4

CONTENTS WTC 600 LP / MP

Service Handbook 08.2004

Contents

3.2.5.2 Perform flocking test...............................................................................................26

3.2.5.3 Evaluate flocking test .............................................................................................26

3.3 Connecting the Equipment ................................................................................ 27

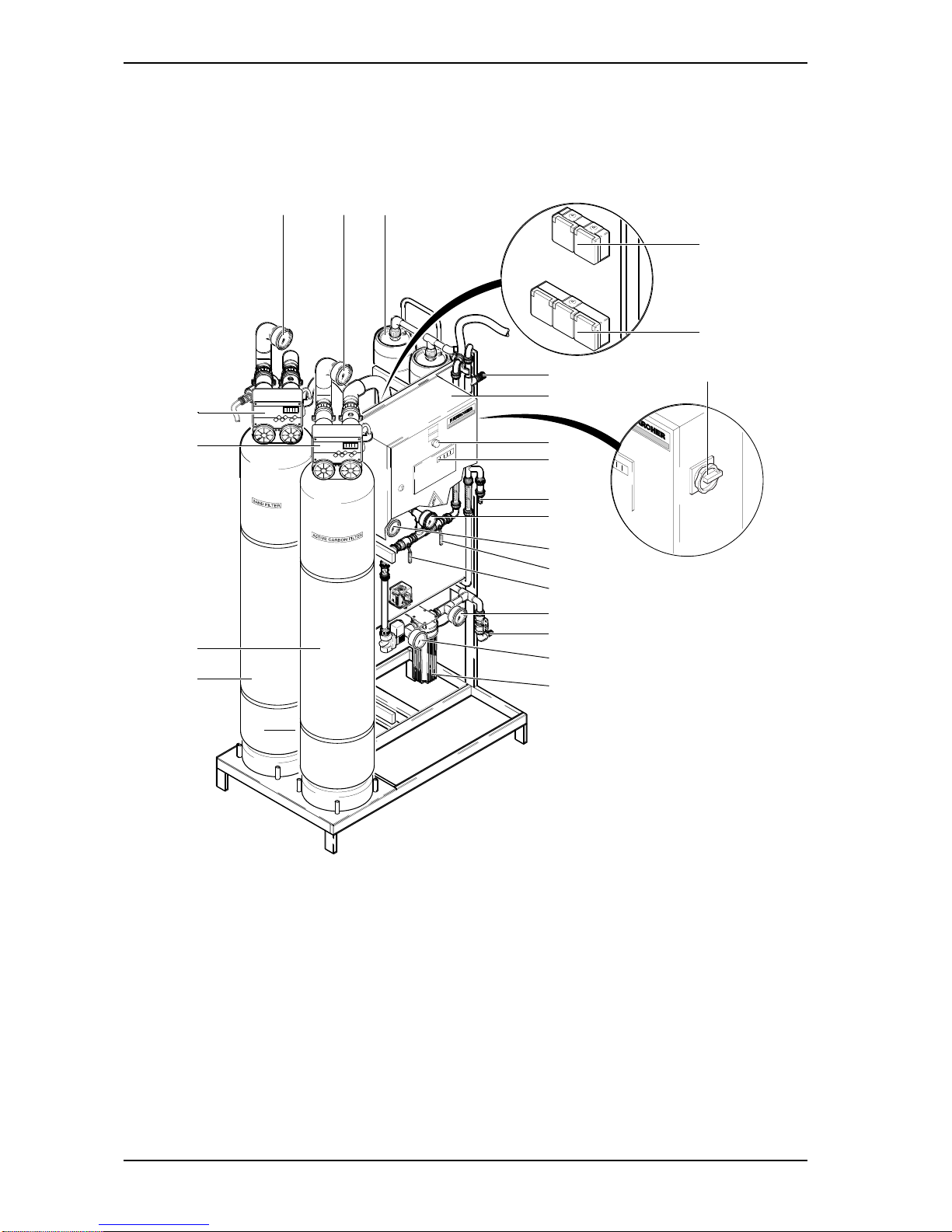

3.3.1 Connections, Valves and Indicators.......................................................................27

3.3.1.1 Pressure-increase Module .................................................................................... 28

3.3.1.2 RO Module with Preliminary Filters....................................................................... 28

3.3.2 Electrical Connections ...........................................................................................29

3.3.2.1 Pressure-increase Pump ...................................................................................... 29

3.3.2.2 Preliminary Filter ................................................................................................... 29

3.3.2.3 MeteringStation .................................................................................................... 29

3.3.2.4 Float Switch........................................................................................................... 31

3.3.2.5 Reverse Osmosis System.................................................................................... 31

3.4 Starting Operation ...............................................................................................31

3.4.1 MeteringStation .....................................................................................................31

3.4.2 Media filter and activated carbon filter ....................................................................32

3.4.2.1 InitialFilling ............................................................................................................ 32

3.4.2.2 Starting Operation ................................................................................................. 32

3.4.2.3 Backwashing / Regeneration ................................................................................ 32

3.4.2.4 Programming......................................................................................................... 33

3.4.3 Starting Operation of the RO System ....................................................................35

3.4.3.1 Operating Levels and Passwords ......................................................................... 35

3.4.3.2 Menu Selection...................................................................................................... 35

3.4.3.3 Selection of an Option ........................................................................................... 35

3.4.3.4 Selecting Several Arguments at the Same............................................................ 36

3.4.3.5 Adjusting Operating Parameters and Balancing Values .........................................36

3.4.3.6 Acknowledging Data Inputs .................................................................................. 36

3.4.3.7 OperationalInterruptions....................................................................................... 36

3.4.3.8 Initial startup...........................................................................................................38

3.4.4 Normal Operation ...................................................................................................40

3.4.4.1 Operating Messages for Normal Operation .......................................................... 41

3.4.5 Putting Out of Operation.........................................................................................42

3.4.6 Disinfection.............................................................................................................43

4 Maintenance.............................................................................. 44 - 62

4.1 Fine Filter ............................................................................................................. 44

4.2 Metering Station WTC 600 CD............................................................................ 44

4.3 Reverse Osmosis Module (RO Module) ............................................................ 45

4.3.1 RO Filter Replacement...........................................................................................45

4.4 Cleaning in Case of Malfunction........................................................................ 46

4.4.1 Design of the Flushing and Disinfection Equipment ...............................................47

4.4.2 Disinfection.............................................................................................................49

4.4.3 Acidic and Alkaline Cleaning ..................................................................................50

4.4.3.1 Cleaning Solution for Acidic Cleaning ................................................................... 51