1

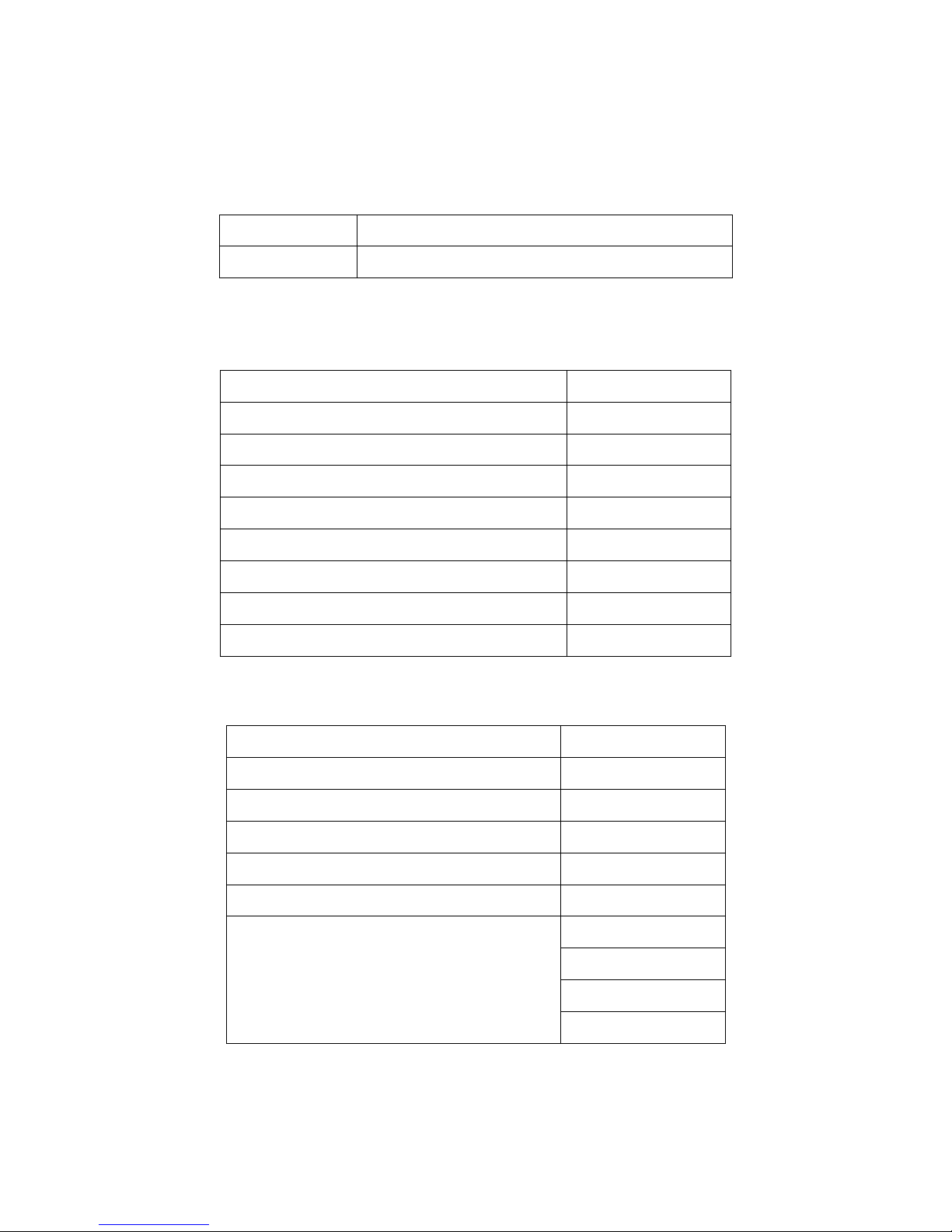

CONTENTS

1.Introduction......................................................................................................................................1

1.1 Product features.....................................................................................................................1

2. Capture Hood Structure...................................................................................................................2

2.1 Instrument Base.....................................................................................................................2

2.2 Main structure.........................................................................................................................3

2.3 Fabric Hood ............................................................................................................................3

3. Installation and Assembling............................................................................................................3

3.1 Capture Hood Installation.....................................................................................................3

3.2 Assembling the Frame (detail).............................................................................................4

3.3 Installing the Portable Handle..............................................................................................4

3.4 Installing the Main structure..................................................................................................5

4. Operation directions.........................................................................................................................5

4.1 Communication and Supplying Power with theACAdapter............................................5

4.2 Supplying Power with Batteries...........................................................................................6

4.3 ON/OFF...................................................................................................................................7

4.4 Keypad Operation..................................................................................................................7

4.5 Incline Adjustment Settings of the Instrument ...................................................................8

4.6 Back Pressure Compensation On / Off Settings...............................................................9

4.7 Measuring..............................................................................................................................10

4.7.1 Start and enter into the main interface...................................................................10

4.7.2 Single Measurement Mode .....................................................................................10

4.7.3 Running Average Measurement Mode..................................................................11

4.7.4 Back Pressure Compensation Measurement Mode............................................12

5. Display Menu settings ...................................................................................................................12

5.1 Test Settings .........................................................................................................................13

5.1.1 Test ID setting............................................................................................................14

5.1.2 Test Mode settings....................................................................................................15