3

PAGE

Repair Instructions

K 350

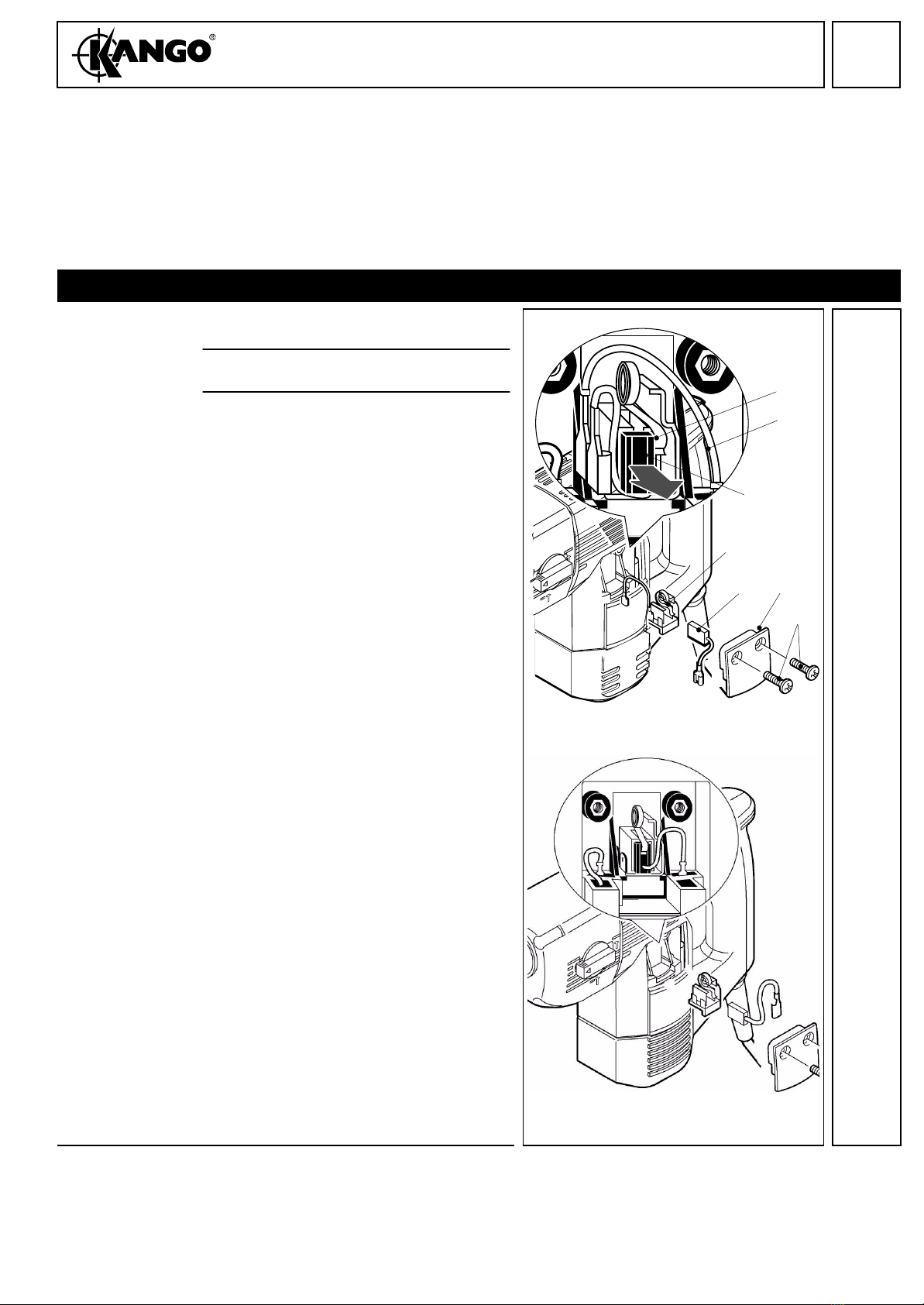

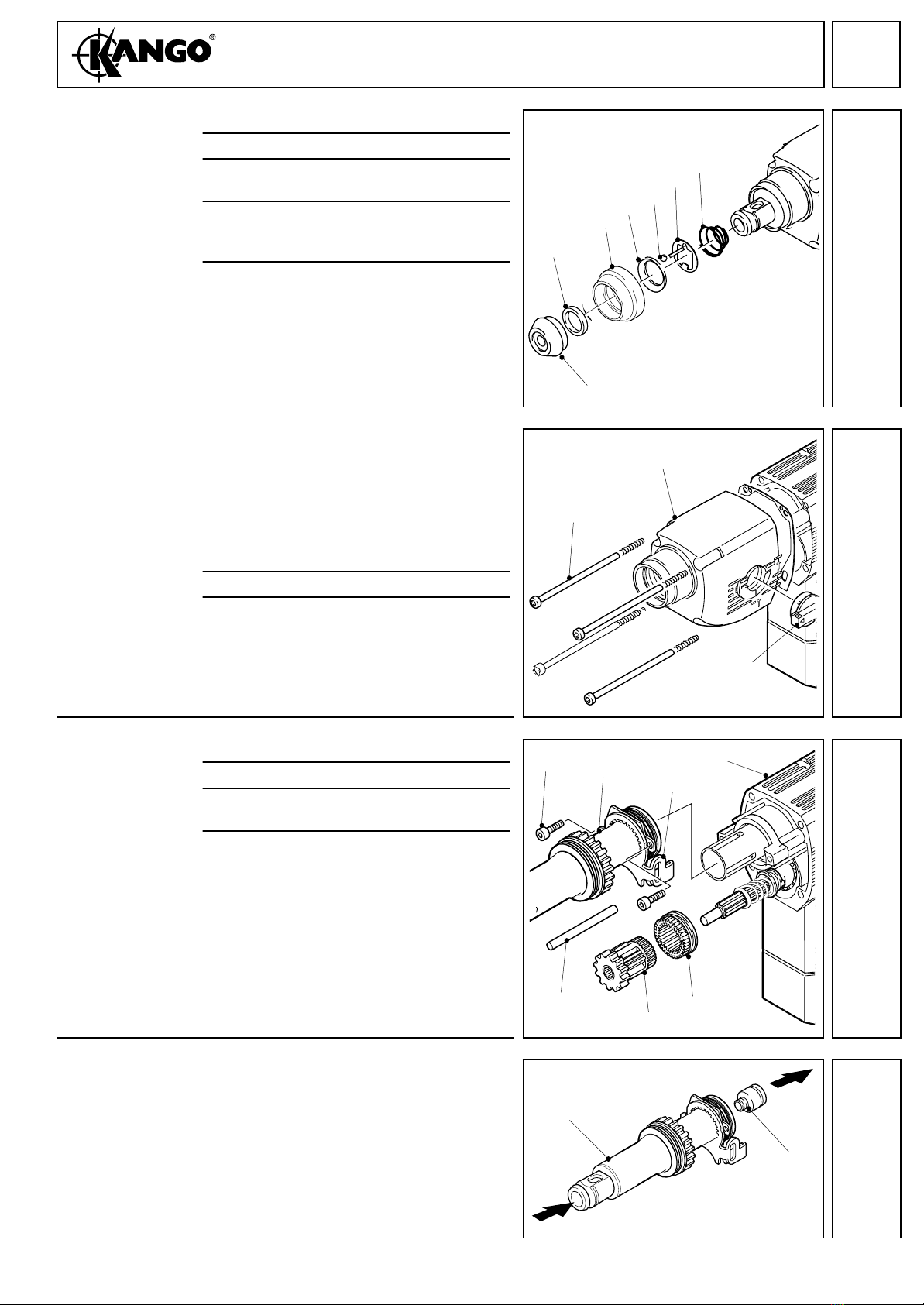

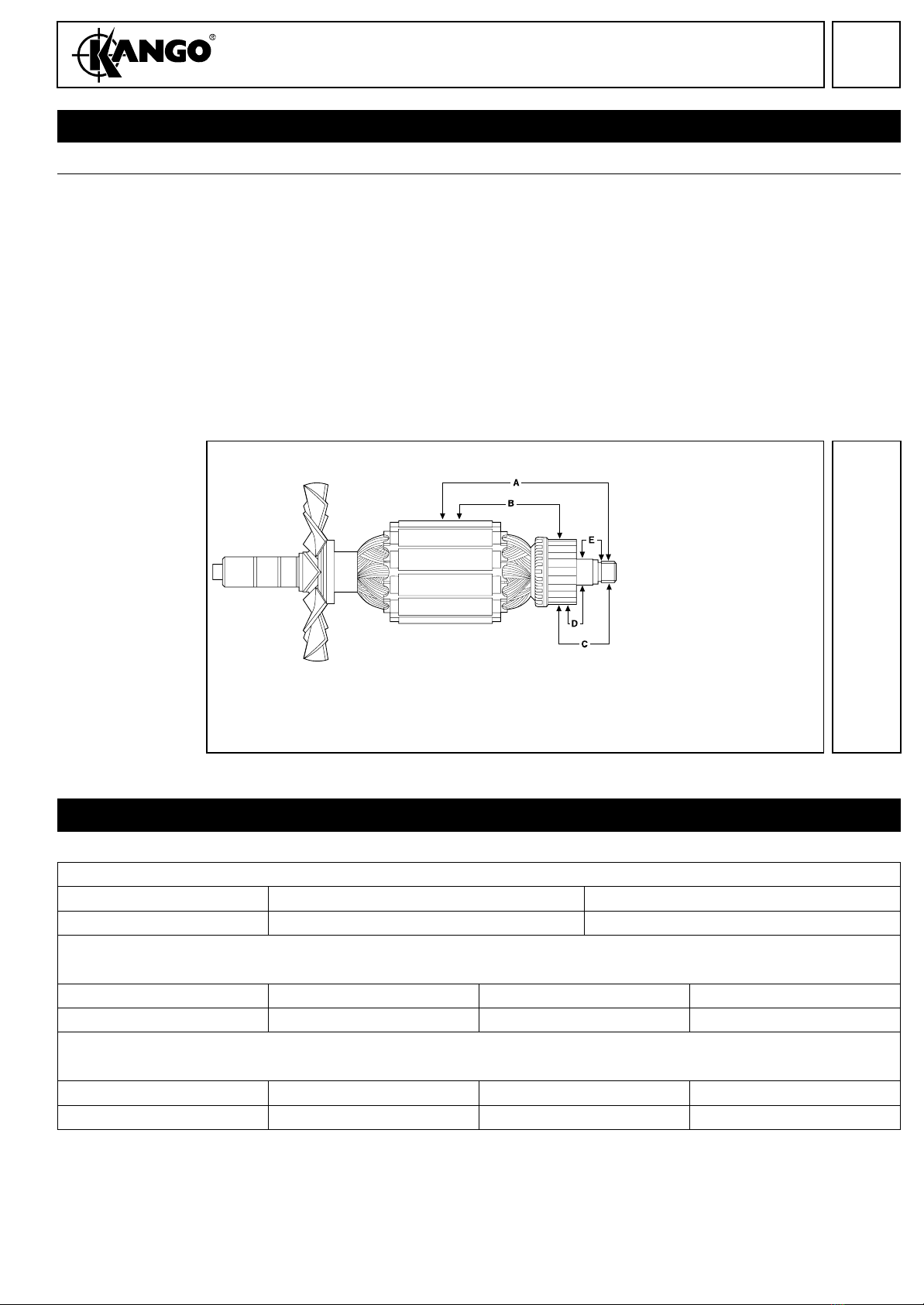

Dismantling the

spindle

(removing the

outer parts)

1Removing the rear thrust bearing assem-

bly: Lever off the spiral clip (53) with a

screwdriver. Remove the thrust bearing

assembly in the following component

parts:

– washer (58)

– thrust bearing (52)

– two compensating washers (65)

– profile ring with damper O-ring (51)

2Remove the retaining plate (45) and the

slider (43).

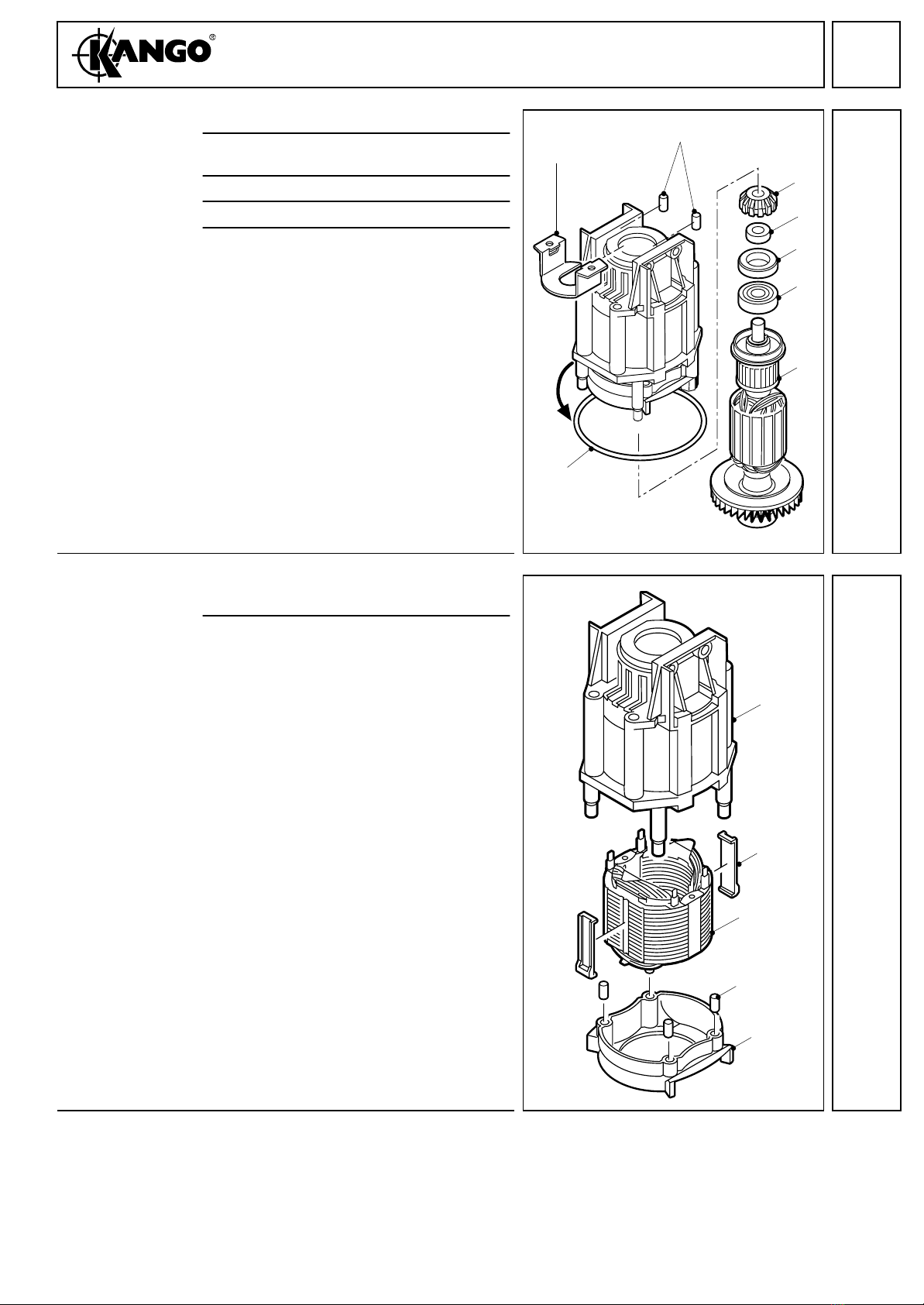

3Removing the spindle gear (49):

Press the spindle gear (49) using a suita-

ble sleeve against the cup springs (47) -

the spring ring (50) is released and can be

removed with pliers. Remove the spindle

gear (49).

4Remove the stop washer (48) and the cup

springs.

Dismantling the

spindle (remov-

ing the inner

locking ring)

To remove the locking ring, service tool

4.931 5990 84 is needed (see illustration 7).

1Turn the locking ring (53) with aid of serv-

ice tool, such that one end projets the

service boring by approx. 2 mm.

2Put a screwdriver through the service bor-

ing and place it under the locking ring (53).

3Move the screwdriver to and fro and at the

same time turn the locking ring with aid of

the service tool in direction of arrow. Turn

the locking ring until it is completely lev-

ered off.

4Press the locking ring from the spindle.

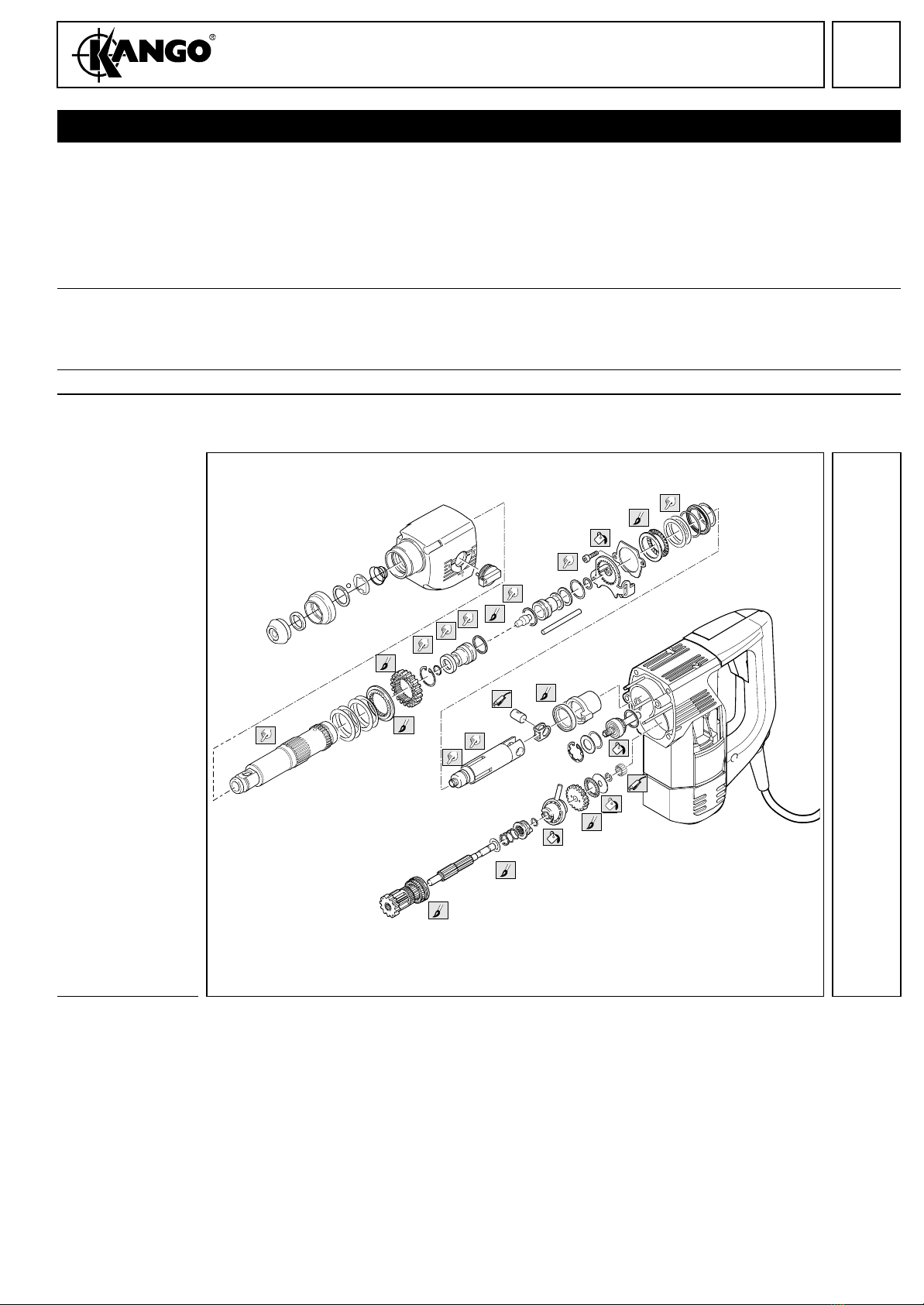

47 48 4950 43 45

53

50

47

49

58

5152

65

53

B

A

53