25-63-50

© Orolia S.A.S.

Abbreviated Component Maintenance Manual

S1825501-01 / S1825501-02

Page 3

AUG 12/2013

B. Technical Data

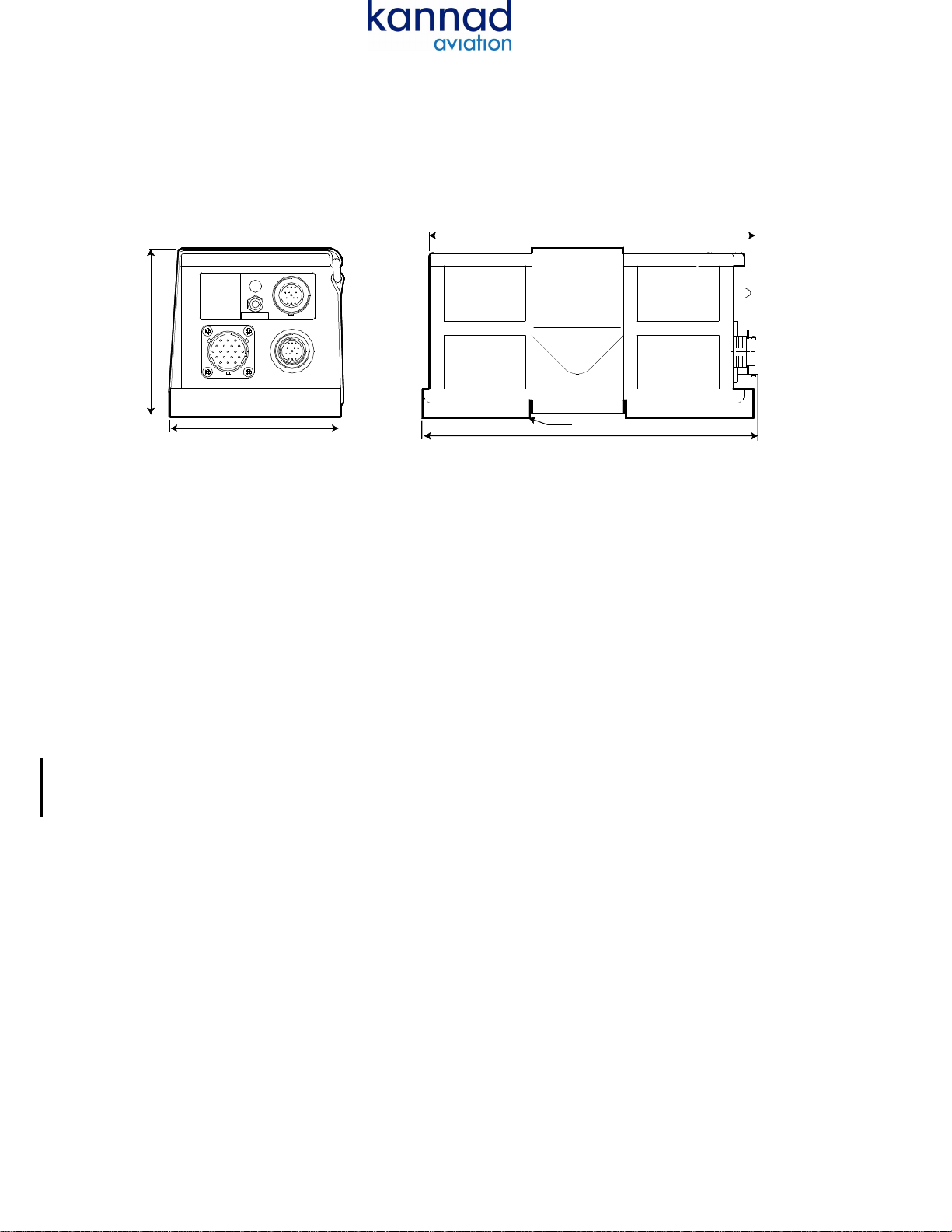

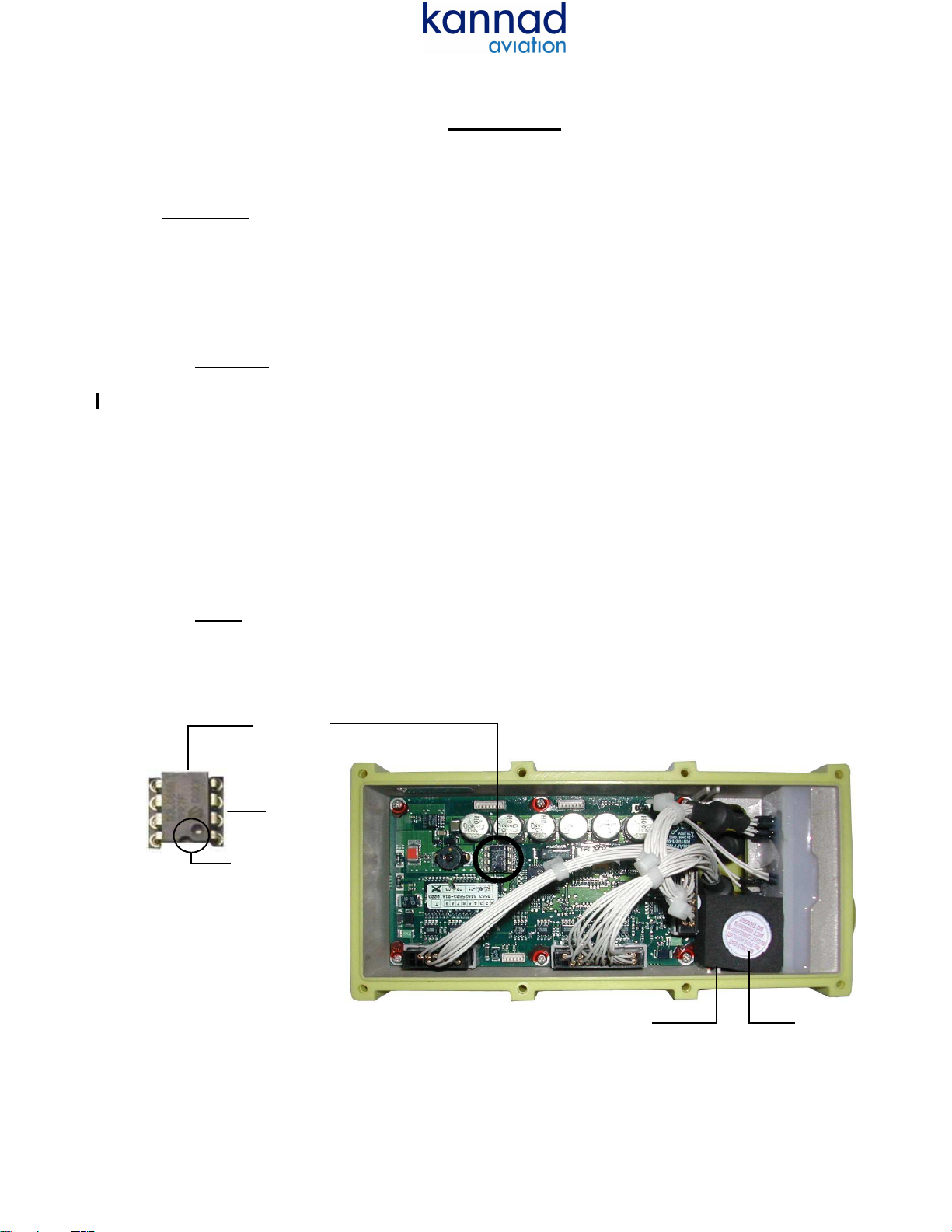

(1) Overall dimensions:Refer to Figure 2

Figure 2 / 25-63-50-991-02

CS144, overall dimensions

(2) Weight

• Typical: 650 g. (1.433 lbs).

• Maximum: 700 g. (1.543 lbs).

(3) Environmental characteristics

• Operating temperature: -55 Degrees Celsius to +70 Degrees Celsius.

• Storage temperature: -55 Degrees Celsius to +85 Degrees Celsius.

• Magnetic effects: DO 160D / ED14D Section 15 Category Z.

• Induced signal susceptibility: not applicable, length less than 1.5 m.

• Radio frequency signal susceptibility: 20 V/m CW and SW.

(4) Compatibility list

• The CS144 is compatible with:

- All KANNAD 406 ELTs except SURVIVAL versions, KANNAD 406 AF-COMPACT,

KANNAD 406 AF-COMPACT (ER) and INTEGRA ELTs families P/N S185X501-XX .

- All remote control panels supplied by Orolia S.A.S. (RC1xx, RC200, RC300, RC400,

RC500, RC600, RC800, RC810).

- Programming dongles, Programming dongles A320 and A320 340, Programming

dongle ASSY

- Tested with the following GPS: HONEYWELL KLN90/KLN94, GARMIN GNS430/

GNS530, TRIMBLE TNL2101 I/O Approach Plus (CS144-RS),

- NMEA 0183 or ARNAV labels A/B (CS144-RS),

- ARINC 429 labels 310/311(CS144-A).

C. Operation

(1) The CS144 Interface module constantly computes a long message by combining the short

message (identification information available in the dongle) and the aircraft position available

from the NAV equipment installed on board the aircraft.

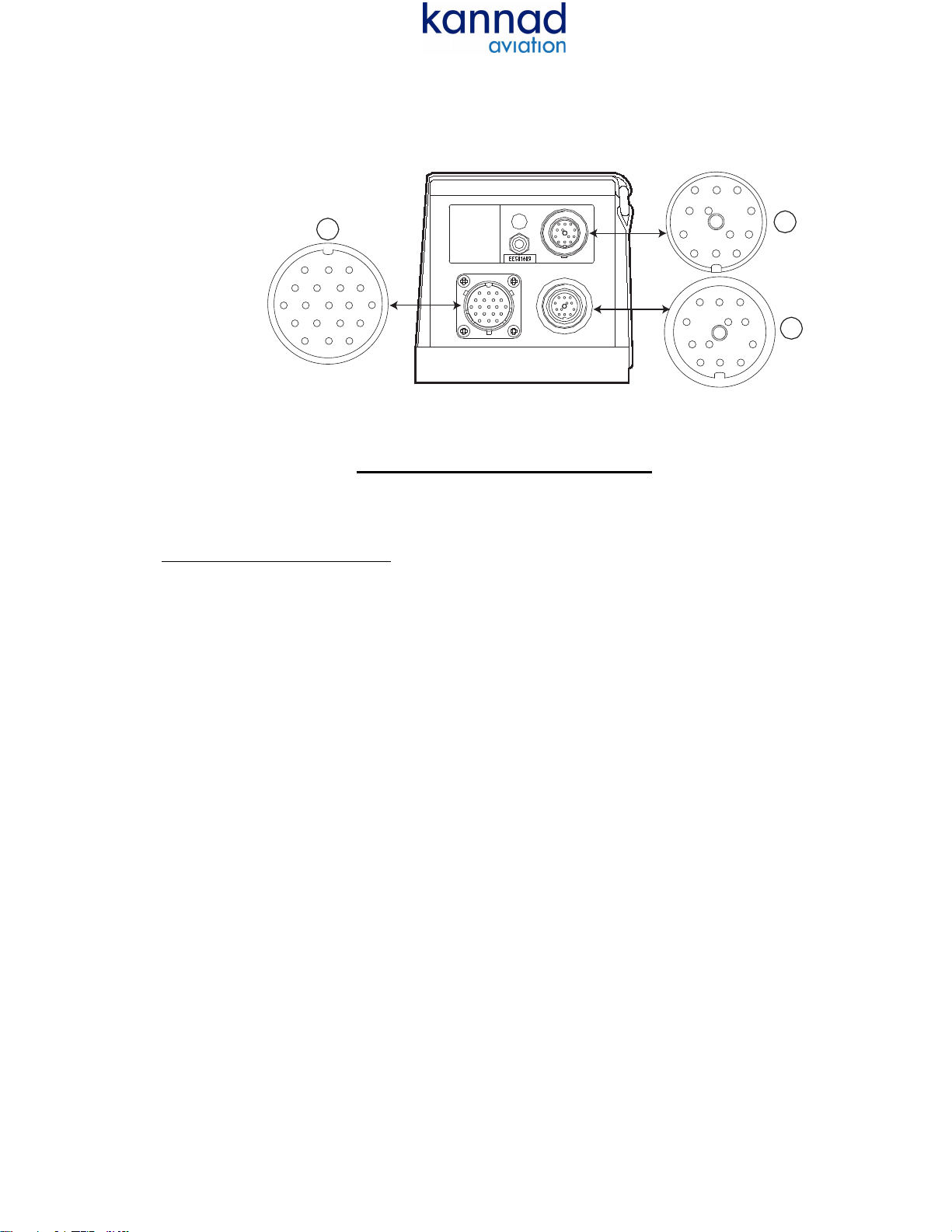

(2) Monitoring is done through a red LED:

(a) Permanently ON when the CS144 is ON and not faulty.

(b) Fast blinking if the CS144 Interface module is faulty.

94 (3.7)

97 (3.82)

180 (7.086)

186 (7.32)

Bracket

Note: all dimensions are in millimeters

(inches in brackets)

OFF ON