1

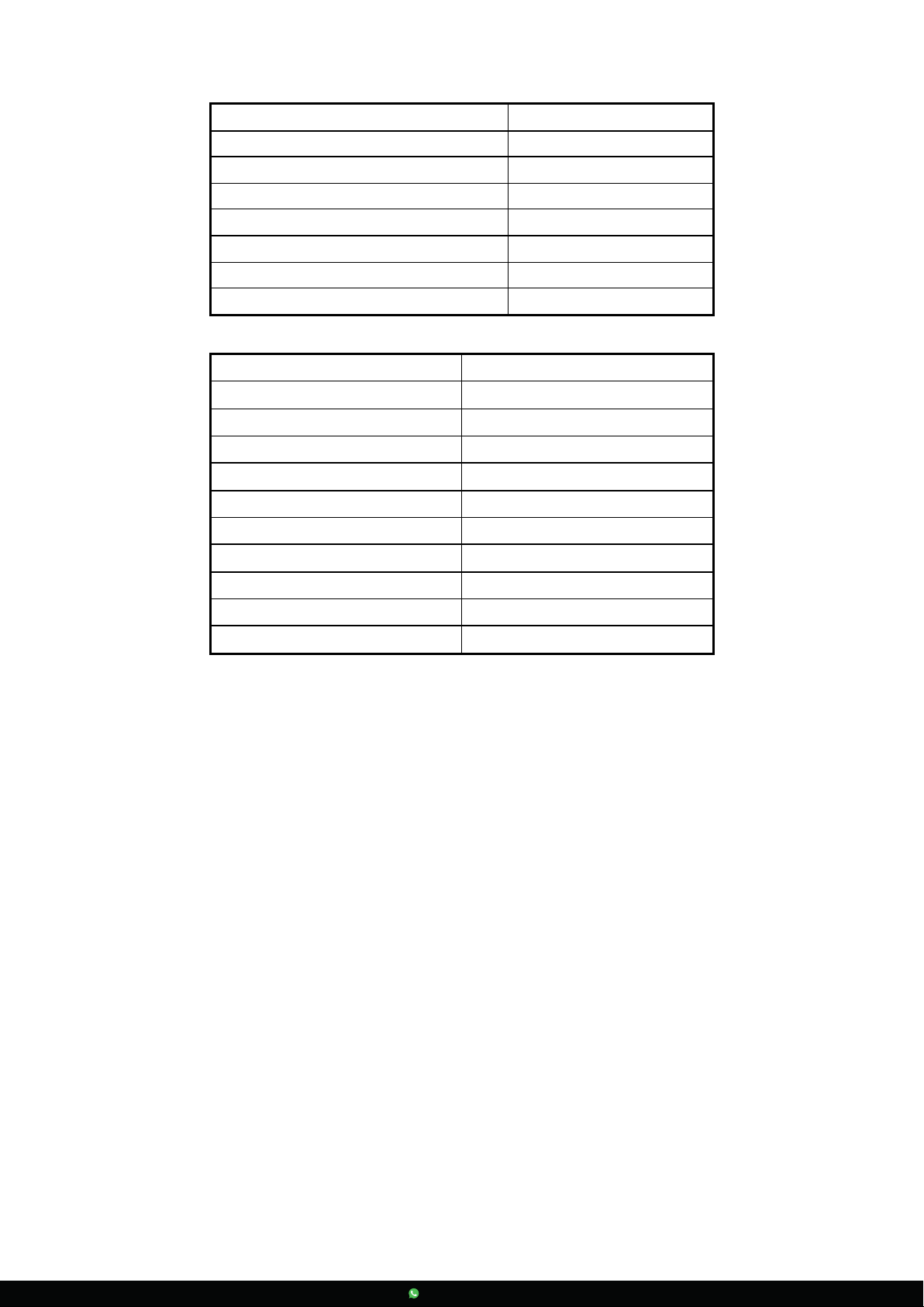

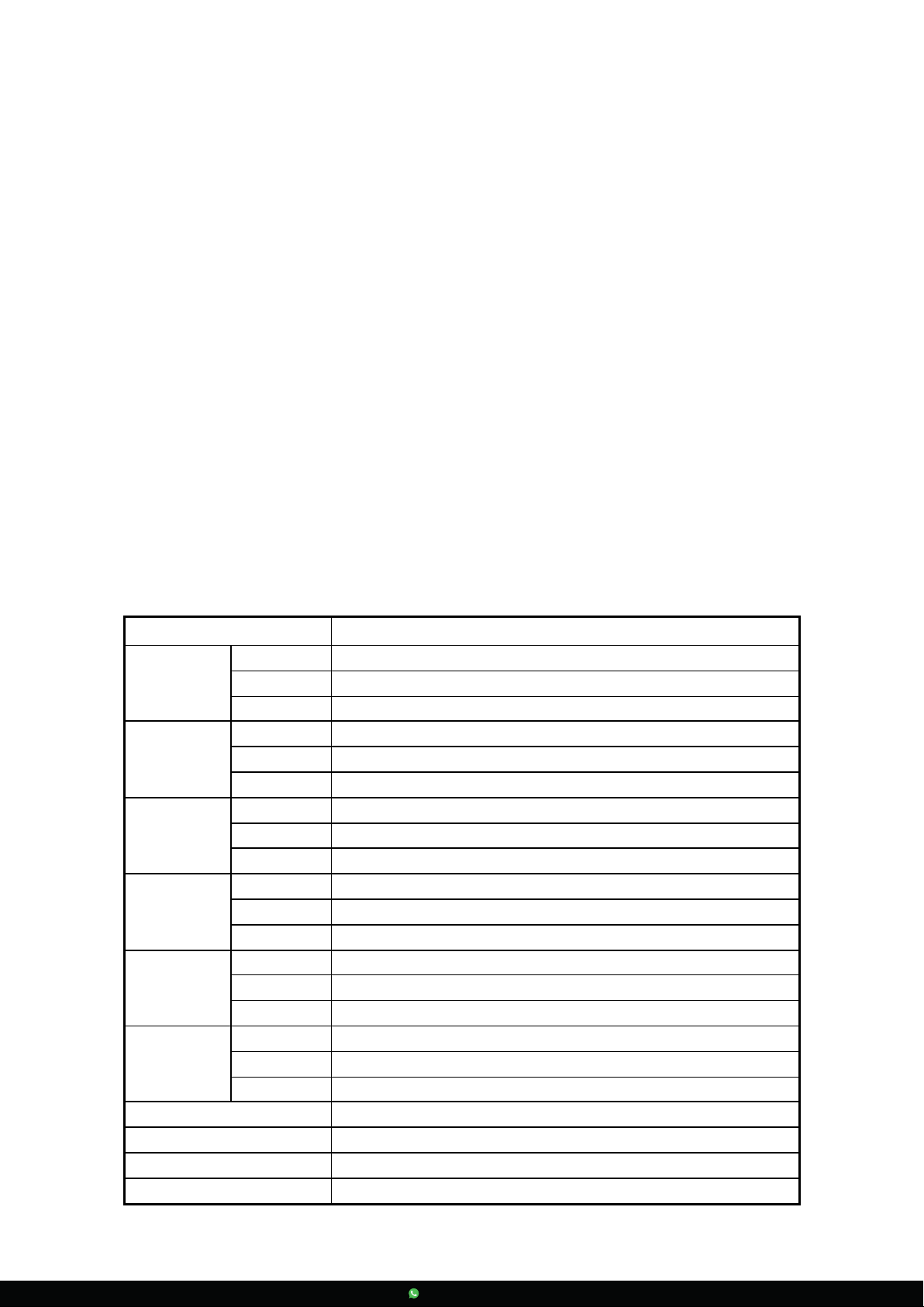

CONTENTS

Product Configuration..................................................................................................................... 3

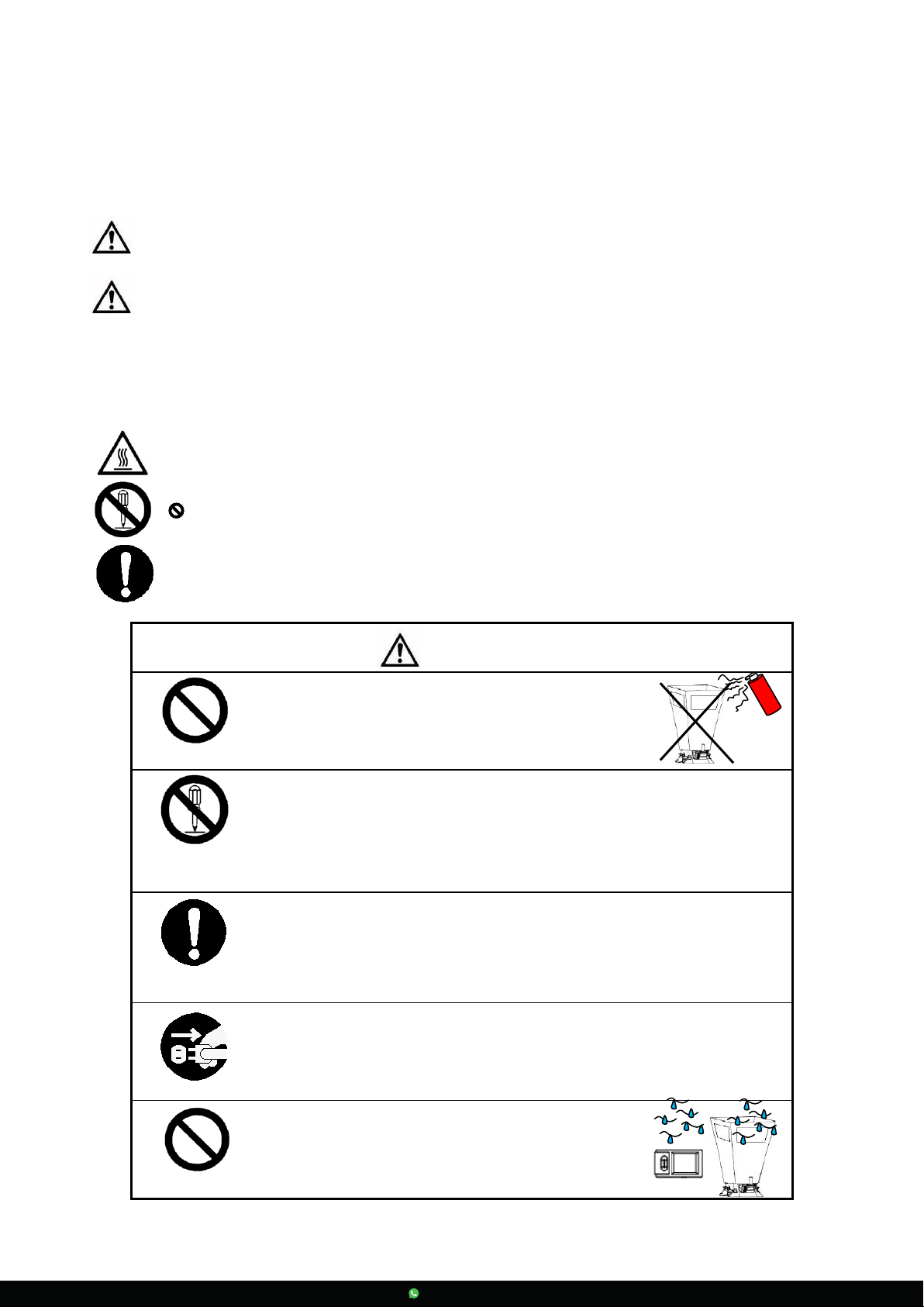

Caution........................................................................................................................................... 5

1. Introduction ................................................................................................................................ 7

1.1. Features............................................................................................................................. 7

1.2. Specifications..................................................................................................................... 7

2. Outlook & Structure.................................................................................................................... 8

2.1. Base structure.................................................................................................................... 8

2.2. Micromanometer ............................................................................................................... 9

3. Se ttubg up................................................................................................................................... 9

3.1. Capture Hood.................................................................................................................... 9

3.2. Velocity Grid.....................................................................................................................10

3.3. Pitot tube..........................................................................................................................11

3.4. Micromanometer ..............................................................................................................11

3.5. Shoulder Strap..................................................................................................................11

4. Operating Instruction .................................................................................................................12

4.1. Power supply ....................................................................................................................12

4.2. Start On / Power Off .........................................................................................................12

4.3. Keypad operation..............................................................................................................13

5. Function test...............................................................................................................................14

5.1. User Interface ...................................................................................................................14

5.2. Single Mode ......................................................................................................................15

5.3. Average Mode ...................................................................................................................15

5.4. Back Pressure Mode ..........................................................................................................15

6. Menu setting...............................................................................................................................16

6.1. General setting..................................................................................................................17

6.1.1. Date........................................................................................................................17

6.1.2. Time .......................................................................................................................17

6.1.3. Auto Off..................................................................................................................17

6.1.4. Backlighting............................................................................................................18

6.1.5. Communication.......................................................................................................18

6.2. Test setting........................................................................................................................19