6

ListofIllustrations Page

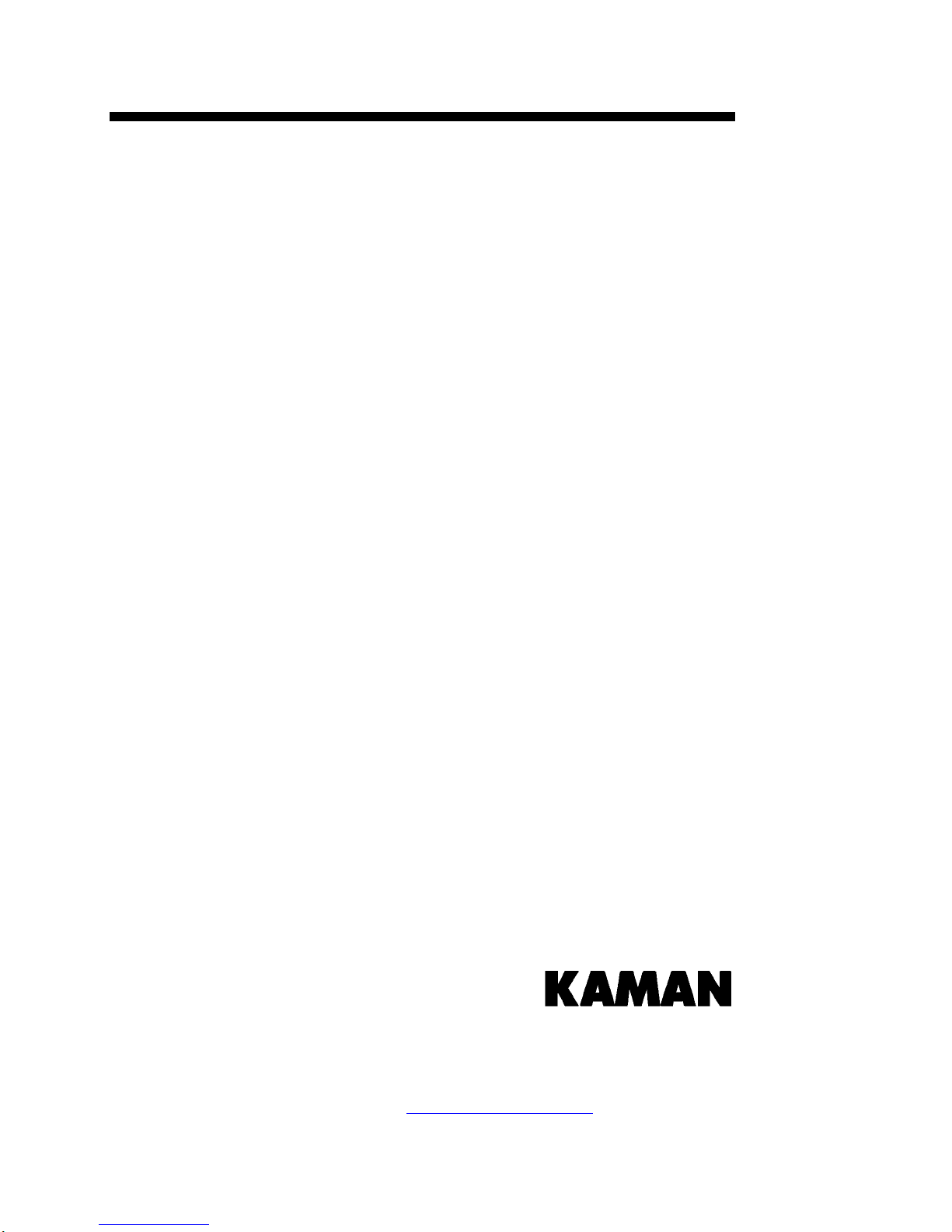

fig. 1 -- Full 19" Subrack Rear/Front Outline drawing 9

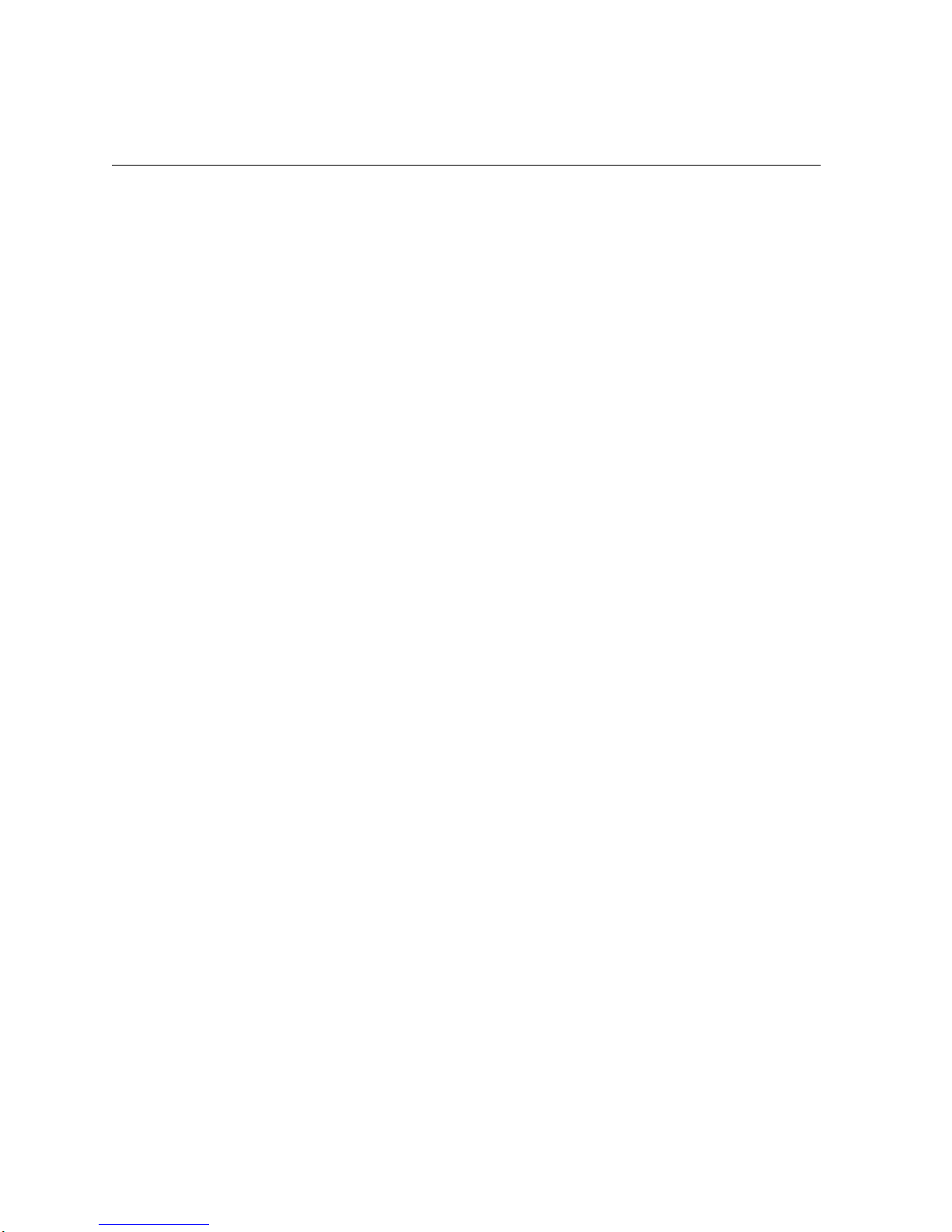

fig. 2 -- Full 19" Subrack Top View Outline Drawing 10

fig. 3 -- Full 19" Subrack Rear/Front with Display 11

fig. 4 -- Full 19" Subrack Rear/Front with Dual Display 12

fig. 5 -- 1/2 Rack with Display Outline Drawing 14

fig. 6 -- 1/2 Rack Outline Drawing 15

fig. 7 -- 3/4 Rack with Display Outline Drawing 16

Table 1 -- Power Supply Specifications 18

fig. 8 -- Power Entry Module 19

fig. 9 -- Accessing the Voltage Selector Card 19

fig. 10 -- Voltage Selector Card Orientation 20

fig. 11 -- Top View of Main board on display. 22

fig. 12 -- Physical Eurocard Pin Locations 23

Table 2 -- Electrical Standards for Pinout 24

fig. 13 -- Single Coil Coaxial 25

fig. 14 -- Dual Coil Coaxial 25

fig. 15 -- Back Plane Template 28

fig. 16 -- Power Entry Module 29

Table 3 -- Terminal Block Labeling 30

fig. 17 -- Back Panel Sensor Inputs 31

fig. 18 -- Typical Module Side Panel Labeling 32

fig. 19 -- Single 1/8 DIN Mounting Panel 814873-001 33

fig. 20 -- Dual 1/8 DIN Mounting Panel 814873-002 34

fig. 21 -- MCD 8000 Front Panel 35

Table 4 -- Displayed Outputs 35

fig. 22 -- MCD 8000 Input Wiring 36

fig. 23 -- MCD 8000 Power Wiring 36

fig. 24 -- Voltage/Current Input Dip Switch 38

fig. 25 -- Diodes For Loop Continuity in Current Mode 38

fig. 26 -- MCD 8000 Adjustment Switches 40

fig. 27 -- Process/Scaling Dip Switch 40

fig. 28 -- Button Function Legend 42

Table 5 -- MCD-8000 Error Message Table 42

Table 6 -- Series 8000 Sensor Family 43

fig. 29 -- Basic Measuring Channel 44

fig. 30 -- Module Reference Dimensions 45

fig. 31 -- VC8000 Voltage to Current Converter 46

fig. 32 -- SC8000 Summation/Comparator 47

fig. 33 -- DY8000 Dynamic Module 48

fig. 34 -- SP8000 Dual Set Point 49