11

Service and Repair Manual

Model 1400KV/1400BV

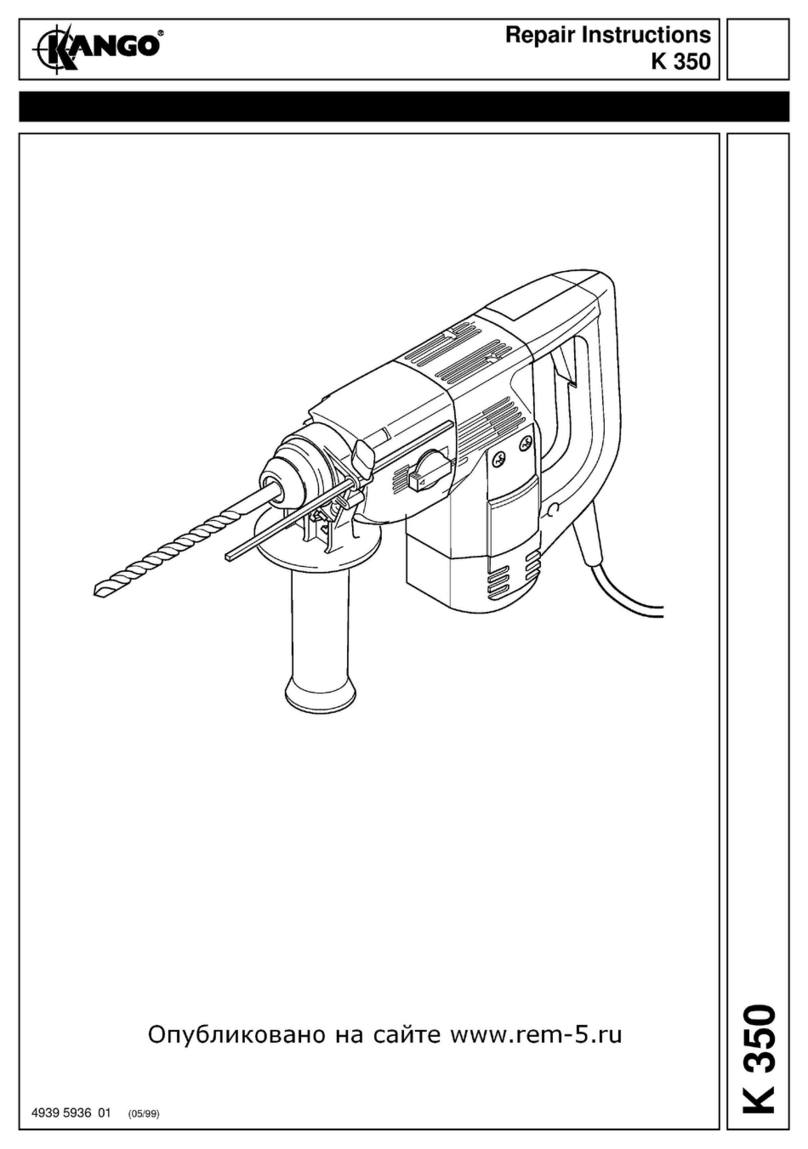

Fig. 14

Removal of

the Motor

Assembly

from the

Bearing

Housing

1. Remove the six Allen bolts (35) from the motor

housing (73) and lift off the motor assembly (A).

A

74 35

73

Dismantling

the Rear

Handle

Assembly

1. Remove the upper handle locking plate screws

(69) and, using a screwdriver, withdraw the

upper plate (80).

2. Using a screwdriver, lever off the upper handle

support (79) together with its associated rubber

handle support (78), releasing both sides at the

same time.

Note: It will be necessary to spread the two locating

clips inside the housing (73).

3. Remove the handle cover retaining screw (82) and

withdraw the rear grip (81).

4. Disconnect the wires from the switch (83).

5. Remove the switch assembly from the handle

(77).

73 79 80

81

83

77

80

79

78

Fig. 16

Fig. 15

Dismantling

the field case

1. Remove two brush cover retaining screws (76)

and remove the covers (75).

2. Release the brush spring (68).

3. Release the locating screws (94) and remove the

brush assemblies (71).

4. Remove the brush (61) and switch lead (64)

assemblies.

5. Remove the four Allen bolts (65) and withdraw

the field casing assembly (66).

6. Remove the baffle (59) from the field case and

withdraw the field coil assembly (60).

7. Remove the baffle gasket (51).

8. Remove rubber supports (62) and (63), and (72).

50 51 59 6061 66

64 62

65 72

82

69

63

75

68

71

94

76

75