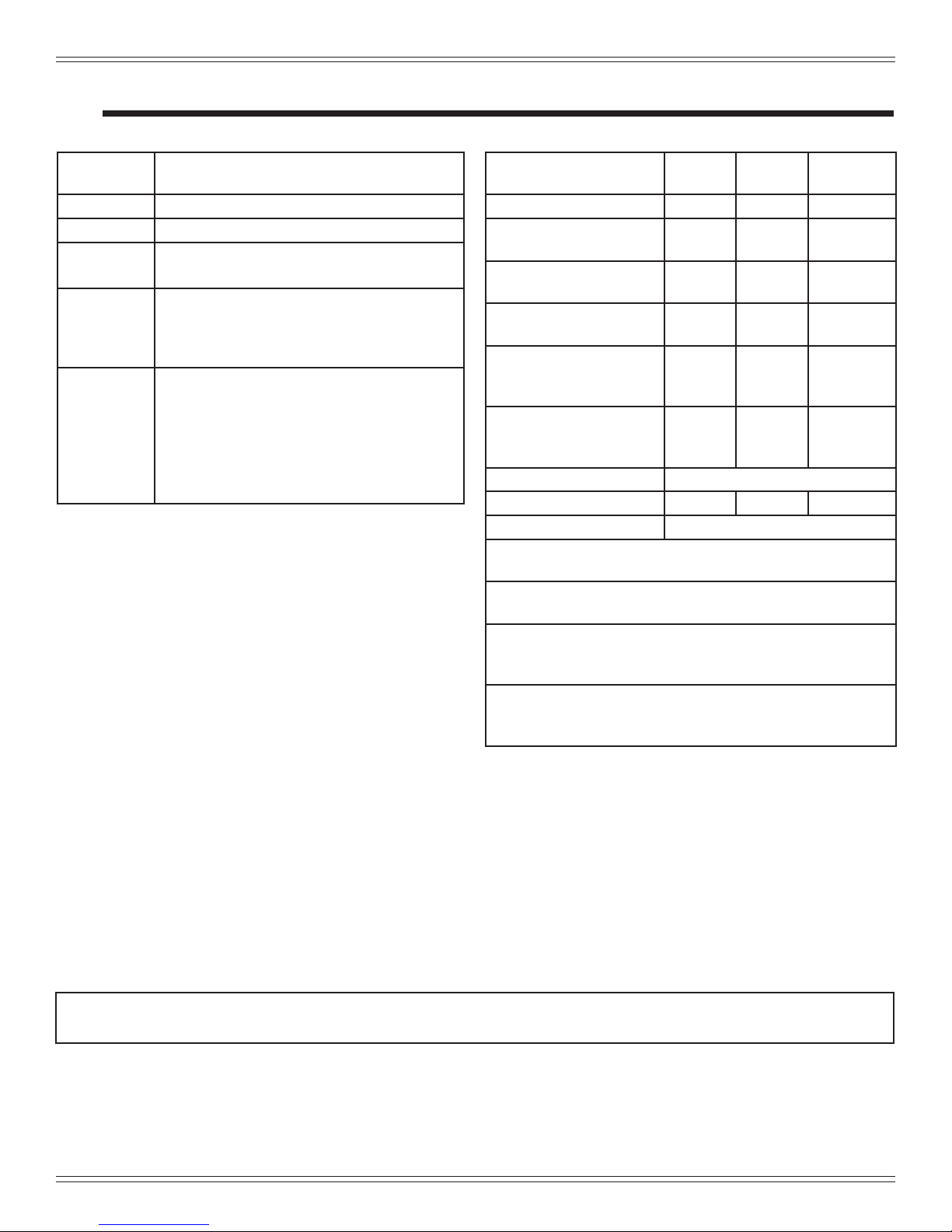

E. Mobile Home Approved

• This appliance is approved for mobile home

installations when not installed in a sleeping room and

when an outside combustion air inlet is provided.

• The structural integrity of the mobile home oor, ceiling,

and walls must be maintained.

• The appliance must be properly grounded to the frame

of the mobile home with #8 copper ground wire, and

use only listed double-wall connector pipe.

• Outside Air Kit, part 811-0872 or OAK-3 must be

installed in a mobile home installation.

• Appliance must be secured to mobile home structure.

C. Glass Specications

This appliance is equipped with 5mm ceramic glass.

Replace glass only with 5mm ceramic glass. Please

contact your dealer for replacement glass.

D. Electrical Rating (on high)

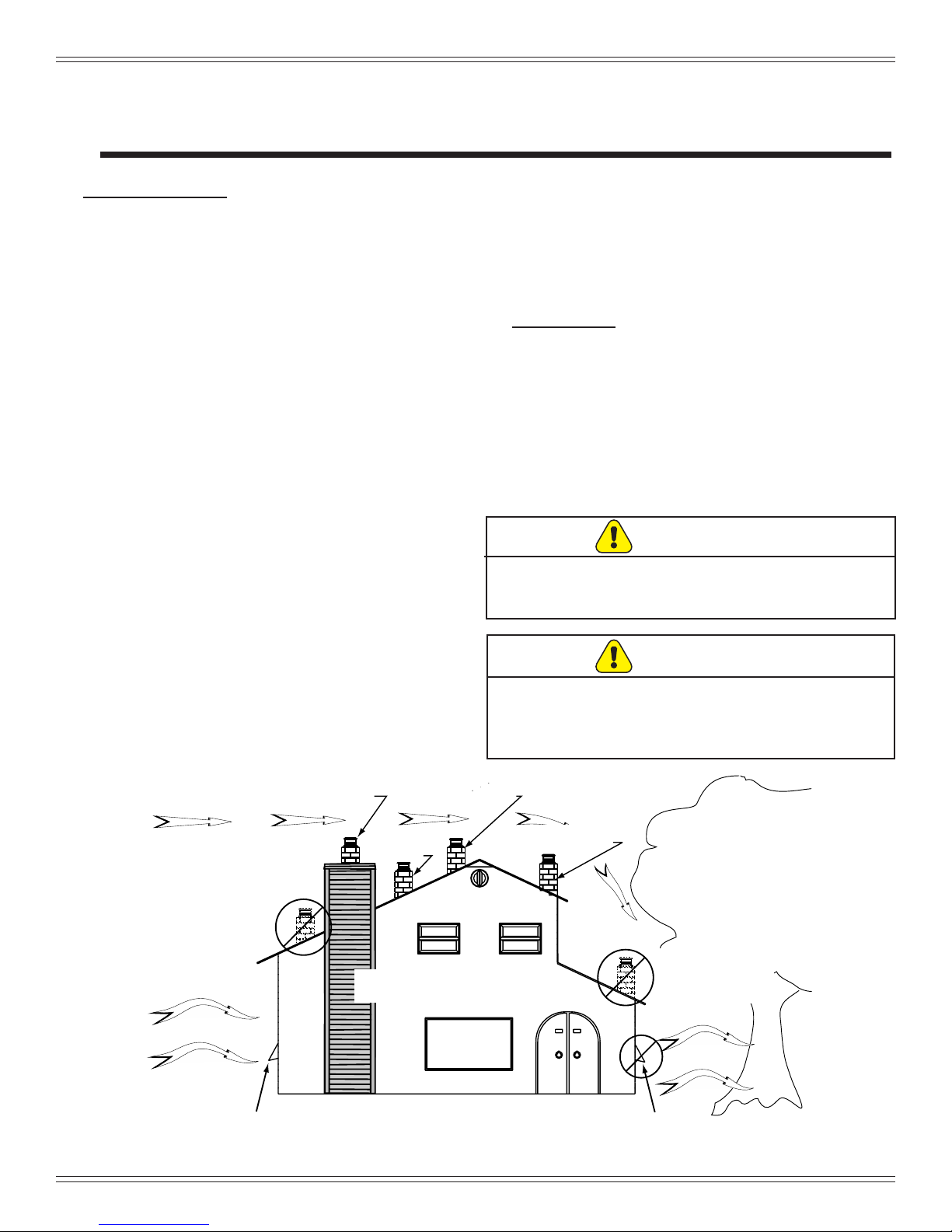

H. Sleeping Room

When installed in a sleeping room it is recommended that

3ft of vertical be installed prior to horizontally exiting the

room and a smoke/CO alarm be installed in the bedroom.

The size of the room must be at least 50ft³ per 1,000 Btu/hr

stove input, if the stove exceeds the room size, out air must

be installed.

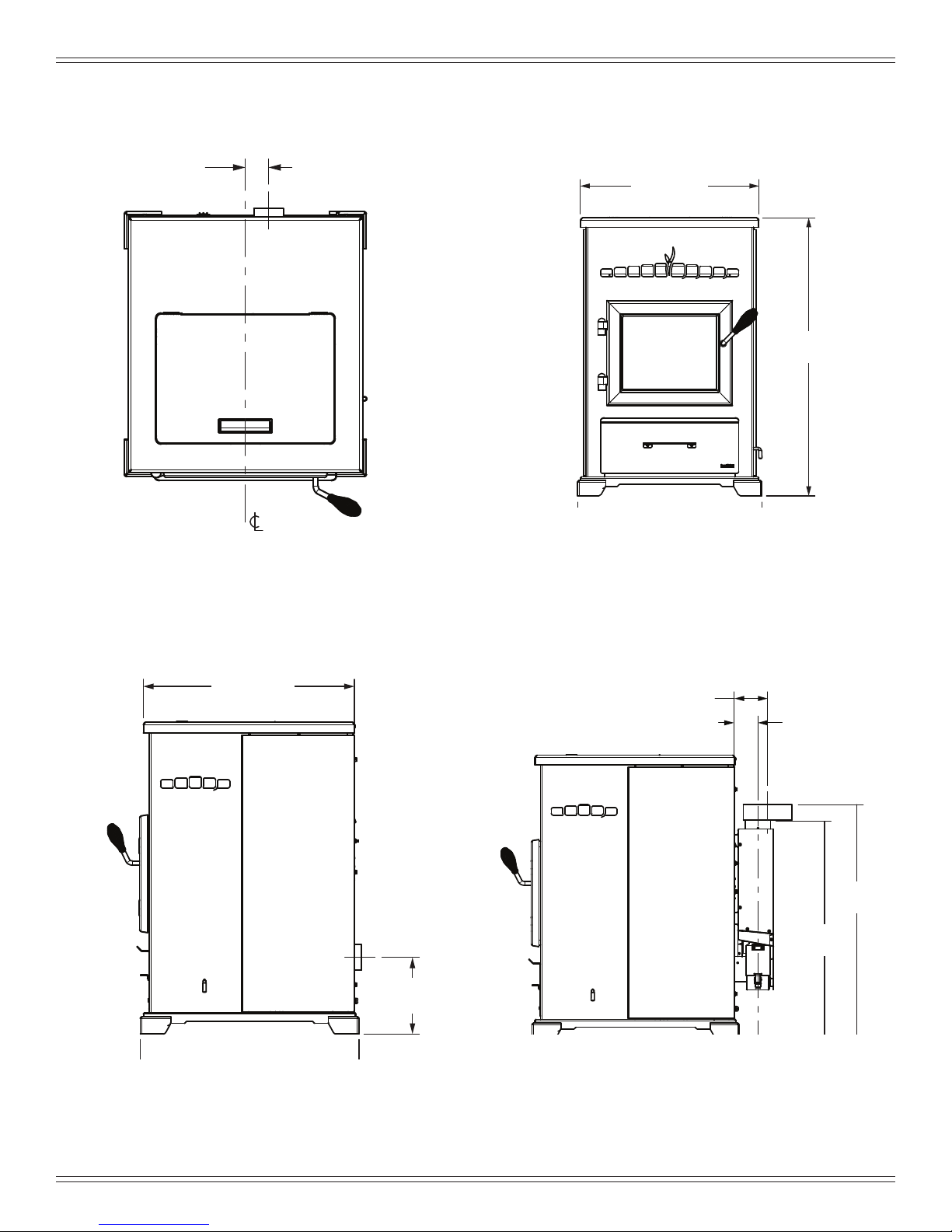

I. Stove Composition

These pellet burning stoves are made of steel, cast iron or

a combination of both with a ceramic viewing glass. These

stoves incorporate a self-feeding system including a fuel

storage hopper and a mechanical feed system which is

controlled by a micro-processing control board. Each model

contains a variable speed distribution blower to circulate

room air through the heat exchanger and out to the room

and a combustion blower which forces the exhaust out of

the stove.

Model PS35: 115 VAC, 60 Hz, Start 3.8 Amps, Run

1.3 Amps

Model PS50: 115 VAC, 60 Hz, Start 5.1 Amps, Run

3.0 Amps

Model CAB50: 115 VAC, 60 Hz, Start 5.1 Amps, Run

3.0 Amps

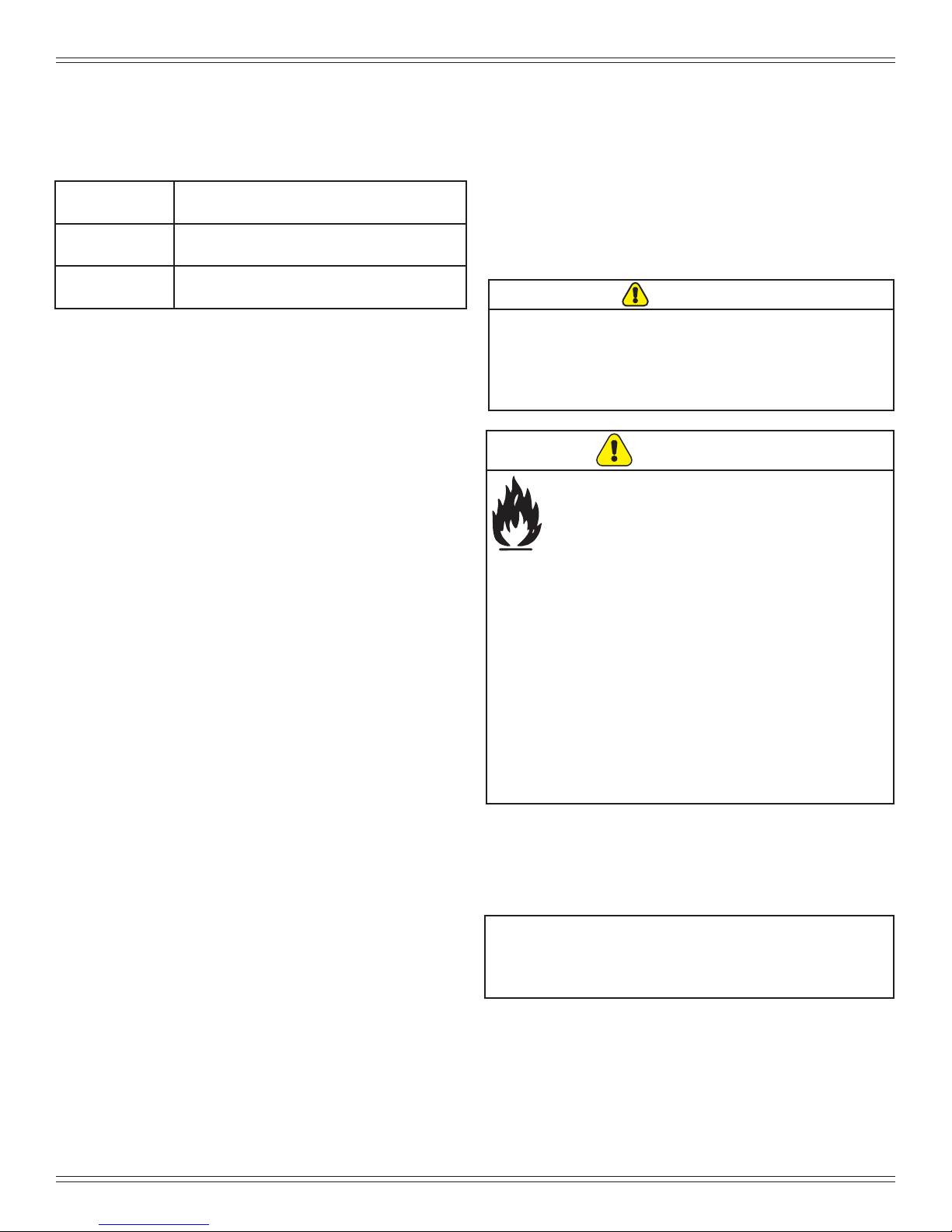

G. Combustible Materials

F. Non-Combustible Materials

Material which will not ignite and burn, composed of any

combination of the following:

- Steel

- Plaster

- Brick

- Iron

- Concrete

- Tile

- Glass

- Slate

Materials reported as passing ASTM E 136, Standard Test

Method for Behavior of Metals, in a Vertical Tube Furnace

of 750° C.

Material made of/or surfaced with any of the following

materials:

- Wood

- Compressed Paper

- Plant Fibers

- Plastic

- Plywood/OSB

- Sheet Rock (drywall)

Any material that can ignite and burn: ame proofed or not,

plastered or non-plastered.

J. California - Prop65

WARNING

This product and the fuels used to operate this product (wood), and

the products of combustion of such fuels, can expose you to

chemicals including carbon black, which is known to the State of

California to cause cancer, and carbon monoxide, which is known to

the State of California to cause birth defects or other reproductive

harm. For more information go to: WWW.P65Warnings.ca.gov

NOTE: Hearth & Home Technologies, manufacturer

of this appliance, reserves the right to alter its

products, their specications and/or price without

notice.

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage.

For assistance or additional information, consult a qualied

installer, service agency or your dealer.

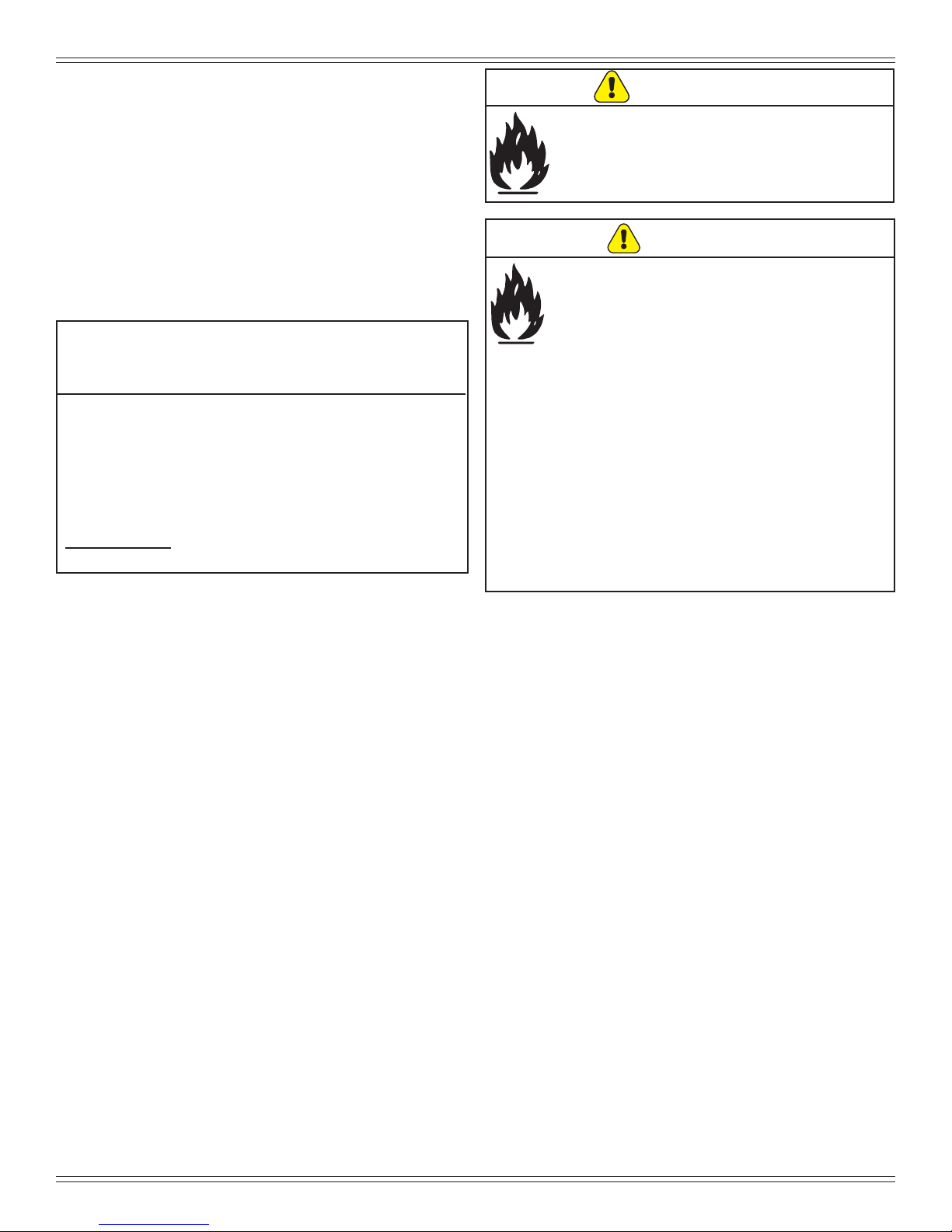

• Installation and use of any damaged appliance.

• Modication of the appliance.

• Installation other than as instructed by Hearth &

Home Technologies.

• Installation and/or use of any component part not

approved by Hearth & Home Technologies.

• Operating appliance without fully assembling all

components.

• Operating appliance without legs attached (if

supplied with appliance).

• Do NOT Over re - If appliance or chimney connector

glows, you are over ring.

Any such action that may cause a re hazard.

WARNING

Fire Risk

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be voided

by, the following actions: